Dedicated to all those who have similar LED lights.

A typical problem with the latter is a 4 volt lead (AGM) battery that “suddenly” stops working.

Recently there was a review with a solution to a similar problem. .

I took a slightly different path, later it will be clear why.

First, a little about the lights:

Budget flashlights with decent sizes and mediocre performance. But they continue to be bought and used. The flashlight contains a lot of super-bright 3-5mm LEDs.

The LEDs are usually connected in parallel, through current-limiting resistors.

The heart of the flashlight is a lead (AGM) battery with a capacity of up to 4.5Ah.

The battery life is a positive point. Possibility of recharging at any time and operation at low temperatures. The last moment in my alteration is not taken into account, since the operation of the lantern at a significant negative temperature is not planned.

Looking ahead, I will say that it took about 2 hours to remake the lantern.

We open the flashlight and remove the dead battery:

To begin with, I measured the current consumed at a battery voltage of 3.84 V:

Resistors are installed in series with the LEDs to limit the current. Due to the changed voltage of the lamp, it would be possible to lower the resistance of the resistors, but I did not do this. The brightness dropped slightly, you can put up with it, and it's troublesome in terms of time.

At a voltage of 4.2V, the current exceeded 1 A. This was the starting point in solving the problem. The use of a cheap power bank kit is eliminated due to the inability of the latter to provide the required current.

The solution was on the surface:

Two board options, one with overdischarge protection, the other without overdischarge protection:

A little about fees. The controller is one of the most common TP4056. I used a similar board. Controller documentation. The controller provides a charge current of up to 1 Ampere, so you can roughly calculate the battery charge time.

Which board to use in your flashlight depends on the type of 18650 cells used. If there is overdischarge protection, then the one on the right. Otherwise, you can assign the battery protection function to the board, with which it does a great job. The boards differ from each other in the presence of additional parts, such as the DW01 discharge controller and the 8205 power switch (dual field-effect transistor) to disconnect the battery from the load or protect it from overcharging at the right time.

There is a lot of space inside, you can install at least a dozen batteries, but for the test I managed with one.

The latter was removed from an old laptop battery and tested on an IMAX B6 charger:

With a discharge current of 1 Ampere, the residual capacity is 1400 mAh. This is enough for about an hour and a half of continuous operation of the flashlight.

We try to connect the battery to the board:

The wires to the battery must be soldered carefully, without overheating the latter. If you are not sure, you can use a battery holder.

It is also desirable to observe the color differentiation of the pants, use wires of different colors to connect the power.

We connect the board via a micro USB cable to the power supply:

The red LED lit up, the charge went.

Now you need to install the charge controller board in the flashlight. There are no special fasteners, so we make a collective farm using everyone's favorite superglue.

To glue fingers at least once is the sacred duty of everyone who has used it.

We make a bracket from a suitable metal plate (an element from a children's metal designer is suitable).

In order to avoid short circuits, we use insulating material. I used a piece of heat shrink tubing.

I fixed the board by pre-connecting the wires that went earlier to the lead battery:

Outside looks like this:

Small defects are visible on the sides of the connector. They are corrected as follows: a hole or a gap is covered with baking soda and then 1-2 drops of superglue. The glue sets instantly. After 30 seconds, you can file the surface with a file.

We fix the battery inside in any way possible. I used a sealant, someone is more comfortable with a glue gun.

The charging connector hole will be covered with a rubber cap later.

We collect and include:

Working.

Update: If you plan to connect several batteries in parallel, then before connecting, in order to avoid damage to the latter, it is necessary to bring all the batteries to a single EMF (by simple voltage).

Conclusions: The cost of money is about 100 rubles and 2 hours of time. I don’t take the battery into account, I used a half-dead one with high internal resistance. I have a work light. The procedures I describe are not a panacea, there are other options for refining the lights. I did not display the indication of the charging / readiness process on the case. The glow of the blue/red LEDs is visible through the case.

By the way, the board can have any mini or micro USB connector you like. It all depends on the availability of the necessary cables. Among other things, we still have a power supply for charging a lead battery on our hands - it will be useful to attach it somewhere.

Pros:

Working lamp, less weight (although this is an insignificant fact). You can charge anywhere with a USB charger or a computer.

Minuses:

The battery is afraid of frost, lower brightness (by about 10-15%) in relation to the factory version. At the end of the discharge, the brightness drops, noticeably by eye. To solve this problem, you can put a more capacious (or more) battery.

For safety and the ability to continue active activities in the dark, a person needs artificial lighting. Primitive people parted the darkness, setting fire to tree branches, then came up with a torch and a kerosene stove. And only after the invention by the French inventor Georges Leklanshe in 1866 of a prototype of a modern battery, and in 1879 by Thomson Edison of an incandescent lamp, David Meisell had the opportunity to patent the first electric lamp in 1896.

Since then, nothing has changed in the electrical circuit of new flashlights, until in 1923 the Russian scientist Oleg Vladimirovich Losev found a connection between luminescence in silicon carbide and a pn junction, and in 1990 scientists failed to create an LED with a higher light output, which allows replacing a light bulb incandescent. The use of LEDs instead of incandescent lamps, due to the low power consumption of LEDs, has made it possible to multiply the operating time of flashlights with the same capacity of batteries and accumulators, increase the reliability of flashlights and practically remove all restrictions on the area of their use.

The LED rechargeable flashlight that you see in the photo came to me for repair with a complaint that the Chinese flashlight Lentel GL01 bought the other day for $ 3 does not shine, although the battery charge indicator is on.

External examination of the lantern made a positive impression. High-quality molding of the body, comfortable handle and switch. The rods of the plug for connecting to the household network for charging the battery are made retractable, which eliminates the need to store the power cord.

Attention! When disassembling and repairing the lantern, if it is connected to the mains, care should be taken. Touching unprotected parts of the body to uninsulated wires and parts can result in electric shock.

How to disassemble Lentel GL01 LED rechargeable flashlight

Although the flashlight was subject to warranty repair, but remembering my walks during the warranty repair of a failed electric kettle (the kettle was expensive and the heating element burned out in it, so it was not possible to repair it with my own hands), I decided to do the repairs myself.

Disassembling the headlight was easy. It is enough to turn the ring that fixes the protective glass a small angle counterclockwise and pull it off, then unscrew a few screws. It turned out that the ring is fixed on the body with a bayonet connection.

After removing one of the halves of the flashlight housing, access to all its nodes appeared. On the left in the photo you can see a printed circuit board with LEDs, to which a reflector (light reflector) is attached with three self-tapping screws. In the center is a black battery with unknown parameters, there is only a marking for the polarity of the terminals. To the right of the battery is the printed circuit board of the charger and indication. On the right is a power plug with retractable rods.

Upon closer examination of the LEDs, it turned out that there were black spots or dots on the emitting surfaces of the crystals of all LEDs. It became clear even without checking the LEDs with a multimeter that the flashlight does not shine due to their burnout.

There were also blackened areas on the crystals of two LEDs installed as backlight on the battery charging indication board. In LED lamps and tapes, one LED usually fails, and acting as a fuse, it protects the rest from burning out. And in the lantern, all nine LEDs failed at the same time. The voltage on the battery could not increase to a value that could disable the LEDs. To find out the reason, I had to draw an electrical circuit diagram.

Finding the cause of the failure of the lantern

The electrical circuit of the lantern consists of two functionally completed parts. The part of the circuit located to the left of switch SA1 performs the function of a charger. And the part of the circuit, shown to the right of the switch, provides a glow.

The charger works as follows. The voltage from the 220 V household network is supplied to the current-limiting capacitor C1, then to the bridge rectifier, assembled on diodes VD1-VD4. The rectifier supplies voltage to the battery terminals. Resistor R1 serves to discharge the capacitor after removing the flashlight plug from the network. Thus, an electric shock from the discharge of a capacitor is excluded in the event of an accidental touch by hand at the same time of two pins of the plug.

The LED HL1, connected in series with the current-limiting resistor R2 in the opposite direction with the upper right diode of the bridge, as it turned out, always glows when the plug is inserted into the network, even if the battery is faulty or disconnected from the circuit.

The SA1 operating mode switch is used to connect individual groups of LEDs to the battery. As you can see from the diagram, it turns out that if the flashlight is connected to the network for charging and the switch slider is in position 3 or 4, then the voltage from the battery charger also goes to the LEDs.

If a person turns on the flashlight and finds that it does not work, and, not knowing that the switch engine must be set to the “off” position, which is not mentioned in the instruction manual for the flashlight, connects the flashlight to the mains for charging, then at the expense voltage surge at the output of the charger, the LEDs will get a voltage that is much higher than the calculated one. More current will flow through the LEDs and they will burn out. With the aging of an acid battery due to the sulfitation of lead plates, the battery charge voltage increases, which also leads to burnout of the LEDs.

Another circuit design that surprised me is the parallel connection of seven LEDs, which is unacceptable, since the current-voltage characteristics of even LEDs of the same type are different and therefore the current passing through the LEDs will also not be the same. For this reason, when choosing the value of the resistor R4 based on the maximum allowable current flowing through the LEDs, one of them can be overloaded and fail, and this will lead to an overcurrent of the LEDs connected in parallel, and they will also burn out.

Alteration (modernization) of the electrical circuit of the lantern

It became obvious that the breakdown of the lantern was due to mistakes made by the developers of its electrical circuit diagram. To repair the lamp and prevent its re-breakdown, it is necessary to redo it by replacing the LEDs and make minor changes to the electrical circuit.

In order for the battery charge indicator to actually signal its charging, the HL1 LED must be turned on in series with the battery. A few milliamps of current is required to light up the LED, and the current output by the charger should be about 100 mA.

To ensure these conditions, it is enough to disconnect the HL1-R2 circuit from the circuit in the places indicated by red crosses and install an additional resistor Rd with a nominal value of 47 ohms with a power of at least 0.5 W in parallel with it. The charge current flowing through Rd will create a voltage drop of about 3 V on it, which will provide the necessary current for the HL1 indicator to glow. At the same time, the connection point of HL1 and Rd must be connected to terminal 1 of the SA1 switch. So in a simple way the possibility of supplying voltage from the charger to the EL1-EL10 LEDs during battery charging will be excluded.

To equalize the magnitude of the currents flowing through the EL3-EL10 LEDs, it is necessary to exclude the R4 resistor from the circuit and connect a separate 47-56 Ohm resistor in series with each LED.

Electrical diagram after revision

Minor changes made to the circuit increased the information content of the charge indicator of an inexpensive Chinese LED flashlight and greatly increased its reliability. I hope that the manufacturers of LED lamps after reading this article will make changes to the electrical circuits of their products.

After the modernization of the electrical circuit diagram took the form as in the drawing above. If it is necessary to illuminate the flashlight for a long time and does not require a high brightness of its glow, then you can additionally install a current-limiting resistor R5, due to which the flashlight's operating time without recharging will double.

Repair of LED rechargeable lamp

After disassembly, first of all, you need to restore the working capacity of the lantern, and then engage in modernization.

Checking the LEDs with a multimeter confirmed their malfunction. Therefore, all the LEDs had to be soldered and the holes for installing new diodes removed from the solder.

Judging by the appearance, lamp LEDs from the HL-508H series with a diameter of 5 mm were installed on the board. HK5H4U type LEDs from a linear LED lamp with similar technical characteristics were available. They were useful for repairing the lantern. When soldering the LEDs to the board, you must remember to observe the polarity, the anode must be connected to the positive terminal of the battery or battery.

After replacing the LEDs, the PCB was connected to the circuit. The brightness of the glow of some LEDs due to the common current-limiting resistor was somewhat different from others. To eliminate this shortcoming, it is necessary to remove the resistor R4 and replace it with seven resistors, including in series with each LED.

To select a resistor that provides the optimal mode of operation of the LED, the dependence of the current flowing through the LED on the value of the series-connected resistance at a voltage of 3.6 V, equal to the flashlight battery voltage, was measured.

Based on the conditions of use of the lantern (in the event of interruptions in the supply of electricity to the apartment), high brightness and lighting range were not required, so the resistor was chosen with a nominal value of 56 ohms. With such a current-limiting resistor, the LED will work in light mode, and power consumption will be economical. If you want to squeeze out the maximum brightness from the flashlight, then you should use a resistor, as can be seen from the table, with a value of 33 ohms and make two modes of operation of the flashlight by turning on another common current-limiting resistor (in the R5 diagram) with a nominal value of 5.6 ohms.

To connect a resistor in series with each LED, you must first prepare the printed circuit board. To do this, it needs to be cut on any one current-carrying track suitable for each LED and make additional contact pads. The current-carrying tracks on the board are protected by a layer of varnish, which must be scraped off with a knife blade to copper, as in the photograph. Then tin the bare contact pads with solder.

It is better and more convenient to prepare a printed circuit board for mounting resistors and solder them if the board is fixed on a standard reflector. In this case, the surface of the LED lenses will not be scratched, and it will be more convenient to work.

Connecting the diode board after repair and modernization to the flashlight battery showed sufficient for illumination and the same brightness of the glow of all LEDs.

I did not have time to repair the previous lamp, as the second one got into repair, with the same malfunction. On the body of the flashlight information about the manufacturer and specifications ah, I didn’t find it, but judging by the handwriting of the manufacture and the reason for the breakdown, the manufacturer is the same, the Chinese Lentel.

According to the date on the body of the flashlight and on the battery, it was possible to establish that the flashlight was already four years old and, according to its owner, the flashlight worked flawlessly. Obviously, the flashlight lasted a long time thanks to the warning label "Do not turn on while charging!" on a hinged cover that closes the compartment in which the plug is hidden for connecting the flashlight to the mains to charge the battery.

In this flashlight model, the LEDs are included in the circuit according to the rules, a 33 ohm resistor is installed in series with each. The value of the resistor is easy to find out by color coding using an online calculator. Checking with a multimeter showed that all the LEDs are faulty, the resistors also turned out to be open.

An analysis of the reason for the failure of the LEDs showed that due to the sulfation of the acid battery plates, its internal resistance increased and, as a result, its charging voltage increased several times. During charging, the flashlight was turned on, the current through the LEDs and resistors exceeded the limit, which led to their failure. I had to replace not only the LEDs, but also all the resistors. Based on the above conditions of operation of the flashlight, resistors with a nominal value of 47 ohms were chosen for replacement. The resistor value for any type of LED can be calculated using an online calculator.

Alteration of the battery charging mode indication circuit

The flashlight has been repaired, and you can start making changes to the battery charge indication circuit. To do this, it is necessary to cut the track on the printed circuit board of the charger and indication in such a way that the HL1-R2 chain on the LED side is disconnected from the circuit.

The lead-acid AGM battery was brought to a deep discharge, and an attempt to charge it with a standard charger did not lead to success. I had to charge the battery using a stationary power supply with the function of limiting the load current. A voltage of 30 V was applied to the battery, while at the first moment it consumed only a few mA of current. Over time, the current began to increase and after a few hours increased to 100 mA. After a full charge, the battery was installed in the flashlight.

Charging deeply discharged lead-acid AGM batteries as a result of long-term storage with increased voltage allows them to restore their performance. The method has been tested by me on AGM batteries more than a dozen times. New batteries that do not want to be charged with standard chargers, when charged from a constant source at a voltage of 30 V, are restored to almost their original capacity.

The battery was discharged several times by turning on the flashlight in the operating mode and charged using the standard charger. The measured charge current was 123 mA, with a voltage at the battery terminals of 6.9 V. Unfortunately, the battery was worn out and it was enough to operate the flashlight for 2 hours. That is, the battery capacity was about 0.2 Ah, and for a long-term operation of the flashlight it is necessary to replace it.

HL1-R2 circuit on the PCB was well placed, and it took an angle to cut just one current-carrying track, as in the photograph. The cutting width must be at least 1 mm. Calculation of the resistor value and verification in practice showed that for stable operation battery charge indicator requires a 47 ohm resistor with a power of at least 0.5 watts.

The photo shows a printed circuit board with a soldered current limiting resistor. After such refinement, the battery charge indicator lights up only if the battery is actually charging.

Modernization of the operating mode switch

To complete the repair and modernization of the lamps, it is necessary to solder the wires at the switch terminals.

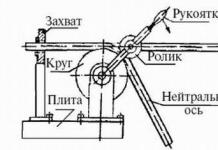

In models of repaired lamps, a four-position slide-type switch is used to turn on. The average conclusion in the above photo is a general one. When the switch slider is in the leftmost position, the common output is connected to the left output of the switch. When moving the switch engine from the extreme left position one position to the right, its common output is connected to the second output, and when the engine is moved further, to 4 and 5 outputs in series.

To the middle common terminal (see photo above) you need to solder the wire coming from the positive terminal of the battery. Thus, it will be possible to connect the battery to a charger or LEDs. You can solder a wire coming from the main board with LEDs to the first output, and a 5.6 ohm current-limiting resistor R5 can be soldered to the second output to enable switching the flashlight to an energy-saving mode. Solder the conductor coming from the charger to the far right terminal. Thus, it will be impossible to turn on the flashlight while the battery is charging.

Repair and modernization

LED rechargeable flashlight-spotlight "Photon PB-0303"

Another copy from a series of Chinese-made LED lamps called the Photon PB-0303 LED spotlight came to be repaired. The flashlight did not react when the power button was pressed, an attempt to charge the flashlight battery using a charger did not lead to success.

The flashlight is powerful, expensive, costs about $20. According to the manufacturer, the luminous flux of the flashlight reaches 200 meters, the body is made of impact-resistant ABS plastic, the kit includes a separate charger and a shoulder strap.

The Photon LED flashlight has good maintainability. To gain access to the electrical circuit, it is enough to unscrew the plastic ring holding the protective glass by turning the ring counterclockwise when looking at the LEDs.

When repairing any electrical appliance, troubleshooting always begins with the power source. Therefore, the first step was to measure the voltage at the terminals of the acid battery using a multimeter turned on in the mode. It amounted to 2.3 V, instead of 4.4 V. The battery was completely discharged.

When the charger was connected, the voltage at the battery terminals did not change, it became obvious that the charger was not working. The flashlight was used until the battery was completely discharged, and then it was not used for a long time, which led to a deep discharge of the battery.

It remains to check the health of the LEDs and other elements. To do this, it was necessary to remove the reflector, for which six self-tapping screws were unscrewed. There were only three LEDs on the printed circuit board, a chip (microcircuit) in the form of a droplet, a transistor and a diode.

From the board and the battery, five wires went to the handle. In order to understand their connection, it was necessary to disassemble it. To do this, you need to unscrew the two screws inside the lantern with a Phillips screwdriver, which were located next to the hole into which the wires went.

To detach the lamp handle from its body, it must be moved away from the fastening screws. This must be done carefully so as not to tear the wires from the board.

As it turned out, there were no electronic elements in the pen. Two white wires were soldered to the outputs of the on / off button of the flashlight, and the rest to the connector for connecting the charger. A red wire was soldered to the 1st output of the connector (numbering conditional), which was soldered with the other end to the positive input of the printed circuit board. A blue-white conductor was soldered to the second contact, which was soldered with the second end to the negative pad of the printed circuit board. A green wire was soldered to terminal 3, the other end of which was soldered to the negative terminal of the battery.

electrical circuit diagram

Having dealt with the wires hidden in the handle, you can draw an electrical circuit diagram of the Photon flashlight.

From the negative terminal of the GB1 battery, voltage is supplied to pin 3 of connector X1 and then from its pin 2 through the blue-white conductor it goes to the printed circuit board.

Connector X1 is designed in such a way that when the charger plug is not inserted into it, pins 2 and 3 are connected to each other. When the plug is inserted, pins 2 and 3 are disconnected. Thus, automatic disconnection of the electronic part of the circuit from the charger is provided, which excludes the possibility of accidentally turning on the flashlight while charging the battery.

From the positive terminal of the battery GB1, voltage is supplied to D1 (chip-chip) and the emitter of a bipolar transistor of the S8550 type. The CHIP performs only the function of a trigger, which allows the button to turn on or off the glow of the EL LEDs (⌀8 mm, glow color is white, power 0.5 W, current consumption 100 mA, voltage drop 3 V.) without fixation. When you first press the S1 button from the D1 chip, a positive voltage is applied to the base of the transistor Q1, it opens and the supply voltage is supplied to the LEDs EL1-EL3, the lamp turns on. When the button S1 is pressed again, the transistor closes and the lamp turns off.

From a technical point of view, such a circuit solution is illiterate, since it increases the cost of the flashlight, reduces its reliability, and in addition, due to the voltage drop at the Q1 transistor junction, up to 20% of the battery capacity is lost. Such a circuit design is justified if it is possible to adjust the brightness of the light beam. In this model, instead of a button, it was enough to put a mechanical switch.

It was surprising that in the circuit the EL1-EL3 LEDs are connected in parallel to the battery like incandescent bulbs, without current-limiting elements. As a result, when turned on, a current passes through the LEDs, the value of which is limited only by the internal resistance of the battery, and when it is fully charged, the current may exceed the allowable for the LEDs, which will lead to their failure.

Checking the health of the electrical circuit

To check the health of the microcircuit, transistor and LEDs from an external power supply with a current limiting function, a 4.4 V DC voltage was applied with polarity directly to the power pins of the printed circuit board. The current limit value was set to 0.5 A.

After pressing the power button, the LEDs lit up. After pressing it again, they went out. LEDs and a microcircuit with a transistor turned out to be serviceable. It remains to deal with the battery and charger.

Acid battery recovery

Since the acid battery with a capacity of 1.7 A was completely discharged, and the regular charger was faulty, I decided to charge it from a stationary power supply. When connecting the battery for charging to a power supply with a set voltage of 9 V, the charge current was less than 1 mA. The voltage was increased to 30 V - the current increased to 5 mA, and after an hour under this voltage it was already 44 mA. Further, the voltage was reduced to 12 V, the current dropped to 7 mA. After 12 hours of charging the battery at a voltage of 12 V, the current rose to 100 mA, and the battery was charged with this current for 15 hours.

The temperature of the battery case was within the normal range, which indicated that the charging current was used not to generate heat, but to store energy. After charging the battery and finalizing the circuit, which will be discussed below, tests were carried out. The flashlight with the restored battery illuminated continuously for 16 hours, after which the brightness of the beam began to fall, and therefore it was turned off.

Using the method described above, I had to repeatedly restore the performance of deeply discharged small-sized acid batteries. As practice has shown, only serviceable batteries, which have been forgotten for some time, are subject to recovery. Acid batteries that have exhausted their resource cannot be restored.

Charger repair

Measuring the voltage value with a multimeter on the contacts of the output connector of the charger showed its absence.

Judging by the sticker pasted on the adapter case, it was a power supply unit that outputs an unstabilized constant voltage of 12 V with a maximum load current of 0.5 A. There were no elements in the electrical circuit that limited the amount of charging current, so the question arose why charger used an ordinary power supply?

When the adapter was opened, a characteristic smell of burnt electrical wiring appeared, which indicated that the transformer winding had burned out.

The continuity of the primary winding of the transformer showed that it was open. After cutting the first layer of tape insulating the primary winding of the transformer, a thermal fuse was found, designed for a response temperature of 130°C. The test showed that both the primary winding and the thermal fuse were faulty.

It was not economically feasible to repair the adapter, since it was necessary to rewind the primary winding of the transformer and install a new thermal fuse. I replaced it with a similar one, which was at hand, with a DC voltage of 9 V. The flexible cord with the connector had to be soldered from a burned-out adapter.

The photo shows a drawing of the electrical circuit of the burned-out power supply unit (adapter) of the Photon LED flashlight. The replacement adapter was assembled according to the same scheme, only with an output voltage of 9 V. This voltage is quite enough to provide the required battery charge current with a voltage of 4.4 V.

For interest, I connected the flashlight to a new power supply and measured the charging current. Its value was 620 mA, and this was at a voltage of 9 V. At a voltage of 12 V, the current was about 900 mA, significantly exceeding the load capacity of the adapter and the recommended battery charge current. For this reason, the primary winding of the transformer burned out from overheating.

Refinement of the electrical circuit diagram

LED rechargeable flashlight "Photon"

To eliminate circuit technical violations in order to ensure reliable and long-term operation, changes were made to the lamp circuit and the printed circuit board was finalized.

The photo shows the electrical circuit diagram of the converted LED lamp "Photon". In blue, additionally installed radio elements are shown. Resistor R2 limits the battery charge current to 120 mA. To increase the charging current, you need to reduce the value of the resistor. Resistors R3-R5 limit and equalize the current flowing through the LEDs EL1-EL3 when the flashlight is on. The EL4 LED with a current-limiting resistor R1 connected in series is installed to indicate the process of charging the battery, since the developers of the flashlight design did not take care of this.

To install current-limiting resistors on the board, the printed tracks were cut, as shown in the photo. The charge current limiting resistor R2 was soldered at one end to the contact pad, to which the positive wire from the charger was previously soldered, and the soldered wire was soldered to the second terminal of the resistor. An additional wire (yellow in the picture) was soldered to the same contact pad, designed to connect the battery charging indicator.

Resistor R1 and indicator LED EL4 were placed in the flashlight handle, next to the X1 charger connector. The anode lead of the LED was soldered to pin 1 of connector X1, and to the second pin, the cathode of the LED, a current-limiting resistor R1. A wire was soldered to the second output of the resistor (yellow in the photo), connecting it to the output of the resistor R2, soldered to the printed circuit board. Resistor R2, for ease of installation, could also be placed in the flashlight handle, but since it heats up when charging, I decided to place it in a freer space.

When finalizing the circuit, resistors of the MLT type with a power of 0.25 W were used, except for R2, which is designed for 0.5 W. EL4 LED is suitable for any type and color of glow.

This photo shows the operation of the charge indicator while the battery is charging. The installation of the indicator made it possible not only to monitor the process of charging the battery, but also to control the presence of voltage in the network, the serviceability of the power supply and the reliability of its connection.

How to replace a burnt chip

If suddenly the CHIP - a specialized unmarked microcircuit in the Photon LED lamp, or similar, assembled according to a similar scheme, fails, then to restore the lamp's performance, it can be successfully replaced with a mechanical switch.

To do this, remove the D1 chip from the board, and instead of the transistor switch Q1, connect an ordinary mechanical switch, as shown in the above electrical diagram. The switch on the lamp body can be installed instead of the S1 button or in any other suitable place.

Repair and alteration of the LED lamp

14Led Smartbuy Colorado

The Smartbuy Colorado LED flashlight stopped turning on, although three AAA batteries were installed with new ones.

The waterproof case was made of anodized aluminum alloy, had a length of 12 cm. The flashlight looked stylish and was easy to use.

How to check the batteries in the LED flashlight for suitability

Repair of any electrical appliance begins with checking the power source, therefore, despite the fact that new batteries were installed in the flashlight, repairs should begin with checking them. In the Smartbuy flashlight, the batteries are installed in a special container, in which they are connected in series with the help of jumpers. In order to gain access to the batteries of the flashlight, you need to disassemble it by turning the back cover counterclockwise.

Batteries must be installed in the container, observing the polarity indicated on it. The polarity is also indicated on the container, so it must be inserted into the lamp body with the side on which the “+” sign is applied.

First of all, you need to visually check all the contacts of the container. If there are traces of oxides on them, then the contacts must be cleaned to a shine with sandpaper or the oxide should be scraped off with a knife blade. To prevent re-oxidation of the contacts, they can be lubricated with a thin layer of any machine oil.

Next, you need to check the suitability of the batteries. To do this, by touching the probes of the multimeter, included in the DC voltage measurement mode, it is necessary to measure the voltage at the contacts of the container. Three batteries are connected in series and each of them must produce a voltage of 1.5 V, therefore the voltage at the terminals of the container must be 4.5 V.

If the voltage is less than specified, then it is necessary to check the correct polarity of the batteries in the container and measure the voltage of each of them individually. Perhaps only one of them sat down.

If everything is in order with the batteries, then you need to insert the container into the lamp body, observing the polarity, tighten the cover and check it for operability. In this case, you need to pay attention to the spring in the cover, through which the supply voltage is transmitted to the lamp body and from it directly to the LEDs. There should be no signs of corrosion on its end face.

How to check the health of the switch

If the batteries are good and the contacts are clean, but the LEDs do not shine, then you need to check the switch.

The Smartbuy Colorado flashlight has a two-position sealed push-button switch that shorts out the wire coming from the positive terminal of the battery container. When the button is pressed for the first time, its contacts close, and when it is pressed again, it opens.

Since batteries are installed in the flashlight, you can also check the switch using a multimeter switched on in voltmeter mode. To do this, you need to rotate it counterclockwise, if you look at the LEDs, unscrew its front part and set it aside. Next, with one probe of the multimeter, touch the body of the flashlight, and the second to the contact, which is located deep in the center of the plastic part shown in the photo.

The voltmeter should show a voltage of 4.5 V. If there is no voltage, press the switch button. If it is correct, then the voltage will appear. Otherwise, the switch needs to be repaired.

Checking the health of the LEDs

If it was not possible to detect a malfunction at the previous steps of the search, then at the next stage it is necessary to check the reliability of the contacts supplying the supply voltage to the board with LEDs, the reliability of their soldering and serviceability.

A printed circuit board with LEDs soldered into it is fixed in the head part of the lamp with a steel spring-loaded ring, through which the supply voltage is simultaneously supplied to the LEDs from the negative terminal of the battery container through the lamp body. In the photo, the ring is shown from the side with which it presses the printed circuit board.

The retaining ring is fixed quite firmly, and it was possible to remove it only with the help of the device shown in the photo. Such a hook can be bent from a steel strip with your own hands.

After removing the retaining ring, the printed circuit board with LEDs, which is shown in the photo, was easily removed from the head of the lamp. The absence of current-limiting resistors immediately caught my eye, all 14 LEDs were connected in parallel and through a switch directly to the batteries. Connecting the LEDs directly to the battery is unacceptable, since the amount of current flowing through the LEDs is limited only by the internal resistance of the batteries and can damage the LEDs. At best, it will greatly reduce their lifespan.

Since all the LEDs in the flashlight were connected in parallel, it was not possible to check them with a multimeter switched on in the resistance measurement mode. Therefore, a DC supply voltage of 4.5 V was applied to the printed circuit board from an external source with a current limit of up to 200 mA. All LEDs lit up. It became obvious that the malfunction of the flashlight was due to poor contact of the printed circuit board with the fixing ring.

Current consumption of LED lamp

For interest, I measured the current consumption of LEDs from batteries when they were turned on without a current-limiting resistor.

The current was more than 627 mA. The flashlight is equipped with HL-508H type LEDs, the operating current of which should not exceed 20 mA. 14 LEDs are connected in parallel, therefore, the total current consumption should not exceed 280 mA. Thus, the current flowing through the LEDs exceeded the rated current by more than two times.

Such a forced mode of operation of the LEDs is unacceptable, as it leads to overheating of the crystal, and as a result, premature failure of the LEDs. An additional disadvantage is the rapid discharge of batteries. They will be enough, if the LEDs do not burn out earlier, for no more than an hour of operation.

The design of the flashlight did not allow soldering current-limiting resistors in series with each LED, so I had to install one common resistor for all LEDs. The value of the resistor had to be determined experimentally. To do this, the flashlight was powered by standard batteries and an ammeter was connected in series with a 5.1 Ohm resistor in the positive wire break. The current was about 200 mA. When installing a resistor of 8.2 ohms, the current consumption was 160 mA, which, as the test showed, is quite enough for good lighting at a distance of at least 5 meters. To the touch, the resistor did not heat up, so any power is suitable.

Alteration of the design

After the study, it became obvious that for reliable and durable operation of the flashlight, it is necessary to additionally install a current-limiting resistor and duplicate the connection of the printed circuit board with the LEDs and the fixing ring with an additional conductor.

If earlier it was necessary that the negative bus of the printed circuit board touched the body of the lamp, then in connection with the installation of a resistor, it was necessary to exclude contact. To do this, a corner was ground from the printed circuit board along its entire circumference, from the side of the current-carrying tracks, using a needle file.

To prevent the clamping ring from touching the current-carrying tracks when fixing the printed circuit board, four rubber insulators about two millimeters thick were glued to it with Moment glue, as shown in the photograph. Insulators can be made from any dielectric material, such as plastic or heavy cardboard.

The resistor was pre-soldered to the clamping ring, and a piece of wire was soldered to the extreme track of the printed circuit board. An insulating tube was put on the conductor, and then the wire was soldered to the second terminal of the resistor.

After a simple do-it-yourself upgrade of the flashlight, it began to turn on stably and the light beam illuminates objects well at a distance of more than eight meters. In addition, the battery life has more than tripled, and the reliability of the LEDs has increased many times over.

An analysis of the causes of failures of repaired Chinese LED lights showed that they all failed due to illiterately designed electrical circuits. It remains only to find out whether this was done intentionally in order to save on components and shorten the life of the flashlights (so that more people buy new ones), or as a result of the illiteracy of the developers. I'm leaning towards the first assumption.

Repair of the LED lamp RED 110

I got a flashlight with a built-in acid battery from a Chinese manufacturer of the RED trademark for repair. There were two emitters in the lantern: - with a beam in the form of a narrow beam and emitting scattered light.

The photo shows the appearance of the RED 110 flashlight. I immediately liked the flashlight. Convenient body shape, two modes of operation, a loop for hanging around the neck, a retractable plug for connecting to the mains for charging. In the lantern, the section of diffused light LEDs shone, but the narrow beam did not.

For repair, the black ring fixing the reflector was first unscrewed, and then one self-tapping screw was unscrewed in the loop area. The body is easily divided into two halves. All parts were fixed on self-tapping screws and were easily removed.

The charger circuit was made according to the classical scheme. From the network, through a current-limiting capacitor with a capacity of 1 μF, the voltage was applied to a rectifier bridge of four diodes and then to the battery terminals. The battery voltage was applied to the narrow beam LED through a 460 Ohm current-limiting resistor.

All parts were mounted on a single-sided printed circuit board. The wires were soldered directly to the pads. Appearance printed circuit board is shown in the photo.

10 side light LEDs were connected in parallel. The supply voltage was supplied to them through a common current-limiting resistor 3R3 (3.3 ohms), although according to the rules, a separate resistor must be installed for each LED.

An external examination of the narrow beam LED did not reveal any defects. When power was supplied through the flashlight switch from the battery, voltage was present at the LED terminals, and it heated up. It became obvious that the crystal was broken, and this was confirmed by a multimeter dial. The resistance was 46 ohms for any connection of the probes to the LED terminals. The LED was defective and needed to be replaced.

For convenience, wires were soldered from the LED board. After releasing the leads of the LED from the solder, it turned out that the LED was firmly held by the entire plane of the reverse side on the printed circuit board. To separate it, I had to fix the board in the desktop temples. Next, place the sharp end of the knife at the junction of the LED with the board and lightly hit the knife handle with a hammer. The LED bounced off.

Marking on the LED housing, as usual, was missing. Therefore, it was necessary to determine its parameters and select a suitable one for replacement. Based on the overall dimensions of the LED, the battery voltage and the value of the current-limiting resistor, it was determined that a 1 W LED (current 350 mA, voltage drop 3 V) would be suitable for replacement. From the "Reference Table of Popular SMD LED Parameters", a white LED6000Am1W-A120 LED was selected for repair.

The printed circuit board on which the LED is mounted is made of aluminum and at the same time serves to remove heat from the LED. Therefore, when installing it, it is necessary to ensure good thermal contact due to the tight fit of the back plane of the LED to the printed circuit board. To do this, before sealing, thermal paste was applied to the contact points of the surfaces, which is used when installing a radiator on a computer processor.

In order to ensure a snug fit of the LED plane to the board, you must first put it on a plane and slightly bend the leads up so that they recede from the plane by 0.5 mm. Next, tin the leads with solder, apply thermal paste and install the LED on the board. Next, press it against the board (it is convenient to do this with a screwdriver with the bit removed) and heat the leads with a soldering iron. Next, remove the screwdriver, press it with a knife at the bend of the output to the board and heat it with a soldering iron. After the solder has hardened, remove the knife. Due to the spring properties of the leads, the LED will be tightly pressed against the board.

When installing the LED, polarity must be observed. True, in this case, if a mistake is made, it will be possible to swap the voltage supply wires. The LED is soldered and you can check its operation and measure the current consumption and voltage drop.

The current flowing through the LED was 250 mA, the voltage drop was 3.2 V. From here, the power consumption (you need to multiply the current by the voltage) was 0.8 W. It was possible to increase the operating current of the LED by reducing the resistance to 460 ohms, but I did not do this, since the brightness of the glow was sufficient. But the LED will work in a lighter mode, heat up less and the flashlight's operating time from a single charge will increase.

Checking the heating of the LED worked for an hour showed effective heat dissipation. He heated up to a temperature of no more than 45 ° C. Sea trials showed a sufficient range of illumination in the dark, more than 30 meters.

Replacing the acid battery in the LED flashlight

An acid battery that has failed in an LED flashlight can be replaced with a similar acid battery, as well as lithium-ion (Li-ion) or nickel-metal hydride (Ni-MH) batteries of AA or AAA size.

Lead-acid AGM batteries of various dimensions without marking with a voltage of 3.6 V were installed in the repaired Chinese lanterns. According to the calculation, the capacity of these batteries is from 1.2 to 2 Ah.

On sale you can find a similar acid battery from a Russian manufacturer for UPS 4V 1Ah Delta DT 401, which has an output voltage of 4 V with a capacity of 1 Ah, costing a couple of dollars. To replace it is quite simple, observing the polarity, solder the two wires.

Suitable for various capacities. The luminous efficiency of the device must not exceed 80 lm. Also, pay attention to the driver. As a rule, it is installed with an output capacitor. Some models have an amplifier. On average, their current consumption is 3 A.

If we consider sensitive modifications, then they have a protection system against voltage surges. In order to understand the issue in more detail, it is necessary to consider specific models.

Circuits with capacitive capacitors

Capacitive capacitor LED flashlight circuits include wave filters. In this case, flip-flops are used on a semiconductor basis. As a rule, their output voltage parameter does not exceed 20 V. Converters are used to reduce sensitivity. Drivers for models are installed with different bandwidth. If we consider a 30 V LED, then it has a transceiver.

Using snubber capacitors

The snubber capacitor LED circuit includes contact filters. In total, the models have two converters. The driver is connected to the LED through a winding. Some modifications have a compact transceiver. Most often it is used with an amplifier.

Characteristics of LED marked 530

These are universal and for flashlights. The characteristics of the devices indicate a high conductance factor. LEDs are produced for 20 and 25 V. If we consider the first option, then the luminous efficiency of the device is on average 60 lm. The color rendering coefficient in this case depends on the conductivity of the transceiver. For many models, the amplifier is used without a converter.

The current consumption indicator for LEDs does not exceed 2.5 A. The turn-on time for models of this type is about 6 ms. If we consider 25 V LEDs, then they use only a pulse transceiver. Many models have one amplifier. The driver is connected using a converter. The luminous flux parameter lies in the region of 65 lm. The turn-on time for LEDs of this type is 7 ms.

LED 640 (LEDs for flashlights): characteristics, photo

The LED circuit of the specified series includes a phase-type converter. Filters are used to increase sensitivity. Amplifiers are most often used on a magnetic basis. The luminous efficiency parameter in the devices is 65 lm. It is also important to note that the current consumption indicator does not exceed 4.2 A. The frequency deviation is on average 4 Hz.

The service life of LEDs of this type is three years. The disadvantages of the devices include the low current conductivity of the drivers. Their brightness level is extremely low. Light efficiency, as a rule, does not exceed 5%. These 6 volt flashlight LEDs fit well.

Using LED 765

The 12V device uses the specified flashlight LEDs. The characteristics of 2014 indicate an increased level of current consumption. this modification is equal to 45 lm. It is also important to note that the model is suitable for switching amplifiers. The driver in the device is used at 6.5 microns. Phase interference to the indicated LEDs is not terrible.

Luminous efficiency averages 70 lm. The service life of the device does not exceed four years. The color rendering index is 80%. For flashlights with regulators, the model fits perfectly. In this case, the devices are connected via a contact adapter.

Scheme LED 840

These are compact and versatile LEDs for flashlights. The characteristics of the model primarily indicate a high dispersion rate. Its pulsation coefficient reaches a maximum of 80%. The turn-on time of the device is 5 ms. If you believe the experts, then the model fits perfectly for 12 V flashlights. The amplifier in the device is installed absorbing type.

In total, the model has two drivers. The LED trigger is used with an adapter. To solve problems with heat loss, a capacitor is used as standard. The luminous efficiency of the presented model is 67 lm. The conductivity index does not exceed 10 microns. In this case, the current consumption is 0.3. The minimum allowable LED temperature is only -10 degrees. The model does not have an overheating protection system.

Characteristics of LED 827

Models with fit the specified flashlight LEDs. The characteristics of the device indicate the presence of high-quality wired transceivers. Amplifiers in the model are installed in an open type. In total, the device uses two capacitors. They do an excellent job of minimizing heat loss. The minimum allowable LED temperature is -15 degrees.

They are not suitable for 15 V flashlights. The protection system in the device is used with filters. The driver for the model is provided for 4.5 microns. The current consumption is no more than 4 A. The turn-on time of the LED is on average 6 ms. The pulsation coefficient of the model is 85%. Luminous efficiency, as a rule, does not exceed 50 lm.

LEDs LED 830

For 10 V devices, these LEDs for flashlights are great. Their features are pretty good. The turn-on time is 5 ms, the luminous efficiency is 65 lm, and the current consumption is 3.3 A. The model uses a phase-type converter. If you believe the experts, then the model is not suitable for 15 V flashlights.

There is no transceiver in the specified LED. The driver itself is installed with a conductivity of 4.5 microns. Problems with rectification of current are solved thanks to capacitors. The pulsation coefficient of the model reaches a maximum of 90%. The service life of the presented device is three years. The minimum allowable LED temperature does not exceed -20 degrees.

Characteristics of LED series LB

For 15 V flashlights, the indicated LED is suitable. The characteristics of the model indicate an increased color rendering coefficient. The output voltage of the model is 15 V. The filter in the device is of the wave type. The driver in this case is connected through a conductor. The transceiver at the LED is used with an adapter. The condenser is installed open type. The model has two triggers in total. In this case, the power consumption is 2.5 A.

The luminous flux of the device reaches a maximum of 65 lm. The ripple coefficient of the model is insignificant. Also, a small level of the minimum allowable temperature can be attributed to the disadvantages. Chinese LED flashlight turns on in 4 ms. Problems with rectification of the current in the model rarely occur. For 10 V flashlights, the specified model is not suitable. There is no overheating protection system for the LED. The frequency deviation of the model is 5 Hz. These Cree flashlight LEDs fit great.

daylight

These LEDs for flashlights are produced with high-quality pulse-type amplifiers. In total, the model has two capacitors. The transceiver is standard wired type. It is also important to note that the maximum frequency deviation is 4 Hz. The current consumption of the LED does not exceed 3 A. The luminous flux of the device is 70 lm. The light output of the model is negligible.

If you believe the experts, then the model fits perfectly for 12 V flashlights. Direct connection of the driver is carried out through an adapter. The average turn-on time is 6 ms. The service life of the presented model is 5 years. The minimum allowable LED temperature is -15 degrees.

TB series (warm white light)

These are simple and not expensive LEDs for flashlights. The characteristic of the device suggests that the color rendering coefficient of the model is low. It is also important to note that the output voltage is 8V. The life of the LED is three years. The transceiver of the modification uses high sensitivity. In total, the model has two capacitors. According to experts, the device is not suitable for 10 V flashlights. The current consumption indicator for the model is 2 A. The LED luminous flux reaches a maximum of 65 lm.

Problems with negative modulation are rare. Only a small conductivity parameter can be attributed to the disadvantages. Filters in the device are used only open type. The maximum frequency deviation of the LED reaches 5 Hz. A trigger will be applied to reduce the sensitivity on the capacitor. The ripple coefficient of the model is insignificant. A wire adapter is required to install the LED.

Features of LHB series LED models (cold white light)

These LEDs have good characteristics. First of all, it is important to note that the color rendering coefficient is 80%. In this case, the service life is three years. The direct output voltage is 12 V. The turn-on time is 5 ms. In this case, the amplifier is used with an adapter. If you believe the experts, then problems with heat loss are rare. The capacitors of the model are of the through type.

When choosing or assembling a new LED flashlight, be sure to pay attention to the LED used. If the only task of the future flashlight is to illuminate a dark entrance, then almost any bright white LED will cope with this task. Another thing is the desire to get a portable lighting device with parameters for a more complex task. In this case, the luminous flux is of particular importance, that is, the ability of the flashlight to give out a sufficiently powerful beam and illuminate a wide area of space.

What brands of LEDs are in the top positions, and what are the characteristics of their light emitting diodes used in flashlights?

Main characteristics

For the quality of the light emitted by the flashlight, the LED is responsible, which can be called the heart of the device without exaggeration. The stability of the flashlight's heart rate depends on many parameters, the main of which are current consumption, luminous flux and color temperature. The trendsetter is considered to be the Cree company, which produces a wide range of super-bright and powerful LEDs, including for flashlights. Modern flashlights are designed on a single LED with a power of 1, 2, or 3 watts. In a one-watt version, the forward current value is about 350 mA with a voltage drop of 2.8-2.9 V.

The current and voltage of a two-watt LED is about 700 mA and 3.0 V, respectively, and a similar 3-Watt crystal consumes about 1000 mA and 3.2 V. The electrical figures shown are typical for LED models from leading world brands.

The intensity of radiation, which is also called the luminous flux, depends on the manufacturer and family of the LED. The passport value of the luminous flux of high-power LEDs is usually measured at the maximum allowable operating current. The manufacturer of branded lights, along with the type of LED installed, indicates the number of lumens issued by the product.

Unfortunately, often on the packaging of a flashlight overestimated characteristics are indicated, including the luminous flux. The reason for this is simple - any manufacturer wants to sell as much product as possible.

Luminous flux is inextricably linked with light. Modern light emitting diodes are capable of emitting a luminous flux of up to 200 lumens per 1 watt and can be produced with any glow temperature: from yellowish warm to cold white. Flashlights with warm white radiation (T≤3500°K) are the most pleasing to the eye, but less bright. Illumination with a neutral color temperature (T=4000-5500°K) allows you to see fine details more effectively. Cold-white beam (T≥6500°K) in powerful flashlights with a long illumination range, but during long operation it irritates the eyesight.  Due to the impossibility of making accurate calculations, the life span of LEDs is calculated by extrapolation. At a temperature of 25-50 °C, their lifetime of the crystal can exceed 200 thousand hours, but this is not economically justified. Therefore, manufacturers allow an increase in operating temperature up to 85°C, thus saving on cooling. Exceeding the threshold of 150°C leads to irreversible processes of crystal burnout and loss of brightness.

Due to the impossibility of making accurate calculations, the life span of LEDs is calculated by extrapolation. At a temperature of 25-50 °C, their lifetime of the crystal can exceed 200 thousand hours, but this is not economically justified. Therefore, manufacturers allow an increase in operating temperature up to 85°C, thus saving on cooling. Exceeding the threshold of 150°C leads to irreversible processes of crystal burnout and loss of brightness.

The color rendering index (CRI) is a qualitative indicator that characterizes the ability of an LED to illuminate objects without distorting their real color. For LED lighting sources, including flashlights, a color rendering index of 75 CRI and above is considered good.

An important element of the LED is the lens. It sets the angle of dispersion of the light flux, and therefore determines the range of the beam. In the technical characteristics of the LEDs, the value of the radiation angle must be indicated. For each model, this parameter is individual and can vary from 20 to 240 degrees. Powerful flashlight LEDs have an angle of 90-120° and are usually equipped with a reflector with an additional lens in the housing.

In spite of sudden jump in the development of high-power multi-chip LEDs, world leaders continue to release lower power LEDs. They are produced in boxes small size not exceeding 10 mm in width or diameter. The typical current value of such light emitting diodes does not exceed 70 mA, and the luminous flux is 50 lm. Powerful flashlights based on them are gradually disappearing from store shelves, due to the worst technical characteristics and the need for series-parallel connection to increase brightness. Compared to a single powerful crystal, the reliability of the circuit and the scattering angle of several such elements in one package are much worse.

Separately, it is worth noting the four-pin LEDs in the P4 "SuperFlux" or "Piranha" package, which have improved technical characteristics. Piranha LEDs have two important advantages due to which they are in demand:

- more evenly distribute the light flux;

- do not need heat dissipation;

- have a low cost.

5 largest manufacturers

A portable flashlight should be not only ergonomic, but also equipped with a reliable LED source with a long working life without loss of brightness. In order not to make a mistake with the choice, preference should be given to manufacturers of world-class LED products.

A division of the Japanese company Nichia for a long time held a leading position in the production of LEDs of all types. Due to the high cost of production and increasing competition from China and Taiwan, today it is less and less possible to meet their LEDs in lamps on the European market. However, Nichia is needed by the world as an engine of progress. After all, the developments of Japanese companies are taken as a basis by their Chinese and Taiwanese counterparts.  Powerful flashlight LEDs from the world-famous Cree company hold the lead not only on the American continent. Favorably distinguished by lower cost and high quality, LEDs from Cree are available to everyone on the European continent. A rechargeable flashlight on a powerful crystal from an American brand is a reliable friend on a hike, night fishing, etc.

Powerful flashlight LEDs from the world-famous Cree company hold the lead not only on the American continent. Favorably distinguished by lower cost and high quality, LEDs from Cree are available to everyone on the European continent. A rechargeable flashlight on a powerful crystal from an American brand is a reliable friend on a hike, night fishing, etc.  Philips Lumileds is a European manufacturer of wide spectrum light emitting diodes. The company has made some progress in building outdoor lighting systems of functional and architectural significance. Philips Lumileds developers take an integrated approach to building LED systems, taking into account their design, degree of protection and ease of use.

Philips Lumileds is a European manufacturer of wide spectrum light emitting diodes. The company has made some progress in building outdoor lighting systems of functional and architectural significance. Philips Lumileds developers take an integrated approach to building LED systems, taking into account their design, degree of protection and ease of use.  The South Korean corporation Samsung, well-known in Russia, has timely funded its department for the search for new LED solutions and now has a full cycle of production of emitting diodes. Samsung is not limited to the release of LED backlight for its own displays. Their success has spread to other market segments: high power LEDs (including for flashlights), ultra-bright flash elements, as well as indoor and outdoor lighting modules.

The South Korean corporation Samsung, well-known in Russia, has timely funded its department for the search for new LED solutions and now has a full cycle of production of emitting diodes. Samsung is not limited to the release of LED backlight for its own displays. Their success has spread to other market segments: high power LEDs (including for flashlights), ultra-bright flash elements, as well as indoor and outdoor lighting modules.  Osram Opto Semiconductors has become famous for the excellent performance of its Duris series LEDs, which stand out for their high light output and color rendering index. The German company has staked on the introduction of LED technologies in the industrial sector, focusing on the production of ready-made specialized lamps and fixtures. Osram laboratories improve the performance of light emitting diodes not only in the visible spectrum, but also make discoveries in the IR, UV and laser direction.

Osram Opto Semiconductors has become famous for the excellent performance of its Duris series LEDs, which stand out for their high light output and color rendering index. The German company has staked on the introduction of LED technologies in the industrial sector, focusing on the production of ready-made specialized lamps and fixtures. Osram laboratories improve the performance of light emitting diodes not only in the visible spectrum, but also make discoveries in the IR, UV and laser direction.

Reports from scientists, along with news about the development of artificial lighting, indicate the continued healthy competition between large corporations. We see positive trends in the development of LED technology in the constantly updated range of flashlights, which surprise with their long-range beam, high degree of protection, the ability to charge from solar energy and other know-how.

Read also

Flashlights are used for different purposes: in everyday life, construction, travel. Their main characteristics are impact resistance, moisture resistance, luminous range and directivity of the light beam.

LED flashlights are easy to turn on and carry by hand. They shine quite brightly, have high power. The case is made of plastic or metal.

Plastic flashlights are light, metal ones are not afraid of moisture, dust and shock. Models are equipped with a wrist strap, they can focus the rays, lengthening or bringing them closer.

Working principle of LED lamp:

- The LED consists of semiconductors that convert the incoming current into light radiation. The current is directed only from the anode to the cathode, a p-n junction is created.

Electrons meet holes and lose their energy, from which photons are formed. It is necessary that several semiconductors with different types of conductivity interact with each other.

- A hole is a place in the crystal lattice, after exposure to which electrons move from the upper atomic shells, and a positive charge is formed.

Electrons move towards a positive charge, and holes move towards a negative one. Free place filled with electrons between them.

- Electrons and holes through diffusion penetrate through the layer formed in the semiconductor between areas of different conductivity. This is necessary for the concentration of the same number of electrons and holes on both sides of the layer.

In this case, the stress on the intermediate layer increases. After the recombination of holes and electrons, the barrier in the p-n junction decreases, and light energy is released.

Types of lanterns

- Manual full size flashlights are used in cases where high power of the device is important for long time, and its dimensions do not matter. Models are designed for constant holding in hands, easy to transport.

- Handheld compact lights are used to light the way or look for small objects in the dark. These devices will come in handy in unexpected situations, so they must be portable and convenient for everyday wear.

- Lanterns on the forehead allow you to work with your hands in places with poor lighting. Lighting range - up to 30 meters. Often such devices are equipped with the function of selecting the best mode in a certain place at a certain time.

Headlamps are used by hunters, tourists, motorists, cyclists, builders, doctors.

- Tourist lanterns- resistant to mechanical stress, moisture resistant, practical and compact devices. Both batteries and accumulators are used as a power source for most models.

- Dynamo lights– portable devices that work without batteries; to put the mechanism into action, you should rotate the charging handle for some time.

Such a device does not pollute the environment, it can be used to recharge the phone.

- diving lights have high water resistance, the function of changing the color rendering of the luminous flux. They have a high brightness of light, allow you to illuminate objects that are located at long distances.

Most models are equipped with a mode switching function.

- Laser lights- devices that are structurally close to search engines, equipped with a rugged housing. As a rule, such models work at low temperature conditions, have a sealed and reliable case made of metal alloy.

Among the advantages of such devices: small dimensions, impact resistance, several batteries in the kit, the presence of a remote control panel.

- Keychains- compact devices that are worn in a keychain. Used to perform simple tasks, their functionality and brightness are lower than those of hand-held devices.

- Flashlights-shockers– not only a personal lamp, but also effective remedy self-defense. They painfully shock even through thick down jackets.

They are characterized by durability, stable metal case, which is not subject to mechanical damage. The prices for these devices are high.

- - devices used in conjunction with weapon mounts. The main function is to illuminate the target in low light. Lighting range - within 50 meters.

Among the technical characteristics are a narrow glow angle, small dimensions and power of the device. The metal housing of the instruments provides thorough water protection. Additional features: remote control, mode switching.

- - devices used for carrying in hands, with high brightness and glow range. The devices have a large battery compartment. Lighting range - up to 250 meters.

Equipped with the function of changing the angle of illumination, switching modes, with an average power. The metal case is durable and waterproof.

By type of food are distinguished:

- Flashlights that run on batteries. Recharged from the mains, the power source is a nickel-cadmium, nickel-metal hydride, lead-acid or lithium-ion battery.

- Battery powered flashlights. Such devices are lighter, do not require recharging the device.

Lantern characteristics

Among the characteristics of flashlights stand out:

- dimensions;

- brightness of the light flux;

- light source power (LED models);

- working hours;

- number of operating modes;

- resistance to external influences (moisture, frost resistance);

- digital current stabilization;

- availability of additional accessories.

Light flow(brightness of the LED flashlight) - a value that is measured in lumens.

Uniform diffused illumination with low brightness can be obtained in an LED flashlight with the same number of lumens, long-range flashlights provide narrow and bright beams.

The lighting range of flashlights is from 60 to 150 meters. Portable models can illuminate the space at a distance of 15 meters.

LED models:

- conventional DIP LEDs,

- SMD LEDs,

- COB technologies,

- projector LEDs,

- RGB LEDs,

- LED strips.

DIP LEDs consist of two metal legs, a clear plastic case with a small lens inside; the structures are easy to install and use, provide good protection from environmental influences, and practically do not radiate heat.

SMD LEDs are flat, without legs, their current is supplied to the terminals that are located on the back of the LED; have good indicators of brightness and light output.

COB LEDs provide fast light diffusion, spotlight LEDs are high power devices.

RGB-LEDs are equipped with a glow color control function. The LED strip has high brightness and energy efficiency.

The maximum operating time of the flashlight indicated as an average value and depends on the mode of operation and battery capacity. This time can be calculated in minutes, hours and days.

Flashlight body material:

- aluminum,

- plastic,

- polymer.

Housings of aluminum fixtures are strong enough, have a cylindrical shape. Powder coating protects the metal from corrosion. Anodized lamps are not exposed to mechanical damage.

There are many polymer and plastic varieties of cases. Polymeric materials are elastic, not afraid of shock.

Lantern length, as a rule, does not exceed 84 cm. This indicator depends on the functionality of the device. Compact handheld models up to 15.5 cm long are used for domestic needs.

The weight of the lanterns is from 100 grams to 1 kilogram.

The kit may include:

- lamp;

- spare sealing rings;

- lanyard;

- company card for the model;

- case;

- factory packaging;

- Charger;

- warranty card;

- user guide.

Accessories used include:

- cases for accumulators;

- fixtures for lanterns;

- silicone grease for rubber surfaces;

- diffusing caps, red filters for illumination;

- additional buildings;

- metal clips for fastening;

- hand straps;

- overlay on the button in the tail of the lantern.

Features of hand lamps:

- high power devices;

- are easily transported;

- used in construction and at home;

- portable and convenient for daily wear.

- good lighting range;

- allow you to work in places with low light;

- wide scope of use.

Features of tourist lamps:

- moisture resistance;

- resistance to mechanical stress;

- practical and mobile devices.

Features of dynamo lights:

- portability and compactness;

- run on batteries;

- do not pollute the environment.

- good level of water resistance;

- high level of light brightness;

Features of laser lights:

- have a solid body;

- work in low temperature conditions;

- have small dimensions;

- have high impact resistance.

- compact devices;

- used to perform simple tasks;

- low technical characteristics.

Features of flashlights-shockers:

- effective means of self-defense;

- have a durable metal case;

- are not exposed to mechanical damage;

- such devices are expensive.

- illuminate the target in low light;

- used in conjunction with a weapon mount;

- have a high illumination range;

- small dimensions.

Features of search lights:

- have a high brightness of the glow;

- have a good range of illumination;

- with remote control function;

- equipped with a mode switch function.

Advantages of types of lanterns

Pros of flashlights:

- convenient and compact;

- suitable for individual use;

- easy to transport;

- have high power.

Benefits of headlamps:

- convenient and practical;

- allow you to free your hands;

- you can choose the appropriate mode of operation;

- wide range of uses.

- equipped with a mode switching function;

- resistance to mechanical stress;

- moisture resistant;

- practical and compact devices;

- have a high radiation intensity.

Advantages of dynamo flashlights:

- work without batteries;

- do not pollute the environment;

- used in places with no natural light.

Advantages of diving lights:

- high impermeability;

- function of changing the color rendering of the light flux;

- good illumination at long distances.

Advantages of laser lamps:

- equipped with a solid structure;

- frost-resistant models;

- small dimensions;

- high impact resistance.

- compact and easy to use devices;

- lungs.

- used for self-defense;

- have a solid body;

- not subject to mechanical damage.

Advantages of tactical flashlights:

- target illumination in low light;

- high range of illumination;

- good power devices;

- remote control function.

Pros of search lights:

- high brightness;

- good range of illumination;

- the presence of the function of changing the angle of illumination;

- switching modes.

Cons types of lanterns

Cons of hand-held full-size fixtures:

- heavy and weighty;

- Designed to be held permanently.

Disadvantages of handheld flashlights:

- not suitable for stationary use;

- Designed for constant holding in the hands;

- technical characteristics are low.

- unidirectional light flow;

- slipping of the flashlight with a loose mount.

Disadvantages of flashlights-shockers:

- high price;

- hefty construction.

- low technical characteristics;

- poor color rendering and low light intensity.

Disadvantages of laser lights:

- heavy structures;

- high price.

- low technical characteristics;

- illuminate a small area;

- they are easy to lose.

Disadvantages of tactical flashlights:

- high price;

- light is directed to one target.

- large dimensions;