Now a very popular weapon is a crossbow. Despite the complexity, a crossbow can be made at home. In ancient times, it was used as a formidable weapon. Now the crossbow is used in sports at shooting ranges at short and medium distances. Nowadays, you can buy everything, including a crossbow. But it is much more interesting to do it yourself. For those who are skilled, know how to use machines and tools, this will not be a big deal.

Earlier we described how to do it, if you are interested, take a look.

For a crossbow, we need a wooden blank and iron.

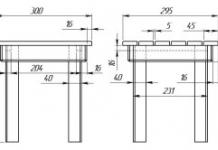

A wooden blank is cut to such dimensions.

We take a spring plate measuring 650 × 100 × 8. Cut off the excess with an angle grinder. In we make an arc with a size of 35 mm - this is in the middle and with edges of 18 mm.

With an emery machine, we reduce the edges from the middle to the edge, reaching up to 5 millimeters in thickness. We pull a steel dart onto the arc (you can use a cable). We firmly fix. In order not to interfere with the arc to bend exactly in the middle, we put a wooden round timber. Simultaneously with the tension, we look at the stresses and the tension gap.

These dimensions are the basis of our work on making a crossbow at home.

We cut the iron billet and get the part that will be the main one in our crossbow-hook, it is also called the “cat”.

To make a lock, we need a trigger and a sear. On top of the axis we make a hole into which the bolt of the strip spring should fall, which fixes the pin from moving

Next, we will make the lock and the case.

We carefully measure and make holes for the pins.

Then we make protection for the trigger and measure it to a wooden base.

Cut out a hole for the lock.

We insert the lock

We fix the whole. We make a "dovetail" and solder an aiming device to it. Depending on the heating temperature during burnishing, this can be done with POS or PSR.

It is necessary to drill holes in the arch, this must be done with a victorious drill. All this is necessary for fastening the clamps.

We sharpen the rollers to the required dimensions.

We cut the clamps to the size we need and then we fix the clamp to the arc of the crossbow.

Making stirrups

I clamp the bowstring (cable) with a vise. Tip, do not try to rivet, you need to squeeze!

In the process of manufacturing.

Detail made.

We make an opening for the guide from a wooden blank

We glue the metal bar in the form of a groove.

With the help of cutters and chisels on wood, we make a butt.

This article will be devoted to such throwing weapons as a homemade crossbow. From the following lines, you will not learn how to make a crossbow yourself, but you will get information about what homemade crossbows are and how well they shoot. Also within the framework of this article we will touch on the issue of the legality and expediency of such a hobby.

This article will be devoted to such throwing weapons as a homemade crossbow. From the following lines, you will not learn how to make a crossbow yourself, but you will get information about what homemade crossbows are and how well they shoot. Also within the framework of this article we will touch on the issue of the legality and expediency of such a hobby.

The material will be critical and we will try to dissuade you from such a dubious undertaking as making a crossbow at home. Let's get started, I hope you enjoy it.

Archery market in Russia is growing year by year. More and more fans of silent and accurate shooting appear in the country, and what could be better suited for this activity than a crossbow? Perhaps a compound bow, but to accurately shoot a bow, skill and some experience are needed.

With a crossbow, everything is somewhat simpler. The form factor of a rifle with a shoulder rest, the ability to install optics or a collimator make shooting from this type of weapon more familiar, and, therefore, more popular among consumers.

There are not many brands in the world that produce high-quality and reliable crossbows. You can count about a dozen companies, and almost all of these manufacturers are represented on our website. But in general, manufacturers satisfy the demand of almost all categories of consumers. The price of a crossbow starts from 5,000 rubles, the question is natural - to whom and why in such a situation to make a crossbow on their own, if you can just buy it in a store.

As a rule, very young people under 20 years old, or experienced men who are fond of designing, and very often designing everything, are engaged in this kind of crafts. Very rarely, almost never, a homemade crossbow is started by a person who is sorry for the money to buy.

In fact, despite the deceptive simplicity of design, making a crossbow on your own is not as easy as it seems. Most often, homemade crossbows are made from bows, or spring-like steel plates with blocks. As a bowstring "Kulibin" uses a metal cable. Such bulky things shoot badly, weigh a lot, and hit crookedly.

If we talk about blocks for a homemade crossbow, then, as a rule, they are either machined on their own, or, in some cases, they use aluminum coils from old tape recorders. The wear of such eccentrics is extremely high and they fly even from an ordinary shot, not to mention a blank

The bed of a homemade crossbow can be either steel or wood. It all depends on the imagination of a particular "Kulibin". As a descent, there are mechanisms from old guns, or everything is made independently on milling machines. Popular among homemade and such a game as making a block crossbow from a recursive one.

As a spoonful of honey, let's say that sometimes very spectacular gizmos are obtained, of impressive size and impressive power. The main problem of homemade crossbows is the accuracy of hits, which cannot be compared with branded models. On various forums, you can see photos of homemade crossbows with a brief description of the technical characteristics. And among the mass of slag, you can find models with a tension force of 40 kg. and a range of about 100 meters. But here's the catch - homemade crossbows, as a rule, have no ballistics, and getting somewhere even from 50 meters, not to mention 100, is almost impossible.

For you to understand, branded models are carefully tested and shot at various types of targets before being released into production, and all detected shortcomings are corrected. Then, already modernized and devoid of flaws from the last test, the crossbow is tested again. And so on, until the declared range and aiming accuracy are reached. Is it necessary to say that in the case of "home-made" all this is not?

Another disadvantage is the legality of such a hobby. If you go too far with increased tension, you can get an impressive administrative fine, provided that the police find the product in your possession. However, the police will be obliged to seize such a thing from you, even if the tension increase does not exceed 40 kg, because you will not have certificates for the product.

If you want to make a crossbow yourself, we strongly recommend that you think carefully before you get started. This activity, although interesting, is labor-intensive, and the result is completely unpredictable. At the exit, you can get either a deadly bazooka or a zilch.

At the same time, remember that it is difficult to call this activity legal. In the best case, the product will be confiscated from you, in the worst case, you will also pay for it. This opinion is a purely personal point of view of the author of the article and may not coincide with yours. In our opinion, it is much easier, smarter and more convenient to buy a crossbow in an online store.

In this case, you will receive a guaranteed result, the declared technical characteristics and a full package of documents, including certificates, that this product is not a weapon.

Twenty years ago, a bow or crossbow for individual use did not exist in nature. Some eccentrics and fanatics of historical reconstructions undertook their manufacture at their own peril and risk, having absolutely no idea what they would get in the end. And all because the process of accumulating experience and honing skills in the manufacture and use of throwing weapons, which lasted several tens of thousands of years, was once interrupted and anathematized in our time.

Now all this rare knowledge has been taken out of dusty chests, people have learned to make bows and crossbows using modern technologies, and the army of followers of William Tell and Robin Hood is growing exponentially. And today we have prepared for you drawings and diagrams that will tell you how to make a crossbow at home.

Despite the abundance of online stores selling throwing weapons, as well as the fantastic breadth of the product range, there are many who want to make a crossbow on their own. Most of them don't know where to start. Today we will tell you about the main design features of the crossbow. This knowledge will help you avoid manufacturing errors, as well as frustration and injury when using it.

Before starting work, you should know two main points.

- In our country, a crossbow is recreational and sporting weapons. Hunting with him is prohibited. Any throwing weapon with a pull force of more than 43 kilograms is considered combat, the right to use which is given by the licensing authorities of the Ministry of Internal Affairs.

- The crossbow is design that experiences enormous loads during operation. Therefore, any carelessness in its manufacture is likely to result in injury. Any part of it must have a multiple margin of safety.

So, let's find out how to make a simple crossbow at home.

The video below will tell you how to make a crossbow at home:

Onion

The energy source of the crossbow is a bow - an elastic plate of complex shape, which has one main bend and, as an option, two additional ones at the ends. It is necessary to start making a crossbow with this part and adjust everything else to it - the choice of the type of tension (recursive or block), the size of the stock, the type of trigger mechanism.

Wood and composite

There is an acute question about what to use as a material for a bow: wood, composite or metal?

- Wood is the worst choice. Available "wood" lying underfoot is garbage, suitable only for kindling stoves. Branches cut down in the forest, as they dry out, lose their elasticity, crack and fall apart. From this material you can only do something for short-term entertainment in the country. Of the models sold in stores, and having a tree in their composition, it is very popular, as well as.

- Composite, created from fiberglass and epoxy binder, is very tempting and outwardly simple. But there is an obstacle - the need for scrupulously precise adherence to the technology of all work. The proportions of the mixture, drying, exposure. At home, this is almost impossible.

Metal

There remains one uncontested option - metal. If you have an old Moskvich with a set of leaf springs on hand, then consider yourself lucky. One sheet is taken from the entire package - the second. If you are not too afraid of the dimensions, then the first one will do. Moreover, he has at the ends of the tube - an almost ready-made bracket for attaching blocks or bowstrings.

A block is used to attach the bow to the stock. This is a U-shaped design, clasping the box in front. It can be welded tightly to the spring leaf, but in this case, when the bow is bent, the welds will experience excessive pull-off stress. Therefore, it is better to fix the ball joint from the VAZ 2108 on the block. The bow is attached to its pin. This is also convenient because there is a hole on the spring leaf.

If you are very strong, then you can stop at the recursive method of pulling the bowstring (as in, etc.). But it is better to choose a block one (as in models, etc.). To attach blocks to the bow, if you have chosen a second spring leaf, you need to fix the brackets at its ends. A bolted (and even better riveted) connection is preferable to welding, since this assembly experiences strong vibration loads. As pulleys, use the parts of the glass lifting mechanism of the same Moskvich.

Regarding the bowstring, an obvious solution suggests itself: a thin metal cable. But it is not entirely true, since steel cables do not withstand variable loads well. It is better to choose a climbing cord with a diameter of 5-8 mm.

Having made a bow and fastened a bowstring to it, you can conduct natural bending tests. It’s great if at the same time you have a dynamometer of kilograms for 100-150. As a result, you will find out two parameters necessary for further work: the length of the bowstring and the load.

How to make a stock on a powerful crossbow at home, read below.

Lodge

For this part of a homemade crossbow, a tree is an uncontested option. But not everyone. In any case, not aspen, alder, spruce or pine. Better beech, elm, oak. A blank dried for twenty years. It is clear that you will never find anything like this anywhere. Therefore, use moisture-resistant plywood with a thickness of 7-9 mm. 3 or 5 contours of the stock are cut out of it, and then this package is glued with epoxy. Not very pretty, but extremely reliable.

- Regarding the form - give up the semi-pistol, use a straight English box. It is not only easier to manufacture, but also stronger.

- When assembling a stock package, both the course of the bowstring and the load must be taken into account. The first determines the distance from the shoe to the groove for the trigger. The second is the thickness of the stock walls at the place of its attachment. It is a straight English stock that will allow you to avoid excessive thinning when moving from the forearm to the butt.

- The most important detail of the crossbow lodge is the arrow guide. It should be smooth and durable. For it, you can use plates framing the side windows of the Moskvich, furniture fittings, and other parts similar in shape.

- If you are using a block type of bowstring tension, then there should be a groove in the forearm under the guide for the cable system. This is another element that weakens the stock, so give up on the thought of making the forearm graceful. High will protect your fingers from falling under the bowstring and traumatic amputation of the phalanges.

Usually crossbows have a plastic stock, such as models, and others.

We will talk about how to make a homemade trigger for a crossbow at home below.

This video will tell you how to make a crossbow out of wood (plywood) with your own hands:

Trigger mechanism

If you are not a mechanic of the sixth category, then give up the idea of \u200b\u200bmaking this element yourself. Apply force and find the trigger from any spring-piston air rifle. In the most difficult case, you will only have to modify its tooth holding the piston - it may be small for a thick bowstring.

Above the trigger mechanism, a casing with a height of 2 to 5 cm is arranged, which is necessary in order to protect it from moisture and dirt, and which is also the basis for sighting devices - slats for optics or a rear sight. Weaver, Picatinny or dovetail rails can be bought at any online store that sells pneumatics.

The front part of the casing above the trigger mechanism is made in the form of a long (no more than 10 cm) elastic “tail”, with which the rear part of the arrow is held on the guide.

Arrow making

Canonically correct ammunition for a crossbow is called "bolt". But many online stores sell crossbow arrows. For crossbows with a rifle stock, lengths of 14, 16, 20, 22 inches are suitable. To be absolutely frank, you won’t find better store arrows. Unfortunately, none of them costs less than 150 rubles. Therefore, it is worth trying to make them yourself.

Canonically correct ammunition for a crossbow is called "bolt". But many online stores sell crossbow arrows. For crossbows with a rifle stock, lengths of 14, 16, 20, 22 inches are suitable. To be absolutely frank, you won’t find better store arrows. Unfortunately, none of them costs less than 150 rubles. Therefore, it is worth trying to make them yourself.

They can be made from wood, straight-grained, without knots. As an option - use furniture details - balusters from chairs, railings of cribs. Good arrows are obtained from aluminum tubes with a diameter of up to 2 cm. If desired, even electrodes of the maximum diameter can be used, but they hopelessly bend when hit and it is difficult to screw plumage to them.

For plumage, thin plastic is used. Natural bird feathers can give an unexpected effect of a chaotic change in flight direction, since they have natural curves that must be taken into account.

The main condition for a good, smooth flight is balancing. The center of gravity of the crossbow bolt should be after the first third of the length from the tip. If it is not metal, then the end of the arrow can be loaded with lead wire wrapped around the shaft.

The issue of equipping an arrow with a tip should be treated without fanaticism. Turning metal on lathes, milling and polishing, giving exquisite forms - these operations are accessible to few. In addition, such a tip is extremely dangerous. If you do not need to pierce knight armor, then a wooden bolt can simply be sharpened at an angle of 30 degrees using a regular knife.

We will tell you how to make a crossbow that shoots with your own hands from paper, pencils and other materials.

Cool shooting games

A toothpick or match shooter can be made from a wooden clothespin. To do this, disassemble it and redo it:

- expand the narrow groove for the spring of one half to 1 cm, on the second make the same, but indented by 1 cm;

- at the front ends of both halves, from the side of the narrow grooves for the spring, make a longitudinal groove 1-2 mm deep;

- collect the halves of the clothespin "inside out" by twisting them with a thread;

- install the clothespin spring with the paws in the cut grooves, and with the spiral outward;

- insert a toothpick into the hole between the halves;

- press the spring coil, shifting it into a semicircular cutout;

The foot of the spring will slide down the long slot, snapping the toothpick and causing it to fly out.

To learn how to make a mini crossbow out of pencils with your own hands at home, see the video below.

If you do not want to buy an expensive crossbow (and prices sometimes exceed $ 1000), you can make a crossbow with your own hands. It is not as difficult as it seems at first glance. The design of the crossbow is quite simple. A crossbow can be made from what is at hand, replacing the missing materials with similar ones. For target shooting, a homemade crossbow is quite suitable.

General view of the crossbow, which you can do with your own hands according to the drawings

The design of this crossbow uses the achievements of manufacturers in the field of weapons. The drawings show a crossbow block design. By following the instructions and observing all sizes, you can make a high-quality and good crossbow with your own hands, even at home.

The general scheme of a homemade crossbow in the assembly:

To begin with, it is advisable to carefully study the drawings of the crossbow and proceed with the assembly with your own hands. Making a crossbow with your own hands is not an easy task. But this increases the interest in the work! After all, a homemade crossbow can bring great joy and respect to the performer.

Crossbow device: bed, shoulders, butt, trigger mechanism, sighting devices, block system. For the manufacture of the bed, natural wood, solid or glued laminated timber, mostly hardwoods, is used. The exact dimensions of the crossbow can be seen on the drawings. You choose the shape of the crossbow yourself, guided by the convenience and ergonomics of the stock, the desired image. When choosing, you must also consider whether you can make such a form correctly.

Drawing of shoulders and crossbow deck:

The use of a stock from small arms can significantly reduce labor costs for the manufacture of a crossbow. The main thing is to choose the right size. The trace from the trunk, remaining in such a box, must be hammered with wooden bars, firmly planting them on epoxy glue. The butt and underbarrel pad of the crossbow can also be made of wood. The butt will be attached to the rail and serve as the basis for the trigger.

Butt drawing:

Offered for assembly with your own hands, the crossbow has a block design. This allows you to compensate for the load when cocking the bowstring and save power. Block crossbows are the most popular among hunters. you can carry the crossbow in the cocked state for a long time. This design is actively used by Horton in the production of its crossbows.

Block assembly details drawing:

Pay special attention to the processing of the arrow and bowstring guides. The clarity of their finish greatly affects the accuracy of shooting. The lines of the guides must be perfectly straight and smooth. The best choice would be grinding on a milling machine and subsequent processing with fine-grained sandpaper. Next comes the polishing of the guides. You can see the dimensions of the boom guide groove in the drawings. The cross, with shoulders attached to it, is installed from the end end of the bed. Usually it is made from an aluminum blank. Wood can also be a suitable material.

The crossbow sight must consist of a rear sight and a front sight. Also, you can install an optical sight on the crossbow, providing a mount for the aiming bar. Vertical adjustments are carried out as a whole, mounted on the trigger cover, and horizontal - with a front sight mounted on the bracket of the elastic element.

There can be many design options for sights and sights for a crossbow, depending on the possibility of manufacturing, the availability of ready-made sights from conventional weapons (air rifles), etc.

It should be borne in mind that the flight path of the crossbow arrow (crossbow bolt) is quite high, so the rear sight must be installed well above the front sight. The angle of elevation of the sighting line depends on the weight of the arrow, the tension of the bowstring, the shooting distance, etc. In our crossbow at a distance of 50 m, it is approximately 6 °.

Convenient are the designs of the rear sight, which allow it to be removed or folded during transportation. It will also be convenient if the rear sight can be adjusted manually by raising or lowering the bar. Thus, you can shoot the crossbow under different conditions (distance to the target, arrow weight).

The crossbow, the manufacture of which is described above with your own hands, is designed for shooting with bolts with a diameter of 8 mm and a length of 450-470 mm. They can be easily made by yourself from a duralumin tube with a wall thickness of 0.5 mm. A tip and an inner are attached to the bolt in front, plumage is attached to the back, as is done for archery. It should be borne in mind that the shank of a bolt for a crossbow, unlike an arrow for a bow, should not have a cutout for the bowstring, it should be flat. It can be carved out of wood in the form of a cork and inserted into the end of the tube, previously lubricated with glue.

In addition, it will be interesting to shoot from such a gun yourself. Everything is done quite simply, here you can completely do with hand tools. The crossbow turned out to be quite powerful, as for training shooting. It uses double shoulders, which increases the rigidity of the bow and allows you to throw wooden arrows at high speed. The author uses self-tapping screws as an arrowhead, but you can show your imagination and come up with something more interesting.

Materials and tools used

List of materials:

- timber;

- PVC pipe;

- two self-tapping screws;

- strong rope;

- wooden rods for arrows;

- adhesive tape (for plumage).

List of tools:

- hacksaw or pendulum saw;

- jigsaw;

- belt sander;

- drill;

- marker;

- roulette;

- screwdriver;

- building hair dryer;

- vice;

- oil for wood processing;

- paint for painting onions (optional).

The process of making a crossbow:

Step one. Cut out blanks

First of all, we will cut the wooden beam, it will be used to make the base. We also need to cut the pipe. You should have two pieces, a long one and a short one. See the photo for dimensions.

Step two. We make a bed

We make a bed from a wooden bar. First of all, we will make the necessary markup using a marker. Well, then we cut out the extra parts using a jigsaw, an electric jigsaw will do an excellent job with this task.

Step three. Let's make a bow

Our bow consists of two parts, which increases its rigidity. Everything is made of PVC pipes that need to be made flat. To do this, we need a vise with a wooden insert so that there are no prints on the pipes. We heat the pipe with a building hair dryer until it becomes soft, and then squeeze it in a vise. Step by step we heat the sections and compress. At the end, we form the desired bow profile.

Step four. Bow mount

To attach the bow, we are looking for its center, and then we drill two holes, like the author. For fastening we use two self-tapping screws, as well as washers. But do not fasten the bow tightly yet, it still needs to be finalized.

Step five. We finalize the bow

The essence of the refinement is to make grooves at the ends of the shoulders, to which it will be possible to tie a bowstring. We make the markup and cut out the extra parts with the help of a jigsaw. As for the short shoulder, then grooves must be made at the ends so that the bowstring does not fly off.

Step six. Setting the bowstring

As a bowstring we use a strong synthetic rope. We cut off two pieces of the desired length and melt the ends with a lighter. Well, then we tie the main bowstring to the ends of the shoulder with a little tension. As for the extra shoulder, you will need another rope to use it. How everything is connected, you can see in the photo.

Step seven. Arrangement of the trigger mechanism

The trigger mechanism is of the trigger type. It consists of two parts, one is a trigger, and the second is a part with teeth, one of which holds the bowstring, and the other rests on the trigger. These parts can be cut out of plywood using a jigsaw.

Step eight. Arrow making

We make arrows from wooden rods. To stabilize the flight, make plumage for them, the author used adhesive tape for this. Well, at the end of the arrow you need to install some kind of weight, the author wrapped a self-tapping screw there. If desired, you can cut off the head and sharpen the rod.