Each cyclist should not only, but also be able to properly care for him, including pulling the chain on the bike. Many questions arise precisely with mountain vehicles. We recommend that you put aside all your affairs and familiarize yourself with the information provided on how to correctly and quickly tension the chain on a mountain bike. This knowledge will come in handy again and again.

The chain is one of the most important elements of the bike, which requires proper installation and adjustment.

The subtleties of installing a bicycle chain

A bicycle cannot be called a very complex device, there are more complicated ones. But still, in its design there are several important and irreplaceable elements on which the operation of the entire mechanism directly depends. The important place is always occupied by the chain. It will only work for a long time if .

It is necessary to monitor its work and quickly respond to emerging problems. For example, a properly installed and serviceable chain should not make extraneous sounds in the form of crackling and squeaking. During the operation of the bicycle, this element can stretch and be subject to wear.

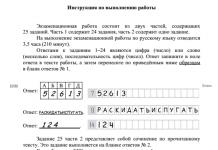

If the installation and adjustment of the chain was performed correctly, then it should sag by 10-12 mm, no more and no less. Pulling the chain with your fingers, it should move away from its original position by 1-1.5 cm. With a greater pull, it is urgent to tighten the chain. Such regulations apply only to two types of bicycles: models with no speed switch or with a planetary gearshift mechanism installed.

When a new chain is installed, it is imperative to adjust the tension level, and after three trips, it is necessary to tighten it. The new mechanism is prone to rapid stretching.

Different ways to tension the chain

With significant differences in design. To correctly tension a chain on a bicycle, you need to know the rules that apply to your type of vehicle.

If the bike is without gears

For a bike that is not provided, the chain mechanism should only sag 5 mm. In order to achieve the correct operation of the transport and not encounter certain problems on the road, it is necessary to tension the chain in accordance with certain rules:

- Position the two-wheeled vehicle so that it is on the steering wheel and seat, and the wheels are on top.

- On the rear wheel, you will need to loosen the mounting nuts or eccentrics.

- By moving the wheel along the inclined grooves (dropouts), it is necessary to achieve the correct slack of the chain mechanism.

- the rear wheel is fixed only if its axis is strictly parallel to the carriage shaft;

- if the chain on the bike is too tight, then the pedaling will be complicated, and the mechanism itself will quickly become unusable;

- with a strongly sagging chain, the cyclist will often have to stop and correct it;

- removal of links on the chain mechanism is required if, during its installation or tightening, further adjustment of the wheel along the dropouts becomes impossible, and the chain is still sagging.

If the bike has several speed modes

The tension force of the chain mechanism on a bicycle, the design of which assumes the presence, directly depends on the stiffness index, which characterizes the spring on the switch.

With a long chain mechanism, the tensioner simply cannot compensate for excessive slack, respectively, the chain will beat against the frame. This problem is worth paying special attention to the owners of bicycles with insufficiently long rear throwers. With a short chain mechanism, it will be very difficult to change speed. As a result, the entire transmission structure will wear out faster. This problem is more pronounced in the case of two-suspension mechanisms.

A common problem during the installation of a new chain on this type of bike is the need to shorten it. To do this, you can use one of two methods:

- The chain mechanism is installed on the largest sprockets in front and behind. We pull for it and take the rear derailleur as far forward as possible. By adding two links, the required chain length can be determined.

- The chain mechanism is transferred in front to the largest sprocket, and behind, on the contrary, to the smallest one. The chain is then tightened until the bezel on the rear thrower points straight down. The required moment can be calculated from the axes of the switch rollers - they must be one line in a strictly vertical direction.

If you have to deal with two-suspension bikes, then the chain setting is carried out according to a slightly different principle. To do this, you need to press down on the rear swingarm so that the front cassette with sprockets is removed from the rear ratchet to the maximum distance. In this position, we make a mark corresponding to the required length of the chain and remove the extra links.

Removing links

We have often mentioned the need to remove extra links as a common problem for cyclists. If in the case of an ordinary bicycle a collapsible chain is used with a lock installed on one of the links, then the vast majority of modern models require the use of non-collapsible mechanisms in which all the links are well connected to each other.

Whole chains are the most difficult, especially for inexperienced users. But with certain knowledge, even in this case, you can remove the required number of links without much difficulty. The secret is hidden in the turning of the pin head on one of the links using emery.

You can choose an easier method, but for it you will need to use a squeeze - a special tool that allows you to separate the rivets on a non-separable bicycle chain mechanism. With the help of squeeze, you can return the mechanism to working condition.

So we have mastered the important procedure that every cyclist faces. Now you do not have to turn to an outsider every time to replace and adjust the chain on your bike.

Almost every modern household today has an electric chain or chainsaw. Sooner or later, most saw owners think about how to properly maintain and operate it so that the tool is in good working order and does not lose performance.

Most users show sufficient care in relation to the engine, while forgetting to pay attention to other important components of the chainsaw, on the serviceability of which its performance and durability largely depend. Proper care of all chainsaw components will save you money and extend the life of the device.

The topic of our conversation today will be the saw unit, which consists of a drive sprocket, tire and chain. The performance of the chainsaw depends on the serviceability of these parts even more than on the characteristics of the engine. After all, it’s not a secret for anyone - it’s not the motor that cuts, but the chain put on the tire and driven by the drive sprocket. Let's see what surprises can be expected after a few weeks or months of operation, how to choose and maintain the components of our chainsaw correctly.

Main characteristics

Despite its low cost, the chain plays a crucial role in the operation of a chainsaw. Not only its performance, but also the safety of other nodes largely depends on how correctly it is sharpened and stretched.

Chains are classified according to the following parameters:

- Step. By this term it is customary to mean the distance (measured in inches) between the first and third connecting rivets, divided in half. In fact, all existing saw chains are divided into five groups: ¼", 0.325", 3/8", 0.404" and ¾". When choosing, you should take into account: the larger the step, the greater the performance, but at the same time, the load on the engine increases significantly;

- Drive link shank thickness. This refers to the depth of landing on the groove of the bar, along which it moves during the sawing process. The deeper the seat, the less likely the chain is to come off the tire.

Manufacturers offer the following modifications:

- 1.1 mm - for miniature instruments;

- 1.3 mm - most household-class gasoline and electric saws are equipped;

- 1.5 mm - semi-professional models;

- 1.6 mm - used on professional chainsaws;

- 2.0 mm - industrial chain saws;

Other circuit parameters:

- Profile. This refers to the height of the cutting edge of the chain above the bar. According to this indicator, saw chains are divided into two types: low-profile and high-profile. Low profile chains are safer to use, while high profile chains provide high performance. In addition, the chains are distributed according to the profile of the cutting teeth: semi-chisel, chisel, rounded and teeth with victorious soldering.

- Cutting depth. In other words, the gap between the saw tooth and the stop. In household chainsaws, it is correct to use chains with a gap of 0.025″ and 0.03″. Chains up to 0.07″ are available on professional and industrial models.

- Number of links. When choosing a chain for a chainsaw, be guided by the length of the bar. For example, if you have a household Chinese saw with a 14″ bar, you most likely need a 52 link chain.

Important! The correct selection of a chain for a chainsaw is carried out in accordance with the parameters specified in the instruction manual.

Causes of a circuit malfunction

Like any other part, the saw chain requires attention and proper maintenance. First of all, these words refer to the break-in period of the chainsaw and saw set. However, their serviceability should be monitored throughout the entire operational period.

The main causes of circuit failure:

- Poor metal quality on budget models;

- Operator's work style;

- Wrong tension;

- Malfunction or excessive wear of the drive sprocket;

- Malfunctions in the automatic lubrication system;

- Curvature, debris or other damage to the saw bar;

- Use of poor quality materials;

- Untimely sharpening of working edges;

- The level of operational loads on the chainsaw;

All this can lead to rather sad circumstances, and significant expenses for the purchase of new spare parts and chainsaw repair:

- Deterioration of operational capabilities and labor productivity;

- Operator safety during sawing operations;

- Premature wear of individual components and parts and the entire chainsaw;

Tire maintenance and operation

An important part in the saw chainsaw is the tire. It is from its serviceability, in many respects, the performance and quality of the device depends.

Premature tire wear is most often caused by improper operation of the automatic lubrication system. Strong friction occurs in the saw zone, which leads to heating and deformation of the metal. As a rule, the driven sprocket fails first. Also, to prevent premature wear, it is important to turn the tire over often - this contributes to the uniform erasure of the rollers of the driven sprocket.

Important: use a bar with the specifications specified by the manufacturer of your chain saw. This will extend the life of both the saw set itself and the entire benzo or electric saw.

The main tire malfunctions:

- Deformation or damage to the tire body;

- Erasure of teeth or complete failure of the driven sprocket;

- Wear of the landing groove and shank;

- Critical damage to oil supply channels;

- Breakage or complete wear of the tensioner;

Do-it-yourself chain shortening

Like any other part, the chainsaw chain gradually wears out, and constant loads and work in different temperature conditions leads to its lengthening. In this case, it cannot be properly tensioned, it periodically flies off the tire. Is it possible to repair such a part at home. As practice shows, this does not require special devices, skills or high qualifications. However, you should take care of the presence of a vise, needle file, hammer, pliers and breakdown.

If you have all these tools, you can safely proceed with the disassembly:

- Determine how much the chain length has increased;

- We fix the chain in a vice;

- We grind off the protruding heads of the rivets with a file or file, while trying not to touch the side parts of the links;

- We dismantle the rivets using a breakdown or a release clamp;

Important: when disconnecting links, be sure to count the guides on the inside. There must be a match between them and the leading asterisk.

- We remove the required number of links and connect the ends of the chain. For this we use old rivets;

- We flare the rivet heads with light blows of the hammer;

- With a file or needle file, we remove burrs and irregularities;

Important: the links can be riveted and riveted quickly enough, however, it should be remembered that after repair they will be weakened and will not be able to last for a long time.

Proper chain adjustment

The quality of the chainsaw largely depends on the correct adjustment and tension of the chain. If the chain is of normal length, then this process will not take much time and effort.

Important: during operation, the metal heats up and expands, which leads to an elongation of the chain. Periodically check the tension and correct it.

The tightening process looks quite simple and takes several minutes:

- Loosen the nuts on the protective roof;

- Adjusting screw correct tension;

Important: A properly tensioned chain moves easily along the bar with a little hand effort, without making extraneous sounds and without stopping. At the same time, with the correct tension, the links should not sag.

- Tighten the nuts and check the tension, correct if necessary;

Video review

Overview of chain shortening

An overview of how to properly rivet and rivet connecting links

The chain is one of the most important structural elements that ensure the movement of the bicycle. And its service life depends on the regularity and quality of care. An indicator that something is wrong with the bike chain is the crackling and creaking during movement, as well as its slippage on the ratchet.

In principle, it is normal for the chain to wear out over time. And a visual sign of wear is chain stretching. The fact that the chain has become unusable can even be felt tactile. In the normal position, this part sags slightly (by 10 or 12 millimeters), and if you pull it slightly, it will succumb by another 10-15 mm. True, this method is relevant only for models that do not have high-speed switching or have a planetary-type transmission.

Adjusting the chain tension on bicycle models without gears

For bikes without gears to function flawlessly, their chain must not be too tight. It is necessary to ensure its free sagging for a length of up to 5 mm. And to pull in this way, you need to perform a certain set of actions in the correct sequence:

For bikes without gears to function flawlessly, their chain must not be too tight. It is necessary to ensure its free sagging for a length of up to 5 mm. And to pull in this way, you need to perform a certain set of actions in the correct sequence:

- Turn the vehicle upside down.

- Loosen the rear wheel mounting - unscrew the nuts or mounting eccentrics.

- Adjust the chain slack to the required amount. To do this, carefully move the wheel along the inclined grooves (dropouts).

- At the end of the adjustment, you should again fix the wheel to its original position. In this case, the wheel axle must be parallel to the carriage shaft.

If the chain is too tight, it will become hard to pedal. And the elements of the chain drive will very soon become unusable. It is also bad if the bike chain is too slack. It will simply jump off the stars at a certain moment and it will be impossible to go further.

When the wheel literally rested on the dropouts and there is absolutely nowhere to move it further, but at the same time the bicycle chain dangles, you will have to remove a couple of links from it. In all likelihood, it was stretched or was not at all in size for a particular model.

Chain tension on a bike with a parallelogram derailleur (rear) is determined solely by the spring rate of the derailleur itself. But the chain, which turned out to be too long, will begin to beat against the frame, since the tensioner will no longer be able to compensate for its sagging.

Chain tension on a bike with a parallelogram derailleur (rear) is determined solely by the spring rate of the derailleur itself. But the chain, which turned out to be too long, will begin to beat against the frame, since the tensioner will no longer be able to compensate for its sagging.

It should be borne in mind that insufficient chain length leads to wear of the main transmission parts, since it makes it difficult to switch them. And especially it is necessary to pay attention to this to the owners of two-suspension bicycles.

When installing a new bike chain on high-speed models, the chain should be shortened. For several links. But to determine exactly how many links need to be removed, you can use two possible methods:

- Pull the chain front and back over the largest sprockets. And then pull the chain, moving the rear derailleur forward and to the limit. It remains to add 2 links, and you get a chain of optimal length.

- Or the chain needs to be transferred in front to the largest sprocket, in the back - to the smallest. And pull on the chain until the rear shifter frame is in the “straight down” position and the derailleur rollers form a horizontal line. This is the optimal chain length, the excess must be removed, and the missing must be added.

On two-suspension bicycles, it is more correct to adjust the chain (or rather, adjust its length) by pressing down the pendulum - to a position at which the front star cassette will be as far away from the ratchet as possible. The resulting chain length is measured and noted, and all unnecessary is removed.

Ordinary speedless bikes are equipped with collapsible chains, one of the links of which has a special lock. But on professional bikes, one-piece chain structures are installed, all the links of which are perfectly riveted.

Ordinary speedless bikes are equipped with collapsible chains, one of the links of which has a special lock. But on professional bikes, one-piece chain structures are installed, all the links of which are perfectly riveted.

However, disassembling a one-piece riveted bicycle chain is also easy. And you can do this in one of two possible ways:

- grind the pin heads on one of the chain links with sandpaper;

- or using a universal tool - squeeze.

By the way, it is not for nothing that pomace is called “universal”. It can not only squeeze out the pin, but also securely fix the newly assembled bicycle chain. After all, the pomace (well, at least most of them) has a couple of special functional and technological grooves. And with one of these grooves, the pin is pressed out of the roller, and the other is pressed in. As for the mounting location, which is located on the squeeze a little further from the pressure screw, it is intended for riveting the chain pin itself.

Slip like a chain defect

Every cyclist is familiar with the problem of chain slippage. The chain stretches over time and its tension weakens. In addition, the chain stretch leads to rapid wear of the bicycle sprockets. It would seem that it is easier - you just need to remove 2 links. But the “trick” is that this can be done only once, and then the chain needs to be changed.

Every cyclist is familiar with the problem of chain slippage. The chain stretches over time and its tension weakens. In addition, the chain stretch leads to rapid wear of the bicycle sprockets. It would seem that it is easier - you just need to remove 2 links. But the “trick” is that this can be done only once, and then the chain needs to be changed.

Regularly tensioning the chain on a chainsaw is necessary not only for efficiency, but also for the safety of the worker. On most devices (especially the Stihl brand), there is a special device on the side, as in the photo, which helps to bring the links into their normal position.

How to install a chain on a chainsaw?

You can install and tension the chain by unscrewing the main screw and putting the links on the drive sprocket and saw bar. It is important to ensure that the tails fall into the groove so that they do not fly off again.

Before tensioning the chain of a Husqvarna chainsaw, it is worth looking at its condition and, if necessary, replacing it with another one. After removing this part, you need to carefully examine the guide groove along which the links go. It is there that dirt accumulates, absorbing oil and interfering with the tension of the cutting part. This place is cleaned with a thin metal object. If these steps are not taken, the oil may not get to the bottom of the bar, and after installing the chain, the links will slide less well, which affects the efficiency of sawing.

How to tension the chain?

In order to correctly tension the chain on a Husqvarna chainsaw with the engine not running, the screws securing the cover are first loosened. After that, the part is rotated to correct the tension. If the links sag at the bottom (even a little), then you need to tighten them. Before you pull the chain on a chainsaw (Husqvarna, for example), you should read the attached documents. After all, the mechanisms of different companies have their own differences.

How should the chain be tensioned on a chainsaw? You can determine this by lifting it up. Normally, the shank should be one third immersed in the groove. If it came out completely, then the chain must be tightened, if it came out less than 2 thirds, loosen it. When scrolling, the links should pass freely along the tire. After the movement of the hand, the links under normal tension pass a little more by inertia. If the chain instantly slows down, then this indicates a pull.

To quickly tension the chain on a Stihl chainsaw, there are special devices that help you do this without keys. To use them, just release the sprocket cover, and then turn the adjusting wheel to the left to loosen, to the right to tighten. All this is done only when the links are cold.

Chain selection

The efficiency of the Husqvarna chainsaw and its service life depend not only on the ability to pull the links, but also on whether it is suitable for a particular brand of device. This detail differs according to several criteria:

- step;

- thickness;

- cutting depth;

- chain length and number of teeth.

The pitch value is the main parameter for the chain, on the basis of which this part is selected. Its value is determined by the gap between the tails. Common options: 0.325, 0.375, 0.404 inches. You can find out which type a particular saw needs by reading the instructions. The smaller the step, the less power the mechanism should have on which it should be pulled.

A large step affects the “aggressiveness” of the tool, that is, the cutting links enter the wood more strongly, and therefore the worker is required to hold the Druzhba chainsaw more tightly. The 0.325 chain is very common among household and semi-professional mechanisms. It can be pulled on Druzhba chainsaws with a power equal to 3 hp. For sawing small trees and construction work, this chain is best suited.

The designation of the number 0.375 is rare, since the marking has been replaced by the value 3/8 for the convenience of buyers, because 75 and 25 are easy to confuse if the purchase is made by a non-professional. The power of the Goodluck chainsaw, for example, should be 4 hp. Otherwise, the instrument may be damaged.

Links with a pitch of 0.404 can only be pulled on professional mechanisms with a power of more than 5 hp.

So, the main markings:

- 0,325;

- 0,375;

- 0,404;

Chain thickness classification

The groove on the saw bar on different units has its own thickness, therefore, for greater work efficiency, it is better to choose the optimal one. The minimum parameter is 1.1 mm. Such a part can only be installed on household mechanisms with low power. A chain with a link width of 1.3 mm is more popular. It is used on both cheap and semi-professional Goodluck chainsaws.

The remaining types are used on powerful tools: 1.5, 1.6 and 2 mm. The last 2 of those listed are only for professional Ural mechanisms. But before choosing a part by thickness, you need to find out which one can generally be installed on the saw bar of a particular tool.

- 1.1 - the simplest saws;

- 1.3 and 1.5 - semi-professional;

- 1.6 and 2 mm are the most powerful.

Proper care of the chain and timely tension is the key to durability. With due attention to the chainsaw Ural or another brand, and the worker himself, it is easier to cope with a well-tuned tool. The presented video helps to understand the principle of handling the mechanism.

The power saw is used for large volumes of joinery and carpentry wherever there is an electrical outlet nearby. The efficiency of working with it largely depends on how correctly the chain is tensioned on its tire, since if it is loosely tensioned, the chain will fly off the tire when the saw is running, and if it is overtightened, it will create a large load on the drive sprocket and the engine of the device. Below are a few practical recommendations on how to correctly tension the chain on the bar of the power saw, almost any Chinese model.

Installing a tire on an electric saw

At one end of the tire web there is a slot and two holes on the sides of it. When installing a tire with a slot, it is put on a special pin on the body of the saw, and one of the holes is put on the pin of the tension mechanism.

The second hole on the canvas serves to transfer lubricant from the oil channel to the tire groove.

Chain installation

The chain is pulled on the drive sprocket located on the saw body, and on the sprocket at the end of the bar. When installing the chain, it is necessary to take into account the correct direction of its rotation, which is usually indicated on the product itself.

After installing the chain, the drive sprocket of the saw is closed with a casing, the clamping nut of which is not tightened all the way so that the tire is not completely clamped.

Chain tension

The chain tension on Chinese electric saws is adjusted using a special tension screw, the head of which has a slot for a screwdriver. It is located at the end of the device case. For a stronger chain tension, it is rotated clockwise.

The tension screw is rotated until the chain slack disappears. After that, it is manually scrolled on the tire towards the body of the saw. This is necessary in order to "straighten" the teeth of the chain in the groove of the bar.

If the chain after scrolling is weakened, then it is tightened again.

After that, the tire is taken by its free end, lifted up to the stop, and in this position, the sagging of the chain is again eliminated.

At the last stage, the clamping nut is completely tightened on the casing that covers the drive sprocket of the saw. The tire is kept in the "raised" position.

A correctly tensioned chain should be freely removed by hands from the grooves of the bar on its two sides by about 3-4 mm, and when lowered, lie back into the grooves.

Tension check after work

When the chain is tensioned, it is possible to finally check the quality of its tension only after a small operational test. For this purpose, several test cuts are made with it.

Often, after trial cuts, the chain on the saw bar weakens. This happens when its links were contaminated, and during operation these contaminations were dissolved by the lubricant.

If this happens, then the chain must be tightened again, after slightly loosening the clamping nut on the casing and lifting the free end of the bar up. The power saw, of course, before this must be disconnected from the network.

At the end of the chain tension adjustment, always check whether it goes in the right direction without tension, whether it is overtightened. To this end, it is unlocked by pressing the start button and pushed forward by the teeth with a screwdriver. If she moves a little by inertia, then everything is fine.