Russian FederationIPBOT

IPBOT 282-2008 Instruction on industrial safety and labor protection for the operator of the washing unit

set a bookmark

set a bookmark

IPBOT 282-2008

LIMITED LIABILITY COMPANY

"SPECIAL PROJECT DESIGN AND TECHNOLOGY

BUREAU OF OIL AND GAS ENGINEERING"

LLC "SKTB NEFTEGAZMASH"

INSTRUCTIONS

on industrial safety and labor protection

for the operator of the flushing unit

AGREED

Trade Union of Oil and Gas Industry and Construction Workers of the Russian Federation

Chairman of the trade union L.A. Mironov

APPROVE

Director of LLC "SPKTB Neftegazmash" M.P. Semashko

Deputy director of LLC "SPKTB Neftegazmash" - GKP Krivtsov V.S.

1 General safety requirements

1.1 Male persons at least 18 years of age after training in specialized centers, who have a qualification certificate in this specialty, who have passed a preliminary medical examination and have no contraindications to perform the specified work, are allowed to work as a driver of a flushing unit.

1.2 The driver of the flushing unit for well treatment must perform the following scope of work:

- maintenance of flushing and acid units mounted on a tractor or vehicle chassis;

- preparation of a flushing unit with a wellhead on a flowsheet;

- installation and dismantling, piping and pressure testing of high and low pressure lines;

- maintenance of mechanisms for flushing, pressure testing, drainage of bottom hole;

- injection of chemicals, acids and alkalis used for well treatment;

- driving a car or tractor;

- refueling a car or tractor;

- production of current repairs of the mechanisms of the flushing unit, car or tractor.

1.3 The driver must know:

- arrangement and rules for the operation of a car or tractor, flushing unit, fittings and well equipment, the technical process of flushing, pressure testing of wells, injection of chemicals (acids and alkalis) into the well;

- physical and chemical properties of drilling fluid, chemicals, acids, alkalis, rules for handling them;

- plumbing in the scope of work performed.

1.4 Preliminary and periodic medical examinations of employees performing work with hazardous and harmful production factors are carried out by medical organizations licensed for the specified type of activity.

1.5 The frequency of periodic medical examinations is determined by the territorial bodies of the Federal Service for Supervision of Consumer Rights Protection and Human Welfare together with employers, based on the specific sanitary-hygienic and epidemiological situation, but periodic medical examinations must be carried out at least once every two years.

Persons under the age of 21 undergo periodic medical examinations annually.

1.6 The driver of the flushing unit undergoes an introductory briefing when being hired. Before admission to independent work, he must pass:

- initial briefing at the workplace;

- an internship at the workplace under the guidance of an experienced mentor lasting no more than 14 working days;

- verification of knowledge by profession and types of work;

- verification of knowledge on the safe operation of a new type of equipment;

- testing knowledge on first aid for victims of an accident at work;

- testing knowledge on fire safety;

- testing knowledge on electrical safety.

The results of the check are recorded in the labor protection certificate.

1.7 The newly hired employee is issued a knowledge test certificate, in which an appropriate entry must be made on the test of knowledge of the instructions and rules specified in clause 1.6, and on the right to perform special work.

Qualification certificates of personnel during the performance of official duties may be kept by the supervisor or with him in accordance with local conditions.

1.8 Admission to independent work is issued by order for the enterprise or structural unit.

1.9 The driver of the flushing unit, who has not passed the knowledge test within the established time limits, is not allowed to work independently.

1.10 The driver of the flushing unit in the process of work must pass:

- repeated briefings under the program of primary briefing at the workplace in full - at least once a quarter;

- knowledge check:

- by profession and type of work;

- for the safe operation of equipment;

- to provide first aid to victims of an accident at work;

- on fire safety;

- on electrical safety - once a year.

1.11 The driver of the flushing unit after 5 years of work must undergo retraining in this specialty.

1.12 When introducing new types of equipment and mechanisms, new technological processes, as well as when new rules and instructions for labor protection are put into effect, the driver of the washing unit must undergo an unscheduled briefing.

1.13 An employee or eyewitness must immediately notify his/her immediate supervisor of any accident or accident.

1.14 Each employee must know the location of rescue equipment, emergency warning signals, rules of conduct in case of accidents, rules for providing first aid to victims.

1.15 At the facilities of ZAO SSK, an employee may be exposed to the following main hazardous and harmful production factors:

1.15.1 chemical:

- heavy and light fractions of hydrocarbons;

- explosion and fire hazard of the oil and gas environment;

- toxicity of the oil and gas environment;

- chemical aggressiveness of individual fractions and components of the oil and gas environment;

- the ability of the oil and gas environment to penetrate into closed cavities and spaces of buildings and structures, accumulate in various recesses and spread over long distances and areas through the air, land and water surface;

- lubricating oils;

- acids;

- alkali.

Effects of the factor: possible irritation of the upper respiratory tract, inflammation of the mucous membranes of the nose, poisoning of the body and other diseases, acute and chronic skin diseases; when acid gets on the skin, dermatitis and burns are formed; sulfuric acid vapors corrode teeth and disrupt the physiological functions of the esophagus;

1.15.2 biological:

- viral infectious diseases. The carriers of these diseases are insects and rodents. A worker can become infected by being bitten by the virus pathogens or by direct contact with them and their secretions;

- the remoteness of production facilities from stationary bases and the inaccessibility of a significant number of production areas for medical care for workers.

Actions of the factor: diseases of hemorrhagic fever with renal syndrome;

1.15.3 psychophysiological:

- the continuous nature of technological processes carried out around the clock, regardless of various climatic and seasonal changes in the state of the environment;

- long periods of continuous operation of the entire complex of technological equipment;

- physical overload (work "standing", the monotony of labor, the severity of labor, the intensity of labor);

- neuropsychic overload (overstrain of analyzers, emotional overload, monotony of work).

Effects of the factor: possible diseases of the musculoskeletal system, prolapse of internal organs, vascular and other diseases, increased fatigue, decreased attention and, as a result, the possibility of injury to the employee, diseases of the cardiovascular system are possible;

1.15.4 physical:

- moving machines and mechanisms;

- significant potentially dangerous destructive properties of process equipment;

- high pressures of pneumo-hydraulic systems and gases;

- high temperatures of equipment surfaces;

- high voltage power system;

- static electricity;

- increased noise level, vibration in the workplace.

Effects of the factor: physical injury to the employee, decreased hearing acuity, impaired functional state of the cardiovascular, nervous system, possible vibration disease;

1.15.5 microclimate:

- increase in air temperature of the working area;

- lowering the air temperature of the working area;

- increased air movement.

Actions of the factor: contributes to the disruption of metabolic processes in the body, the occurrence of various acute and chronic colds, frostbite of certain parts of the body;

1.15.6 insufficient illumination of the working area.

Effects of the factor: there is visual fatigue, pain in the eyes, general lethargy, which leads to a decrease in attention and the possibility of injury to the employee;

1.15.7 severity and intensity of the labor process:

- units of external mechanical work per shift (kg m);

- weight of the lifted and moved cargo manually (kg);

- stereotyped work movements (number per shift);

- the value of the static load per shift while holding the load;

- application of effort (kgf s);

- working posture;

- complex working environment combination factors.

Effect of the factor: diseases of the musculoskeletal system, metabolism, cardiovascular and other diseases are possible.

1.16 Production personnel must work in PPE, issued free of charge in accordance with the approved standards in ZAO SSK.

Control over the correct application and issuance of PPE is carried out by the employer. Production personnel are responsible for the use of PPE. Accounting for the issuance of PPE is carried out on a personal personnel card in accordance with Appendix N 2 (book 1).

1.17 Maximum permissible concentrations (MPC) of harmful substances in the air of the working area are indicated in Appendix N 3 (book 1).

1.18 When an employee appears at the workplace in a state of alcoholic or drug intoxication, the head of work removes him from work with an entry in the shift log of the time and reason for suspension. An act is drawn up on the presence of an employee at the workplace in a state of intoxication signed by at least 3 persons, a medical examination of this employee is carried out. The work manager writes a report addressed to the head of the enterprise.

1.19 Smoking is allowed only in specially designated and equipped areas.

1.20 Production personnel are subject to compulsory social insurance against industrial accidents and occupational diseases in accordance with the provisions of paragraph 1 of Article 5 of Federal Law No. 125-FZ dated July 24, 1998.

1.21 Compliance with the requirements of instructions on industrial safety and labor protection is mandatory for both the employer and production personnel. In case of non-compliance with the requirements of the instructions on labor protection set forth in this collection, production personnel may be brought, depending on the severity of the consequences, to disciplinary, administrative, criminal and material liability in accordance with the legislation of the Russian Federation.

1.22 The illumination of the workplace must comply with the requirements of sanitary norms and rules in accordance with Appendix No. 6 (book 1).

1.23 The driver of the washing unit, working in hazardous conditions, has the right to receive free milk or other equivalent food products according to the established norms, as well as the right to replace dairy products with monetary compensation.

1.24 Moving to the place of work and back is carried out in passenger buses or specially equipped cargo on-board vehicles, in difficult terrain - on all-terrain vehicles or on sled tractor trailers.

1.25 Standing or sitting on the sides of the car, jumping on the footboard of the car or jumping off it while driving is prohibited.

1.26 Driving on tractors, pipelayers, bulldozers, in the bodies of dump trucks, on trailers, on vehicles equipped for the carriage of long loads, in the bodies of vehicles when transporting flammable substances or goods in them, as well as on other self-propelled vehicles not intended for transportation people is prohibited.

1.27 When introducing new types of equipment or mechanisms, new technological processes, introducing new Rules and Instructions on labor protection, as well as when transferring from one type of unit to another, the driver must undergo special training and targeted instruction.

1.28 The use of open fire on the territory of the facility, near fuel depots and in places of possible accumulation of combustible gases is prohibited.

1.29 When performing work at explosive and fire hazardous facilities, the driver is obliged to strictly observe the fire safety rules (use a copper-plated tool, monitor the serviceability of the spark arrester, fire fighting equipment, do not use open fire, etc.).

1.30 The unit must have a supply of clean water, as well as a 2% solution of bicarbonate soda in an amount of 5 liters, a 10% solution of ammonia in a volume of 1 liter and a solution of boric acid in an amount of 1 liter.

2 Safety requirements before starting work

2.1 Before starting work, you must:

2.1.1 put in order overalls. Sleeves and floors of overalls should be fastened with all buttons, hair should be removed under a headdress. Clothing must be tucked in so that there are no hanging ends or fluttering parts. Shoes must be closed and low-heeled, it is forbidden to roll up the sleeves of overalls and tuck the tops of the boots;

2.1.2 make a detour of the serviced equipment along a certain route, visually check the condition (integrity) of units, mechanisms and tools, the presence of reagents, instrumentation and instrumentation;

2.1.3 obtain the necessary information from the shift hander about the condition of the equipment, malfunctions requiring immediate elimination, and orders for the upcoming shift;

2.1.4 familiarize yourself with all entries in the journals: operational, defects, accounting for work on orders and orders, orders issued during the time elapsed from the previous duty.

2.2 After completing the round, inform the work manager about the readiness to accept the shift.

- test the equipment before accepting a shift;

- leave the shift without registering the acceptance and delivery of the shift.

2.4 Before starting work, the machine operator must:

- familiarize yourself with the task;

- check the serviceability of the unit and equipment and, if faults are found, take measures to eliminate them;

- check the presence of a protective pin in the safety valve and its compliance with the set of plungers installed in the pump;

- check the serviceability of the pressure gauge on the pressure line of the pump;

- after pouring the acid, close the filler caps tightly;

- install the unit on a flat area no closer than 10 meters from the wellhead on the windward side and so that its cabin is not facing the well;

- install folding railings on the tank in a vertical position and fix them;

- prepare the intake line for operation and connect the injection pipeline of the unit to the head at the wellhead;

- inspect all moving parts and remove foreign objects, cover the hydraulic part with a casing.

2.5 Prior to pumping the acid solution into the well, the injection line must be pressurized to 1.5 times the expected working pressure. A non-return valve must be installed in the line.

3 Safety requirements during work

3.1 Acid treatment of the well should be carried out by a machinist and minder under the guidance of a complex engineer.

3.2 While pumping the acid solution into the well, the driver must be on the platform of the tank, and the minder-driver - in the cab of the vehicle.

3.4 During the operation of the unit, the driver must:

- monitor the tightness of the connection between the valve and cylinder covers and, in the event of a leak, stop the pump and eliminate the defect;

- monitor the operation of all units, mechanisms and parts available for external inspection;

- in case of extraneous knocks and noises, stop the unit and troubleshoot;

- monitor all connections of the pipelines of the unit and, in case of a leak, stop the unit, relieve pressure to zero and only then eliminate the leak;

- monitor the temperature of bearings and other rubbing parts;

- monitor the health of the pump lubrication system and the amount of oil supplied to the plungers;

- monitor the condition of the safety valve. If the control pin is sheared, stop the unit and replace it;

- if the safety valve does not respond to an increase in pressure beyond the allowable one, stop the unit, disassemble the valve and eliminate the malfunction;

- follow the reading of the manometer;

- monitor the level in tanks using level gauges;

- acid sludge should be drained in a specially designated place;

- Carry out steaming and car washing in a specially designated place.

3.5 During operation, it is prohibited:

4 Safety requirements in emergency situations

4.1 In the event of an emergency, incident (accident, fire, breakdown of the unit's mechanisms, etc.), immediately stop work, report the incident to the work manager and act in accordance with the instructions.

4.2 In the event of a fire, it is necessary:

- stop all technological operations;

- report a fire

- turn off the power at the drilling rig;

- take measures to remove people from the danger zone;

- skillfully and quickly fulfill the duties set out in the emergency response plan;

- isolate the fire from the surrounding air;

- fill burning volumes with non-combustible gases or steam;

- take measures to artificially reduce the temperature of the burning substance.

In most cases, combustion is eliminated by the simultaneous use of several methods.

4.3 In case of an accident, it is necessary to immediately release the victim from the impact of the traumatic factor, provide him with first aid and inform the immediate supervisor about the accident.

If necessary, call an ambulance or send the victim to a healthcare facility.

4.4 If hydrofluoric acid gets on the body, wash the affected area with water for 10 minutes, then lightly wipe with gauze soaked in ammonia solution, then rinse again with water and apply a bandage with magnesia ointment (one part of magnesium oxide and two parts of medical vaseline).

4.5 In case of burns with hydrochloric acid, wash the affected area with a stream of water for 10-15 minutes, and then with a solution of bicarbonate of soda. In the absence of a solution of bicarbonate of soda, you can use a solution of soap, chalk, tooth powder in water.

4.6 If acid gets into the eyes, rinse them with a solution of boric acid 1 tsp. to a glass of water.

4.7 In case of second-degree burns, when blisters have already formed, it is impossible to open and pierce them. A sterile bandage should be applied to the burned area and the victim should be immediately taken to the nearest medical center.

4.8 In case of poisoning with acid vapor, immediately deliver the affected person to the nearest medical center.

5 Safety requirements at the end of work

5.1 Upon completion of work, it is necessary:

- disassemble all induced communications, lay them on the unit and securely fasten them;

- close the hatches of the tank, fix the caps of the level gauges, put the railing in the transport position;

- carefully check that there are no loose tools and parts left on the machine.

5.2 Upon returning to the garage, the unit should be subjected to an external inspection. Faults found both during operation and during inspection must be eliminated.

5.3 Familiarize the shift host with all changes and malfunctions in the operation of the equipment that occurred during the shift.

5.4 Remove protective equipment, overalls and safety shoes, put them in order and put them in storage places (team dryer).

5.5 Wash hands and face with warm soapy water or take a shower. For hard-to-remove dirt, use special cleaning agents.

5.6 After working with cleaning solutions, first wash your hands under running warm water until the "slipperiness" is eliminated. Lubricate your hands with a nourishing and skin regenerating cream.

Checks the serviceability of fixtures, tools, inventory Availability of a qualification certificate, official work experience of at least 2 years. Driver s washing unit..IN...

Samara, Samara region

3 |

Checks the serviceability of fixtures, tools, inventory Availability of a qualification certificate, official work experience of at least 2 years Driver s washing unit..Wa...

IP Sharangovich E.S. (Agency)

from 132000 rub. per month | schedule: Rotational method

Novosibirsk, Novosibirsk region

4 |

Responsibilities: Maintenance washing unit; Training unit to work on site; Requirements: Secondary technical education The presence of a document on qualifications for the profession " Driver washing unit 6 digit&...

Integra, Group of companies

Omsk, Omsk region

5 |

driver but washing unit or minder CA 320; - Driver's license cat. B, C; - ADR, a driver card is desirable. Responsibilities: - delivery of chemical reagents and technical liquids by a flushing unit to the exact...

Cresol

from 40000 rub. per month | Schedule: Full day

6 | washing machine operator

cat driver. "C", DOPOG Driver's license cat. Responsibility Punctuality A category C driver's license is required Absence of bad habits, conscientiousness, courtesy, discipline, diligence, experience as a driver...

CJSC "IMPULSE NEFTESERVIS"

from 50000 rub. per month

7 | Flushing unit operator 5th grade-5th grade

Responsibility Possession of a certificate driver but washing unit 5th category The presence of a certificate driver but washing unit 5 rank...

LLC "TRANSSERVICE".

from 27000 rub. per month | Schedule: Variable schedule

9 |

Responsibilities: Workover maintenance, Injection of chemicals, acids and alkalis used for well treatment. Participation in the technological process of chemical treatment of the bottomhole zone of the well and carrying out cementing work.Requirements: Possession of a certificate...

LLC "RN-Transport" branch in Nefteyugansk

from 116 rubles per month

Nefteyugansk, Tyumen region

10 |

Driving license (categories B, C); - Possession of a driver's license driver a (tractor driver) category AIII; - the presence of a document on qualifications for the profession " Driver washing unit 6 digits"; - have...

Surgutneftegaz

up to 62779 rubles. per month | Schedule: Flexible schedule

Surgut, Tyumen region

12 |

DRIVER BUT washing unit

Neftekhimservice - Samara

Salary not specified | schedule: Rotational method

Buzuluk, Orenburg region

13 |

The company Neftekhimservice - Samara LLC, in connection with the development of the enterprise, opens a recruitment for the position - DRIVER BUT washing unit/ (Motor driver CA SN 320) to carry out work on the territory of customers. Tasks: - Preparing equipment...

Neftekhimservice - Samara

Salary not specified | schedule: Rotational method

Buguruslan, Orenburg region

14 |

The company Neftekhimservice - Samara LLC, in connection with the development of the enterprise, opens a recruitment for the position - DRIVER BUT washing unit/ (Motor driver CA SN 320) to carry out work on the territory of customers. Tasks: - Preparing equipment...

Neftekhimservice - Samara

Salary not specified | schedule: Rotational method

Orenburg, Orenburg region

15 | Flushing unit driver/Motorist CA 320

The company Neftekhimservice - Samara LLC, in connection with the development of the enterprise, opens a recruitment for the position - DRIVER BUT washing unit/ (Motor driver CA SN 320) to carry out work on the territory of customers. Tasks: - Preparing equipment...

OOO Neftekhimservis - Samara

S/P not specified

Buzuluk, Orenburg region

16 | washing machine operator

Qualification: Responsibilities: Maintenance of flushing and acid units mounted on a tractor or vehicle chassis. Training washing unit for work on site, tying (attachment) unit. Maintenance of mechanisms for flushing, pressure testing ...

Regional reserve

from 80000 rub. per month

Krasnoyarsk, Krasnoyarsk Territory

17 |

Pilot plant Neftekhim

from 90000-110000 rub. per month | schedule: Rotational method

Ufa, Republic of Bashkortostan

18 | Flushing unit operator/motor operator 320

Responsibilities: - periodic pumping, flushing, etc.; - preparation of killing solutions, solutions of KCl, caustic soda, etc. - delivery of chemical reagents and those. liquids by a flushing unit to injection points; - treatment of wells with chemical reagents...

JSC Pilot Plant Neftekhim

from 90000 rub. per month

Ufa, Republic of Bashkortostan

19 | washing machine operator

Requirements: - Possession of a certificate driver but washing unit or minder CA 320; - Driver's license cat. B, C; - ADR, a driver card is desirable. Responsibilities: - delivery of chemical reagents and technical liquids by a flushing unit to injection points ...

Krezol LLC

from 40000 rub. per month

Neftekamsk, Republic of Bashkortostan

20 | washing machine operator

Driver required washing unit Requirements: - The presence of training in the profession "Machinist of the flushing unit" - the presence of ADR - the presence of a driver's license February 2020...

Pasha

from 70000 rub. per month

Lyantor

Well drilling is a very important technological process in the field of oil and gas production. When descending many meters into the earth's crust, it should be borne in mind that the well must be cleaned of excess materials. In such cases, a flushing unit comes to the rescue, capable of preparing a well for pipe installation, using process fluids and reagents.

Qualification ranks:

A professional washing machine operator must regularly take care of his knowledge, for this there are qualification courses for increasing the level. Thanks to the experience and knowledge of our specialists, we conduct courses for washing machine operators in order to increase their knowledge and enable students to excel in the future in production.

Training program:

Our training center provides a training program that includes basic knowledge about the structure of wells and the rules for their operation, types and types of process fluids and reagents, the composition and design of flushing units, the basics of safety in production.

Frequency of training:

The driver of the flushing unit is required to receive a specialized education. Anyone who has reached the age of majority can pass the initial training. After completing the training, the student receives a crust indicating the assigned rank in the specialty, which can be increased at any time by contacting the training center to take a refresher course.

What form does the training take?

Training can be conducted both in full-time and part-time form, when the student is present in the classroom during the day or evening, and remotely. The latter form of education is convenient in that it is possible to undergo training when it is convenient, being outside the educational institution, doing ordinary household chores. The number of hours of training does not change, and the document received upon completion of the training will not differ.

Job Description. Maintenance of washing and acid units mounted on a tractor or vehicle chassis. Preparation of the flushing unit for work at the facility, piping (connection) of the unit to the wellhead according to the technological scheme. Mounting and dismantling, piping and pressure testing of high and low pressure lines. Maintenance of mechanisms for flushing, pressure testing and drainage of bottom hole. Injection of chemicals, acids and alkalis used for well treatment. Participation in the technological process for chemical treatment of the bottomhole zone of the well and carrying out plugging operations. Monitoring the consumption of drilling fluid, chemicals and the operation of the mechanisms of the unit. Driving a car or tractor. Refueling a car or tractor. Production of current repairs of the mechanisms of the flushing unit, car or tractor.

Must know: device and rules for operating a car or tractor, flushing pump, fittings and well equipment; technological process of flushing, pressure testing of wells, injection of chemicals (acids and alkalis into a well); physical and chemical properties of drilling fluid, chemicals, acids, alkalis, rules for handling them; plumbing in the volume of work performed.

When working on flushing and acid units with a working pressure of up to 10 MPa (100 kgf / sq. cm) inclusive - 4th category;

when working on flushing and acid units with a working pressure of more than 10 to 35 MPa (100 - 350 kgf / sq. cm) inclusive - 5th category;

when working on flushing and acid units with a working pressure of more than 35 MPa (350 kgf / sq. cm) - 6th category.

Requires secondary vocational education.

Training a working profession as a washing machine operator in Moscow guarantees a demand for a specialist in the labor market, moreover, over the past years, the Russian economy has experienced a clear lack of qualified technical specialists. You can get this profession in 3-16 weeks in our training center, where, after completing the classes, a ready-made specialist will receive knowledge and a certificate that will significantly raise his status in the eyes of the employer.

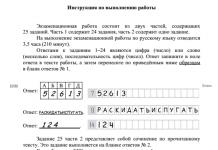

Course Information

| Program code | 14065 |

|---|---|

| Direction | Job training |

| Well | washing machine operator |

| Hours/Discharge | (4-6 category) |

| Type of training | Distance learning in Moscow |

| Type of training | Education |

What does the training include

Teaching a working profession involves the study of theoretical material, as well as the acquisition of practical skills through the performance of tasks and analysis of situations related to further work.

Important point! A qualified specialist must understand all the nuances of the technological process, be able to use modern equipment, and apply different techniques for solving production problems.

Certificate sample

ETKS (Unified Tariff and Qualification Directory of Works and Professions of Workers)

Important point! Depending on the category assigned to the student, the timing of theoretical and practical classes may vary.

The training program Washing unit operator covers the following theoretical and practical issues:

Washing machine operator training course

Characteristics of works.

Maintenance of washing and acid units mounted on a tractor or vehicle chassis. Preparation of the flushing unit for work at the facility, piping (connection) of the unit to the wellhead according to the technological scheme. Mounting and dismantling, piping and pressure testing of high and low pressure lines. Maintenance of mechanisms for flushing, pressure testing and drainage of bottomholes. Injection of chemicals, acids and alkalis used for well treatment. Participation in the technological process for the chemical treatment of the bottomhole zone of the well and carrying out plugging operations. Monitoring the consumption of drilling fluid, chemicals and the operation of the mechanisms of the unit. Driving a car or tractor. Refueling a car or tractor. Production of current repairs of the mechanisms of the flushing unit, car or tractor.Must know:

device and rules for the operation of a car or tractor, flushing pump, fittings and well equipment; technological process of flushing, pressure testing of wells, injection of chemicals (acids and alkalis into the well); physical and chemical properties of drilling fluid, chemicals, acids, alkalis, rules for handling them; plumbing in the scope of work performed.When working on flushing and acid units with a working pressure of up to 10 MPa (100 kgf / sq. cm) inclusive - 4th category;

when working on flushing and acid units with a working pressure of over 10 to 35 MPa (100 - 350 kgf / sq. cm) inclusive - 5th category;

when working on flushing and acid units with a working pressure of more than 35 MPa (350 kgf / sq. cm) - 6th category.

Requires secondary vocational education.

Sign up for a course

Who is vocational training aimed at?

Applicants who meet the following requirements can get a useful, and most importantly, a working profession in demand in the labor market in Moscow:- age from 18 years; the state of health corresponding to the profession; the presence of a certain qualification (when assigning categories of the highest level).

Required documents

In order to enter courses for the development of a working profession, it is important to take care of the preparation of such documents :- copy of the passport; (passport data)

a copy of the document on education (secondary, secondary special, higher);

medical certificate depending on the chosen profession (not always required);

listener's request

If an organization sends a trainee to the profession "Flushing unit operator" for training, then a card with its details is attached to the package of papers.

What are the benefits of vocational training?

We conduct training for workers in the profession Washing unit operator by assigning ranks in Moscow, as a result of which they can carry out full-fledged labor activities within the framework of the chosen profile, and if they are assigned higher ranks, they can count on an increase in salary. At the same time, we guarantee:complex classes taking into account all qualification requirements;

flexible class schedule;

strict consideration of the requirements of the Ministry of Labor of the Russian Federation, the Ministry of Health of the Russian Federation and the Ministry of Education of the Russian Federation.

Stages of training for a working profession

Before enrolling in the course, you must complete the following steps:Important point!After passing the final test, course participants receive a certificate certifying their qualifications with an indication of the category. Teaching a working profession is a way to gain a sought-after qualification in a short time, improve your rank, and activate the interest of employers. Attending courses for the assignment of the next category is considered as an advanced training.

What does Job Training look like? Sample.

Other Programs: Job Training

| The code | Name | Clock | |

|---|---|---|---|

| Firing receiver-observer | Get trained | ||