ThemeFire fighting water supply. Purpose and device of a fire hydrant and a fire column

Activity type: class-group

Allotted time: 2 academic hours.

Literature: textbook "Fire fighting equipment"

Detailed lesson plan.

Water supply in the system of measures to ensure fire safety

Water supply system is called a complex of engineering structures intended for the intake of water from a water source, its purification, storage and supply to places of consumption.

Purpose of fire water supply consists in ensuring the supply of the necessary volumes of water under the required pressure during the standard time for extinguishing the fire, provided that the operation of the entire complex of waterworks is sufficiently reliable. The main regulatory requirements for water supply are set out in building codes SNiP 2.04.02-84 “Water supply. External networks and facilities ".

Water supply systems (water pipelines) are classified according to a number of characteristics:

According to the reliability of water supply- they fall into three categories:

1st category of reliability- enterprises of the metallurgical, oil refining, petrochemical and chemical industries, power plants; utility and drinking water pipelines in settlements with a population of more than 50,000 people - it is allowed to reduce the water supply by no more than 30% of the calculated standards for up to 3 days.

2nd category of reliability - enterprises of coal, mining, oil production, machine-building and other types of industry; utility and drinking water pipelines in settlements with a population of up to 50,000 people and group agricultural water pipelines - it is allowed to reduce the water supply by no more than 30% of the calculated standards, lasting up to 1 month or interruptions in the water supply for up to 5 hours.

3- I category of reliability- small industrial enterprises; irrigation systems for agricultural land; utility and drinking water pipelines in settlements with a population of up to 500 people - a break in the water supply of up to 1 day or a decrease in water supply by no more than 30% of the calculated standards for a period of up to 1 month is allowed.

By type of serviced object water supply systems are subdivided into urban, settlement, as well as industrial, agricultural, railway and others.

By the type of natural sources used there are water pipelines that take water from surface sources (rivers, reservoirs, lakes, seas) and underground (artesian, spring). Mixed water supply lines are also available.

By the way of water supply There are pressure water pipelines with mechanical water supply by pumps and gravity (gravity), which are arranged in mountainous areas when the water source is located at a height that provides a natural supply of water to consumers.

By appointment water supply systems are divided into household and drinking systems that meet the needs of the population; industrial, water-supplying technological production processes; fireproof and combined. The latter are usually arranged in populated areas. From the same water pipelines, water is also supplied to industrial enterprises, if, according to the conditions of the technological process of production, they require drinking-quality water. With high water consumption, enterprises can have independent water supply systems that provide their household, drinking, industrial and fire-fighting needs. In this case, they usually construct economic and fire-fighting and industrial water pipelines. The combination of a fire water supply system with an economic one, and not an industrial one, is explained by the fact that the industrial water supply network is usually less ramified and does not cover all volumes of the enterprise. In addition, for some technological production processes, water must be supplied under a strictly defined pressure, which will change when extinguishing a fire. An independent fire-fighting water pipeline is usually arranged at the most fire-hazardous facilities - petrochemical and oil refining industries, oil and oil products warehouses, timber yards, liquefied gas storages, etc. Fire-fighting water pipelines are of low and high pressure. In low-pressure water pipelines, the required head at the shafts is created using mobile fire pumps installed on hydrants. In high-pressure water pipelines, water is supplied to the fire site through hose lines directly from hydrants under pressure from stationary fire pumps installed in the pumping station.

Plumbing and non-water supply. water supply, classification of external water pipes

In accordance with two categories of natural water sources, water intake facilities are also divided into two groups: structures for receiving water from surface sources and structures for receiving groundwater. The choice of one or another source of water supply is determined by local natural conditions, sanatorium and hygienic requirements for water quality and technical and economic considerations. Wherever possible, preference should be given to underground water supplies.

Surface sources include: rivers, lakes and, in some cases, the sea. The location of the water intake is determined in such a way that the following conditions are satisfied:

the possibility of using the simplest and cheapest way of taking water from the source;

uninterrupted receipt of the required amount of water;

ensuring the flow of as clean water as possible (cleaning from pollution);

the closest location to the supplied facility (to reduce the cost of water pipelines and water supply).

Groundwater occurs at different depths and in different rocks.

For water supply use:

water of confined aquifers, overlapped from above by impermeable rocks that protect groundwater from pollution;

unconfined groundwater with a free surface contained in strata that do not have a waterproof roof;

spring (spring waters, i.e. underground waters that independently come out to the surface of the earth);

mine and mine waters (more often for industrial water supply), i.e. groundwater flowing into drainage facilities during mining.

Types of fire hydrants:

Moskovsky

Leningradsky

Rostov (Nakhichevan)

Modern water supply systems are a complex complex of engineering structures that provide reliable water supply in the required amount and pressure to each consumer. One of the categories of the water supply system is fire fighting water supply. It is determined by a set of measures to ensure the required volume of water for consumers, which is sent to extinguish fires. Therefore, even at the design stage of an object, it does not matter if it will be a residential building or an industrial area, not only utility and drinking water supply or technical, but also fire-fighting is immediately taken into account.

Fire water supply system

Fire water supply system

Varieties of fire water supply

Basically, fire water supply is divided into two types:

- high pressure;

- low.

The first is a system that can supply water with the required pressure to extinguish the largest building of the projected facility. In this case, the supply of water with a large volume should begin to be supplied within the first five minutes. For this purpose, specially installed stationary pumps are used. For them, a separate room or a whole building is usually allocated. Such a water supply can extinguish a fire of any complexity without involving fire trucks.

The second group is a water supply system, from which water is supplied through hydrants and with the help of pumps to the fire extinguishing zone. Pumps with hydrants are connected with special fire hoses.

Pumping station

Pumping station

It should be noted that all structures and the equipment installed in them are designed in such a way that so much water is allocated for fire measures, which would be enough to extinguish a fire. But at the same time, both the drinking water supply and the technical (technological) pipeline were working in full force. That is, one type of water supply should not interfere with the rest. In this case, water is necessarily backed up as an emergency reserve. It usually accumulates in underground reservoirs, in outdoor pools or in water towers.

The fire-fighting water supply scheme also includes a pumping and hose system. In fact, these are installed pumps (of the first and second lift), pipelines through which water is supplied to each object, as well as fire hoses, which are twisted and put into special boxes. The latter are colored red, indicating the relationship to the fire-fighting water supply system.

Fire box

Fire box

Other classification options

There is another division of fire water supply systems.

The fire water supply itself is divided into external and internal. The first is the pumping stations, pipeline and hydrants located on the territory. The second is pipelines scattered inside buildings and connected to an external water supply complex.

In small settlements, in small factories and plants, the fire water supply system is not arranged as a separate unit of engineering structures. It is combined with other water supply networks, that is, water, for example, is taken directly from the drinking water system to extinguish a fire. Although in many places the fire safety system is organized from special machines that replenish their water supply from open or closed sources directly. That is, as such, there is no pumping and hose system of fire water supply.

Water intake from an open reservoir

Water intake from an open reservoir

Sources of water supply

So, two sources of water intake are also determined by two groups of fire-fighting water supply systems. The choice of one of them is determined by local conditions, which must provide the necessary volume for extinguishing a fire. That is, if there is a river next to the object, then it is best to draw water from it. But the use of the source should be determined by the following conditions.

- the required volume of water;

- the easiest way to collect it, that is, economically justified;

- it is optimal if the water in the source is clean without a large degree of pollution;

- the closer it is to the subject, the better.

As mentioned above, open reservoirs and deep structures can be sources of external fire-fighting water supply. With open ones, everything is clear. But as for the deep ones, there are several positions that differ from each other by different aquifers in terms of structure and location.

- Water-pressure layers, which are protected from above by waterproof layers.

- Non-pressure layers with a free surface that are not protected by waterproof layers.

- Spring springs. In fact, these are underground waters that lie close to the surface of the earth, therefore, they make their way through a small layer of soil to the surface.

- The so-called mine waters. This is industrial water that is discharged into drainage facilities during mining.

Well hydrant

Well hydrant

Fire water supply schemes

The layout of the external part is the simplest, because it is defined by a pipeline running from the source of the water intake to the pumping station and further to the buildings. But the internal fire-fighting water supply can be different. And they are based on the conditions for creating a pressure inside the system, which is necessary to extinguish a fire.

The simplest scheme is a system in which there are no other devices and devices besides pipes. That is, the water pressure from the external fire water supply is enough to solve fire safety problems.

The second scheme is a pipeline into which an additional pump is installed. It is usually called a second lift pump. It is installed only if the head in the main water supply line is small. That is, it is not enough to extinguish a fire. But this pressure completely supplies the household drinking system with water. Therefore, the pump is installed after a fork in the pipeline, which divides the entire water supply system into two parts: utility and drinking and fire-fighting.

Attention! The start of the second lift pump and the opening of the valve after it is carried out automatically immediately after pressing a button in any fire box.

The third scheme is a fire-fighting water supply, in which a storage water tank and a pump are installed. It is used when the pressure in the main network is low. The scheme works like this: the pump pumps water into the tank, and from there it goes to the hydrants throughout the scattered piping. In fact, the tank itself acts as a pressure-regulating tank. At the same time, it is provided with float-type automation. When the water in it drops to a certain level, the pump immediately turns on, which pumps water into it.

Diagram of a fire water supply system with a water tank

Diagram of a fire water supply system with a water tank

This scheme works well for an integrated system, when a fire water supply and a drinking water supply are connected in one circuit. That is, the fire pump provides the necessary pressure and systems for household and drinking needs. In this case, excess water flows directly into the tank. By the way, such containers do not have drain pipes, that is, water is not discharged into the sewer. It just goes online. If the volume of consumption increases sharply, then the pump starts to work continuously.

One more pump can be additionally installed in this scheme. That is, one will pump water for household needs, the second will turn on only in case of fire, when water consumption increases sharply, and the first pump unit cannot cope with the supply. By the way, the photo above shows this very scheme, where number one is a pump for household needs and drinking, and number two is a fire unit.

True, it should be noted that such a fire-fighting water supply system is used only in high-rise buildings. The thing is that the most difficult thing in this scheme is to install a water tank at the required height, which should provide the entire system with pressure.

In the fourth scheme, instead of a water-pressure tank, a pneumatic tank is mounted, and instead of a pump, a compressor. Sometimes two tanks are combined. That is, both water and pneumatic are installed. The principle of operation of such a system is that the air pumped into the tank creates the necessary pressure in the system, which is enough to create a pressure of water to extinguish the fire. But it is clear that the water tank will be emptied, so a pump is installed in the circuit that will fill it. It turns on automatically from a float switch installed in the tank itself. This scheme is used only if the pressure in the main water supply does not exceed 5 m and it is possible to install the water tank at the required height.

Fire water supply scheme with two tanks: water pressure and pneumatic

Fire water supply scheme with two tanks: water pressure and pneumatic

All the above schemes shown in the photo are dead-end. That is, their ultimate goal is a consumer in the form of a hydrant. But there are also ring networks, the main advantage of which is the ability to turn off one section while all the others are working. For example, if this section is emergency. Typically, such schemes are used where there is always a need for water consumption, and at the same time the fire-fighting water supply itself performs the functions of a technological or economic one. For example, in the baths.

Attention! The circular internal fire protection system must be connected to the external water supply in at least two places.

Ring diagram of a fire water supply system

Ring diagram of a fire water supply system

Features of fire water supply

- The requirements that determine the standards for the construction and operation of fire-fighting systems are based on the set of rules "SP8.13130-2009".

- Based on the joint venture (external and internal fire water supply), it is necessary to strictly observe the design studies, which determine the scheme of the system, materials and equipment that are included in its design. This mainly concerns the material and diameter of the pipes, as well as the capacity and head of the pumping equipment.

- If possible, it is better to combine various water pipelines into one network. But here it is necessary to take into account the intensity of use of each network. Therefore, it is best to combine the fire and utility networks. If technical (technological) and fire-fighting are combined, then it is necessary to take into account the mode of water consumption for technical needs.

So this is all about fire fighting water supply. As you can see, the fire extinguishing system is quite complex. And although with a small amount of equipment in it, as practice shows, it is quite ramified. And the more places on the object that fall under the category of fire hazard, the more points where the pipe from this system should be laid.

ATTENTION: You are watching the textual part of the content of the abstract, the material is available by clicking the Download button

Classification of fire-fighting water supply systems

Brief historical background

The first ideas about outdoor fire-fighting water supply from special devices date back to the 80s of the 19th century. Engineer N.P. Zimin was the head of the Neptun company, which was a conductor of advanced technologies in the field of water supply and sewerage in Moscow. Water-lifting machines of the Worthington system were installed at Moscow water pumping stations, two of which transmitted movement to two vertical pumps, the third - for expansion. In addition, it was required to set up a water tower, in the upper settling tanks of which water came from the mine, and from the settling tanks it was sent to mechanical filters on the lower floors. The water supply network was designed to pass 120,000 buckets 1 per day, in the hour of the largest water intake - 6700 buckets. Pipes with a diameter of at least 4 inches 2, the total length of the network is 17 versts 3. Fire hydrants were installed every 60 fathoms 4.

1)1 bucket = 12,3 liter ;

2)1 inch = 2,54 cm ;

3)1 verst =1,07 km ;

4)1 fathom = 2,14 m .

At the end of the 19th century, the City Administration of Ufa signed a contract for a water supply system project with engineer S.M. Kirpichnikov. Moreover, the main condition was that the external water supply system should supply water for household and drinking needs, as well as, in addition, to extinguish the fires in the city that became more frequent at that time. The design of the water supply system was based on the following conditions of city management: the amount of water for household purposes was determined in the amount of 200,000 buckets of daily consumption, which amounted to an average consumption per hour of 8333 buckets or 1 cubic foot 5 (5 1 foot = 304,8 mm ; )per second; city trunk network, pipe diameter and pump head of the engine room must meet these requirements. By the decree of the Duma of November 3, 1898, a network of city pipes with a length of 21 versts 372 soot was approved.

The fire pressure was approved in such a size that the cars and the city network could in all points of the city give an amount of water of 100 buckets per minute from the two fire hydrants closest to the place of the fire, with an average distance of 60 running fathoms between them. At the same time, the free head at the end of the hose was supposed to be 12 sazhens of the height of the ejected jet, subject to the termination of the water intake on the pipe network for household needs. By the decree of the water supply commission, it was determined to install 4 barrel taps and 20 manual water taps on the city pipe network. As a result of the successful completion of all construction work on June 13, 1901, at a meeting of the City Duma, the first Ufa water pipeline was put into operation.

Since the beginning of the century, the population of Ufa has increased from 50 thousand people in 1901 to 100 thousand in 1913, so the need for water has increased. If in the first years after the commissioning of the water supply system the city consumed about 60,000 buckets of water per day, then in 1913 the maximum supply was 136,000 buckets per day. The equipment of the station was working at its limit, however, there was not enough water. The length of the main network was 22 versts 136 sazhens, the number of fire hydrants was 144, the number of water-folding booths was 13, the number of water supply branches was 416, of which 22 were free and 16 were on preferential terms. The street water supply network was laid only in the city center.

Based on historical information about the first external water supply system with fire hydrants, it can be seen that the development of fire water supply has been calculated for a long time.

Fire-fighting water supply is a set of measures to provide water to various consumers to extinguish a fire. The problem of fire-fighting water supply is one of the main problems in the field of fire-fighting. Modern water supply systems are complex engineering structures and devices that provide reliable water supply to consumers. With the development of water supply to settlements and industrial enterprises, their fire protection is improving, since in the design, construction, reconstruction of water pipelines, the provision of not only economic, industrial, but also fire safety needs is taken into account. The main fire safety requirements provide for the need for the flow of standard volumes of water under a certain pressure during the estimated time of extinguishing fires.

Classification of plumbing fire-fighting water supply systems

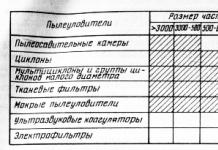

These systems are classified according to a number of characteristics:

- according to the type of the serviced object, the water supply systems are divided into: urban, village, industrial, agricultural, railway, etc.

- according to the purpose of the water supply system, they are subdivided:

a) combined (economic - fire-fighting, household and drinking - fire-fighting, production - fire-fighting);

b) fire-fighting, providing a supply and supply of water only for extinguishing fires.

An independent fire-fighting water supply system is usually arranged at the most fire hazardous facilities - at enterprises of the petrochemical and oil refining industries, timber yards, oil and liquefied gas storage facilities, etc.

Fire-fighting water pipelines (independent or combined) during design are divided into: external and internal.

The external water supply includes all structures for the intake, purification of water and its distribution by the water supply network before the inputs to the buildings.

Internal water pipelines are a set of devices that provide water from the external network and supply it to the water taps located inside the building.

External water supply systems are subdivided:

- depending on the type of network, into ring and dead-end;

- depending on the pressure on the high and low pressure water pipelines.

The minimum diameter of the water supply pipes, combined with the fire-prevention one, in settlements and industrial enterprises must be at least 100 mm, in agricultural settlements - at least 75 mm.

Ring water supply networks are such networks where there are at least two supply routes to any point of the water supply network.

Dead end network – it is a network where there is only one path from each node of the dead-end network to the water supply point.

A dead-end network is allowed to be used:

- to supply water for fire-fighting or economic and fire-fighting needs, regardless of the water consumption for fire extinguishing with a line length not exceeding 200 m;

- in settlements with a population of up to 5 thousand people and a water consumption for external fire extinguishing up to 10 l / s, dead-end lines with a length of more than 200 m are allowed, subject to the installation of fire tanks or reservoirs, a water tower at the end of the dead end.

The advantage of ring water supply networks over dead-end:

- the flow rate of ring networks is almost twice as high as that of dead-end networks;

- in case of an accident in any section of the network, this section can be turned off without interrupting the supply of water to subsequent sections.

High pressure water supply This is a water supply system that, within 5 minutes after reporting a fire, creates the pressure necessary to extinguish the fire without the use of fire engines, i.e. water for extinguishing is supplied through fire hoses directly from a fire hydrant installed on a hydrant. For this, stationary fire pumps are installed in the buildings of pumping stations or other separate rooms.

Low pressure water supply This is such a water supply system to provide the necessary pressure during a fire, fire fighting equipment is used, which is installed on fire hydrants.

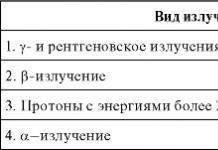

The fire hydrant is designed to take water using a fire pump from the water supply network when extinguishing a fire.

The fire hydrant consists of: riser, valve, valve box, stem, threaded mounting head and cover.

Steam generator throughput is not more than 40 l / s.

Types of plumbing.

Classification of the water supply system by pressure.

According to their purpose, water pipelines are divided into household and drinking, industrial and fire-fighting. Depending on the pressure, high and low pressure fire-fighting water pipes are distinguished. In the high-pressure fire-fighting water supply, within 5 minutes after the fire is reported, a pressure is created necessary to extinguish a fire in the tallest building without the use of fire engines. For this, stationary fire pumps are installed in the buildings of pumping stations or in other separate rooms. In low-pressure water pipelines during a fire, fire pumps are used to create the required pressure, which are connected to fire hydrants using suction hoses. In high-pressure water pipelines, water is supplied to the fire site through hose lines directly from hydrants under pressure from stationary fire pumps installed in the pumping station. All water supply structures are designed so that during operation they pass the estimated water consumption for firefighting needs at the maximum water consumption for household, drinking and industrial needs. In addition, an emergency supply of water for extinguishing fires is provided in clean water tanks and water towers, and fire pumps are installed in pumping stations of the second lift. Pump and hose systems, which are collected when extinguishing fires, are also elementary high-pressure fire-fighting water pipelines, consisting of a water supply source, a water intake (suction grid), a suction line, a combined pumping station of the first and second rise (fire pump), water pipelines (main hose lines ), water supply network (working hose lines). Water towers are designed to regulate the pressure and flow rate in the water supply network. They are installed at the beginning, middle and end of the water supply network. The water tower consists of a support (trunk), a tank and a tent-device that protects the tank from cooling and freezing water in it. The height of the tower is determined by hydraulic calculations, taking into account the terrain. Typically, the height of the tower is 15 ... 40 m. The capacity of the tank depends on the size of the water supply system, its purpose and can vary widely: from several cubic meters in low-power water pipelines to tens of thousands of cubic meters in large urban and industrial water pipelines. The size of the regulating tank is determined depending on the schedules of water consumption and the operation of pumping stations.

In addition, they include an inviolable fire reserve for extinguishing one external and one internal fire for 10 minutes. The tank is equipped with injection, collapsible, overflow and mud pipes. Discharge and collapsible pipes are often combined. A variety of water towers are water reservoirs, which are designed not only to regulate the pressure and flow in the water supply network, but also to store the fire-fighting water supply for extinguishing fires for 3 hours. The reservoirs are located in elevated places. Water tanks and towers are included in the water supply network in series and in parallel. When turned on in series, all the water from the pumping stations passes through them. In this case, the discharge and collapsible pipes are not combined, and they work separately. At a minimum water consumption, excess water is accumulated in a reservoir or in a tank, and at a maximum, this supply is sent to the water supply network. When connected in parallel to the water supply network, excess water flows into the reservoirs and tanks (at minimum water consumption), and at maximum water consumption it is sent to the network.

In this case, the delivery and distribution pipelines can be combined. Measuring devices are provided to control the water level in tanks and reservoirs. By the type of the serviced facility, water supply systems are divided into urban, settlement, as well as industrial, agricultural, railway, etc. By the type of natural sources used, water pipelines are distinguished that take water from surface sources (rivers, reservoirs, lakes, seas) and underground (artesian, spring ). Mixed water supply lines are also available. According to the method of water supply, water pipelines are pressure-driven with mechanical water supply by pumps and gravity (gravity), which are arranged in mountainous areas when the water source is located at a height that provides natural water supply to consumers. According to their purpose, water supply systems are divided into household and drinking systems that satisfy the needs of the population; industrial, water-supplying technological production processes; fireproof and combined. The latter are usually arranged in settlements. From the same water pipelines, water is also supplied to industrial enterprises if they consume an insignificant amount of water or, according to the conditions of the technological process of production, drinking quality water is required.

At high water consumption, enterprises can have independent water supply systems that provide their household, drinking, industrial and fire-fighting needs. In this case, they usually construct economic and fire-fighting and industrial water pipelines. The combination of a fire water supply system with an economic one, and not with an industrial one, is explained by the fact that the industrial water supply network is usually less ramified and does not cover all volumes of the enterprise. In addition, for some technological production processes, water must be supplied under a strictly defined pressure, which will change when extinguishing a fire. And this can lead either to an increase in water consumption, which is economically inexpedient, or to an accident of production devices. An independent fire-fighting water supply system is usually arranged at the most fire hazardous facilities - enterprises of the petrochemical and oil refining industries, oil and oil products warehouses, timber yards, storage facilities for liquefied gases, etc. Water supply systems can serve as one object, for example, a city or industrial enterprise, or several objects. In the latter case, these systems are called group systems. If a water supply system serves one building or a small group of compactly located buildings from a nearby source, then it is called a local system. To supply water under the required pressure to various parts of the territory of the settlement, which has a significant difference in elevations, they arrange zonal water supply. A water supply system serving several large water consumers located in a certain area is called a district one.

Water supply schemes for settlements

On the territory of most settlements (cities, towns), there are various categories of water consumers that impose various requirements for the quality and quantity of water consumed. In modern urban water supply systems, water consumption for the technological needs of industry is on average about 40% of the total volume supplied to the water supply network. Moreover, about 84% of water is taken from surface sources and 16% from underground. The water supply scheme for cities using surface water sources is shown in the figure. Water enters the water intake (head) and flows through gravity pipes 2 into the coastal well 3, and from it, by the pumping station of the first lift (HC-I) 4, it is supplied to the sedimentation tanks 5 and then to the filters 6 for cleaning from contamination and disinfection. After the treatment plant, water enters the storage tanks.

Water supply scheme of the settlement

1 - water intake; 2 - gravity pipes; 3 - coastal well; 4 - pumping station of the 1st rise; 5 - sedimentation tanks; 6 - filters; 7 - spare reservoirs of clean water; 8 - pumping station of the II rise; 9 - water conduits; 10 - water tower; 11 - main pipelines; 12 - distribution pipelines; 13 - entry into buildings; 14 - water consumers of clean water 7, of which it is supplied by a pumping station of the second rise (NS-P) 8 through water pipelines 9 to a pressure-regulating structure 10 (a ground or underground reservoir located on a natural elevation, a water tower or a hydropneumatic unit). From here, water flows through the main lines 11 and distribution pipes 12 of the water supply network to the inputs to buildings 13 and consumers 14.

Water supply scheme for an underground water source

1 - artesian well with a pump; 2 - spare tank; 3 - HC-II; 4 - water tower; 5 - water supply network located on different sides of the settlement. Such a water supply allows you to get a more even distribution of water throughout the network and its flow to consumers. The unevenness of water consumption with an increase in the population in cities is largely smoothed out, which makes it possible to do without pressure control structures. In this case, water from the NS-P flows directly into the pipes of the water supply network.

Water supply for firefighting purposes in cities is provided by fire trucks from hydrants installed on the water supply network. In small towns, additional pumps in the NS-I are turned on to supply water for extinguishing fires, and in large cities, fire consumption makes up an insignificant part of water consumption, therefore, they practically do not affect the operating mode of the water supply system. In accordance with modern standards, in settlements with a population of up to 500 people, which are located mainly in rural areas, a combined high-pressure water supply system should be arranged to provide household, drinking, industrial and fire needs. However, it is not uncommon for only a drinking water supply to be built, and water is supplied for firefighting needs by mobile pumps from reservoirs and reservoirs replenished from the water supply. In small settlements, for economic and fire-fighting needs, local water supply systems are most often arranged with water intake from underground sources (mine wells or wells).

Centrifugal and piston pumps, Airlift systems, wind power plants, etc. are used as water-lifting devices. Centrifugal pumps are the most reliable and convenient in operation. As for other water-lifting devices, due to their low productivity, they can only be used to replenish fire water reserves in reservoirs, reservoirs, water towers. Sources of water supply According to the two categories of natural water sources, water intake facilities are also divided into two groups: facilities for receiving water from surface sources and facilities for receiving groundwater. The choice of one or another source of water supply is determined by local environmental conditions, sanitary and hygienic requirements for water quality, and technical and economic considerations. Wherever possible, preference should be given to underground water supplies. Surface sources include rivers, lakes and, in some cases, seas.

The location of the water intake is determined in such a way that the following conditions are satisfied: the possibility of using the simplest and cheapest method of taking water from the source; uninterrupted receipt of the required amount of water; ensuring the flow of as clean water as possible (cleaning from pollution); the closest location to the facility supplied with water (to reduce the cost of water pipelines and water supply). Groundwater occurs at different depths and in different rocks. For water supply they use: water of confined aquifers, overlapped from above by waterproof rocks that protect underground waters from pollution; unconfined groundwater with a free surface contained in strata that do not have a waterproof roof; spring (spring) waters, i.e. underground waters that independently emerge to the surface of the earth; mine and mine waters (more often for industrial water supply), that is, groundwater entering the drainage facilities during the extraction of minerals. Fire hydrant device and requirements for operation in winter and summer A hydrant with a fire hydrant is a water intake device installed on the water supply network and designed to take water when extinguishing a fire.

A hydrant with a column for extinguishing a fire can be used, firstly, as an external fire hydrant in the case of connecting a fire hose to supply water to the place of extinguishing the fire and, secondly, as a water feeder for the pump of a fire truck. Depending on the design features and conditions of fire protection of the protected objects, hydrants are subdivided into underground and aboveground. Underground hydrants are installed in special wells with a lid. The fire column is only screwed onto the underground hydrant when in use. An overhead hydrant is located above the surface of the earth with a column attached to it. A fire hydrant is designed to take water from the water supply network for extinguishing fires, it consists of a riser, a valve, a valve box, a stem, an installation head with a thread and a cover. If the water table is high, a check valve is installed on the drain hole of the valve box.

The hydrant column is installed on the water supply network using a fire stand without a well device. The capacity of the combined hydrant is 20 l / s. The fire column is used to open and close a fire hydrant, as well as to connect fire hoses when taking water from the water supply network to extinguish fires. The main parts of the column are the body and the head. At the bottom of the body there is a threaded ring for connecting the column to a fire hydrant. The upper part contains the column control and two branch pipes with connection heads and two valves. A central key (tubular rod) with a square sleeve at the bottom and a handle at the top passes through the gland in the column head. The handle is rotated with the valves of the pressure pipes closed. When the valves are open, the handwheels will fall into the field of rotation of the handle. Thus, the column has a lock, which prevents the central key from turning when the valves of the pressure pipes are open. Remove the column from the hydrant only with the hydrant valve closed.

Fire hydrant requirements:

- fire hydrants should be located along highways at a distance of no more than 2.5 m from the edge of the carriageway, but no closer than 5 m from the walls of the building. It is allowed to place them on the carriageway;

- the distance between the hydrants is determined by a calculation that takes into account the total water consumption for fire extinguishing. This distance must meet the requirements of SNiP and not exceed 150 m. The arrangement of fire hydrants on the water supply network must ensure fire extinguishing of any building, structure or part of it served by this network, at least:

a) from two hydrants with an external fire extinguishing flow rate of 15 l / s or more;

b) from one hydrant - with a water flow rate of less than 15 l / s, taking into account the laying of hose lines with a length of no more than 200 m on paved roads.

- the distance from the hydrant cover to the top of the well hatch should not be more than 40 cm and less than 15 cm. In this case, the axis of the installed hydrant should be located no closer than 17.5 cm from the wall of the well hatch neck and no more than 20 cm from it.

- the locations of fire hydrants should be provided with light indicators or other made using reflective coatings with applied fire hydrant symbols, digital values of the distance in meters from the indicator to the SG, internal diameter and type of water supply.

Requirements for the operation of fire hydrants in winter and summer

There are mandatory rules for the operation of fire hydrants. Inappropriate handling of fire hydrants can lead to water breakdowns, disruption of the water supply and accidents. Preparation of fire-fighting water supply for operation in winter conditions is carried out: city water supply - during the autumn inspection by the mobile teams of the automatic control system REVS (departments); facility water supply - during the autumn inspection by the facilities' water supply services.

Preparation of fire-fighting water supply for operation in winter conditions includes: pumping water from the risers of Moscow-type fire hydrants and sealing the drain holes with wooden plugs; at a steady minus temperature of the outside air, pumping out water from the wells of the hydrants filled above the level of the riser, followed by paragraph 1; fire hydrants susceptible to flooding by groundwater and melt water are taken on a special account (Appendix No. 1 "Instructions ...") by linear sections of the REVS and district fire departments with a mandatory mark in the fire-fighting water supply inspection book, followed by control of their condition by REVS, pumping out water from risers after thaws (if necessary) and the mandatory transfer of information to the district fire departments; filling hydrant wells with a special heat-insulating filler.

Internal water supply - a system of pipelines and devices that provide water supply to sanitary appliances, fire hydrants and technological equipment, serving one building or a group of buildings and structures and having a common water measuring device from the water supply network of a settlement or industrial enterprise.

Internal water pipelines are also subdivided into household and drinking, industrial, fire-fighting and combined.

Internal fire hydrants

Free heads at internal fire hydrants should provide compact jets with a height necessary to extinguish fires at any time of the day in the highest and most remote part of the building.

Fire hydrants are installed at a height of 1.35 m above the floor of the room and placed in cabinets that have the ability for ventilation, adapted for sealing them, visual inspection without opening and bearing the inscription "Fire hydrant" (PC).

Each fire hydrant should be equipped with a fire hose of the same diameter 10, 15 or 20 m long and a fire barrel. The fire hose, attached to the barrel and the internal fire hydrant, is laid with an accordion or double roll.

Internal fire hydrants should be installed mainly at entrances, on heated staircases, in lobbies, corridors, walkways and other most accessible places, while their location should not interfere with the evacuation of people.

In addition to the above main elements, the internal water supply, in case of insufficient pressure in the external network, can be equipped with water tanks, pumping units.

Pumping units that ensure the normal operation of internal fire hydrants should be arranged with manual and remote start of pumps - boosters, and for buildings with a height of more than 50 m, as well as cinemas, clubs, houses of culture, assembly and conference halls - with manual, automatic and remote management.

With remote control of booster pumps, start buttons are located directly at the installation site of internal fire hydrants.

Requirements for fire reservoirs and piers

Natural water sources include rivers, lakes, streams, etc.

For artificial - ponds, canals, wells, digging, various decorative and other pools, as well as fire tanks with water, reservoirs.

For the convenience of taking water by fire engines from natural water sources and supplying it to the fire site, they should be equipped with access roads and platforms, piers or coastal wells.

The width of the piers, and their design and material, are selected to ensure the safe operation of three fire trucks;

- the pier platform should be located no higher than 5 m from the level of the low water horizon and be equipped with a drain chute for suction hoses;

- platform flooring, etc. with a slope towards the coast and have a solid side fence with a height of 0.7-0.8 m;

- at a distance of 1.5 m from the longitudinal edge of the platform, a thrust bar with a section of at least 25x25 cm is laid and strengthened.

In those cases when it is impossible to arrange a pier, coastal wells are arranged.

The volume of the coastal well should be not less than 5 cubic meters The depth of the pipe, supplying water to the well, d.b. below the level of soil freezing by at least 0.2 m. The diameter of the intake pipe should be not less than 200 mm, and its end is located above the bottom of the reservoir at least 0.5 m and a metal mesh is reinforced from the side of the reservoir.

In cases where a water supply system or natural water sources cannot provide the estimated amount of water for extinguishing a fire or they are absent, fire reservoirs (reservoirs) are built.

In practice, various types of artificial fire reservoirs, buried, semi-buried, are used.

The placement of reservoirs or reservoirs should take into account the conditions for their service of buildings located within the radius:

- 200 m - in the presence of auto pumps;

- 100-150 m - in the presence of motor pumps (depending on their type).

When placing fire reservoirs, it should be borne in mind that the water supply to any point of the fire must be provided from two adjacent reservoirs at the same time.

The volume of fire reservoirs must be determined based on the estimated water consumption and the duration of extinguishing fires (depending on the purpose of buildings, the volume of buildings, number of storeys, the degree of fire resistance, categories of production for fire hazard).

1. General concept of p / p water supply.

Fire-fighting water supply - a set of measures to provide water to various consumers to extinguish a fire. The problem of fire-fighting water supply is one of the main problems in the field of fire-fighting.

2. Basic concepts of hydraulics

Fire jets. Fires are usually extinguished with water and foam jets. As the practice of fire extinguishing has shown, for the successful elimination of combustion, water jets must have a sufficiently large impact force at the highest possible flow rate and maximum flight range.

Such jets are obtained from a nozzle consisting of a conical and a cylindrical part. The conical part of the nozzle increases the outlet speed, while the cylindrical part of the nozzle maintains the shape of the jet and prevents it from splashing. The flight range of the jet from the conical nozzle is greatest when it is tilted to the horizon of 30 degrees, in this case it is 4 times higher than the maximum lift height. To extinguish external fires, the compact part of the jet must be at least 17 m.

Water hammer is a sharp increase in pressure in pipelines (fire hoses) as a result of a change in the speed of the fluid moving in them with a rapid shutdown of the flow. Water hammer is especially dangerous in long pipelines, in which significant masses of liquid are moving at high speeds, as it can lead to pipeline rupture. The phenomenon of water hammer is observed with a sharp closing or opening of a fire barrel with a plug valve. The pressure from a water hammer propagates through the water supply in the form of an elastic wave at a speed that depends on the elasticity of the fluid and the walls of the water supply. For example, the speed of propagation of a water hammer wave in steel and reinforced concrete pipes is 700-1300 m / s, in fire hoses 50-120 m / s.

The waves that have arisen at the regulating device propagate against the movement of the liquid flow, and when they reach the pump or the free surface of the liquid, they again move to the regulating device, reducing the pressure in the water supply system that previously appeared from the direct wave. After stopping the operation of the regulator, the water hammer phenomena are rapidly attenuated due to energy dissipation. If the closing time of the valve is longer than the travel time and water hammer back waves, the pressure does not reach its maximum value.

3. Rates of water consumption.

Water consumption rates for extinguishing fires in cities and towns are calculated depending on the number of residents, the number of simultaneous fires and the number of storeys of buildings. Cities and settlements have an extensive network of artificial fire reservoirs, as well as comfortable entrances to natural reservoirs and sites (piers) for the installation of fire engines.

The minimum supply of water in fire reservoirs is 3 thousand m 3 per 1 km 2 of the city's buildings. In cities with a powerful fire-fighting water supply, the water supply in fire reservoirs can be reduced to 1.5 thousand m3 per 1 km2 of buildings. The estimated number of simultaneous fires at industrial and agricultural enterprises depends on the area they occupy: one fire for an area of up to 150 hectares, two fires for more than 150 hectares.

When calculating water consumption for external fire extinguishing at industrial and agricultural enterprises, the degree of fire resistance, the volume and width of the building, and the fire hazard category of production are taken into account. For example. The minimum water consumption per fire in an industrial enterprise is 10-100 l / s, in an agricultural one 5-30 l / s. The duration of extinguishing a fire in a village or at an enterprise is at least 3 hours.

4. Fire-fighting water supply.

Fire-fighting plumbing.

According to their purpose, water pipelines are divided into household and drinking, industrial and fire-fighting. Depending on the pressure, high and low pressure fire-fighting water pipes are distinguished.

In the high-pressure fire-fighting water supply system, within 5 minutes after the fire is reported, the pressure is created necessary to extinguish a fire in the tallest building without the use of fire engines. For this, stationary fire pumps are installed in the buildings of pumping stations or other separate rooms.

In low-pressure water pipelines during a fire, fire pumps are used to create the required pressure, which are connected to fire hydrants using suction hoses. All water supply structures are designed so that during operation they pass the estimated water consumption for firefighting needs at the maximum water consumption for household, drinking and industrial needs. In addition, an emergency supply of water for extinguishing fires is provided in clean water tanks and water towers, and fire pumps are installed in pumping stations of the second lift.

Pump and hose systems, which are collected when extinguishing fires, are also elementary high-pressure fire-fighting water pipelines, consisting of a water supply source, a water intake (suction grid), a suction line, a combined pumping station of the first and second ascents (fire pump), water pipelines (main hose lines ), the water supply network (working hose lines) Water pipelines are designed to transport water from the pumping station of the second rise to the water supply network of the city or object. Always provide at least two water pipelines so that in case of an accident on one through the second, at least 70% of the estimated water consumption for extinguishing fires is supplied. Water pipelines are connected by jumpers with valves, with the help of which emergency sections can be disconnected.

Water towers are designed to regulate the pressure and flow rate in the water supply network. They are installed at the beginning, middle and end of the water supply network. The water tower consists of a support, a tank and a tent-device that protects the tank from cooling and freezing water in it.

The height of the tower is determined by hydraulic calculations, taking into account the terrain. Usually the tower height is 15-40m. The capacity of the tank depends on the size of the water supply system, its purpose and can vary widely: from a few cubic meters to low-power water pipelines up to tens of thousands of cubic meters in large urban and industrial water pipelines. The size of the control tank is determined depending on the schedules of water consumption and the operation of pumping stations. In addition, they include an inviolable fire reserve for extinguishing one external and one internal fire for 10 minutes. The tank is equipped with injection, collapsible, overflow and mud pipes. Discharge and collapsible pipes are often combined.

A variety of water towers are water tanks, which are designed not only to regulate the pressure and flow rate of water in the water supply network, but also to store the fire-fighting water supply for extinguishing fires for 3 hours. The reservoirs are located in elevated places.

Water tanks and towers are included in the water supply network in series and in parallel. When turned on in series, all the water from the pumping stations passes through them. In this case, the discharge and collapsible pipes are not combined, and they work separately. With a minimum water consumption, excess water is accumulated in a reservoir or in a tank, and at a maximum, this supply is sent to the water supply network

5. Water supply network.

The water supply network serves for and uninterrupted transportation of water to consumers in the required quantities under a pressure sufficient to supply water to the most distant and highest point of water intake, as well as to extinguish fires.

Water supply networks are divided into ring and dead-end. In ring water supply networks, in contrast to dead-end networks, it is possible to turn off emergency pipeline sections without interrupting the water supply to subsequent sections, in addition, they have less water hammer force. At the same time, the total length and, consequently, the cost of ring networks is much higher than that of dead-end networks.

In this regard, ring networks are usually used in urban and industrial water pipelines, and dead-end networks are used to supply small villages, livestock farms, etc. So that the water in the pipes does not freeze in winter, they are laid below the depth of soil freezing. For example, for the middle zone of our country, the depth of the water supply networks is taken to be 2.5 - 3 m.

6. Fire hydrant.

A fire hydrant is designed to take water from the water supply network to extinguish fires. It consists of a riser, valve, valve box, stem, threaded set head and bonnet. If the water table is high, a check valve is installed on the drain hole of the valve box.

Hydrants are placed at a distance of no more than 150 m from one another in wells on fire stands. The throughput of the hydrant at a pressure loss of 0.1 MPa 40 l / s, it retains its tightness at a network pressure of up to 1.5 MPa.

7. Column fire.

The fire column is used to open and close a fire hydrant, as well as to connect fire hoses when taking water from the water supply network to extinguish fires. The main parts of the column are the body and the head.

At the bottom of the body there is a threaded ring for connecting the column to a fire hydrant. The upper part contains the column control and two branch pipes with connection heads and two valves. A central key with a square sleeve at the bottom and a handle at the top passes through the gland to the column head.

The handle is rotated with the valves of the pressure pipes closed. When the valves are open, the handwheels will fall into the field of rotation of the handle. Thus, the column has a lock, which prevents the central key from turning when the valves of the pressure pipes are open. Remove the column from the hydrant only with the hydrant valve closed.

8. Rules for the operation of fire hydrants.

Inappropriate handling of fire hydrants can lead to water breakdowns, disruption of the water supply and accidents. Mandatory rules for the operation of fire hydrants have been developed. When using a hydrant, an indicator is installed next to the well in the daytime, and at night they illuminate the rear headlight of a car or a lantern. In winter, after the end of work, water is removed from the fire hydrant riser through the drain hole, and if it is closed, it is pumped out with a foam mixer.

The use of fire hydrants in winter is notified to the appropriate divisions of the water supply service. The technical condition of all fire hydrants is checked twice a year: before the onset of the spring-summer and autumn-winter periods - jointly by representatives of the water supply and fire fighting services.

The check begins with an inspection of the hydrant. A column is installed on the hydrant and water is released, water is pumped out of the riser, in the absence of check valves, the drain hole is closed. The results of the check are drawn up by an act.

The fire department has the right to selectively check hydrants without a representative of the plumbing service with water starting only at positive air temperatures. If the air temperature is minus (not lower than 15C), then the hydrants are inspected only externally, and at lower temperatures it is forbidden to open the covers of the wells. Water-operated hydrants are checked only with a fire hydrant. The water supply dispatcher is immediately notified of hydrant malfunctions and the elimination of defects of each fire hydrant is monitored, a sign is posted indicating its location. Clearing the hydrant covers from snow, purchasing, installing and monitoring the condition of the indicators is entrusted to the relevant housing and operating organizations, enterprises, institutions and organizations on whose territory or in whose interests the hydrants are installed.

The service dispatcher notifies the fire department about the repair work on the water supply network. The cover of the well is opened with a hook or crowbar. at the same time, make sure that it does not hit the threads of the hydrant riser. Since various flammable and poisonous gases can penetrate into water wells, it is forbidden to smoke or use open fire when opening the lid and during work.

When installing a fire hydrant on the hydrant, the valves are closed, the column is screwed on smoothly, without effort. The column is considered to be fully worn if the entire thread of the hydrant riser is closed and the column is tight. When screwing in the column, its center key must be fixed.

To open the hydrant valve, smoothly turn the central key of the column until the characteristic noise of water appears filling the hydrant riser and the column body. Water inflow can also be determined by the exit of the trickle from the hydrant outlet. After filling the hydrant and the column with water, the hydrant valve is opened (turn the central key of the column until it stops), and then the valves of the discharge branch pipes of the column.

9. Internal fire-fighting water supply.

Internal fire-fighting water supply system is designed to extinguish fires mainly in the initial stage of development. It is arranged in residential and public buildings, industrial buildings, warehouses and bases.

In high-rise and high-rise buildings, the internal fire-fighting water supply usually serves as the main means of extinguishing fires on the floors. The duration of extinguishing fires from internal fire hydrants is 3 hours.

The number of jets and the flow rate of water depend on the degree of fire resistance of the buildings, the fire hazard category of production and the volume of the buildings. The main parts of the internal fire-fighting water supply: inputs, bypass lines at water meters, a water supply network with risers, fire hydrants. An internal fire-fighting water supply system is combined with a drinking water supply or industrial water supply system. Under normal conditions, the water pressure in the fire and drinking water supply is the same.

If the fire valve is activated, the pressure in the fire-fighting water supply network drops, water from the drinking water supply system begins to flow into the fire-fighting water supply system through a check valve and a liquid flow control relay. As soon as water begins to flow through the relays, they are triggered and turn on fire pumps, as well as electric valves. Fire pumps and electric valves can also be switched on remotely using buttons installed at fire hydrants.

10. Fire reservoirs.

In the absence or low capacity of the fire-fighting water supply, water for extinguishing fires is taken from fire reservoirs. They are natural (rivers, lakes) and artificial. Improved dead-end roads with loop bypasses at the water source or areas of 12x12 m for the installation of fire engines and their maneuvering are made to the fire reservoirs.

Depending on the steepness of the coastal slopes, seasonal fluctuations of the water horizons, the availability of building materials, various bank protection works are carried out, receiving wells and sites for installing fire engines are built.

In winter, on open water sources covered with ice, for water intake, ice holes are made with a size of at least 0.6x0.6 m. A barrel without a bottom with two lids is frozen into an ice hole, between which a heat-insulating material is placed. The location of the fire hole is indicated by a pointer. When arranging fire reservoirs and reservoirs, the distances between them are reduced to 250 m in cities and industrial enterprises and up to 150 m in rural areas. The capacity of reservoirs and reservoirs is taken on the basis of extinguishing fires within 3 hours.

11. The procedure for organizing accounting, control and performance of work to check the external fire-fighting water supply, as well as interaction with the services involved in its operation.

The constant readiness of fire water sources for their successful use on fires is ensured by carrying out the main preparatory measures:

high-quality acceptance of all water supply systems upon completion of their construction, reconstruction and repair. Joint preparation of fire-fighting water supply sources for operating conditions in the spring-summer and autumn-winter periods; Periodic testing of water supply networks for water loss:

establishing a close relationship between operational water supply services.

In order to qualitatively check the technical condition of the steam generator, the following work procedure is carried out:

1.The presence of the index is checked according to GOST, the correspondence of its data to the actual one.

2.The fire column is installed on the hydrant, while the correspondence of the square on the rod of the hydrant with the square coupling of the fire column is revealed,

Convenience of connecting the pressure-suction hoses and the correspondence of the location of the neck of the well relative to the hydrant 3. Water is launched by opening the ball valve with the help of a fire column

4. The operation of the drainage hole is checked, the SG drainage hole is closed after the water has been drained at the groundwater level above the flange of the fire column in order to avoid water ingress into the hydrant riser (in the autumn-winter period), the neck of the well is closed with a lid

5.The presence of an entrance with a width of at least 3.5 meters is checked

6. Based on the results of checking the technical condition of fire hydrants, an act is drawn up. (Appendix 3)

7. Once a year, water supply networks are tested for water loss. Based on the test results, acts are drawn up, signed by the representative of MUP "Vodokanal" and the head of the guard

8. The guard on duty checks the SG when working out operational cards (according to the schedule), and in winter, under the following conditions:

10. At temperatures from -10C to -20C, external inspection of the hydrants is allowed. The launch of water is prohibited.

11. It is prohibited to open the covers of the wells to inspect the hydrant at temperatures below -20C in order to avoid heat loss.

12.In all cases, during inspections, it is prohibited to use a socket wrench to open the steam generator.

13. If, during the inspection by external inspection, defects are revealed that can serve as a hindrance to the possibility of using the steam generator for extinguishing a fire, an act is drawn up. (Appendix 4)

14 The dispatcher of the CPPS OGPS-16 is obliged to immediately notify the operating company of all detected faults by fax, indicating the exact address of the faulty hydrant, the nature of the malfunctions, the name of the transmitting information, the date of transmission of the information, the name of the recipient of the information. (Appendix 5) Control over troubleshooting is established. The proposed terms of troubleshooting are indicated in Appendix No. 6. After elimination of the SG malfunction, a message is made to the fire department of the branch by the operating enterprise. After verification, a note is made in the appropriate journal and these hydrants are removed from the register as faulty.

15. All inspections of the steam generator are carried out by the guard on duty with a representative of the MUE Vodokanal (operational service) in the summer, and in the winter, based on the results of inspections by external inspection, if there are any comments, a representative is invited and an act is drawn up (Appendix 4).

16. When disconnecting a network section, no more than 5 SGs should be disconnected.

17. If it is necessary to disconnect the sections of the water supply system on which more than 5 SGs are installed, the representative of MUE “Vodokanal” is obliged to arrive at OGPS-16 no later than 5 days before the disconnection and agree with the head of OGPS-16.

18. Annually, the director of the branch and the director of MUE Vodokanal agree on the combination of work in their schedules for GHG inspections and water loss tests.

12. Requirements for the acceptance into operation of new sources of semiconductor water supply. Requirements for external networks of p / n water pipes, installation of fire hydrants.

1. The depth of the pipeline should be 0.5 m greater than the calculated depth and penetration into the ground of the field temperature (ie 2.5 - 2.8 m + 0.5).

2. External fire-fighting water supply should be provided in the form of an annular circulation system with constant circulation of water in it. The device of dead-end networks is not allowed.

3. Fire hydrants should be of the Norilsk type and installed on main sections at a distance of 100 m from each other.

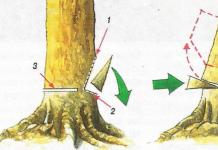

4. The main lines of the fire-fighting water supply system should be located no further than 2.5 m from the edge of the carriageway with the provision of measures to protect fire hydrants from snow drifting by arranging booths (pyramids)

5. In places where hydrants are installed, the carriageway of roads should be made with a width that allows vehicles to pass along the road when installing fire trucks on a hydrant. The water supply network should be divided into repair sections by sections with valves. When one of the sections is turned off, no more than 5 hydrants should be turned off.

13. Requirements for ground, underground fire tanks designed to store fire water supply.

1. Ground fire tanks should be insulated with heat-insulating materials and heated water, ensuring its temperature is not lower than + 5 degrees.

2. Fire tanks should be equipped with devices for direct water intake by pumps of fire trucks.

3. The volume of open water bodies must be calculated taking into account the possible evaporation of water and the formation of ice. The excess of the edge of an open reservoir above the highest water level in it must be at least 0.5 m.

The number of fire tanks or reservoirs must be at least two, while each of them must store 50% of the water for fire extinguishing.

14. The procedure for checking p / p water sources, frequency and form of reporting on the results of the check.

Inspection of water supply sources is carried out by workers on duty guards in accordance with the schedule according to pre-developed routes, as well as during the development, compilation, adjustments of OP and OK, PTZ, vocational school, fire extinguishing, elimination of accidents and natural disasters.

Checks are usually carried out in the afternoon according to the schedule. The time (period) of the inspection is agreed in advance with the person responsible for the technical condition of the water supply networks and the maintenance of water supply sources.

The department with the chief of the guard leaves for the check and checks the water sources. The head of the guard on duty, based on the results of the check, draws up an act (Appendix No. 2), and when checking in the winter period, an act (Appendix No. 3).

15. Checking fire reservoirs.

Fire reservoirs provide a supply of water for fire extinguishing purposes in the absence of water supply networks.

When checking the PV, it is necessary to check:

- the presence of a pointer in accordance with GOST 12.4.009PZ, the compliance of its data with the actual;

- the presence of an entrance to the PV.

To the place of water intake from the water supply, an entrance with a width of at least 4 m, a platform for turning fire trucks with a size of 12x12, a hatch and ventilation should be arranged. (PV must have a hatch with a size of at least 0.6x0.6 m with double covers and a ventilation pipe with an area of \ u200b \ u200b250-300 cm2.

16. Testing water supply networks for water loss.

The test is carried out by the head of the guard on duty together with a representative of the facility (water supply service) in order to establish the possibility of taking the estimated amount of water for fire-fighting needs.

Preparatory measures and practical testing of sections of water supply networks include the readiness of the necessary equipment for these purposes, theoretical training of personnel is carried out once a year and is timed to the spring-summer inspection of sources and networks of fire-fighting water supply.

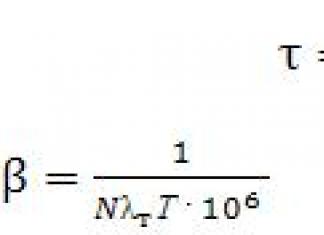

To test sections of low-pressure water supply networks from technical means, it is necessary to have a fire hydrant equipped with a smooth-bore pipe with a diameter of 65 mm and a length of 500 mm, and a plug with a pressure gauge.

When water is supplied from the fire column, according to the readings of the manometer, after 2 minutes, the water consumption is determined using the table (Appendix No. 5 to the methodological recommendations for checking the water supply p / n No. 55/3/645 of 05/21/1998.

It has been established that in the territories of settlements and urban districts there should be sources of external or internal fire-fighting water supply. As provided in Part 2 of Art. 62 of the commented Law, natural and artificial reservoirs, as well as internal and external water pipelines (including drinking, household and drinking, household and fire-fighting) can be used as sources of fire-fighting water supply (see the commentary to this article). Accordingly, in part 2 of the commented article, two types of sources of external fire-fighting water supply are named: 1) external water supply networks with fire hydrants; 2) water bodies used for fire extinguishing purposes in accordance with the legislation of the Russian Federation. The provisions of the commented article are devoted to the requirements for these two sources of fire-fighting water supply. The requirements for internal fire-fighting water supply are established in Art. 86 of the commented Law. Along with this, in Art. 99 of this Law separately provides for requirements for sources of fire-fighting water supply of a production facility.

Among the norms to which the provision of clause 2, part 2 of the commented article refers, it is necessary to indicate, first of all, the following provisions of Art. 53 of the RF VDK on the use of water bodies to ensure fire safety: the intake (withdrawal) of water resources for extinguishing fires is allowed from any water bodies without any permission, free of charge and in the amount necessary to extinguish fires (part 1); the use of water bodies intended to ensure fire safety for other purposes is prohibited (part 2).

the water consumption for external fire extinguishing (per fire) of residential and public buildings for calculating the connecting and distribution lines of the water supply network, as well as the water supply network inside the microdistrict or block should be taken for the building that requires the highest water consumption, according to table 6;

water consumption for outdoor fire extinguishing at industrial and agricultural enterprises for one fire should be taken for a building that requires the highest water consumption, according to table 7 or

The indicated tables 5,, and SNiP 2.04.02-84 * are reproduced, respectively, in tables 7 "Water consumption from the water supply network for external fire extinguishing in settlements", "Water consumption for external fire extinguishing of residential and public buildings", "Water consumption for external fire extinguishing of industrial facilities and warehouse buildings "and" Water consumption for external fire extinguishing of industrial facilities and warehouse buildings "of the appendix to the commented Law. The notes contained in SNiP 2.04.02-84 * are partially reproduced in the provisions of the commented article (see the commentary to the indicated tables).

As stated in clause 2.29 of SNiP 2.04.02-84 *, a fire-fighting water supply system should be taken at low pressure, a high-pressure fire-fighting water supply system is allowed to be accepted only with appropriate justification. In the high-pressure water supply system, stationary fire pumps must be equipped with devices that ensure the start-up of the pumps no later than 5 minutes after the fire signal has been given (according to note to clause 2.29 for settlements with a population of up to 5 thousand people, in which professional fire protection is not provided, the fire-fighting water supply must be high-pressure).

In accordance with clause 2.30 SNiP 2.04.02-84 * the free head in the low pressure fire water supply network (at ground level) during fire extinguishing must be at least 10 m. The free pressure in the high pressure fire water supply network must ensure the height of the compact jet not less than 10 m with full water consumption for fire extinguishing and the location of the fire nozzle at the level of the highest point of the tallest building. The maximum free head in the combined water supply network should not exceed 60 m.

Clause 8.16 of SNiP 2.04.02-84 * stipulates that fire hydrants should be provided along highways at a distance of no more than 2.5 m from the edge of the carriageway, but no closer than 5 m from the walls of buildings; it is allowed to place hydrants on the roadway. In this case, the installation of hydrants on the branch from the water supply line is not allowed. The placement of fire hydrants on the water supply network must provide fire extinguishing of any building, structure or part of it served by this network from at least two hydrants with a water flow rate for external fire extinguishing of 15 l / s or more, and one - with a water flow rate of less than 15 l / s, taking into account laying hose lines with a length not exceeding that specified in clause 9.30 on paved roads. The distance between the hydrants is determined by a calculation that takes into account the total water consumption for fire extinguishing and the throughput of the installed type of hydrants in accordance with GOST 8220-85 "Underground fire hydrants. Technical conditions" (for this standard, see.