Hello, there have been no new entries for a long time, so catch it. Another part about creating a gaming table. This time we will talk about the playing field. In fact, our table is almost ready, there is very little left, stay tuned =)

Required drawings

The playing field is made from 29mm MDF sheet. Both sides of the workpiece need to be reinforced, so we glue HPL sheets on both sides. This is done to avoid warping of the material later.

First, blanks for the playing field are cut out from MDF and HPL. The dimensions of the field should be approximately 121x70 cm. As you can see, it is allowed to make a small error in the drawing. Be careful, the following explains why this is needed.

Using a notched trowel, we evenly spread a layer of glue on the surface of the MDF and the inside of the HPL. It should take about 15 minutes to dry, after which the top layer of glue will appear dried.

MDF with adhesive applied.

When the glue dries a little, we put an HPL blank on the MDF. We do this carefully, as it will be difficult to fix a bad overlay. Next, we roll the entire surface of the HPL with a roller to secure the connection, as well as to drive out residual air.

After the field is covered with HPL on both sides, we proceed to polishing the surface of one of the sides. This must be done with a grinder with fine sandpaper. Do not apply excessive force, otherwise you can wipe the coating through.

The coating will be ready as soon as it becomes evenly matte.

Then we proceed to lay out the defensive and midfield areas. For convenience, you can use a stencil or masking film. It is preferable to use a masking film, since paint can flow under the stencil and become ugly stains.

After all the lines are outlined, you can remove the masking film. To cut a circle, you can use a compass with a sharp knife or scalpel at the end.

(Picture can be enlarged)

In this photo you can see part of the removed masking film.

Then, all unprotected parts of the playing field are covered with paper. Check that there are no gaps anywhere.

We cover the necessary places with white paint. You can use regular spray. The paint is applied in several thin layers so that there are no smudges and bubbles. Let the paint dry before removing the film.

(Picture can be enlarged)

This is what we get after removing the film and paper.

After the paint is completely dry, we use a circular saw to make 45 degree cuts from the underside of the playing field near the corners. The depth of the cut should be chosen in such a way that 3-6 mm remain until the end.

In these cuts, we insert auxiliary rails with a thickness equal to the saw blade.

With the help of glue, the slats are attached to the grooves. For better fixing, lightly tap them with a hammer.

Now that the playing field is ready, you can bring it to the dimensions indicated on the drawing: 119.5x69cm.

In order to be sure that the ball will roll off the edges of the field, we made another cut along each of the two sides. For this, the tool that was described in the last part was used. The cutting depth is about 2.5-3 cm, the distance from the surface is 3-5 mm.

(Picture can be enlarged)

We insert the slats smeared with glue into the cuts, as in the previous steps.

Thus, we see that the edges are slightly raised relative to the rest of the field, thereby preventing the ball from stopping at the walls of the field. On my own behalf, I want to note that not all tables have this kind of elevation, so I think you can only get by with cuts in the corners.

Now we insert the playing field into the "body" of our future table. Through the holes in the side walls of the table, we pass pencils in order to keep our field. This is done in order to mark places on the bottom of the field for drilling holes for special screws. Later we will attach special holder rails to the side walls on which the playing field will be held.

(Picture can be enlarged)

In the marked places, we make holes 20 mm deep for special screws, as in the photo above. The groove for the screw can be made with a hacksaw.

The final view of the playing field.

Football do-it-yourself "Making a board game Football"

Teacher Kozhina Tatyana Nikolaevna

Relevance : From early childhood, the ball was and remains the favorite and one of the first toys and amusements for the child.Football - a sports game with a ball, one of the most popular games in our country and the world. Children love to playfootball .

Problem : Not always children can playfootball on the street . Children's toy stores sell board games« Football » which are expensive and not everyone can buy it. So I decided to try making a board gamedo it yourself from improvised materials.

Target : create a board game "Football " .

Tasks of the master class:

1. To present pedagogical experience in the use of modern pedagogical technologies in the education of preschool children.

2. Motivate teachers to use methods, techniques, game tasks in their practice.

Hypothesis

: I assumed that if you make a board game yourself«

Football

»

, then it is interesting and you can play at any time of the year.

Methods research : Conversations about the history of occurrencefootball , reading information, drawing, viewing photos.

Main part : In 2018, our country will host the Worldfootball, including . Rostov-on-Don. Children love to playfootball but you can't play this game in winter. I decided to make a minifootball to play with children in a group. I suggest making a minifootball from waste material. At home with their parents, the children watchedfootball on tv , and we discussed this game with the children. The children drew pictures aboutfootball , we read a fairy tale about the ball, guessed riddles, looked at pictures with the imagefootball field how it looks.

Dear colleagues, I present to your attention a didacticboard game " Football ", which I recommend to make together with children.A game consists of a large playing field with marks.A game designed for children of middle and older preschool age. At the same time canplay a subgroup of children .

Master Class

For the manufacture of desktopfootball we took : a box, scissors, glue, colored paper, wooden skewers, colored pencils and felt-tip pens. We cut the box and glued it with colored paper, marked the field, made the gate and installed it. Draw two teams on cardboardfootball players , glued the figures together and put them on skewers. Holes were made on the sides of the box and skewers were inserted there so that they could move freely. We made different balls from foil, paper and adhesive tape, foam rubber. Our minifootball ready .

I offer you several options for the game.

For example : put awayfootball players and replace them with fingers turned fingerfootball , put the ball from cotton wool in the center of the field and blow it into the goal, it turns out to be breathablefootball , can replace cardboardfootball players on figurines from Kinder Surprise.

Well, now a little about the benefits of thisgames : after all, past such an important development of fine motor skills, with the help of it you can achieve many other goals. For the game, you can use figures from kinder surprises, the players are attached on a magnetic basis and the soccer ball is also a painted magnet, so now my children have experimentally found out that magnets can not only attract, but also repel each other.

Players of different teams differ in the color of the form, so in the process you can fix the name of the colors.

Our “football players” have a number on the jerseys, so repeating the score will also not be difficult.

Since our football players are animals, it is possible to repeat wild and domestic animals. Of course, with the help of this game, you can expand the horizons of children and replenish their vocabulary, and most importantly, make them want to play sports and, of course, positive emotions.

And we in the senior group arranged a match between boys and girls, the children really liked it, it was fun.

Conclusion : I came to the conclusion that the game was madeDIY is interesting , informative, and you can also play at any time of the year.

Thank you for attention!

At the beginning, I decided to make a trial model in order to identify the difficulties that may be in the manufacture of a more complex version. All material was found at home. The most difficult thing was to figure out what to make barbells for football players from. 10 mm aluminum tubes came up, however, bought for another homemade product.

The main material for the manufacture of this exciting game was plastic panels and sandwich panels. And for assembly, gluing and decoration, various types of adhesive tape and multi-colored electrical tape came up. Useful and no longer suitable children's felt-tip pens. No complicated tool was used - everything is simple and fast enough.

The basis was a ready-made coffee table 61x43 cm with a small rim. The parameters of all other materials depend on the size of the table. The football field itself is assembled from plastic panels, interconnected with colored tape. I glued the side walls of sandwich panels with locksmith tape and pasted homemade labels with football club logos.

For the manufacture of the gate, I used a mosquito net on a frame from the same sandwich. I didn’t bother with the figurines of football players - it’s still the same sandwich. Cool pictures of football players became a highlight. The assembly consisted in gluing the side walls with the inserted bars with the players and the playing field with extra strong adhesive tape. From felt-tip pens I made bushings in the side walls for the rods (760mm.) And the handles themselves.

This is how a long-awaited toy appeared in our house from construction debris in a short time and at no extra cost to the delight of everyone.

The base of the game (see. Fig.) - plywood size 1160x580x20 mm. Side walls with a height of 160 mm are also made from it. Holes are drilled in the walls through which the rods will be passed, "controlling" the players. The structure is fastened with glue and screws, and the corners are reinforced with metal squares. To prevent the ball from lingering in the corners, glue triangular blocks into them.

Make the rods for the game, to which the figures of athletes are attached, from a thin metal tube Ø 10 mm. The handles for them can be made of wood or plastic tubes with an internal Ø 10 mm can be used.

Holes in the side walls for the rods are made according to their outer diameter. A support is attached to the opposite wall for each rod: a flange with a soldered tube into which the rod will be inserted.

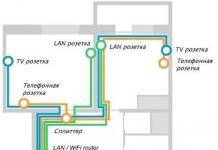

A - playing field; B - control rod with support: 1 - support, 2 - metal plate, 3 - tube, 4 - pin, 5 - plastic sleeve. 6 - felt ring, 7 - limiter ring; B - placement of players: 1 - goalkeeper line, 2 - defenders, 3 - midfielders, 4 - forwards. X is the distance of the longitudinal movement of the rod.

Each rod has a restrictive plastic ring; the distance between him and the wall will determine the lateral movement of this row of players.

Make figures of football players from plywood 5 mm thick and attach them to the rods with M3 bolts.

Gates can be made of iron or measuring wire Ø2 mm and wire mesh.

The soccer ball is a wooden, rubber or plastic ball Ø 25-30 mm.

A couple of months ago, it was decided to make a table for playing table football out of wood and Aliexpress. 9 items were bought from 5 sellers. There are a lot of letters and photos under the cut, about how I got to this point, and what came of it.

At one of the youth parties in a rented cottage, instead of traditional billiards, the hosts set up table football. I was hooked, and spent the whole night at the table, forgetting about the party and getting enough cuffs for it. Over time, the desire took shape in confidence, and since the place for installation was just found in the attic, from which it was decided to make a recreation room with football and air hockey (Can be seen in the background of the finished product).

In the vastness of the well-known store, a lot of goods on this topic were found. In terms of size, everything was taken at random, and in the end I turned out to be successfully right. There are several sizes of goods available on Ali, which differ in the thickness of the rod that they will wear. I tried to find information which is better and more correct, but I could not. The choice fell on 5/8 inches, that is, 16 mm in Russian.

Purchased in total:

Excellent players, they sat perfectly and tightly on the pipe. However, the screw hole is designed for 4 mm, on the reverse side there is a 6-sided groove for the nut, the usual 4 mm nut dangles there. A 5mm nut fits perfectly. (Perhaps you can find oversized 4 mm nuts on sale, but I have not come across such ones). The problem was solved - 5 mm was placed under the 4 mm nut, since the height made it possible to do this so that nothing sticks out and does not interfere from the outside.

The handles worked without any problems. They do not slip in the hand, they sit tight. The hole is the entire length of the handle, so it does not bend to the sides.

They turned out to be the most problematic part along with the rods, but I will discuss this below.

They work like springs. The bar with a sharp push can bounce off the walls 2 times.

The same problem as with the figurines of football players, I had to put 5 mm nuts. Everything else is fine.

Everything is fine. They protect great. Once I got a barbell on my arm without a plug, I don’t take them off anymore.

They count correctly. Didn't notice any difference :) Chosen solely for reasons of low price.

The balls worked very well. After reading about the types of soccer balls, I decided to order both types. White plastic ones, they jump perfectly, there is practically no friction. But they turned out to be too small, and now they lie like a dead weight.

Cork ones jump noticeably weaker and very dull, and plus they haven’t been polished properly yet, but they already fit well in size, and you can play with them. However, the seller was generous, and added 3 more plastic purple balls in addition to them, and now they turned out to be the best. The size is slightly smaller than cork, but due to the fact that plastic ones are very convenient to play with.

I will describe the assembly process, focusing on the most memorable moments.

Tolerable drawings were found somewhere on the Internet. I started to do according to them, then I switched to independent calculations, since the assembly methods there were ancient, like those of a caveman. The thickest plywood that I could find available in my city was used. Fastened with corners. HPL plastic, bought from furniture makers, was pasted on the table. Bought by the roll. In the background of the photos you can see an air hockey table that I make from the leftover piece of HPL plastic. (I also took washers and bits on Ali, I’ll write a review when I finish). A stencil of borders was cut out on a protective film, and painted with a spray can. There were certain difficulties with the internal structure of the gate, I had to break my head. This was all done before the arrival of the players themselves. All that remained was to wait for these little men.

Bearings and football players came. And then the most interesting began. I knew what I was getting into, I decided to buy bars. 16 mm chrome-plated pipes in everyday life are sold as furniture fittings for the kitchen. They were purchased from a furniture store. Only for furniture makers there is not much difference from the wall thickness of these pipes, they also will not suffer from the imperfectly round section of the pipe, and the fact that their pipes are not 16 mm at all, but from 15.8 mm to 16.1 mm in diameter, they also do not particularly care . So the first purchased pipes were sent to the basement, where everything that is a pity to throw away is stored, and the search for new, more suitable ones began. And this turned out to be a difficult task. Thick-walled pipes (1.5 mm or more) only on order with a waiting time of 2 weeks, and not the fact that they will be 100% round and exactly 16 mm. The price didn't appeal either.

As a result, 60 meters of pipe were bought in bulk (for the price they came out to me just like 8 meters of pipe from 1 batch, i.e. about 2 tr.). The walls were 0.9 mm thick, the diameter was ideal for football players, the pipes were round, with a small protruding seam. As a result, the wall thickness was not enough, the bar of the defenders (the longest) with a sharp attack from the extreme elongated position, it bent and clamped in the bearing. Epoxy was poured into the pipes, which gave them both a pleasant weight and the rigidity I needed so much.

Bearings are a separate issue. I bored them at least 5 times, because. I was afraid to take too much. Apparently, it was the bearings that were made according to all the canons of metric systems, and were exactly 15.8 mm, which corresponds to 5/8 inches. The pipes were also made by the Chinese, and some of the samples I selected reached 16.2 mm in diameter. But I squandered it, lubricated it with silicone grease, and now they drive like clockwork.

Still tormented with the corners of the table. After watching the Internet, diagonal cuts were made in the table at the corners, and the corners were raised by 5-7 mm so that the ball rolled out of the corner back to the players. I read on the same Internet that it would be nice to make a cut along the side wall, but it seemed to me an unnecessary perversion and everything remained as it is. As a result, the shock absorber turned out to be a little thicker than we would like, and if the ball is near the wall, then it is unrealistic to pick it up from there by the player of the same line. You have to pass to the enemy. Everything is solved by installing a small side.

I spent about 2 weeks on everything, since there is enough free time. Collected, sanded, painted. I play with my younger sister. Happy as an elephant.

Some photos of the assembly process

And what came of it

In conclusion, I can say that I am satisfied with all the goods. In Russian online stores, everything is much more expensive, but something is not there at all. It's nice to play. Everyone is happy at home. After the final assembly, the understanding came that everything had to be done on a metal frame. Would have avoided many problems with backlash and wood bends (I think I will mount a frame of square pipes from below in the near future, to give a pleasant heaviness and torsional rigidity). If you have time, desire and hands, and most importantly where to put it, then I advise.

P.S.: I don’t see the point in fully considering the assembly with all the subtleties, sizes and types of connections. This is not a specialized forum for this. Considered a product bought on Ali and shown to make an excellent kicker for the home.

P.P.S.: The photo shows a lot of assembly jambs and my curvature, but please refrain from giving advice on how it could be done better.

I plan to buy +21 Add to favorites Liked the review +43 +83