A reliable support base of the house ensures its long-term operation. The design of the foundation depends on the soil on which it will be installed, and on the degree of watering of the site. Neglect of any of these circumstances leads to premature wear of the foundation up to its complete destruction. And this is due to the loss of the entire building and the costs incurred for construction.

How pile foundations are arranged

The design of the foundation is always selected depending on the nature of the soil at the construction site. In some cases, the construction on piles of various types will be the most reliable and durable.

Advantages and disadvantages of pile foundations

In real construction conditions, various types of piles can be used. But regardless of the design of such products, a number of advantages can be distinguished that foundations on pile foundations have:

The main disadvantage of the pile foundation is the shrinkage of the supporting base. The result can be a warp of the foundation, leading to the destruction of the superstructure. The reasons often lie in the incorrect installation of piles when they are not deepened to stable solid soils. It is also possible to choose the wrong type of supports that are not suitable for the nature of the soil at the construction site. Therefore, on the selection of the type of piles, it is better to consult with an experienced specialist.

Some types of piles, such as screw piles, are quite expensive, which can also be attributed to their relative disadvantages.

Types of pile foundations and their features

Pile-driven foundations

On weakly bearing soils, it is necessary to use piles that are driven into the ground to the depth of the location of strong layers and are interconnected by a slab or grillage.

Driven piles look like square-section pillars made of concrete. At the end immersed in the ground, a sharpening is cast. Immersion is carried out by pneumatic or hydraulic hammers. Such a support base is the most durable.

Instead of reinforced concrete products, other materials can be used as piles:

- Wooden poles. They use hardwoods such as oak, ash, larch or pine. The diameter of the log under the pile must be more than 18 centimeters. The front end is equipped with a metal cap, the rear end with a metal ring to prevent splitting during driving. The disadvantage of such piles is a limited service life. But it can be increased by using protective compounds.

- Metal profiles - beams, channels and pipes. These products are easier than others to sink into the ground to the desired depth.

When driving piles, you need to control the sinking speed with each impact. The cessation of downward movement indicates that the supporting structure has reached solid ground. At this point, the deepening of the pillar can be completed. After installing all the piles according to the foundation plan, the upper ends are trimmed to one level.

A dangerous phenomenon when driving a pile is the termination of immersion when the support is stuck in a stone. Outwardly, it looks like the formation of the desired density. But subsequently the stone can move, and the pile will lose its support. A sign of such a situation may be a significant deviation in height of the driven support from the rest. In this case, the pile must be removed and the shaft drilled.

When constructing a foundation on heaving soils, piles are connected by an incomplete grillage. The lower plane of the grillage is at a distance of 15–20 centimeters from the ground. After casting, a layer of sand and gravel mixture is poured under it. Its purpose is to perceive and compensate for the load from the heaving soil.

The durability of wooden piles is achieved by processing with protective compounds.

Metal foundation supports are made from various hot rolled profiles such as beams, channels or pipes. The immersion of these piles requires significantly less labor compared to concrete piles. In addition, if it is necessary to extend the support, it can be welded by electric welding. The durability of metal supports can be greatly increased by anti-corrosion surface treatment.

When buying piles, you need to check the quality of the material by visual inspection and require the presentation of a quality certificate. Cracks, chips and other mechanical defects on the surface are not allowed.

Pile-monolithic foundation

Another name for this type of support base is "pile-slab" or SPF. It is a combination of two types of foundation - pile and slab. The reasons for using such a denouement are the following circumstances:

Construction technology

In fact, the SPF is built in two stages:

The time for complete crystallization of the foundation is 28 days, after which construction work can be continued.

In the hot season, the foundation must be covered with a film and periodically, 1-2 times a day, sprinkle it with water. Premature drying of water in concrete can lead to cracking..

It should be noted that 85% of the load is taken by the pile system, the rest falls on the slab. But this structural element gives the foundation stability.

The number of piles for the foundation is determined by the length of the foundation and the distance between the piles. Usually it is chosen equal to from 3 to 6 diameters of one support. For example, for a pipe with a diameter of 400 millimeters, it will be 1.2–2.4 meters. You can choose the average value so that the distance is the same. In this case, you need to remember about the distribution of the load.

We install a pile foundation from asbestos pipes

This design is chosen for reasons of economy for the construction of auxiliary buildings for household purposes, such as:

- barn;

- hozblok;

- summer cuisine;

- workshop;

- a garage without a viewing hole and other structures of a similar purpose.

The basis of the foundation for such buildings are piles of asbestos pipes. According to the results of exploratory drilling, their number and depth of immersion are determined. One of the weighty arguments in favor of the use of such a foundation design is the construction on a site with a slope.

Foundation installation

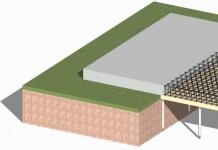

This operation consists in installing floor slabs on a pile foundation. For this, ribbed plates are usually used, which, with less weight, are close to solid ones in terms of bearing capacity. Installation of plates is carried out using lifting equipment. For small buildings, hollow core slabs up to 15 centimeters thick can be used.

It should be noted that for such structures, a combined foundation with a grillage is more applicable. It's more expensive, but more reliable.

Various conditions in the construction sites require the use of an appropriate type of foundation. So, for weak peat and marshy soils, the ideal option is the foundation of the house in the form of separate vertical supports of a round or rectangular cross section, called piles. The types of such foundations and the features of their manufacture will be discussed later.

Pile foundations yesterday, today, tomorrow

The technology of manufacturing buildings for various purposes on free-standing supports has been known to mankind for thousands of years. And today it remains relevant and improved. The very first pile foundation consisted of hewn round-section pillars driven into the ground, which were tree trunk trimmings. The installation process was quite complicated and time-consuming, but it was widely used, especially in the area of frequent flooding.

At present, this technology has practically disappeared, since it is unreasonably expensive and physically costly to make a pile foundation for a house with your own hands from logs. Already in the last century, they began to be widely used as supports vertically installed in the soil, which were also driven into the ground with the help of one or another. This version of the supports had a number of advantages:

- The strength of the rods was incomparably higher compared to wooden ones, which preserved them during installation and further operation;

- Reinforced concrete supports made it possible to significantly increase the total load on the foundation, which made it possible to build multi-storey structures on such foundations without fear;

According to the cross-sectional shape, such piles were produced mainly in three types - round, rectangular and hexagonal. Each of them was justified for certain specific soil and climatic conditions that were available in the construction zone.

Gradually, the pile foundation technology was corrected and changed significantly. Instead of using ready-made reinforced concrete supports driven into the soil, they began to manufacture them directly in the construction zone, preliminarily of a suitable diameter and depth. This technology was called a pile-rammed foundation, which became possible to make even for non-professional builders.

As noted above, building a foundation for a house on piles with your own hands or by professional workers is advisable for fairly loose, unreliable soils. The pile is introduced to the depth of a solid geological layer and rests on it, thus transferring the entire load from the structure. Similarly, the rods work with their entire lateral surface, using the force of friction.

The limitation for the use of pile foundations are rocky soils, as well as those with a high level of rock outcrop. In this case, the introduction of supports of any kind will be complicated, and may not be achieved.

We make the foundation of piles correctly

The general arrangement and construction of a pile foundation with your own hands in modern conditions can be represented as follows:

- The basis of the structure are vertically located supports, buried in the ground for several meters. The installation depth is determined based on the architectural features of the house, the materials used for its manufacture and the soil in the construction area.

- To strengthen the pile foundation, the upper part of the reinforced concrete rods is combined with a concrete strip, which can be located at different levels relative to the soil. When using beams or logs as wall materials, it is possible to mount them directly on the pile support pads.

Below we will consider how to make concrete piles for the foundation yourself, i.e. with your own hands. To work, you will need the following tools and fixtures:

- Garden drill or motor drill or automobile drilling rig;

- Bulgarian with discs for metal and stone;

- Electric concrete mixer;

- Tools for planar marking - a strong cord and a set of pegs.

We mark the supports

Before making a foundation on concrete piles, it is necessary to calculate the required number of future supports. It is performed on the basis of calculating the total mass of the future structure, taking into account all the building materials used and even the furniture, windows and doors intended for installation. It is better to entrust this type of work to professionals, since mistakes at this stage can lead to the futility of all further efforts.

Having determined the required number of piles, it is necessary to calculate the step of their installation. To do this, divide the perimeter of the walls by the total number of supports. Now you can mark the places of their installation. For this, pegs made of metal or wood and a strong long cord are useful. The process consists in deepening the tags to a shallow depth along a pre-tensioned rope. Do not forget to mark out a sufficient number of piles under the load-bearing partitions.

Drilling of the wells

In order to make bored piles with your own hands, you must first make cylindrical recesses in the soil. They can be made with both manual and mechanical tools. The most affordable is a manual garden drill, which is a steel pipe with blades welded on the working end. To overcome the resistance of the soil in the upper part of the tool there are transverse holes for the handles.

The process of mechanical drilling is more productive. For it, motor drills or on automobile chassis are used. Of course, their rent will adjust the total construction budget upwards, but the speed of work will be incomparably higher. Regardless of the method of making wells, you must first decide how deep to drill piles for the foundation.

Ideally, it is desirable to achieve a cylindrical shape of the pile with a slight expansion at the bottom. Thus, it will be possible to obtain a larger support sole. To achieve this result, special pile drill cutters should be used. The diameter of the pile drill must exceed the design parameters of the support for the thickness of the formwork.

Installation of pile formwork

To make reinforced concrete piles yourself, it is necessary to prevent the rapid removal of water from the concrete mixture. For this purpose, the side walls must be fixed and insulated. For this purpose, builders recommend using the following materials:

- - its sheets of the required length are folded along and lowered into a pre-drilled well. Under the pressure of poured concrete, the material is pressed against the walls and copes well with the tasks described above.

- Plastic sewer pipes of sufficient diameter are a worthy alternative to more expensive counterparts. It is enough to purchase the required amount at the construction base and connect them together.

For our conditions, only weather-resistant orange pipes are suitable.

- Asbestos-cement pipes are a professional solution for do-it-yourself pile foundation formwork. This is the most expensive option available. Its disadvantage is the sufficient fragility of the material.

Manufacturing and installation of a reinforcing frame

A long time ago, builders noticed that the introduction of steel rods into concrete, arranged and connected in a certain way, contributes to a significant increase in the strength characteristics of the mixture after solidification. It is recommended to reinforce bored piles after drilling of wells for the foundation and installation of formwork has been completed.

As a basis for the reinforcing frame, special steel rods with a corrugated surface are used. Their diameter is selected depending on the diameter of the piles and the required strength. Usually use reinforcement from 12 to 16 mm. Be sure to fix transverse inserts between the longitudinal rods by welding or knitting wire. For them, you can take reinforcement of reduced diameter up to 8 mm.

Immediately before installing the reinforcing frame in the cavity of the future pile, it is recommended to fill the bottom of the well with a layer of sand and gravel. It is already possible to install pre-connected reinforcing bars on it. As a rule, the design of a pile foundation from bored piles contains frames of four racks connected by inserts.

Production and pouring of concrete

To give strength to the pile foundation allows the use of high-quality concrete. It can be purchased at the nearest specialized enterprise or made independently. For this purpose, you should purchase or rent an electric concrete mixer. It will be difficult to manually prepare a sufficient amount of concrete.

Concrete is poured into the pile cavity in portions, compacting each with a special construction vibrator. This technique will allow you to get a high-quality foundation of concrete piles for the house and not harm the future structure. When using supports of small diameter, it is convenient to use special buckets.

Trimming pile heads

Drilling piles under the foundation on their own is not always performed to the required depth. The reason for this may be various elements in the soil. Thus, the upper ends of the piles can be located at different levels. Trimming is used to bring them into a common horizontal plane.

In fact, not a single building is complete without creating a foundation for it, that is, a foundation. As you know, in the construction industry there is a wide variety of their types. This article will focus on the features of the device pile foundation. Consider the main stages of work on installing this type of foundation with your own hands, we will study its design.

What is a pile foundation, design features

The pile foundation is a foundation of rigid piles immersed in the ground, which are placed along the perimeter of the structure of the future building. These same piles are of various types, they are classified according to many criteria:

- according to the method of deepening the support;

- according to the method of impact on the soil;

- by material;

- by section type, etc.

It is worth clarifying that this type of foundation is most often used when building in difficult areas dominated by heaving soil. The pile itself is a rod, the upper part of which is called the head, and the lower sole. The sole itself can be expanded or pointed, it is also purchased either in finished form, or made independently at the workplace. The table shows the main types of piles, according to the method of deepening the support.

Regarding the method of impact on the ground, hanging - and pile-racks are distinguished. The first type implies the distribution of loads that appear as a result of friction of the earth against the sides of the support. The second transfers the load to a solid layer of the earth, it is not characterized by sediment.

As for the division of piles into types relative to the material, here they distinguish:

- reinforced concrete;

- wooden;

- steel piles.

Reinforced concrete supports are distinguished by durability, steel supports are high financial costs, and wooden ones are cheap.

Pile-type foundations are of the following types: field, tape, single and cluster. The simplicity of the installation process is distinguished by single piles, they are used as supports in the construction of a porch, etc. For the construction of frame structures, a tape type is used; it is economical and reliable. Cluster piles are used on large, overall construction sites, with an increased load on the land area. Field piles are usually placed at regular intervals. They build multi-storey buildings. The choice of one or another type depends on the climatic features of the territory, the relief of the land plot, the technical characteristics of the planned building.

A number of advantages of using a pile foundation with a grillage include:

- minimization of financial costs for construction;

- reduced terms for the construction of the foundation for the building;

- make it possible to do without wet work, when installing stuffed and screw piles;

- the ability to carry out construction work at any time of the year;

- minimal harm to the environment;

- installation work on the grillage does not harm the nearest buildings;

- on properly selected soil, the service life of such a foundation is more than 100 years;

- pile foundation structures are famous for their reliability and durability.

When and why choose a pile foundation

As a rule, a pile foundation is chosen during the construction of low-rise, civil, industrial, small-sized houses. This type of foundation is considered an excellent option when creating country cottages, summer cottages. The pile foundation is implemented on such types of soil as:

- vegetable soils;

- quicksand;

- loess-like;

- clay soils, etc.

In areas with high density soil, the choice of a pile foundation can significantly reduce labor-intensive excavation. This type of foundation does not require heavy digging of the pit.

Another reason for using a pile foundation is the high level of groundwater. It is suitable for soil that is prone to deep freezing in winter, but the pile foundation is not able to conquer the rocks.

Steps for installing a pile foundation

The creation of a pile foundation can be described based on several stages and it is worth noting that it does not require lengthy preparation before starting work. So,

Stage 1. Digging holes for piles. It is customary to place them around the entire perimeter of the construction site, while the diameter of the excavated pits depends on the future dimensions of the structure.

Stage 2. Installation of roofing pipes. At this point, it is worth considering that the length of this type of pipe should be 3 meters the length of the very depth of the pit, since the formwork of the building structure is created on the basis of the upper parts of the piles. Installations without the use of a ruberoid pipe have a lot of problems and inaccuracies, they are prone to rapid destruction.

Stage 3. Concreting and reinforcing piles. First, the reinforcement process takes place, which consists in the use of reinforcing bars to connect the supports to the grillage. After that, concreting can begin, which, by the way, also depends on the use of roofing materials, since their absence leads to the diffusion of cement laitance. The process of concreting piles involves pouring the mortar in portions so that the concrete layer does not exceed 5 meters.

The most common foundation options for the construction of small country, private houses are the foundation on screw and self-leveling piles.

The creation of the first option requires the presence of such tools as a welding machine, a building (water) level, a tape measure, etc. The whole process of installing the foundation on screw piles can be displayed in a step-by-step manner.

1. Marking the site. For this reason, it is better to use a hole breakdown of the territory; the use of peg and cord in this case is not a rational option. It should be borne in mind that these holes should not be deep, otherwise it will disrupt the entire technological process.

3. When all the supports are installed, they are concreted and the grillage is mounted.

As for the foundation on self-leveling piles, the process of its installation is considered more costly, financially and materially, as well as complex. But be that as it may, practice shows that it is quite realistic to build it. For this:

- with the help of a cord and a peg mark the construction area;

- hand drill, in the indicated places, foundation pits are created for piles. Their depth should be at least 1.5 meters.

- piles are treated with waterproofing material (roofing material), it is better to do this in two layers, for reliability. The roofing material protects concrete supports from moisture provided by nearby groundwater.

- all piles are connected by a reinforcing cage.

- after reinforcement, the pits with piles are poured with concrete. At this stage, you will need a special vibrating technique that allows you to compact the solution.

- it is possible to deal with the foundation grillage only after the concrete layer has completely dried.

Well drilling, concreting and reinforcement. grillage device

After marking the territory allotted for the construction of the foundation, you can start drilling pits for piles, the number of which depends on the estimated weight of the future building. The diameter of a hand drill for this purpose is no more than 30 cm, and they can be purchased at almost any industrial store. Such designs allow you to make a pit up to 5 meters deep. In cases where it is planned to create a multi-dimensional building and the installation of significant supports is required, then motorized and electric drills are used, the diameter of which is 50-60 cm. In difficult areas, drilling machines are used.

In construction, the grillage is divided into two varieties: prefabricated, represents the construction of iron sticks, and monolithic. For both, there are weighty rules that should not be ignored:

1. The height of the grillage must be more than 3 meters.

2. The width must be less than 4 meters.

For prefabricated devices, fastening on the head of the supports is typical; for this, at the stage of concreting, the piles are supplemented with T - shaped rods. A reinforced rod is additionally fixed in a horizontal position on the pile head.

The formation of a monolithic grillage takes place in several steps.

1. Installation work on the creation of formwork.

2. Reinforcing piles.

3. Filling the grillage tape.

It is worth pointing out that the main task of the grillage is to evenly distribute the loads on the foundation. No less significant is the classification of the grillage with respect to the level of penetration into the soil. Allocate high, advanced and in-depth levels. The first is located above the ground, the second is installed at ground level, and the third is completely in the soil.

Basic location and materials of piles

Most often in construction there are metal and reinforced concrete piles. In the production of the first type, metal beams of various diameters are used, which depends on the dimensions of the foundation. In addition to beams, steel profiles and pipes are used. Metal structures have one of the main advantages - strength. Before sinking into the ground, this type of pile is carefully treated with anti-corrosion solutions. Piles from are widely used for:

- construction of various fences, fences;

- arrangement of non-permanent foundations of non-stationary structures such as, for example, shopping pavilions.

- construction of the foundation of small-sized, lightweight structures made of foam concrete, panel panels, etc.

Reinforced concrete piles are resistant to any type of soil. The structures are suitable for the construction of houses with more than 5 floors, as they are considered sufficiently resistant to heavy weight and loads. This group of piles is actively used for:

- creating a foundation for hydraulic structures;

- laying the foundation of auto- and - railway bridges.

- when constructing engineering structures such as power lines.

- arrangement of hangars, etc.

Restrictions on the use of pile foundation

Along with a wide range of applications, due to its price and advantages, the pile foundation also has limitations in use. This type of base is not suitable for:

- A horizontally moving type of soil that is not resistant to overturning. Therefore, at each construction site, before starting work, it is recommended, without fail, to send the soil to the laboratory for geological examination.

- The pile foundation has difficulties with the construction of the basement, in which cracks form between the piles, in order to neutralize them (create a pick-up), large financial investments will be required.

Necessary materials and tools for installing a pile foundation

In the process of installing a pile foundation, you will need the following tools:

- shovel;

- metal rods;

- roulette;

- building level;

- welding machine;

- cord etc.

A number of necessary materials include crushed stone, mortar cement, sand, etc.

The most important tool in the production of a pile foundation, of course, is considered to be a drill, with the help of which the number of wells for piles necessary for the construction site is prepared. Drills are different in design and type, but most often, a hand drill is used to create such a base. Such a tool does not require special skills and technologies of use and has an affordable market price. Some amateur craftsmen are engaged in assembling the drill at home. Properly selected tools will allow, without unnecessary physical costs, to make the required depth of pits, while maintaining their qualities of strength and heat resistance.

For more information on the topic, watch the video:

An inexpensive pile-screw foundation is an excellent alternative to a strip concrete foundation. Its use is especially relevant on complex wet or loose soils and uneven terrain. Piles are widely used in private construction and to reduce the cost of outbuildings: baths, garages, greenhouses, verandas, etc.

On what soils is a screw foundation used?

Water-saturated soils, sands, sandy loams and loams are most susceptible to winter heaving of the soil. At the same time, even a fairly deeply laid foundation can begin to push out of the ground. In the spring, during thawing, its uneven shrinkage occurs.Reliable support is also required when building on loose soils: after all, you have to go deep to too great a depth. The use of a strip foundation in such cases becomes unprofitable. In such cases, piles come to the rescue.

The first cast-iron screw piles were developed by the Englishman A. Mitchell in 1933 as an alternative to driven piles. They had the form of a pipe, one of the ends of which was made in the form of a blade of a special shape and was pointed. Thanks to this design, the pile was easily screwed into the ground, additionally compacting it, much lower than the freezing depth and securely fixed in it.

The structure and appearance of piles

Initially, such structures were used only in the construction of bridges and temporary structures, and only then they began to be widely used for the construction of foundations for residential and industrial buildings and military facilities, moorings, wharfs.

In our country, they are most often used for the construction of buildings in permafrost conditions (in the regions of the Far North and the Far East). In private construction, in recent years, pile-screw foundations have been used in the construction of housing in wetlands, the close passage of groundwater, and for the construction of outbuildings.

Scope of pile foundations

There are two types of screw piles:

pile peaks: with a pointed tip; designed for light and loose soils;

pile pipes: with a serrated crown at the lower end; used on sticky soils.

Types of piles

TO main advantages piles include:

the possibility of a device on any, including complex soils and even on water;

ease of installation, the minimum amount of time spent on their installation, the absence of earthworks;

the ability to install in the winter;

such structures are not susceptible to push-out loads;

if necessary, the possibility of dismantling and re-installation;

high strength: depending on the type of piles, they are able to withstand a load of 4-18 tons;

increased seismic resistance;

durability;

economic benefit: their cost is 30-60% lower than the price of a concrete foundation.

TO shortcomings pile-screw foundation can be attributed to:

the inability to install them in soils with a lime layer, peat bogs, flowing soils and in rocky areas;

it is very problematic to equip a basement in a house installed on piles - its insulation will be equal to the cost of the foundation itself.

Calculation of the required number of piles

First of all, it is necessary to determine foundation load. To do this, sum up:

the weight of the building, including not only external, but also internal walls, overlap between floors, roof, facade decoration;

interior items in the house, furniture, equipment, etc.;

weight of people in the house: according to SNiP for private residential buildings, data are taken at the rate of 150 kg per 1 sq. m;

snow load, determined by SNiP, depending on the area of \u200b\u200bresidence.

Snow load map

The resulting weight is multiplied by coefficient 1.2. To find out the ultimate load (bearing capacity) of each pile, you should know soil resistance. To do this, use a special table (see photo).

The depth of their dive i depends on the degree of soil freezing (these data vary for each area). For example, for the Moscow region, the depth of soil freezing is 1.4 m.

Piling installation

The work is carried out in the following sequence:1. With the help of stakes, the locations of the piles are marked in the selected area. To avoid mistakes, you should check the distance between them with the drawing, as well as carefully measure the dimensions of the corners and diagonals.

2. To simplify the screwing of the piles, a small hole slightly wider (by 2-3 cm) than the diameter of the blade. The depth of such a hole is 10-15 cm. Too deep holes that loosen the soil are unacceptable.

Piling hole

3. Piles with blades up to 300 mm can be screwed in manually without the use of machinery. For this, preparation lever arm from scrap, which is inserted into the hole in the upper part of the pile, and pieces of pipe 3 m in size. As the screw deepens into the ground, the pipes will be put on scrap to increase the length of the lever arm.

4. At least three people will be needed for the work. Since the pile must be installed strictly vertical, it is necessary that during its screwing in one of them controls the process of its installation.

The pile must be installed strictly vertically

Advice. If, when installing one or two piles, an obstacle appears on the path, and they no longer enter the ground, it is allowed to cut off the top and leave them in that position. But in the corners of the house piles should only be installed to full depth.

Screwing in a pile by hand

5. After installing all the piles, their excess length is cut off according to the level.

6. For strengthening, concrete is poured into the hollow pile shaft.

concreting

7. On-site trim at the top of the pile head is welded.

Head welding

Manufacturing grillage

The grillage is the upper part of the foundation, which unites the pile heads and provides a more uniform load on the foundation. Thanks to such a rigid ligament, in the event of failure of one support, the severity will be transferred to the rest. Rostverk can be made from:concrete;

timber or boards;

tee beam;

metal channel or corner.

Advice. If the house is made of timber, the first row of the wall can be used as a strapping.

When constructing a concrete grillage, a formwork is prepared on top of the piles, a reinforcing belt is installed and a solution is poured. Channel, I-beam and corner are welded. The wooden grillage is assembled on bolts.

Types of grillage

At the base of a house being built on a site with weak soil, it is advisable to make a pile-strip foundation with your own hands. The choice of this option is due to the negative impact on the concrete tape, the presence of clay, peat, humus, groundwater in the area in the upper layer of the earth, creating quicksand.

Under a concrete structure in the form of a tape (grillage), three types of piles are used: ready-made concrete piles, screw piles and bored piles.

Soil category, impact on concrete base

In summer, weak soil in some places under the foundation is washed out, subsidence occurs, and then the foundation is destroyed. With the advent of cold weather, wet soil freezes and swells, pressure is created on the foundation, which also leads to its destruction.

The problem is solved with the help of piles buried below the soil freezing line, resting on a solid layer of earth.

A shallow strip foundation is cast on piles and does not depend on the changing state of the upper soil layer. The number and dimensions of piles, the dimensions of the tape depend on the load and location of the building under construction.

Piles under the tape are made in a bored version, forming a single monolithic structure. The choice of foundation for the house depends on the category of soil. With heaving soil, it is advisable to use a pile-tape base.

Concrete foundation technology on piles under the house

The foundation for a house on piles can be done on your own, knowing how to make a pile-strip foundation with your own hands in order to avoid mistakes during independent work.

It is important to study the technology and step-by-step instructions for making the foundation. To get acquainted with previously built similar structures and ask the performers about possible problems during the construction of the foundation. Examine all the component materials required for construction.

The device of the strip foundation with piles

The device of the strip foundation with piles

The production of a strip pile foundation can be carried out without the involvement of expensive equipment, renting the necessary equipment.

The concrete base, depending on the purpose of the building being erected, provides for the insulation of piles and tape or is limited to waterproofing. The technological process is reflected in the executive project and, taking into account the preparatory work, includes operations performed sequentially. In the step-by-step instructions for making a pile-strip foundation with your own hands, these operations are reflected:

The house for permanent residence must have a warm base, as heat loss will be 30%. Compliance with the instructions will allow you to perform high-quality work in a short time.

Do-it-yourself base for a house

To make a pile-strip foundation with your own hands, it is advisable to have practical experience or work together with a professional.

To make a pile-strip foundation with your own hands, it is advisable to have practical experience or work together with a professional.

Before starting work, it is necessary to provide the construction site with electricity and water (no centralized - local).

Prepare hand and measuring tools, rent the necessary equipment. Bring materials and accessories to the site:

- formwork for piles from asbestos-cement pipes;

- sand gravel mixture;

- cement;

- reinforcement d = 12 mm and d = 6 mm;

- edged lumber t = 50 mm;

- fixed formwork made of cement particle board with accessories t = 35 mm;

- insulation from expanded polystyrene boards t = 50 mm;

- expanded clay insulation;

- ruberoid;

- built-up waterproofing;

- hardware.

M400 cement is suitable for the production of concrete mix

M400 cement is suitable for the production of concrete mix

Do-it-yourself construction of a pile-strip foundation will save money, but it will require you to conscientiously study and consistently perform all technological operations.

Work begins with cleaning the site, removing the vegetation layer, leveling the site for your house.

They also plan a ditch to drain groundwater and rainwater from the base of the house.

In addition, a trench is laid out for the tape, its depth is determined, taking into account the bearing capacity of the soil.

Before starting work, it is necessary to study the top layer of the earth on the site, determine the level of soil freezing and the presence of groundwater. Make an accurate calculation of the size and number of piles for the foundation.

Well device and tape

We dig, we plan the bottom of the trench, controlling the horizontal position with the help of a level. On the compacted bottom of the trench, we outline and drill wells for the piles. The depth of the well should exceed the depth of soil freezing and go into dense soil by 0.5 - 0.6 m.

We insert the formwork into the drilled wells, which should be made of asbestos-cement pipes protruding 0.3 m above the bottom of the trench. At the bottom of the trench, pressing against the outside, we lay a drainage pipe around the perimeter and lead it into a ditch to drain water.

The pipe is pulled out of the well by 15 cm so that a pillow forms during pouring

The pipe is pulled out of the well by 15 cm so that a pillow forms during pouring

We fill the bottom of the wells and trenches with a drainage layer of sand and gravel, plan and tamp, spilling water.

We pull out pipes from the wells by 0.15 m, so that when concrete is poured under the pipes, gravel is impregnated with a solution, and a pillow is formed to support and hold the piles.

We line the bottom of the trench with a layer of roofing material so that when pouring the concrete does not mix with the drainage layer.

We cut out the roofing material above the wells, leaving holes open for filling with concrete.

Mounting the formwork

Having prepared wells and a trench for a pile strip foundation, we proceed to the installation of reinforcing frames for piles and strips. We install connected frames of reinforcement in the wells, which should protrude from the bottom of the trench to the height of the reinforcing frame of the tape.

Having prepared wells and a trench for a pile strip foundation, we proceed to the installation of reinforcing frames for piles and strips. We install connected frames of reinforcement in the wells, which should protrude from the bottom of the trench to the height of the reinforcing frame of the tape.

Along the axis of the walls of the house on the roofing felt and the drainage layer in the trench, we mount a reinforcing frame made of mesh. The meshes are connected to the protruding pile frames and create a single structure.

On both sides of the reinforcing frame, we mount a fixed formwork made of moisture-resistant cement-bonded particle board. Inside the outer wall of the formwork, we install a heater made of polystyrene foam boards. The sides of the formwork are interconnected by special bonds that determine the width of the foundation strip and hold the formwork walls and insulation in the structure. For more information about pouring the foundation, see this video:

After the formwork has been assembled, the entire structure is reinforced on both sides with edged board stops. With a leveling tool, we check the exposed formwork for the verticality of the walls and the horizontality of the upper edge.

The foundation tape, as the basis for the house, rests only on piles, is not supported by soil, so it is important that the structure is monolithic. We fill the formwork with M300 concrete in one go. First, we fill the wells with concrete, then fill the tape.

The foundation tape, as the basis for the house, rests only on piles, is not supported by soil, so it is important that the structure is monolithic. We fill the formwork with M300 concrete in one go. First, we fill the wells with concrete, then fill the tape.

We compact the concrete in the wells with a deep vibrator, remove air bubbles. After the concrete mixture has hardened, we dismantle the reinforcement of the formwork and apply welded waterproofing on the upper part of the foundation. For the house, the pile-strip foundation is insulated, for which the earth under the building is covered with a layer of expanded clay with a thickness of 0.2 m.

A well-insulated foundation will reduce home heating costs by 30%.

Self-construction of a strip foundation on piles will save money and build a reliable, durable foundation for your home.

Do-it-yourself pile-tape foundation: step by step instructions

At the base of a house being built on a site with weak soil, it is advisable to make a pile-strip foundation with your own hands.