We will send the material to you by e-mail

Today, perhaps, it is no longer possible to surprise someone with the decision of architecture when building a house. But not a domed house! This type of building is unique in itself, as it is unusual for our area. But this is not the only advantage of a domed house. Each project will be different from the other, as there is the possibility of variation in literally every detail of the house. This is a significant plus of such buildings, because the usable space in such a house is as functional as possible. Therefore, such an architectural solution is becoming increasingly popular in construction. In this article, we will look at domed houses in detail: projects and prices, photo examples of finished buildings.

The construction of a spherical shape is a great way to stand out from the monotony of neighboring houses

Formally speaking, a domed house is a building with a spherically rounded roof. Outwardly, it may resemble the dwelling of the Eskimos - an igloo. But, nevertheless, in their execution, modern domed houses have stepped much further. The design of projects can translate into reality, it would seem, tasks that are completely impossible from the point of view of construction.

So, one main sphere can be combined with five attached ones, which will present us with an abstract and bold designer's decision. Yes, exterior photos, projects and prices of domed houses will largely depend on the imagination of the architect-designer team.

History of domes

Domed houses appear in the Byzantine period. It is hard to even imagine in what year the Eskimos began to build houses from rounded snow in the north. The northern peoples of Scandinavia used a more durable material, like stone, in rounded buildings.

One thing can be said unequivocally - houses in the past enjoyed their popularity. And most likely, appearance is not the main requirement for a spherical house. People have noticed that the wind resistance of such houses is much higher than that of corner houses. Seismic resistance and much more can be added here.

For your information! Buckminster Fuller in 1951, noticing the spherical shape as an option for building houses, decided to patent the design solution in architecture.

Photos of domed houses

And it really is possible to make it a reality! The smooth lines of such a house look very natural in nature. Such houses fit perfectly into any picture of the landscape. Wherever you build such a house, in the photo it will always look like a dream house.

Related article:

Projects of frame houses with photos and prices. From this review, you will learn about the technologies for building frame houses, prices for some models and many myths about frame houses.

Technologies for the construction of domed houses

In order to build a domed house, you first need to build a frame. The material for this requires strong enough, although it can be light. Wood is ideal. It is very convenient in installation, because it does not require additional costs, installations, etc.

Foundation for building

The frame is placed on a foundation of tape or pile type. Here is a little more. For each locality, the layer of black soil will be of different sizes, but it must be removed. Having reached the clay layer, it is necessary to compact the area where the foundation is planned. goes in one layer of the grid, the cell of which is 10X10 cm - 15X15 cm. The thickness of the reinforcement can be from 8 mm to 16 mm. The mesh is knitted with a run of plus 10 cm or more, on each side of the intended wall thickness. The layer and brand of concrete is calculated depending on the mass of the building, according to the construction project.

Frame erection and finishing

The frame, as already mentioned, can be built from wood, but metal can also be used, which makes construction more expensive. It is also possible to build domed houses from polystyrene foam.

In some cases, an additional, so-called temporary frame or supports may be used. Its role is to support the dome until the materials are collected, after which it will be dismantled. Sometimes the project provides for supporting columns or piers, on which the dome also rests. They are erected simultaneously with the frame. The main frame, external, is mounted according to the principle of triangular faces, which allows you to vary the shape of the house in any direction.

Helpful advice! To obtain an even sphere, it is better to make frame fragments according to one template, then putting them together and checking them. The more accurate copies are made, the less will be the offset during editing.

At the junctions of triangular blocks, as well as on the dome vault, it is better to use special production connectors called dome connectors. They pass technical control on loadings and operational properties.

When using basalt insulation, it will be correct to use waterproofing impregnation. Having soaked the cotton blocks with such a solution, the humid environment will not subsequently threaten the development of fungus or mold on the walls.

Openings in round houses should be with reinforced frames. This is especially true for doorways. As for windows, unlike doors, they can be of completely different shapes. Spherical houses can be covered with shingles, which is very convenient because of its flexible properties. In operation, bituminous tiles are unmatched. Its waterproofing properties are today of the highest level. For the owner of the house, it remains only to decide on the choice of the manufacturer of this material.

Interior decoration is carried out with the same materials and work procedure as ordinary houses. Gypsum and cement-sand putties, cement screeds, wooden lining, tiles, parquet, linoleum, wallpaper - all this is easily applicable in round houses.

Layout of a domed house with your own hands: highlights

A real flight of fancy begins with the layout of the interior space. The spherical design allows you to realize very interesting design ideas. It is worth noting that not all of them can be due to practicality and functionality. We offer to see projects, photos of round houses:

Advantages and disadvantages of spherical houses

The advantage of domed houses over conventional houses:

- Appearance;

- Wind resistance;

- Seismic resistance;

- Small mass of the building;

- Lightweight foundation;

- Does not require the participation of special equipment;

- Possibility of all-season construction;

- Profitability;

- Energy intensity;

- Ease of maintenance;

- 100% functionality of the area;

- A feeling of unparalleled comfort.

Among the shortcomings it is worth noting:

- The complexity of calculating the project and building materials due to the spherical shape;

- To perform work, it is better to contact builders specializing in buildings of this type (this way you will incur minimal costs);

- Non-standard window shapes, which can complicate their manufacture and cost;

- Finishing any curved surface will cost more, whether it's wallpaper, plaster, tile or drywall.

Related article:

The houses, the photos of which can be seen in the article, look beautiful not only from the inside, but also from the outside. What are the features of such structures, the cost and possibilities of interior decoration?

Dome houses: projects and prices, photos of structures

Through search engines on the Internet, you can easily find domed houses, projects, prices and photos, as well as a highly qualified team for the construction of this type of structure. It has always been and remains the best decision to seek help or advice from specialists. Only through practical experience can you competently approach the construction. Especially when it comes to non-standard solutions.

A spherical building complicates the work by an order of magnitude and requires mathematical, geometric, physical and mechanical calculations. And this is not all that such a project requires. Geodetic data, landscape measurements - in a word, many directions in the calculations during the construction of a domed house indicate that qualified specialists should be invited to the case.

About the cost of domed buildings

You can buy a domed house at a price of about 30% lower than usual. First of all, the cost is reduced due to roofing materials, since their supporting structure is not needed. The walls of the house serve as the basis. And the savings in masonry material is hidden in the very formula of a spherical figure. With detailed calculations, this becomes visible to the naked eye.

See what sketches and designs of domed houses can look like!

First, examples of house layouts are given, consisting of one dome, which is divided into different functional zones.

At the same time, one dome with a diameter can act as one whole room-house, an individual space for one family member. And the house - to be a complex of domes, united into a single common space. Below are examples of multi-dome compositions.

These examples are provided so that you can think about the location of functional areas in your domed and multi-dome houses, the assignment of rooms, taking into account your interests, hobbies, activities, as well as functional areas on your site. And create for yourself the best home for a long and happy life.

HOUSE 202 sq.m.

The dome house is a unique, powerful, energy-saving structure that provides tremendous opportunities for developing interior and exterior design and is a reliable and comfortable home.

The dome house is a unique, powerful, energy-saving structure that provides tremendous opportunities for developing internal and external design and is a reliable and comfortable home.

Features of the distribution of light and sound, ergonomic advantages, non-traditional vaults for a dwelling, reminiscent of temples, fresh ideas in the design of all interior elements and, of course, energy saving also increase the value of the dome house. Of undoubted interest is the appearance of such a structure - the shell-dome easily fits into any landscape - a forest, a mountain slope, a field, without violating its natural harmony.

There are dozens of advantages of such future technology. We list the most important of them:

A sphere has maximum volume with minimum area.

- High heat capacity of the house, because the sphere has no seams.

— Very simple and efficient ventilation system.

- The surface of a sphere is approximately 25% smaller than the surface of a cube, for the same volume. Thus, a quarter less materials will be spent on the construction of a domed house.

- The dome house has low weight and high strength. Such buildings will be appropriate in seismically active areas.

- If necessary, all materials for completing the construction of the house can be delivered by two or three cars or by helicopter, which allows the use of such construction technologies in hard-to-reach areas.

- You can build entire architectural ensembles that harmoniously combine with each other.

The domed house has a successful functional layout that includes smooth transitions, such as from the kitchen-dining room to the living room, as well as closed rooms, such as an office on the ground floor and domed bedrooms on the second. However, there are no planning restrictions for domed house projects. The house itself is original and the layout in it depends only on the flight of the owner's imagination.

Architects around the world believe that domed houses are the future, and according to the French, they are among the most durable (such a domed house can stand without a general overhaul for more than 50 years). That is why we make these stylish and original houses, combining them with the concept of building exclusively from environmentally friendly materials.

house plan

HOUSE 285 sq.m.

HOUSE 245 sq.m.

Most private houses are constructed according to standard and typical technologies for all, which are represented by a kind of cubic building forum. But not everyone wants to build typical structures. One of the most beautiful and practical options is to build a spherical house.

Domed houses are distinguished by an unusual, attractive exterior, non-standard shape and allow you to practically and competently build all the necessary systems that ensure a comfortable life. Dome houses have many advantages and design features.

Description

The first thing that distinguishes dome structures is their high level of strength. Their main feature is that the level of the bearing capacity of the structure increases with an increase in its diameter. It is also important that the strength characteristics of the structure do not change depending on what materials are used for its construction.

The domed house is a kind of constructor. Its constituent elements are typical and calculated independently. To calculate the parameters of the base-frame, there is a special domed house calculator. For convenience, when creating the foundation of the structure, there is a calculator for a domed house in Russian. Assembling such a constructor is quite simple and fast. This technology is used to build wooden domed houses.

The assembly of the base frame of the domed house is easy to do manually. All the elements necessary for the construction are characterized by small dimensions and weight. Due to the fact that the geodesic house is ideal in terms of aerodynamic properties, it can be built in an unstable climate. For example, in an area with frequent hurricanes or earthquakes.

Kinds

The essence of a spherical design is the division of space using vectors. Based on the type of dome, the following types of domed houses can be distinguished:

- dome-type houses, the elements of which are based on a tetrahedral polyhedron;

- the base is the icosahedron. The design is considered the most optimal. The greater the frequency of vectors used to break down the space, the higher the strength of the entire structure.

According to the difference in the forms of the house are:

- waist;

- convex;

- oval;

- consisting of several polyhedra;

- semicircular.

You can build a domed house from various materials. The construction construction technology depends on this. The simplest is the frame, in which the main material for construction is wood. There are other building options.

Styrofoam

For the manufacture of domed houses using Japanese technology, they use polystyrene foam. Foam panels are produced in such a way that during assembly they are firmly fastened to each other. During production, concrete is applied to the surface of the foam, which gives the material increased strength properties.

Dome houses using Japanese technology are quite simple to build, you just need to order the required number of panels, build a foundation and assemble a house. The domed house made of expanded polystyrene turns out to be very light, therefore it does not need a solid and massive foundation. The price of a domed house made of foam plastic was set at $300-400 per 1 m2.

Reference: Despite the fact that foam is used to build the house, Japanese domed houses are strong and reliable, as well as safe to live in.

from brick

Brick dome house erected without a frame. Carry out the laying of brick material, depending on the selected shape of the geodesic dome.

Concrete

One of the modern technologies used for the construction of a domed house is "inflatable" or using a pneumoframe. Construction material - concrete. Thanks to this technology, monolithic domed houses are obtained.

The walls of the building are erected by a special inflatable ball, which is previously spread on the foundation. The inflatable ball is represented by a durable membrane. A wooden formwork equipped with steel reinforcing reinforcement is installed on its surface. On top of it, the concrete mixture is evenly distributed.

After waiting for the moment when the concrete "grabs", but has not yet completely hardened, the membrane is inflated. Together with the ball, the concrete rises, which takes on the desired shape. After that, we can assume that the domed concrete house is ready. When the concrete has completely hardened, the membrane is blown off. It is subsequently reused.

from straw

dome building is also quite simple. The building will require a strip or column foundation on which the frame is attached. Any shape of the dome is allowed. Straw bales are used as wall material, but they are broken in half during laying. Sheaves are laid in a horizontal plane, after which they are pulled together with a strong cord.

A domed thatched house requires mandatory plastering. To do this, the surface of the bales is covered with a mesh, on which a plaster solution is applied. Clay or lime plasters are used for exterior and interior decoration.

Advantages and disadvantages

The properties inherent in a spherical design determine the positive characteristics that a domed house has. The benefits are:

- the volume inside the house turns out to be significantly larger than when building a "rectangular" structure with the same usable area parameter. It is not too expensive to build a domed house, its price is reduced by 30% compared to the usual one;

- given that the outer surface of the building is smaller, this reduces the cost of. In winter, the house does not give off heat energy to the outside, and in summer it does not heat up;

- due to the light weight of the entire structure of the house, there is no need to build a powerful foundation;

- the presence of windows and doors in the house does not affect its strength characteristics. Mono windows can be placed in any quantity and in any place;

- characterized by a high level of seismic resistance;

- the domed house in winter is able to withstand heavy snow loads;

- ideal aerodynamic properties allow the construction of dome structures in regions with frequent hurricanes;

- due to the fact that the domed house is round, it can be placed on the site as you like;

- domed house is a warm floor. There is no need to install any other heating systems as the heat from the floor surface is distributed throughout the house;

- the layout of the domed house is absolutely free. The design of the house does not imply the presence of load-bearing walls, and therefore it is possible to install room partitions in any convenient place. This also allows you to make the design of the domed house exactly according to the wishes of the residents;

- comfortable living in the house also provides a smaller amount of noise that penetrates from the street. This happens due to the smaller surface area of the structure;

- the interior of a domed house is as easy to organize as in a conventional cubic design. Ordinary furniture with sharp corners fits perfectly into the premises;

- the appearance of the domed house is unusual and attractive.

Despite the large number of advantages of the structure, for those who want to build a domed house, the disadvantages also play an important role. The dome house has the following disadvantages:

- it is difficult to carry out calculations for the construction of the foundation of a house. It is not possible to draw in two planes. It is necessary to have not only a good spatial imagination, but also be able to use 3D programs designed to create a layout. This moment can not be taken into account if it is possible to order a finished project;

- technology specificity. Such a house cannot be built by an ordinary builder, since the technology for building domed houses does not apply to classical housing construction. It is necessary to find professionals in dome building;

- geodesic dome house requires the use of specialized elements. For example, standard windows for the house will not work; it is necessary to install triangular-shaped windows.

Manufacturers

The construction of domed houses can be ordered from the following companies:

- Dome-dom. If there is no desire to build a domed house with your own hands, then the company will build a turnkey domed frame house. If it is possible to do construction without anyone's help, but there is no desire to carry out the calculation of a domed house, then the company will provide a kit for assembling the frame of the house.

- Skydom. Produces high-strength frame for self-assembly. It builds turnkey domed houses, the cost of the minimum designer (Sky7.7) is 1,790,000 Russian rubles.

- Dobrosfera. Manufacture and deliver home kit. Will provide all the necessary information necessary for the assembly, and will also accompany in its process. The price of a house kit with a minimum radius (Z4) is 32,000 rubles.

How to build

Calculations and a project are the first thing that is needed for those who want to build a domed house with their own hands. A calculator is essential for this. When the project is ready, the construction of the domed house begins with preparatory work.

To build a domed house with your own hands you must first prepare the site, clear the soil and level it. After that, the surface of the soil is covered with gravel and sand. You can build a stratodesic domed house using the following technology:

- Initially, a decagon is constructed instead of the foundation, on which the entire structure will rest. Depending on what load is expected on this basis, a certain section of the boards for the polygon is chosen.

- Purchased boards are cut using an electric saw. You need to get the output shape of a trapezoid.

- The sand cushion is dug up with roofing material and trapezoidal boards are laid out on top, fastening them with screws.

- Further work is carried out in a vertical plane. For the first row of the wall, you will need boards fastened together in squares.

- Further erection of walls consists in assembling triangular-shaped elements. If a ready-made frame constructor was purchased, then this greatly simplifies the task. You just need to assemble it according to the instructions.

Important: Each wooden element requires pre-treatment with special antiseptic preparations.

- After the erection of the frame, they begin to sheathe it with OSB panels from the inside. Elements are pre-cut in accordance with the design parameters.

- For external finishing of the structure, it will be necessary to cover its surface with roofing material and sheathe it using, for example, flexible tiles.

- It is recommended that the whole process be carried out alternately, moving from one triangle to another. Having cut the roofing material of the desired shape, attach it to the frame and install the tiles.

- It is better to fix the roofing material with resin or glue.

- When all work is completed, proceed to the interior decoration. Using the selected materials, floors are built, all communications are carried out and the walls are insulated, after which they are pre-finished.

The device of the domed house will give warmth and comfort in the winter season, freshness and coolness in the summer. There are several varieties and features of the construction of domed houses. We will analyze how to build a domed house further.

General information about domed houses

A domed house is a dwelling that has a round base. The roof in such a house has the shape of a cone. Walls are made from a variety of materials such as wood, stone, concrete.

Domed houses were widespread among the Celtic peoples. Dome houses of the modern type were invented by American designer Richard Fuller.

The use of domed houses is relevant in the case when it is necessary to obtain the maximum volume of the room, using the minimum amount of materials that significantly reduce the weight of the structure.

The shape of the dome is used for arranging:

- stadiums,

- exhibition centers,

- scientific facilities,

- industrial buildings.

Studying the reviews about domed houses, we highlight the following advantages of using domed houses:

- unusual appearance,

- the construction of a domed house takes no more than two months,

- lack of walls and the possibility of free planning,

- installation in various climatic conditions,

- lack of requirements for the arrangement of the foundation,

- the cost of building a domed house is much lower than usual,

- aerodynamic shape provides high wind resistance,

- resistance to earthquakes, since the dome consists of triangular parts, the load is distributed evenly throughout the house,

- the domed house looks aesthetically pleasing and modern,

- high level of energy efficiency: a small area provides good heat dissipation and a good ventilation system,

- the domed house has low acoustic properties.

Dome houses photo:

Varieties of domed houses

Dome houses are equipped in the form of a geodesic dome, which come in several types. A geodesic dome is a figure based on the distribution of space into vectors.

Depending on the type of geodesic dome, there are:

- domed houses, which are based on tetrahedral polyhedra,

- a domed house in the shape of an icosahedron is the most optimal option for dividing space into vectors; the strength characteristics of the structure depend on the frequency of division.

Depending on the shape of the dome, there are:

- domed belt type houses,

- convex domed houses,

- houses in the form of an oval dome,

- polygonal domed houses, which consist of several polyhedra,

- semicircular domed houses.

The main stages and technology for the construction of domed houses

The construction of a domed house consists of two main stages.

The first stage includes a number of preparatory work and the manufacture of the main structural elements, processing, marking, disassembly and packaging of these elements.

Works on the preparatory stage:

- first you need to take measurements, determine the place where the domed house will be located, divide the site and make markings for building a house;

- then proceed to the preparation of budget documentation and draw up a sketch of the domed house;

- in order to choose the right model of a domed house, it is necessary to take into account the shape, size of the cells, the number of connectors and rafters;

- if possible, make a computer calculation of the domed house;

- then you should proceed to the manufacture of connectors, rafters, plywood elements of the house;

- metal connectors should be treated with anti-corrosion compounds.

After completing these works, proceed to the second stage of work on the domed house, which includes:

- carrying out foundation works;

- installation of communication systems;

- preparation of parts for assembly;

- assembling the frame of a domed house;

- sheathing of the domed house from the outside;

- installation of windows and doors;

- roofing works;

- insulation work;

- interior lining of the house;

- installation of floors, walls and partitions in the room;

- finishing the interior of the house;

- work on communications.

Making a domed house with your own hands

A connector is a metal element that is a connection node for the wooden parts of a domed house.

Separate connectors:

- five-point type

- six-point type.

The connector is used to make large and spacious domed houses. When arranging a domed house of small diameter, it is possible to use a non-connector method.

The roof of a domed house happens:

- aluminum,

- ruberoid,

- made of flexible tiles.

The foundation for a domed house is:

- tape,

- in the form of a concrete pillow,

- constructed from wood or concrete slabs.

To calculate the amount of material, when building a domed house, there are special calculators.

New developments make it possible not to use connectors for the construction of a domed house, but are based on the CONE technology, which implies precise manufacturing of ribs, connection with a minimum number of seams.

The size of the cross section of the bars depends on the load on the dome of the house.

When using double: inner and outer skin, the size of the bars must be increased.

The technology of a domed house is quite complicated, but compared to a conventional house, a domed house will require much less building materials, time and money.

There are several ways to connect edges, such as:

- use of internal metal plates with screws,

- or screwless CONE.

Dome houses projects:

The assembly sequence of the domed house consists of:

1. Choosing a site for building a house.

2. Laying a support consisting of ten corners.

3. Installation of vertical walls.

4. Installation of window and door structures.

5. External cladding of vertical walls.

6. Rib blanks for the construction of the dome frame.

7. Erection of a frame structure.

8. Sheathing frame structure.

9. Finishing the dome with roofing felt or shingles.

10. Interior decoration of the house.

Materials for the manufacture of a domed house:

- bars with a section of 5x5 cm,

- screws,

- sheet of galvanized metal 250x125 cm,

- screws,

- nuts,

- self-tapping screws,

- nails,

- mounting foam,

- roofing materials in the form of roofing material or flexible tiles.

To create a domed house, you must have:

- roulette,

- level,

- electrical corner,

- hacksaws,

- jigsaw,

- electric drill,

- woodworking machine,

- roofing scissors,

- hammer,

- gloves

- brushes,

- grinders,

- cross screwdriver.

Instructions for making a domed house with your own hands

1. Preparatory work includes: preparing a place for a domed house. The radius of the domed house must be cleared of the ground cover and covered with rubble, and then sand.

2. Instead of the foundation, we install a supporting decagon, for which ten boards are required, the cross section of which depends on the load on the structure.

3. It is necessary to make trapeziums from the boards using a jigsaw or electric saw.

4. Roofing material and trapezoid should be laid on a sandy base. Using a level, check the evenness of the structure. Trapezoids are connected with screws.

5. The next step involves the construction of a vertical wall, for which you will need bars connected with screws.

6. For the manufacture of the door frame, use two vertical and two horizontal boards.

7. The location of windows and doors depends on the height of the domed house.

8. To sheathe vertical walls, use boards that need to be nailed in such a way that water does not enter the house during oblique rain.

10. Before installing the ribs, the surface should be coated with varnish and special impregnations that prevent the formation of mold and fungus.

11. To make plate connectors, use plates, which should be cut from a sheet of metal.

12. To do this, you need a grinder, with which you should cut out pentagonal or hexagonal connectors, depending on the type of construction.

13. After the connectors are ready, you should start pouring them. For these purposes, bakelite resin or polyurethane foam is suitable. The second option is more successful, since it does not contain substances harmful to human health.

14. To build the frame of the dome, pay attention to the drawing of the domed house and calculate the number of parts. To connect the parts, use the carpentry table and screws.

15. For the inside lining of the dome, use ordinary wood plywood, which can control the humidity in the room, and is also an environmentally friendly and harmless material.

16. After completing the work on finishing the interior of the room, proceed to the exterior decoration of the walls using roofing material and flexible tiles.

17. To do this, apply layers of flexible tiles and roofing material sequentially. Triangles from roofing material should be cut on the carpentry table.

18. To fix the roofing material, use resin or special glue.

19. After that, proceed to the interior decoration of the domed house, which includes:

- flooring,

- provision of water supply,

- ventilation,

- wall insulation,

- wall decoration.

1. If sewerage and water supply are planned in the domed house, two pits should be additionally provided.

2. If there is a bedroom or a second floor, provide several windows with opening sashes.

3. To insulate the structure of a domed house, it is possible to use sawdust.

4. The best option for making a domed house would be to use white acacia, which has high strength characteristics.

5. Take care of the availability of sockets, lamps and other electrical appliances in the house.

Dome houses video:

In recent years, domed houses in our country have moved from the category of exotic to the category of unusual buildings. Their owners are no longer perceived as developers who simply decided to stand out from the background of typical cottages, but as people who have made a conscious choice of such a design.

But the mass distribution of domed houses, as usual, is hampered by stereotypes and a lack of practical information on the design of such structures. Therefore, in this article we will cover:

- What is the difference between a stratodesic domed house and a geodesic one.

- How to build a domed house yourself.

- How to build a domed house without using connectors.

- How much does it cost to build a domed house.

The difference between a stratodesic domed house and a geodesic

As practice shows, people who first saw or learned about domed houses are most often divided into two categories. These are those who unconditionally accept such a form of a house and, we note, a way of life, and those who consider such structures to be a fad or, as an option, a house not under permanent residence, but a summer cottage "not like everyone else."

We will not go into details of the discussion of the advantages and disadvantages of domed houses (and they, like any building technology, have them) and will concentrate on practice. So, there is a developer who wants to build a domed house. Where to begin? An excellent example of a competent and thorough approach is the story of a portal user with a nickname Rustad.

Rustad FORUMHOUSE user

I decided to build a domed house with a relatively small area, about 100 square meters. m, near St. Petersburg. The site is on a slope. The house will be mainly used in the summer with infrequent visits in the winter. I will build a geodesic domed house using a non-connector technology. Such a structure is an exact mathematical model. It is impossible to build it without calculation and project, because. the error in the assembly of the frame and in the manufacture of parts should not exceed 1 mm. If you do not follow this rule, then with the accumulation of jambs, the frame will “leave”.

Before we talk about the nuances of designing and building a house, shown in the photo below, we will answer the question that is one of the first to arise for any person who has decided to build a domed house.

What is the difference between a stratodesic domed house and a geodesic one? Without going into a detailed description of the technology, let's say that the key difference lies in the way the frame is erected.

Stratodesic dome It is built from racks, for example, made of bent glued wooden beams, and its assembly steps are in many ways reminiscent of the usual frame building technology.

A feature of this technology is its resistance to vertical loads and the possibility of using standard windows and doors in the construction.

geodesic dome built differently. First, individual sections are made, for example, in the form of triangles, which are then, step by step, connected to each other.

When assembling the ribs (sections) of a geodesic dome, the technology of a connector connection (for example, using a metal connector) can be used.

Or (less common in Russia) connectorless technology.

Rustad I settled on the last option and, as we said above, started with the development of the project.

Rustad

Building a domed house without a project or scribbling something with a pencil on a piece of paper is a hopeless task. From the experience of friends I can say that this always leads to only one thing - alterations and endless restructuring of what happened. Also not a panacea - to give the project at the mercy of the designer.

A designer can draw beautifully, but in terms of practice, what he created is often simply impossible to bring to life. A person with a specialized education should design a house, but even a design engineer may not take into account the position of the building on the site relative to the cardinal points, the wind rose, and the dimensions of finishing materials. That's why Rustad, having two free months at his disposal, he sat down to design a domed house, and that's what he ended up with.

It should be noted that the project has been modified several times during this time, taking into account the recommendations of experienced builders, the availability of materials, the peculiarities of furniture arrangement and the wishes of the household.

Stages of construction of a geodesic domed house

Having completed the stage of designing a domed house, Rustad proceeded to build it. We will immediately give a few user recommendations regarding the organization of construction.

Rustad

I wanted to build the house in the shortest possible time, so I attracted assistants - one person who is well versed in the features of frame construction and a helper. I will say right away, yes, this is an extra expense, but if I built a house alone, it would take me 3 summer seasons. At the same time, it would most likely not be possible to achieve high-quality work. Because purely physically, it is impossible for one to hold the knots (ribs of the frame) on the weight and at the same time fasten them to each other. When assembling, you always have to tighten or bend something. The second and third pair of hands are vital. Otherwise - the accumulation of errors from row to row and, as a result, a "jamb" with the upper contour.

According to the user, he supervised the construction, and his personal - physical contribution is about 30%. The experience of the master (to avoid mistakes) of the frame builder also came in handy. Also, the speed of assembly of the circuit has increased significantly, tk. 2 people do the work 4 times faster than 1, and 3 people “turn” the same amount of work 8 times faster.

Therefore, the entire construction is divided into a number of successive stages, each of which requires careful monitoring.

1. Building a foundation for a domed house.

The site is on a slope. The angle of inclination is about 12 degrees. As a foundation Rustad chose pile-screw. The pile field consists of 24 piles with the following sizes:

- pile diameter - 108 mm;

- pile length - 2.5 m.

Piles spun in 2 days, carrying until night. The user notes that, having trusted the foreman of the workers, he himself did not mark the pile field.

As a result: several piles were not where the nodes of the house are located. To correct the error, the “16th” channel had to be welded on.

2. Making a frame: ribs, racks and rafters.

For the frame, we bought a winter forest and cut all the blanks to size on a miter saw in advance, in accordance with the project.

It took the user 4 days off.

3. Assembly of the domed house.

Construction of the house began in April. The weather was, to put it mildly, “not flying”: either rain, or snow, or wind.

The construction of the domed house began with the installation of the riser (cylindrical base).

Raiser was recruited from triangles to make the house look like a single whole.

At this stage, the question arose of how to make a takeaway under the terrace. The user did not want to turn the piles under each log - it would have turned out to be one continuous pile field. This is not economically viable, and besides this, the terrace would look ugly.

Rustad decided to make a terrace in the form of a "balcony" - a departure, which is a continuation of the floor of the first floor. It remains to choose a material that can withstand such a load.

Rustad

When I took up this issue and turned to companies, I was recommended to make a takeaway from glued I-beams. Comparing these beams (OSB wall 18 mm thick) withLVL beam, section 51x300 mm, I did not see any particular economic benefit in purchasing an I-beam, but doubt the strength and bearing capacityLVL beam is not necessary. He placed it.

Having mounted the logs, they laid a temporary floor from the boards on them, because. weather conditions did not allow to do normal.

It took 2 days to assemble the dome (in snow, strong wind and heavy rain).

Important nuance: to fasten the ribs and beams together, the user used 6x140 mm structural self-tapping screws.

Unlike ordinary self-tapping screws (especially the so-called hardened “black” ones, which cannot withstand dynamic loads and break), a structural self-tapping screw can be bent into an arc, and it will not burst. A special notch cuts through, rather than pushes apart the fibers of the wood, so the self-tapping screw can be screwed into a knot or into the edge of the board and it will not crack.

Also, the self-tapping screw is stronger than usual, and the “asterisk” head does not allow the bit to break and cut off the edges, which simplifies screwing.

To assemble one knot of six ribs, 12 pieces are required. self-tapping screws.

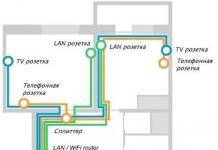

Engineering communications - water pipes, electric cables were laid in the floor.

The electrical box was also assembled in accordance with the project at home and placed in the "basement".

The next stage is the sheathing of the assembled dome with a moisture and windproof membrane, with obligatory gluing of overlaps special tape. Stuffing the crate under the ventilation gap. Installation of OSB (bases for flexible tiles).

The "pie" of the dome practically repeats the "pie" of the roof for the installation of a soft roof.

Important nuance: the dome cladding was made from patterns (triangles) from OSB-3 sheets, 18 mm thick, 1220x2440 mm in size.

Sheathing was nailed with 6x60 mm bristled nails.

Rustad

This nail holds very well. You can pull it out only with “meat”, and it gets clogged faster than turning self-tapping screws.

Having made the outer contour, the builders began to insulate the floor. Ecowool was blown into the floor with a layer of 30 cm, using a home-made installation based on a garden vacuum cleaner and a plastic barrel.

After insulation, the floor was covered with sheets of moisture-resistant GSP (gypsum particle boards) 12 mm thick, laying them in 2 layers.

Having mounted the base, we proceeded to the insulation of the walls. For this, a synthetic non-woven material (insulation) 5 cm thick was used, laying it in 3 layers.

Rustad

It is a pleasure to work with this type of heater. It is not prickly, not afraid of moisture, light. Only cutting with a knife is difficult, it is better to use scissors or a special electric carpet cutter. And I will add: it is better not to put heavy objects on the insulation, and also not to store the rolls in height. The insulation may not recover its shape after the load is removed. It is better to act according to this algorithm - they brought it and immediately put it.

Having insulated the walls, they pulled a vapor barrier over the frame and also sewed everything up with gypsum particle boards, but only 10 mm thick.

At this stage, the house has already acquired a finished look. After the erection of partitions, the installation of engineering systems and finishing processes began.

This includes the following works.