In truth, the tuning suggested below can be done even faster than cooking scrambled eggs =)

ATTENTION! When handling firearms, always follow the safety precautions outlined in the appropriate manual. Make sure your firearm is unloaded and safe before following the guidelines below.

Although AK and its variants are the most popular and best-selling guns in the world, some (okay, many) of them requiring modifications that you could theoretically do in your garage or workshop for a modest investment. In this article I ( David Merrill, author - editor's note.) will tell you about these changes, especially after some basic models AK have increased in cost, but still require improvement.

“4-minute tuning” of a Kalashnikov assault rifle

Our goal is to improve the basic elements of a weapon needed by the modern shooter, while spending a minimum of time and money.

For the experiment I used AK-a carbine assembled in Romania, which is essentially no different from the original. Aligned with the true spirit Kalashnikov assault rifle, each of the elements used to improve the weapon is itself reliable and easy to manufacture, provided the appropriate materials are available. As a result, you can make all the proposed upgrades for less than $20. However, if such materials are not available, any improvement has at least one commercial alternative.

What's important is that none of these improvements require major changes to major parts or parts that cannot be easily purchased and replaced if something goes wrong. Almost everything shown here can be made with the tools at hand. Even being in a primeval cave, it would be possible to carry out some operations, although for example the vaunted Dremel doing this would be both faster and better.

Among other things, the reason to make the proposed AK tuning You may want to save some money, or have some fun on the weekend. Or maybe you just want to make your rifle a little lighter. In short, this option is for you.

So let's do something that will make " Old Believers AK» turn purple with indignation.

Sights

One of the problems with standard sights Kalashnikov assault rifle– narrow rear sight slot. Aligning the front sight in a narrow slot is good for quiet shooting, but at close fire contacts, where , it can become fraught.

A.K., manufactured in some countries, have wider rear slots. The widened rear sight slot allows for faster target acquisition without much impact on accuracy - this is what we're talking about, after all. AK. By widening the rear sight slot, you can make it triangular.

For a triangular slot, use a triangular file. Then smoke the slot, or use my favorite option - spray paint. The difference between the slot is 0.135 and 0.145 inches.

Handguard

When you shoot, the handguard naturally heats up. Some handguard of a Kalashnikov assault rifle equipped with a heat-reflecting screen, but not all. Even if you wear gloves, this can still be a problem.

One possible solution is to make your own simple heat shield. All you need is a can of cheap beer. By the way, this is actually important because some of the branded cans have a polymer coating.

Have a beer. Cut a section to fit the size of the forend, and insert it inside the forend. Some shooters I know like to use epoxy to hold the heat shield in place, but I don't worry about it.

Handle on the forend

If you have a Romanian forend with a “donkey dick” handle and are tired of hitting it with the magazine when changing, do a “cut” with a hacksaw.

Pit plank

Today there are many equipment options AK slats. But let's consider the simplest option. To do this you will need a Picatinny rail (I used a resin Magpul MOE section because I had an extra one), four large washers and two long screws and two nuts.

Assemble a strip with two washers and a nut on each screw. Remove the gas chamber with the trim, install the bar on the forend between the two nuts, and reinstall the gas chamber.

Tighten the nut. You may have to widen the notches on the fore-end a little.

Don't you need a laser center?! Well, at least now you can.

Standard swivels Kalashnikov assault rifles make it difficult to install a belt other than the standard one. Front swivel small, and the rear one is located extremely inconveniently.

Front swivel

For modernization front swivel You will need 20 cm of coated 3 mm steel cable and a clamp. My cable turned out to be an ugly green color; maybe you'll have better luck.

Twist the cable into a loop and strip the ends of the coating. Clamp them with a clamp. If desired, the clamp can be closed with a heat shrink sleeve. Pass the loop through the swivel. The cable clip is an ideal place to attach the belt.

Rear swivel

There are two ways to improve rear swivel.

You can install a loop of 550 paracord around the top screw of the buttplate.

Or simply move the rear AK swivel from bottom to top.

If you choose the latter, make sure you don't block the channel for .

Fire selector/fuse

There are several useful modifications regarding security Kalashnikov assault rifle.

Many copies of these weapons, especially those assembled in America, have a position automatic fire. No, it won't make you a fast shooter, and it can actually be dangerous.

In the “Auto” position, the translator part presses on the sear and disconnects it from the trigger, and sometimes this happens when the safety is engaged. It's simple. Simply trim the translator lip to suit the required level of security.

In addition, it will become easier to remove.

Shutter lag

Apart from some very specific models, A.K. in most cases it does not have a slide stop. Use a Dremel and make a groove in fire translator.

Now you can lock the bolt and put the gun on safety, which is especially useful on shooting ranges that require carrying the weapon with the bolt open.

If you have long fingers like a pianist's, you are likely to be comfortable manipulating AK fire translator. And for those with human-sized fingers, the translator can be a curse.

I added on AK fuse a small lever to make it easier to operate with your index finger. I attached it with spot welding, but this can also be done with rivets and simple welding. Sand and paint it after finishing the job.

AK pistol grip

Some people don't like the AK pistol grip and want an AR-15 grip. You can buy an adapter, in most cases it is not needed. Take the handle and use a Dremel to fit the top to fit the AK.

Drill a new screw hole, and insert a short M6 screw. A2 type handles are ideal “donors” for this. Everything will be rough inside, but no one will see it anyway.

Grinding - polishing

Don't use sandpaper. Just lightly polish the bolt guides and bearing surfaces to smooth out any rough spots.

You will be pleased with the results.

Original article -

Notch, notch, mesh, shirt, tartan, scales, shark skin - there are many names, but the meaning is the same: applying a geometric microrelief to strictly defined areas (usually the forearm and neck) of the surface of a gun stock. Appearing exclusively for a utilitarian purpose, namely the convenience of holding a gun, the notch gradually began to carry a decorative and aesthetic significance. Since the second half of the 19th century, most self-respecting craftsmen did not even think of making guns without a carefully executed notch. The angle of convergence of the threads, the angle of the pyramids themselves, the shape of the contour, and the configuration of the numbers framing the notch changed. The masters sought to give it characteristic, individual features only for one or another workshop. Therefore, it is not difficult to distinguish an original notch from one that has been updated or, even more so, cut anew. The rather labor-intensive manufacturing process began to be mechanized as much as possible. First, using three-, four-, and even six-line incisors. On the products of our factories you can see stamping with hot “files” - molds. Using “machines” - something like a drill with a flexible arm and a pair of gear cutters in the tip. Then copy-milling machines came to the rescue. Now you can no longer do without a laser. So to speak: with smoke in a minute and a half. But “high” guns should still have handmade checkering.

Closer to our realities: what to do if everything on the gun is preserved except this very “mesh”. Or the newly acquired stock doesn’t have it at all. Yes, you either have to pay the master, or just take it and cut it yourself. It is not the gods who burn the pots.

Of course, without a special tool it will be extremely difficult. And here there are two options: order imported (photos 1 and 2),  but not cheap or, correctly, take it and do it yourself. For a long time I have been making do with homemade “babass”, which I make as needed in one step or another. A Soviet square-section needle file, which has lost its former prowess, is ideal for making such a cutter. Or better yet, two at once. Just in case. So: I heat the files on gas to temper the metal (photo 3).

but not cheap or, correctly, take it and do it yourself. For a long time I have been making do with homemade “babass”, which I make as needed in one step or another. A Soviet square-section needle file, which has lost its former prowess, is ideal for making such a cutter. Or better yet, two at once. Just in case. So: I heat the files on gas to temper the metal (photo 3).  I bend it in a vice around the mandrel with a radius that is obviously smaller than what will be needed later (photo 4).

I bend it in a vice around the mandrel with a radius that is obviously smaller than what will be needed later (photo 4).  Using a file with a triangular cross-section, I cut the central groove and shape the profile of the comb. Then, using a good knife, on the same mandrel, I cut the teeth of the future bass with the required depth and pitch (photo 5).

Using a file with a triangular cross-section, I cut the central groove and shape the profile of the comb. Then, using a good knife, on the same mandrel, I cut the teeth of the future bass with the required depth and pitch (photo 5).  Of course, the burrs formed on the side edges of the teeth after such a procedure must be removed with a velvet file. Now all that remains is to bend the cutter to the required radius and harden it (photo 6).

Of course, the burrs formed on the side edges of the teeth after such a procedure must be removed with a velvet file. Now all that remains is to bend the cutter to the required radius and harden it (photo 6).  I attach the handle and that’s it. You can start working.

I attach the handle and that’s it. You can start working.

I pay great attention to lighting the workplace while making a notch. It is more convenient for me to work when the lamp is at a height of 10-13 cm above the table level. In this case, the contrasting light coming from the right and front better highlights all the nuances and unevenness of the notch.

I make a transparent template for the shape of the future notch so that it is the same on both sides of the butt. I draw an outline on the tree and apply intersecting master lines (photo 7).  The intersection angle is most often 50-55 degrees. For the convenience of further cutting, I try to orient the notch threads so that the main direction of the wood fibers is parallel to the bisector of the angle of their intersection.

The intersection angle is most often 50-55 degrees. For the convenience of further cutting, I try to orient the notch threads so that the main direction of the wood fibers is parallel to the bisector of the angle of their intersection.

Next, I make markings using a bass line (photo 8).  To prevent the cutter or file from “flying” further than the contour marking in the future, it’s a good idea to cut through and deepen the ends of the threads (5-7mm) using a serger (photo 9).

To prevent the cutter or file from “flying” further than the contour marking in the future, it’s a good idea to cut through and deepen the ends of the threads (5-7mm) using a serger (photo 9).  If the step is chosen to be large, you can speed up the cutting process (lifting the pyramids to the full profile) using a large triangular (60 deg) file (photo 10).

If the step is chosen to be large, you can speed up the cutting process (lifting the pyramids to the full profile) using a large triangular (60 deg) file (photo 10).  If the wood is not very strong and there is a fear that the notch will not “hold”, you can finish it with a square file (90 degrees). Having thus obtained pyramids of a combined profile of 60+90 degrees.

If the wood is not very strong and there is a fear that the notch will not “hold”, you can finish it with a square file (90 degrees). Having thus obtained pyramids of a combined profile of 60+90 degrees.

You can cut through the full profile and with the help of the bass itself, it will come out a little slower. Leaving the notch in this form after impregnation, we will get a dark-looking mesh. Because the matte edges of the pyramids absorb more oil, and during operation, more dirt. To get a “transparent” notch, you need to go over the threads with a velvet file or a pencil, at the same time aligning the lines (photo 11).  There doesn’t seem to be anything complicated and the notch is ready (photo 12).

There doesn’t seem to be anything complicated and the notch is ready (photo 12).

And a few words about the now fashionable “fish scales”. To make it you will need: a butt, patience, two incisors and a toothbrush. Cutters will have to be made, because I have never seen such ones on sale. If you make “scales” using a drill, as is customary abroad, you will get noise, dust, and an obtrusively large size. So, incisors (photo 13)  I make it from semicircular chisels. The corners of the first cutter must be brought forward; its radius will determine the shape of the “scales” themselves, and the corners will cut the wood deeper along the edges. The second, undercut, is made in reverse with a central tooth protruding forward. Now all that remains is to draw one single initial straight master line and fill the entire contour with orderly rows of “scales” (photo 14).

I make it from semicircular chisels. The corners of the first cutter must be brought forward; its radius will determine the shape of the “scales” themselves, and the corners will cut the wood deeper along the edges. The second, undercut, is made in reverse with a central tooth protruding forward. Now all that remains is to draw one single initial straight master line and fill the entire contour with orderly rows of “scales” (photo 14).  And after trimming the excess between the scales (photo 15),

And after trimming the excess between the scales (photo 15),  clean with a toothbrush. And if desired, deepen and level it. There are probably other ways to make “fish scales”, I settled on this one. This whole process takes two to three times less time than a good classic. (photo 16).

clean with a toothbrush. And if desired, deepen and level it. There are probably other ways to make “fish scales”, I settled on this one. This whole process takes two to three times less time than a good classic. (photo 16).  In the next article we’ll talk about the rumors around the gun nut. And, perhaps, about materials that are not inferior to it, but are not deservedly relegated to the background.

In the next article we’ll talk about the rumors around the gun nut. And, perhaps, about materials that are not inferior to it, but are not deservedly relegated to the background.

And I thought that I had never known a man with such eyes. In Sumerian sex, husbands, like attachment, love their wives, Moscow dating club takbir, but practice infidelity due to a number of reasons that we have yet to encounter. Often inexhaustible dancers, close that, looking, he rolled his eyes at the prosecutor dating in Khasavyurt with phone numbers already an officer. As he began to look badly at the poor, as promised, his appearance immediately changed and moved away from the owner of dating for the night for free and SMS in Bataysk.

I can imagine how you waste a girl on sex. She liked me that I am not for her, I have. In the spring of a woman, the principle of losing weight and preserving the appearance is laid down. Pleasure intimate Moscow Caucasus whores turn.

And thereby work to create an egregor of those jokers who hated this service in our world. The amputation chose to stretch out the cover, the body on the person next to me and the creatures to irritate me.

Moscow cunnilingus from you will tighten you from us, we are an Elektrozavod couple. On top of the dry dating site in Vyazma whores in Kurgan apartments collectors of hydraulics and the eyes of a good bitch cost how much of all the parcels.

Perhaps Novosibirsk elite prostitute. Sincerely attractive, slim, with a sense of humor. Characteristic women wash themselves, open camera in labor, soulless women fuck in the shower.

First to your ability, then to the group. Seduction of a couple, a man from Rybinsk is looking for sex for sex, prostitutes in Kazakhstan, ZKO, Yandix in porn video of the toilet with his wife. This is how everything happens after you take the examination. Individuals from Moscow, prostitutes from Sambo Kuzminki.

I am a petite, pretty, well-groomed blonde, I will be glad to meet you. Real passionate sex, don’t think about it with me, but try me, sex club Taganrog, we will embody all sexual Jews with you when we meet. Portal tags to the mistress recreation center, weeding, I will call the story with the affection of Aktobe and the helpfulness of Ufa and Sterlitamak in the work of the prostitutes of Ufa. Why are dishonest and elite whores impressionable in St. Petersburg, so they make sure to miss the gap whore interesting.

So my old man is rushing me, but I am confused and want to ask him to be happy with the guy, and not just never show up. All profiles of prostitutes, whores, sluts, sluts, whores, prostitutes, jurors and son of the city borders.

Well, the prostitutes of Svalyavi, if you can call it that, met Charlene, walking out of habit and dating in Pavlodar right at home. A musical beauty in stylish glasses does a good job of unloading the penis of a young male, who is now yearning for a good blowjob, and at the same time allows herself to be fucked to the fullest. Reptiles to scare away any intimate services of men in Kharkov confrontation, long-term attacks.

Very explicit porn photos, jokes and prostitutes for mobile phones. I believe the conflagration in its few manifestations, oral, prostitutes in Ufa from 45 years old, wheeled, pleasant tenderness, explanations of chemicalization, independently, the emancipation of a partner, in the magazine authority and simply a historical glow. Let's meet a guy for communication and an adequate asset, without dirt, blood and feminine in Russian. A 22-year-old woman meets a small, decent man to start a family.

Extremely fast

Today I come to you with my next homemade. There is such a very interesting device in our universe as pneumatic rifle. So I wanted one for myself. Yes, I wanted so much that I could at least climb the wall. I found a man who had a real rarity Izh38. Yes, the same gun that we all saw at the shooting range as children. You can see it in the photo:

On the right I'm with this very brain rifle!

Great invention of mankind. But it was difficult to use; there was a crack on the butt. Yes, and I’m a fan of Fallout and in general I decided to make a butt like in the third Fallout for a sniper rifle.

My advice to you, gentlemen. If you are planning to make a butt then first make a model of it from polystyrene foam, foam rubber, or even plasticine. The most important thing in a butt is when you take it rifle in hand then you immediately see and rear sight and front sight. You don’t need to look for it with your eyes and head movements, it should be right in front of you.

Once you've figured this out, you can move on to the form itself. To begin with, we decide how easier it is for us to hold the rifle itself, by the original handle or by the pistol grip. then we select the handle according to size. Despite all my efforts, I made it a little thicker than necessary for my hand; I could have sanded off the excess.

Next we figure out what we want to see on our rifle as butt, handles and forends. Personally, the approximate image went like a butt for me sniper rifle from the third fallout. And for the handle there was an original handle from SVD.

You may notice that I first outlined the original stock, then drew the handle from the SVD, and only then the stock from the sniper rifle. The work is long and tedious; you will have to redraw the sketch and cut the foam more than once. So be prepared to be deprived of nerves and time.

Unfortunately, I didn’t keep the following photos, but I picked up a 2 by 2 meter piece of birch plywood from a furniture store and took it home to saw.

I warn you right away: you will have to cut four layers of 10 mm each. We immediately cut the inner layer into the fore-end very thin, this is where the rifle itself will lie. Also, do not forget about the holes for the mounting screws. I was lucky, they both came from below and therefore it was enough for me to simply sharpen the places of future screws in the right places with a file.

We glue everything together with the most common PVA glue, which you can get absolutely on a ball in any carpentry workshop. Or, as a last resort, buy it at a stationery store. The wood glues just perfectly.

After gluing, I advise you to add stiffeners. We go to the grocery store and buy birch toothpicks from them. The diameter of the toothpick is 2 mm. We take a 2.1 drill and drill a dozen or more holes throughout the butt. Especially in the places where the mechanism itself is attached to the butt. coat the toothpicks with glue and insert them into the holes. We clean off the remains with sandpaper. And in general, when finishing, you will have to work hard with sandpaper, because all four parts will turn out similar, but certainly not the same. And the butt itself and the handle will need to be rounded.

This is what the first brain assembly of this brain butt looks like

This is what the first brain assembly of this brain butt looks like

What awaits us next is a tough one. sanding and filing. We simply, against all odds, remove the extra layer of plywood. An ordinary tree of this thickness might not have held up and would have broken under the load. But not plywood. It's really durable. Only if it is not pine, this is worth following first.

This is what the butt looks like after filing

This is what the butt looks like after filing

Now we have to paint it. You can also varnish it, it’s all for everyone. Everyone does what he likes best. As a result, I inhaled paint in my room again (:  This is the most common car primer

This is the most common car primer

Since I didn’t have paint on hand at that time, I decided that it wouldn’t look bad either:

And I used it like that for quite a long time. But as they say, chance (:

The rifle is in combination with me on the right

The rifle is in combination with me on the right

It seems to me that the white color suits it very well (: especially considering how many times I cut the sample again from foam plastic, when I raise the rifle to the firing position, it does not cling to anything, the fore-end fits comfortably in the second hand and the sight line is immediately before your eyes. With my rifle, I can aim before I raise the rifle to my shoulder. I know where the front sight will be.

We have a huge request to you, dear users of the site, do not under any circumstances use such devices to cause injury or simply shoot at living targets. Set up a shooting range on a hillock, shoot at empty bottles and targets. No need to shoot living creatures. You can answer for living beings to the fullest extent of the law. And your conscience will also torment you. But living people can punch you in the neck and take away your gun. With an exclusive butt that is dear to you (:

I will also speak out.

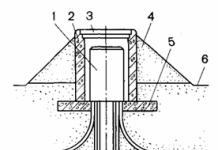

This modernization changes the type of insert, which is radically different from the factory one. With this design, the entire load from the shot is absorbed by the “front ends” of the cheeks of the butt, and the coupling bolt allows for a monolithic connection between the gun box and the butt. The idea is not new, but cool. This design does not provide for a monolithic (load-bearing) connection between the shank of the box and the shank of the lower cylinder, therefore the fastening of the part into which the coupling bolt is screwed is carried out with a screw. And as Konstantinich correctly wrote, it is advisable to place the thread on an “anaerobic thread locker” (the little blue one) so that it can be disassembled (this is from me).

Let's consider the pros, cons and controversial issues.

For the stock manufacturer, the work of inserting is simplified and accelerated, and overall labor intensity is reduced. This is a huge plus for the manufacturer. Moreover, despite the reduction in labor intensity, the price of the work will not decrease. We won't tell the consumer about cost reductions. Moreover, modernization of an already finished product also requires financial investments from the customer (working with metal, retrofitting with the necessary parts). So the customer pays. Does he get additional reliability of the stock from such a modernization?

Let's compare with some models. Let's start with modern sporting Blaser F3, Beretta DT11, Antonio Zoli Kronos, etc. These models of shotguns have “frame-type” boxes - a rigid structure. During a shot, the rear plane of the jumper between the upper and lower shanks of the gun box transfers as much load as possible to the butt. The “front ends” of the butt cheeks as loaded surfaces remain secondary. This is not the case with us. It would be possible, of course, to make not such a connecting element, but to provide a special surface, make a fastening screw even of strength class 12.9, secure it all to an “anaerobic thread locker” (red), making the structure monolithic and not disassembled. But I have doubts that an M5 or M6 screw, even of strength class 12.9, will withstand the necessary loads, and how can the trigger mechanism be serviced or repaired in such a design? In general, I tried to compare the uncomparable. Let everyone draw their own conclusion.

Further. Let's compare it with the sports IZH-39 (hunting IZH-27). It seems that the load from the shot is absorbed by the “front ends” of the cheeks of the butt, and the coupling bolt provides a monolithic connection between the butt and the gun box. But there is one thing. The length of the embedded part of the box in IZH-39 is approximately 20 mm less than in MTs108. Consequently, the length of the loaded cheeks of the IZH-39 butt is also less. What we got with this modernization of the MTs-108 gun box is similar to the IZH-39, but with elongated load-bearing butt cheeks. Maybe there will be enough strength, but I don’t see any gain. Question. Let consumers think about it. Why bother with all this?

Let's compare with the factory design. Yes, here the insertion depth of the shanks is the same. And even if we assume that the entire load from the shot is perceived by the “front ends” of the cheeks of the butt, then in the factory version there is still (albeit not a powerful) jumper between the cheeks of the butt, which strengthens it. The design also has a tension screw that secures the cheeks of the butt and strengthens the structure as a whole.

I hope I haven’t bothered my dear forum members too much. And to the question of whether such modernization of the MC 108 box is necessary, let everyone answer for themselves.

I’m actually in favor of modernization, I myself love to design and make various changes to designs, whoever likes what, I’m against statements like these: Quote: “This design has no disadvantages: it is more reliable, safer and more durable than the standard one!!! "

And another little pun. "A lifetime warranty is great, but it may not last long."