The main purpose of decorative plaster - exterior decoration of the building. Here plaster for the facade is indispensable - which one is better suited, you decide. Her choice is varied. At the same time, the coating has not only an aesthetic purpose, but also performs protective functions - Protects from the harmful effects of the weather.

Types of plaster for finishing facades

Wet facade plaster- the most common way to ennoble the treated surface and protect it from the effects of precipitation, ultraviolet radiation. It is carried out on a previously leveled, cleaned and primed basis. A finished layer is created not only for decorative, but also for protective purposes, which does not require additional finishing, has a peculiar texture, as well as a certain color.

The classification of plaster mixtures is carried out according to several principles - structural differences, composition, method of application. There are ready-made solutions that are immediately suitable for use after mixing and dry mixes that require dilution with water.

Kinds by invoice:

- lamb (fur coat);

When applied to the surface of a building, each of the varieties gives a different relief, a certain structure.

Classification composition:

- mineral;

- silicone;

- acrylic;

- silicate.

Of all the above varieties, mineral plaster for facades is provided by manufacturers in a dry form, the rest are ready-made.

According to the methods of applying the mixture are divided into:

- universal appointments;

- mechanized application;

- for manual use.

Solutions for universal use can be used for both machine and manual application.

Textured plaster

Its structure is a parameter of decorative and aesthetic nature. It does not affect the duration of operation or strength. The implementation of each type of texture is carried out through the use of materials with a certain grain size of the filler. Allocate invoices traditional, and modern. The former are structured from old, time-tested mixtures, while the latter are innovative in composition.

Relief is formed using various techniques, devices:

- special graters;

- trowels;

- sponges;

- texture rollers.

Surfaces give absolutely any structure you like or apply a bas-relief pattern. There are standard - the most commonly used types of plaster to form the desired texture.

bark beetle plaster- the most common and with many variations. Traditional methods include applying vertically, horizontally, in a circle and crosswise. For lovers of a creative approach, you can advise a wavy texture or your own version.

The relief is formed by grouting the plaster layer with a plastic float. The drawing depends on which direction and with what movements to wipe the solution applied to the surface of the building.

Pebble plaster- a universal tool for making a textured pattern in the exterior decoration of buildings. The material allows you to make drawings of varying complexity, carved compositions in different colors - "sgraffito", small and large bas-reliefs, traditional - "fur coat", "polka dots". It is a coating densely sprinkled with crumbs with a fraction of 1-3 mm.

The structure of the coating is given with a plastic grater by grouting. Special rollers, palette knives, trowels, brushes, spatulas are used for scratching, smearing, printing patterns and textured elements. The most diverse figures can be drawn on the surface.

Mosaic plaster- a separate variety, which is performed exclusively in the form of a flat, transparent surface. In its composition, granules of stone chips of natural origin are visible - durable mineral rocks. From an aesthetic point of view - most noble texture.

It is applied in one layer and rubbed to a state of uniformity. Astringent components - silicone or silicate give lightness and transparency to the coating. It does not need further painting or varnishing.

Lamb plaster or fur coat- the traditional method of forming invoices. It is done by throwing the solution on the wall and does not require further grouting. Cement-sand, cement-lime mixtures are suitable for the formation of such a relief.

Features of the composition of building mixtures

The active components of the solution and its high-quality base are the key to a successful repair. Building mixtures facilitate work, have good technical characteristics. The peculiarity of the application of each of them is due to their composition. There are ready-made plaster solutions, as well as dry ones, which need to be diluted with water.

| Type of facade plaster | Release form | Purpose | Compound | Layer thickness | Properties |

|---|---|---|---|---|---|

| Cement | dry mix | Implementation of textured patterns, drawings | Cement, mineral filler, modifiers | 2-5 mm | Plasticity, wear resistance. |

| Acrylic | Ready solution | Pebble, traditional relief | Acrylic resin, sand filler, modifiers | 3-4 mm | Durability, ease of application, high adhesion to the surface |

| silicate | Ready mix | Suitable for all types of textures | Silicate binder (liquid glass), modifiers | 4 mm | Water resistance |

| Silicone | Ready solution | Universal | Silicone resin, mineral filler, modifiers, emulsifier | 3-4 mm | Great resistance to mechanical damage, high degree of adhesion. Elasticity, antiseptic properties. |

Whatever material you choose, plaster for the facade, when applied correctly, will create the necessary relief, and will also please you with a high-quality result.

Advantages and disadvantages

It cannot be unequivocally said that all types of material have the same advantages or disadvantages - it all depends on the composition, purpose and properties of the plaster, but some features can be distinguished.

Advantages:

- Ecological purity. Thanks to the use of natural, non-toxic ingredients.

- Fire resistance. The coating does not burn and does not contribute to the maintenance of the combustion process.

- Ease of operation. The facade of the building is easy to repair and clean.

- Frost resistance.

- Thermal insulation. Provides heat conservation in the room.

- Work can be carried out manually, as well as without the involvement of specialists.

- Aesthetic beauty.

- Modest weight. The weight of the plaster is very small, so additional repair work, as well as strengthening the foundation, are not required.

Flaws

- Low mechanical strength. Low resistance to mechanical stress is possible if a reinforcing mesh was not used, the facade plastering technology was not performed. Then chips and cracks may appear on the surface of the building.

- The complexity of installation work. The complexity lies in the need to strictly follow the recommendations for applying the mixture and professionalism. Creating an invoice takes a long time.

- Dependence on seasonality makes us focus on the temperature regime not lower than +5 degrees, which limits the time and possibility of carrying out repair work. If this requirement is not observed, the applied solution will dry for a long time and adhere poorly to the base.

- The material is expensive - the cost of decorative plaster is higher than normal.

Decorative bark beetle plaster is a popular finishing material that is widely used for interior and exterior work. The plaster got its name due to the texture, reminiscent of wood gnawed by bugs. It is used for various finishing options for both public buildings and private houses. The material has excellent appearance and good performance.

Material Features

A characteristic pattern is created by fractions of various diameters that are part of the bark beetle plaster. The technology for applying the composition and the appearance of the finish depend on the size of the fractions.

In the construction markets, the mixture is presented in three types:

- for interior work;

- for external works;

- universal.

Plaster also differs in chemical composition:

Initially, the bark beetle is white. In the process of work, it is tinted.

Advantages and disadvantages

The advantages include the following features of the material:

The disadvantages of the material include a rather complicated application. When working, you can not rush, as inaccurate movement can smear the entire pattern. As a result, you will get the usual scratched plaster.

How to choose the right composition

When choosing plaster, you need to focus on the following characteristics: grain size, type of composition and time of its useful use.

Graininess affects not only the appearance of the coating, but also the material consumption. This is due to the fact that the thickness of the plaster layer should not be less than the size of the fractions. So, the larger the fraction, the more material will be required for work.

Another important parameter is the type of composition. Suspensions are convenient for work, as they do not require preparation. Thanks to special additives, they differ in plasticity. But you can't store them. Their cost is higher than that of dry plasters.

Dry plaster must be prepared before work. It's easy to follow the instructions. The composition can be prepared in the required volume, and the remainder of the powder can be stored in a closed container.

Bark beetle application technology

Plastering works are carried out in two stages:

- the mixture is distributed over the base;

- produce the formation of patterns;

Before you start plastering, the base must be carefully prepared.

Work surface preparation

The quality of adhesion of the composition to the surface, and hence the quality of the coating, depends on careful preparation.

Bark beetle can be applied to facades that are not subject to shrinkage. The usual ones are covered with concrete, brick, cinder block walls. For wooden buildings, it is better to choose other types of finishes.

Bark beetle can be applied to facades that are not subject to shrinkage. The usual ones are covered with concrete, brick, cinder block walls. For wooden buildings, it is better to choose other types of finishes.

Before applying the bark beetle, the surface must be leveled with a cement composition. It is applied directly to the walls or to the insulation.

Surfaces are cleaned of dirt. Oil stains are removed with a solvent. Fungus and mold spots are cleaned and disinfected with an antiseptic. Repair damage to the wall with cement.

Using the rule, check if there are deviations from the plane. If the deviation exceeds 2 mm, then the surface is leveled with a putty mixture. A wall painted with oil paint is sanded over the entire area.

After preparation, the surface is primed. The primer improves adhesion of materials and strengthens the surface. For work, it is necessary to use a mixture from the same manufacturer as the plaster itself.

It is best to prime with compositions containing quartz sand. They penetrate deep into the base and make it waterproof, as well as improve grip. Under colored plaster use a primer to match. This is done so that it does not shine through when applying patterns. The primer is applied to a dry base. Use a roller or brush to apply. Work must be carried out in dry weather.

One layer of primer is applied to a solid surface, two to a dust-forming one. Primed walls should be allowed to dry for four to six hours.

Preparation of working solution

If you are using a dry mix, then carefully prepare the solution. Mixing should be done in parts, as the bark beetle dries quickly. It is necessary to strictly observe the proportions indicated on the package.

The solution is prepared as follows:

- To prepare the mixture, you can use a ten-liter bucket. Pour water into it according to the instructions. Its temperature should be at room temperature.

- Dry bark beetle is added gradually. A homogeneous solution is difficult to obtain manually, so a drill with a nozzle is used for mixing. The mixer is completely lowered into the bucket so that air bubbles do not form. Mix at low speed.

- The mixed solution should be allowed to brew for five minutes, then mixed again.

To get colored plaster, color is added when mixing the solution. To avoid streaks, it must be thoroughly mixed. Manufacturers recommend adding color to the suspension, and paint the plaster prepared from the dry mix after application to the facade.

Applying bark beetle plaster

The composition is applied using a metal trowel and a spatula. A portion of the plaster is placed on a trowel with a spatula and applied to the wall in an even layer. The layer thickness should be equal to the grain size.

The trowel should be kept at a slight angle to the wall. The application of decorative bark beetle plaster is carried out vertically in strips slightly overlapping each other. The force of pressure should be the same everywhere.

The trowel should be kept at a slight angle to the wall. The application of decorative bark beetle plaster is carried out vertically in strips slightly overlapping each other. The force of pressure should be the same everywhere.

To prevent the solution from settling, it is constantly stirred. During operation, a fresh composition should always be at hand. Do not interrupt work and allow the plaster to dry, as ugly stripes will be visible on the wall. If the wall size is large, then you need someone to prepare new portions of the mixture.

After the wall is covered with bark beetle, a drawing is applied to it. Grouting is carried out on wet plaster. Readiness for grouting is determined by placing a hand on the wall - if it does not stick, then you can apply a drawing.

The drawing is performed with a plastic grater - it is applied to the surface and evenly moved in one direction. Movements are performed carefully, without rushing. The drawing is applied in areas one and a half meters wide. Joints are constantly moistened with water.

The texture of the coating can be formed in various ways:

- "Rain" - the grater moves from top to bottom vertically;

- "Diagonal rain" - movements are performed from the upper left corner to the lower right;

- "carpet" - a cruciform texture is formed by alternating vertical and horizontal movements;

- "Lamb" - the grater is moved in short circular motions.

Sanding and painting the drawing

The applied plaster must dry completely. This usually takes about two days. After that, the coating must be sanded with fine sandpaper to remove crumbs and level the surface.

If you used acrylic plaster, then the work is finished. The cement-based mixture after grinding is painted with silicone or acrylic paints.

Before painting, the surface is coated with a deep penetration primer and allowed to dry. Painting is carried out in two layers: the first is performed with vertical strokes, the second with horizontal strokes. A roller or brush is chosen with a long pile - this allows you to cover all the grooves with high quality.

When working, it is better to use all materials from one manufacturer. This ensures their compatibility.

When working, it is better to use all materials from one manufacturer. This ensures their compatibility.

For people who do not have enough experience in applying plaster, it is better to start work from the far edge of the wall, since it is not immediately possible to get a beautiful drawing right away.

Work is carried out in dry, warm and calm weather. Only under these conditions, the coating will turn out to be of high quality and durable. Strong wind and direct sunlight lead to cracking of the plaster. If the facade is in the bright sun, then work should be carried out in the evening so that the plaster has time to compact during the night.

Any building, regardless of its purpose, should have a stylish and presentable appearance. Therefore, when designing it, great attention must be paid to the decoration of the facade. To date, the modern market is represented by a variety of facing materials. Especially popular among them is decorative bark beetle plaster, which allows you to create original design masterpieces.

Peculiarities

This material is characterized by high performance, it is easy to apply and looks perfect in a different style direction. Facade plaster "bark beetle" is considered a unique finishing material. When covering the base, it creates a surface with many pits, stripes and grooves. Due to such an original texture, you can hide the flaws of the walls, mask their irregularities.

They produce acrylic and gypsum-based plaster as a dry powder or as a ready-to-use mixture. The granular structure gives an unusual design to the coating. It consists of small marble chips. Grain sizes can be different (from 0.8 to 3.5 mm). Depending on this, the relief of the finish acquires small or large grooves.

With the help of such plaster, you can beautifully decorate any surface. It is in great demand when performing outdoor work, when the facade is clad. Usually the color of the material is white or grey. Therefore, immediately after its application, the surface of the facade is painted, choosing for this a shade corresponding to the design.

Advantages and disadvantages

The main advantages of plaster "bark beetle" include several advantages.

- High strength and environmental friendliness. The material is made from natural raw materials. The special production technology makes it reliable in operation.

- Light weight. The mineral fillers included in the plaster provide it with lightness. They reduce the level of mechanical stress on the structure of the building.

- Resistance to environmental influences. Plaster perfectly tolerates direct sunlight and temperature changes, it is not afraid of moisture. In addition, this finish does not fade and does not lose its original color during the entire period of operation.

- Fire resistance. The material has a low flammability factor.

- Resistant to the formation of fungus and mold. The special composition of plaster mixtures reliably protects the surface from the development of microorganisms.

- Huge selection of colors. Even though the base material is white, you can change its hue as you wish.

- Affordable price. The market presents products of domestic and foreign manufacturers. Anyone can purchase material that fits their budget.

As for the shortcomings, they are few. If the bark beetle finish has undergone serious mechanical damage, it is difficult to eliminate them. To restore the appearance, you will have to redo the lining, removing the damaged coating. Applying plaster is not easy. It requires a special application technology. Often, to perform a complex decor, you can’t do without the help of specialists.

However, not everyone can reproduce the texture of wood chiselled by beetles professionally. There are also secrets here. For example, you need a special trowel. Furrows are created by moving the tool up and down. Then the lining is somewhat smoothed. The difficulty of cleaning the surface also matters. Dust can get into the furrows. It is difficult to remove dirt from a relief surface.

Material types

Decorative bark beetle plaster is offered on the market of finishing materials in two varieties: based on gypsum and acrylic. The acrylic mixture is applied using special technologies, thanks to which the facade is attractive. But in order for the walls to acquire a visually rich decor, you need to take into account many nuances of decoration. Material is sold in buckets of different sizes. The mixture can be applied to DSP walls and concrete bases.

To give acrylic plaster the desired color, it is necessary to use special colors. This is usually done using computer technology on special machines, since it is difficult to get the right shade manually. The composition of the material includes abrasive granules. At the same time, manufacturers can add various minerals and marble chips to it. The grain size of the acrylic variety depends on the size of the abrasive and ranges from 0.1 to 3.5 mm.

The service life of the plastered coating is up to 15 years. The unique structure ensures a perfect application of the mixture, which, after drying, is not exposed to external influences and does not crack. In addition, the material has high adhesion. To obtain any color of plaster, it is not necessary to additionally paint the facade. The only disadvantage of acrylic plaster is the complexity of the finish.

The gypsum-based analogue is easier to use and economical in consumption. The complexity of working with the mixture lies in the fact that before using it, it is necessary to prepare the solution yourself by mixing the dry powder with water. Gypsum plaster is produced from ecological raw materials, it is easy to apply it to the walls manually. The material is inexpensive and has high strength.

Depending on which binder is included in the plaster, the "bark beetle" is silicate and silicone. The silicate version is produced on the basis of liquid glass. It is characterized by microbiological resistance and vapor permeability. Silicone plaster is made from modified acrylic substances and silicone resin. It is resistant to chemical attack and is often used when working with stone.

Color spectrum

To give the design bright colors, the mixtures need to be tinted to the desired shade. Gypsum-based material is easier to paint, as it is sold dry. When mixing it, you can add any dye. As for acrylic plasters, getting the actual color is much more difficult. Care must be taken when coloring, otherwise the shade will be too saturated.

However, the material does not have to be tinted at all: the plastered surface can be painted with enamel, choosing a paint for this on the same basis as the plaster. Today, modern facade design is dominated by warm colors of the palette. The wall decoration in yellow, red, brown and beige looks beautiful. It is necessary to choose the color of the facade taking into account the general style of the design of the land. A good option for country houses would be the facade cladding in gray and green. At the same time, it is not necessary to decorate surfaces in a single color, it is better to create compositions consisting of several colors.

Manufacturers Overview

Facade plaster "bark beetle" is produced by many brands. The main sales leaders are Ceresit, Baumit, Dufa. Their products have proven themselves from the best side and received positive feedback from customers. This plaster allows you to decorate surfaces in an original way and reliably protect building structures from the negative effects of the external environment. Working with such plaster is simple: the mixture is sold ready-made, there is no need to spend extra time on its manufacture.

The Unis group of companies, consisting of foreign and Russian manufacturers, also deserves special attention. Plaster "Unis" has high strength and durability. Mixes are available in ready-made and powder form. Plastered surfaces with the effect of "bark beetle" are resistant to the formation of fungus and mold, they withstand low temperatures and do not fade in the sun.

Necessary calculations

The main point when working with a mixture of "bark beetle" is the correct calculation of its consumption. This must be done in order to prepare the required amount of solution, since its use is limited. If you cook a lot of the mixture, the excess will have to be thrown away. If it is not enough, you will have to break away from the workflow, which will entail a poor-quality finish (the edges will instantly seize, the texture will be broken).

The amount of plaster depends on the characteristics of the base on which it will be applied. In the event that the coating has irregularities, it will be necessary to increase the thickness of the cladding layer. As a rule, each manufacturer indicates on the box recommendations on how to calculate the consumption of the mixture. On average, up to 3 kg of plaster is needed per 1 m2. However, if the walls absorb the composition well, the consumption will increase.

Plastering technique

Exterior decoration of the house is considered the most important stage of construction work, as it gives the building a final image.

Finishing technology consists of several successive steps.

- First, carefully prepare the work surface. To do this, you need to install beacons on the wall and level the coating under them.

- Then priming is carried out. You can apply regular and acrylic mortar. The best will be the option with greater penetrating power.

- After the base is ready, the mixture is applied. Facing the facade is best done with coarse-grained plaster. The solution is spread over the wall with a steel spatula.

- In the event that it is necessary to decorate not the entire surface, but only a separate section, the adjacent walls are insulated with masking tape.

- The next step is to create a texture with a grater. To do this, in a circular motion, a grater is carried out over the plaster. At first, the drawing will turn out to be not very attractive. The final effect will be noticeable only after the finish has completely dried.

- The final stage is the coating of decorative finishes with a protective varnish, which will give the surface a matte or glossy look.

When working, it is necessary to observe the layer thickness, which should be equal to the grain size. The application technique is similar to the classic putty, but in this case, the plaster is slightly stretched over the surface until grooves are formed. It is impossible for the material to stick to the grater when forming patterns. If this is observed, you should give the plaster time to dry, after which you can repeat the steps.

Repair is a complex and lengthy process. After the construction of the house, the main hard work begins - finishing. This process is multi-stage, and the range of goods on the market is huge. Often in the decoration, namely plastering, the tool "Bark beetle" is used. This is a unique coating that attracts the attention of all builders.

Decorative plaster "Bark beetle" (there is a photo of it in our article) is used for the facades of buildings, as well as for interior decoration. Oddly enough, but everyone can do the work himself. True, before starting, it is worth considering the main indicators of this plaster: the pros and cons, application technology, etc. The work process should go in several stages, and you should not miss anything.

Distinctive qualities

Before you make a choice in favor of decorative bark beetle plaster (there is a photo of the coatings in our article), you need to understand why it is so good. We list its positive aspects:

- With the help of such plaster, everyone will create an unusual pattern. The main thing is the imitation of any finishing material (brick, stone, etc.). You can simply create a rough surface. Such a coating is obtained as reliable and beautiful as possible.

- It is safe for humans, as the composition is completely natural and environmentally friendly.

- The service life is long, which attracts a lot of attention. Special care is not required, which is important for many.

- The cost is low.

- In addition, the plaster is resistant to fire. Does not react to ultraviolet, humidity and corrosion.

For the listed qualities, many make a choice in the direction of such a finish. In addition, it is not required to call a specialist, because the work process is simple and accessible to people without experience.

What types of plaster are found?

Like any other material, decorative bark beetle plaster has several types. Moreover, each differs in its qualities and application methods. And another distinguishing feature is the cost. For many, this indicator comes to the fore. It will be easier to make a choice after all types of plaster are considered:

- Textured mix. It is white in color and is applied with the addition of color or in its original state. The main advantage is that the mixture is a plastic mass that is easy to work with. With the help of such decorative bark beetle plaster, interesting reliefs and unusual effects can be made. If a professional takes on the work, then with the help of it he realizes his most unique ideas, creating unique motives in the room.

- structural view. The base contains quartz granules. After the composition is on the wall, a small pattern appears and a non-uniform surface. By the way, she easily copes with flaws in the working area.

- Venetian plaster. Its masters consider it the most expensive, but at the same time it has its own characteristics when applied, and not everyone can handle it. However, the result is a beautiful wall surface with imitations of various materials. It is necessary to make several layers, while each is pre-rubbed. The composition contains marble flour, thanks to which it turns out to make a unique pattern.

- Mineral plaster. The basis is taken crumb, which can create a unique appearance. The composition remains at the first stage of application for a long time, and the price for it is low. Elements of interspersing bring their own zest, making the interior special. The composition is quite suitable for the home. This is an environmentally friendly material, which is sometimes still used in the decoration of building facades.

Decorative polymeric plaster "Bark beetle" is unique - everyone tries to choose their own version and do the work. True, masters often say that it is difficult to perform high-quality application without experience. But if you do the whole process according to the scheme, taking into account the features of each type, then everything will turn out beautifully and evenly.

Price

If we talk about the cost, decorative bark beetle plaster (25 kg) will cost about 550 rubles. In this case, the mixture has the following characteristics:

- White color.

- The water consumption per kilogram of the mixture is 250 milliliters.

- Use temperature - from 5 to 30 °C.

- The grain size is 2 mm.

- The surface area to be treated is 10 m² (provided that the layer thickness is 2 mm).

- The drying time of the mixture is 3 days.

- The density of the solution is 1500 kilograms per cubic meter.

- Water-holding capacity - about 99%.

- Adhesion strength (adhesion) is not less than 0.5 MPa.

- Shelf life - 12 months.

Differences in the composition and material of the bark beetle plaster

Decorative plaster "Ceresit", for example, has several more varieties:

- Mineral. Here, cement is taken as the basis. You don't need to have any experience to apply. The material is inexpensive.

- silicate. Liquid glass is used here. After application, a good texture is obtained. It is worth noting the long service life. A good plus is that after such a finish, the wall lets air through. This is important for living quarters. However, the cost of such decoration will hit the family budget.

- Silicone. Several tools are used in the creation process. This plaster is the most popular and reliable. But finding a quality composition is not so easy, because the market is filled with fakes. Before buying, you should pay attention to the certificates.

- Acrylic. Resin is taken as the basis. Most often used for interior decoration. But there is a downside. When exposed to sunlight, the composition changes its original color.

The manufacturer of mixtures always gives instructions on which the work takes place. But at the same time there are general rules that should not be violated. So, even beginners can succeed if:

- Do not dilute plaster with water.

- Work by hand if it contains large particles.

- Have only a special tool at hand.

Note that before starting the application, the walls are subjected to additional processing with primers. The technique of the process depends on the type of plaster chosen.

What is worth knowing?

Builders note that the surface covered with bark beetle decorative plaster attracts the eye, as it has a unique texture. It resists well to many natural influences and may not lose its properties for many years. In addition, everyone copes with the application technology. This kind of work doesn't come cheap.

Where is this plastering most often used? Best of all, such walls will look like:

- in the living room;

- bedroom;

- kitchen;

- corridor.

Although today you can find a similar coating in the bathroom. Before starting work, it is worth choosing the right type in order to achieve the desired result. As a result, any interior style is obtained in the room: classic, avant-garde, modern, etc.

Before starting work, it is worthwhile to figure out how the bark beetle decorative plaster is consumed. This will save money and time.

What is this mixture

Most often, such a finishing material contains:

- Marble chips with different particles.

- acrylic copolymers.

In addition, special fibers can be added for strength. Most often it is white, which changes simply with the addition of color (some paint the plaster). On sale there is both a dry mixture and ready-made. But it may vary depending on the manufacturer. What to look for:

- The first is the different size of the fractions. If the stones are large, then the pattern is more pronounced and interesting. Although for the room you need to choose small particles, but for the facade of the building you should make a choice towards large particles and realize your wildest ideas.

- level of adhesion. This is no less important indicator, because it depends on what surface you have to work on.

- Adhesive base.

Each manufacturer indicates in the instructions what to pay attention to, and according to these characteristics, everyone decides which composition suits him best and how to work with it.

What surfaces is it applied to?

Finishing with decorative bark beetle plaster is made only on the walls. It does not make sense to apply it to other surfaces. In this case, the walls must be solid. It is good to distribute primers over the entire area before work. On loose foundations, not a single species will be fixed. At the well-known brand Ceresit, decorative bark beetle plaster is recommended to be applied to certain surfaces. And most often the basis becomes:

- concrete;

- brick;

- stone, etc.

It is not necessary to use drywall or wood as a base, but provided that they are not covered with putty. When preference is given to the compositions that have to be prepared, then it is worth following the instructions. If something is violated, then soon the entire composition will simply depart. The consumption of the mixture depends on what grains are in it.

Surface preparation

As already noted, the surface must be reliable and even. When the area for work has no errors and all conditions are suitable, you can start finishing. If not, then you have to do the following:

- Remove old trim.

- Remove existing cracks. Gypsum putty is suitable for this, because it dries quickly.

- Then plaster is applied for leveling, and additional protective compounds are applied.

And only after that the primer is applied. This is necessary for the finish to take well. If preference is given to bulk formulations, then they are diluted depending on the data in the instructions. The composition should be made homogeneous, so it is better to use a drill with nozzles or a construction mixer. When the composition hardens, it should not be re-diluted with water. Also, you do not need to immediately make large batches, so as not to throw away unused material. Finishing one wall should not stretch for a period of two days.

After mixing the composition, wait a couple of minutes and repeat the process. The best is considered to be a mixture comparable in consistency to thick sour cream.

But it is difficult to work with a mixture that is too liquid or thick. To create any color, it is better to paint the wall after application than to add color. Since you have to constantly make batches, and it is not so easy to calculate the additional composition.

Application

How to apply decorative bark beetle plaster? For this, a spatula of medium width is used, although everyone chooses depending on personal convenience. It is better to make movements from the bottom up, trying to level the layer as much as possible.

The excess is immediately removed. Movements in work are comparable to standard puttying, when the composition is stretched along the wall. After application, they are passed over the entire area with a wooden grater (but without excessive pressure).

After 10 minutes, when the surface begins to thicken, they again pass over it with a grater. But after the first treatment, it is worth washing the tools. If sticking to the grater is observed during the second work, then it is better to wait a bit.

Depending on the movement of the tool, grooves are formed. Active movements will lead to the achievement of a smooth surface.

To make a decision and see clearly what happens, you need to practice on a drywall sheet before the main work. Before starting to create a perfect surface with a pattern, a grater or other tool is slightly moistened, and then movements are made. Much will depend on the size of the granules in the composition.

Application technology involves working on one area in one go. The creation of joints is completely excluded. However, not everyone will be able to do work on a large area at a time without experience. To do this, the cultivated area is determined, and a construction tape is fixed at its ends. It is removed after drying. When the treated area dries, masking tape is fixed on its borders, and only after that work continues. This technique completely eliminates the appearance of joints if the work is carried out gradually.

- Work will be done faster and better if it is done by two people.

- It is best when the air temperature is low. Otherwise, rapid drying and cracking occur.

- On the sunny side, you should not apply decorative plaster of the walls "Bark beetle".

- After complete drying, paint is applied to change the color. But before that, the surface is treated with a primer.

- To get a good result, they prefer the same manufacturer.

- Some sometimes use surface varnish.

- In order to please the result, at least two layers of application of any coloring agent are applied. The first must penetrate into all the cavities. But the second application is less massive and superficial. At this stage, it is important that all the convex parts are missed.

Conclusion

Many use decorative bark beetle plaster in decoration. This is a suitable option for walls and buildings. If the process is carried out in compliance with all the rules, everything turns out qualitatively and reliably. The described surface easily accepts any color solution and matches the chosen interior. However, without experience, you should not experiment and do something unusual.

To improve the facade, materials are used that not only have aesthetic indicators, but also have such characteristics as strength, resistance to natural influences, and durability.

The proven facade material is plaster: it has been used for a long time, besides, the latest technologies make it possible to produce this type of cladding with better characteristics.

How to choose a plaster for the facade and not make a mistake, we will find out in this article.

The plaster for the facade is different from the plaster used indoors.. Components are added to the facade that help to increase the strength of the material, its frost resistance, and moisture resistance.

Facade material differs in indicators:

- good adhesive properties;

- long shelf life of the dry mixture without changing properties;

- resistance to mechanical stress, strength;

- moisture resistance;

- good performance of the coating over a wide temperature range;

- does not emit harmful substances;

- easy care (some species are distinguished by the ability to self-clean);

- good vapor permeability, which provides a comfortable microclimate;

- some types have soundproofing properties;

- a wide range of.

plastered facade

With all the advantages of this type of lining, a significant disadvantage of the coating is a high degree of water absorption. When choosing this option for facade coating, you should take care of waterproofing by painting the coating.

Types of decorative plasters

Mineral

This type of cladding includes  minerals and natural ingredients.

minerals and natural ingredients.

Mineral lining is an environmentally friendly material and safe for health.

The composition of the mineral coating includes:

- lime hydrate;

- binders - Portland cements, which give the material a light tone;

- natural stone granulated;

- marble or granite chips;

- mica, glass, ground ceramics;

- colored clay;

- quartz sand;

- modifiers that enhance the qualitative characteristics of the material: its strength and ductility.

The composition of mineral plaster should not contain chemical components.

The presence of such characterizes the material as not meeting the requirements of the mineral composition.

Material advantages:

In addition to the fact that the mineral facing mixture consists of natural materials (except for modifiers), it has other positive characteristics:

- strength;

- resistance to mechanical stress;

- resistance to natural factors (snow, rain, hail);

- breathable porous structure;

- maintaining performance over a wide temperature range;

- fire resistance;

- decorative.

Material disadvantages:

The mineral-based coating has no disadvantages that could affect the choice of the buyer. The limited color palette of the material does not always make it possible to realize design tasks. To solve the problem, it can be painted in any suitable color.

mineral plaster

Acrylic

The main component of this facade coating is acrylic resin.

Acrylic plaster has a high plasticity index and is suitable for any substrate (wood, concrete, drywall, brick).

Material advantages:

In addition to the fact that the material is plastic, has high strength and resistance to the aggressive effects of natural factors, it has other positive properties:

- ease of application;

- the composition does not require dilution with water: it is sold ready-made;

- durability.

Material disadvantages:

The main disadvantage of this type of mixture is its low vapor permeability. However, acrylic resin has a high degree of weather resistance, so the vapor barrier does not significantly affect the microclimate of the building.

acrylic blend

Silicone

Front covering on a silicone basis.

The silicone type of coating, in addition to decorative design, is capable of leveling the surface of the wall when applied.

Material advantages:

In addition to the fact that silicone reliably protects walls from the influence of natural aggressive factors and mechanical damage, its service life without additional repairs can last up to twenty years.

The coating has a number of other positive characteristics:

- good thermal insulation performance;

- moisture resistance;

- the ability to let steam out;

- ease of installation;

- resistance to fungi, moss and mold;

- suitable for application in places of increased pollution;

- resistance to ultraviolet radiation.

The silicone mixture is distinguished by a variety of shades and colors.

Material disadvantages:

The main disadvantage of this type of facade decorative coating is high price. Not recommended for covering walls with external insulation.

Silicone finish

silicate

The silicate-based facade coating contains liquid glass and additional components that determine the main quality of this plaster - vapor permeability. It is advisable to apply this type of facing coating on the surface of aerated concrete. The material is flexible and easy to apply.

Material advantages:

The silicate facade coating repels water, keeping the surface dry at all times. In addition, this type of plaster has its advantages:

- ease of application;

- fire resistance;

- resistance to mechanical damage;

- economical application (it is required to cover the wall with a thin layer).

The silicate coating does not require special care and additional cleaning products.

Material disadvantages:

The main disadvantage of this type is the limited range: silicone coatings do not differ in a variety of colors and have a similar texture.

NOTE!

When purchasing silicate plaster, it should be borne in mind that when exposed to oblique rain on the facade, it is able to change color.

This is not a significant disadvantage, especially since after the coating dries, the color returns to the original.

silicate plaster

Wet plaster

Wet lining is called so precisely because a large amount of water is used to prepare it. It can be purchased in a ready-made substance, or you can prepare the coating yourself using a dry mix.

Material advantages:

Wet plaster for outdoor use is light in weight, which does not create a load on the walls, easy to clean, durable. In addition, wet coating has the following advantages:

- soundproof properties;

- low thermal conductivity;

- a wide range of palettes.

Material disadvantages:

Despite the ease of application and the low weight of the coating, wet-type plaster has a number of disadvantages, which are more related to working conditions:

- application is recommended only in warm and dry weather(it is required to take into account that for complete drying it is necessary up to two days without rains);

- in bright sun, the facade should not be applied wet in order to avoid cracking.

Wet plaster requires increased accuracy during application, it must be applied to perfectly cleaned walls.

If dust or dirt gets on the coating before it dries, this will affect the appearance of the facade.

Wet plaster

Variety of textures

The texture of the facade is solely an indicator of the decorative design of the building. This indicator does not determine the characteristics of the coating: strength, durability or moisture resistance.

Invoices for the facade can be:

- old generation (texture depth no more than 5 mm);

- modern (requires the use of modern materials).

For applying plaster, devices are used that contribute to the construction of a textured pattern: textured rollers, graters, sponges and other tools.

The classification of textures is determined by three types:

- bark beetle;

- mosaic;

- pebble.

Types of invoices

In addition, the textured coating can be painted in any color or glazed to add brightness to the facade and additional decorative effect.

The texture of the bark beetle is the most common type of design, which has several varieties:

- vertical;

- horizontal;

- circular;

- cross.

Bark beetle plaster contains special grains, which, with a certain method of application, form a pattern similar to the moves of a bark beetle.

Mosaic plaster in its composition has granules of stone chips of natural origin from one or more mineral rocks. Such inclusions ensure the strength of the coating and the decorative design of the facade.

The pebble texture is obtained from plaster containing many small pebbles.. The drawing is performed with various tools, which scratch out the desired texture.

This plaster is a universal option, since any textured solutions can be realized from it.

What is the best plaster for the facade?

It is difficult to determine the best version of the decorative facade coating, which is optimal for a particular structure.

It is important to be guided by the characteristics of the coating, which must correspond to high strength, moisture resistance, durability, as well as the feasibility of application in each case.

For example, in places with high pollution, it is advisable to choose a mixture with a high self-cleaning index(dirt-repellent), for a private house - less demanding to care, but with a good vapor barrier.

In addition to the technical parameters of the facade coating, an important indicator when choosing it is the wall material itself, on which plaster is to be applied.

Despite the fact that almost all decorative coatings can be considered universal, there are some features that can be considered when choosing a plaster.

Coatings with cement composition suitable for any type of wall and have the highest rating among consumers.

In the case of an external insulation, it is required to apply plaster on the reinforcing mesh.

For walls made of porous materials (aerated concrete or gas silicate), it is advisable to use a silicate mixture.

Any type of decorative coating is suitable for brick and block walls: brick does not require special alignment of the walls, it is not difficult to apply plaster on it.

NOTE!

You can add decorativeness, brightness and individuality to the facade of any building with the help of decorative plaster. This type of coating does not require much effort during application, durable and not expensive.

Useful video

Expert advice on choosing a facing material:

Bark beetle plaster - a mixture of texture consistency with the addition of fine marble chips to give a unique structure. It is the inclusions that determine the texture of the pattern with a fancy pattern. It can be said that wall plastering with bark beetles is not so much processing the wall with a composition with marble chips, but rather the technique of applying the mixture by one of the four main methods.

Fine finishing with decorative plaster walls is the most important work in the repair process. The appearance of the room, durability and practicality of the finish depend on the type of material. For many, it is important that the material is not only reliable, durable and long-lasting, but also does not have a harmful effect on health, and is environmentally friendly.

The walls need to be leveled before decorative finishing. For this, plaster or drywall sheets are used. You can save time and money on finishing by using a universal material, namely decorative plaster. When adding dye to the solution, you can solve several problems at once - align the walls and decorate them.

Plaster bark beetle advantages and disadvantages

You can list a number of advantages of this method of wall decoration. The first advantage - decorative plaster allows you to create the most unusual design. You can apply a pattern that imitates other wall coverings (brick, natural stone), reptile skin, or simply create a rough surface. Unlike wallpaper, finishing with decorative plaster makes it possible to realize bas-relief surfaces.

The second advantage is the safety of the material for health, it is absolutely natural and environmentally friendly. Decorative plaster does not require special care, it lasts a long time, does not lose its color and texture. The most important advantage is the resistance of the material to fire, as well as its relatively low cost.

Types of decorative plaster

Like any other type of finishing material, internal decorative wall plaster has its own varieties. Each type has its own characteristics - aesthetic, practical, operational. They also differ in price, method and complexity of application.

Horizontal application technique - bark beetle plaster

The first type includes textured plaster - it is a white mixture that is painted after application to the wall, or color is added beforehand. The material is quite plastic, this is its main advantage. You can create unique bas-reliefs, panels and other decorative effects. In the hands of the artist, decorative plaster used for interior wall decoration of a living space turns from an ordinary building material into an element of creativity.

The structural type of plaster is quartz granules. After application, a wall with a non-uniform, granular surface is obtained.

Venetian plaster is the most expensive, spectacular and rather difficult to apply. She creates unique images - imitates natural stone, making the room beautiful, interesting, luxurious. It is applied in many thin layers, each of which needs grouting. Venetian decoration with decorative plaster brings Italian luxury combined with intelligent modesty to the house.

Venetian style

Mineral plaster contains mineral chips in its composition. It creates an original appearance, is quite durable and affordable. Inclusion elements are especially relevant when decorative plaster is applied to the interior wall surface of your home.

Decorative plaster is divided into several main types. Among them:

- - structural plaster (easy to apply, easy to clean, perfectly masks minor flaws and uneven walls),

- - stone plaster (contains stone chips in its composition, therefore it is an excellent option when creating the effect of natural facing stone),

- - mineral plaster (it is environmentally friendly, it can be used not only for interior, but also for exterior wall decoration),

- - Venetian plaster (it has marble flour in its composition, therefore it is relevant when imitating the surface under natural marble).

Each consumer who prefers this material chooses for himself the type that is most suitable for his case. At the same time, of course, it is very important that the process of applying decorative plaster on the walls is carried out by professional craftsmen who are able to cope with tasks of any complexity at a high level.

The facade is finished with bark beetle plaster - vertical application technology

According to the composition and material, plasters are divided into:

1. Mineral - the composition is based on cement. The most practical and inexpensive type of plaster, easy to apply with your own hands, without requiring professional skills.

2. Silicate - the main component of liquid glass. Sufficiently durable type of finishing material, the plastered wall retains its original properties for a long time. Good vapor permeability does not clog the wall and after finishing it continues to “breathe”. A significant disadvantage of silicate plaster is the high price.

3. Silicone - a complex formula of an inorganic chain of molecules with an organic resin attached. High-quality and most demanded types of plaster mixes. Unfortunately, the high popularity has led to the fact that the market was flooded with fakes. Carefully study the quality certificate before buying silicone plaster in the store and especially in the market.

4. Acrylic - based on acrylic resin. Plaster coat, suitable more for interior work. The disadvantage of acrylic plaster is poor resistance to ultraviolet rays.

It is necessary to apply a specific type of plaster according to the instructions, which are always indicated by the manufacturer. There are a number of rules that you need to know when working with this material.

- Firstly, liquid types of plaster are not diluted with water.

- Secondly, compositions with large fillers are applied to the wall only manually.

- Thirdly, marble chips are applied only with a special spatula.

- Decorative plasters are applied to the surface of the walls, which are pre-treated with a primer. The application technique depends on the pattern and type of material.

Decorative plaster Bark beetle

Plastering is most often used for finishing facades and for decorating interior walls. It is fast and cheap, and the preservation of the appearance of the plastered surface is guaranteed for decades. One of the varieties of this finish is bark beetle plaster, which is gaining popularity from year to year. It successfully imitates the texture of wood damaged by woodworm.

Stucco bark beetle looks especially attractive in the interior of the hallway

The surface covered with bark beetle attracts the eye due to its original texture. It perfectly resists precipitation and low temperatures, has strength, does not fade in the sun. You can also note its relatively low cost and the possibility of applying it yourself. It is worth noting that you do not need to have experience in plastering to apply bark beetle. On the contrary, even a beginner can cope with the task, because the texture of the coating is able to hide all surface defects.

Plaster bark beetle emphasizes the harmony of the interior

Currently, among the actual premises where walls are finished with decorative plaster, there is a living room, a bedroom, a kitchen, a children's room, a corridor and even a hygienic space. For each option, the most suitable type of material is selected, it is determined which texture will be performed. As a result, it is possible to use products in a variety of stylistic directions: classic, modern, minimalism, avant-garde, hi-tech, country, art deco.

What is bark beetle plaster?

The plaster consists of a part of white cement, a part of marble chips with a particle size of 1-3.5 mm, and a part of an acrylic copolymer. May contain fibers that increase the strength of the coating. The standard color is white, but it can be changed with colors. You can also paint already finished surfaces.

Textured bark beetle plaster is sold as a dry mix and may vary from manufacturer to manufacturer:

- Firstly, the main difference is the size of the fraction of marble chips. A larger stone allows you to get the most pronounced, with a clearly visible textured pattern. When choosing bark beetle plaster for internal, home walls, you should buy the smallest possible fraction, then patterned stains will not be striking. When decorating the facade, it is advisable to use a large crumb - it will help emphasize the ideas of the artist.

- Secondly, different compositions of bark beetle plaster have different degrees of adhesion and are used by brand for surfaces with different textures. The overall picture can be obtained by referring to the table of mixtures from a well-known brand. Dry mixtures are separated not only by the size of the stone chips, but also by the adhesive composition. We give a table to get acquainted with the typical characteristics, which approximately correspond to the products of all well-known manufacturers.

On what surfaces can bark beetle be safely applied?

Decorative bark beetle plaster is applied exclusively on vertical surfaces, that is, on walls. It does not hold well on the ceiling, and it does not fit on the floor at all, as it has a high degree of porosity.

The walls must be solid. Or pre-plastered or coated with a deep-penetrating primer, since the bark beetle will not hold on to bulk materials. It is even better if the surface is covered with a primer like ST-16 produced by Ceresit, which contains quartz sand in its composition. In addition to hardness, such paint will deprive the surface of the ability to absorb moisture.

Concrete, brick, cinder block, stone are well suited as surfaces. Bark beetle cannot be laid on drywall and wood unless these surfaces are first coated with putty. If the surfaces are pasted over with foam, then it must be covered with a layer of putty, inside of which there is a mounting plastic mesh.

We warn you! On the packaging container, ready-made plaster mixtures, instructions for dilution are prescribed. Strictly follow the regulations, otherwise you risk getting poor quality coverage. Failure to follow the instructions will cause the material to peel off the wall and inevitably fly off after a short time. Advice from the builders

Bark beetle plaster: application technology

Surface preparation

Bark beetle plaster is well saturated with moisture, so the surfaces to be treated must be primed. If the application is made on old walls, then, in order to avoid the appearance of rust spots, all nails and screws should be removed from the wall, and the walls should be covered with waterproofing primer. For example, primer Elf D-15, Hydrostop, BOSTIK 6030, Acrylit-021 and others.

Application of the composition

It is advisable to use dry mixes, which are much easier to work with than with already diluted ready-made formulations.

1. The mixture is poured into a container with water and mixed with a mixer until sour cream is thick. In this form, it is aged for about 15 minutes, and then mixed again.

2. The solution is applied to the wall surface with a wide spatula. The ideal application thickness is the diameter of the largest crumb. For example, 2-3 mm.

Leave the plaster for 5-10 minutes until completely swollen and mix again

3. Having applied the solution to a certain area, leave it and wait until the bark beetle plaster sets. We need about 5-15 minutes, depending on the density of the solution. If the hand attached to the surface does not stick, you can apply the pattern.

Attention! If there is a delay in work, as a result of which the mixture has hardened, do not add water to the solution. This will cause the bark beetle plaster to delaminate in the near future. Advice from builders

4. The decorative pattern is applied with a plastic float. Leading it in different directions, grooves of different configurations are obtained.

We warn you: to ensure maximum quality, work should be carried out at a temperature of +5 to +30 degrees Advice from builders

5. After finishing work, for 2 days it is necessary to protect the surface from moisture and sunlight.

6. The walls are primed.

7. Surfaces are painted in the desired color.

1. It is highly undesirable to work in sections. In this case, the joints will be visible. Try to plaster the entire wall at once.

2. In hot weather, bark beetle is better not to apply. There is a high probability of rapid drying of the surface and cracking of the coating.

3. It is better to use exterior paint of the desired shade for painting.

The master, guided by the composition of the plaster, determines the application technique:

Bark beetle plaster is performed in four basic application techniques

- Chaotic character, - bark beetle plaster is applied with movements with directions executed according to the laws of chaos - not having a strict sequence. As a result, the wall strives to acquire a complex, multidirectional, unique pattern.

- circular directions clockwise or counterclockwise with a trowel will leave characteristic stains with circles of various diagonals.

- vertical stripes- leaves a trowel as a result of successive movements up and down. The technique resembles the texture of a tree bark pattern.

- Horizontal direction- less commonly used. The application is technologically similar to the vertical method, except that the progressive movements are carried out parallel to the floor covering.

Bark beetle plaster, work and application - video review Part 2:

Applying bark beetle plaster, with at least a little experience, is not difficult. The most important thing is not to skip the mandatory steps mentioned above. Then the appearance of the walls will delight you, and the coating will stand without complaints and repairs for decades.

The main purpose of facade plaster is to finish the walls of the building from the outside. This finish is affordable, the coating is quite durable and has decorative properties. To figure out which plaster is best for the facade, consider its varieties and features.

There are 5 main types of this finishing material. All of them have their advantages and disadvantages, differ in the method of application and technical characteristics.

Features of facade plasters

Plaster compositions for outdoor use differ from coatings intended for indoor use. They contain additional additives that increase the strength, frost resistance, water-repellent properties and plasticity of the coating.

Facade plaster based on cement is made with the addition of its high-strength grades (M400 and higher). The proportions of the main active ingredients also differ. So when preparing a mortar for outdoor work, the percentage of cement and sand will be 1:3, and not 1:4, as is the case with a mixture for interior decoration.

Primary requirements

Compositions for outdoor work must meet a number of requirements. Facade plaster can be considered as such only if it:

- moisture resistant;

- resistant to temperature extremes;

- strong enough to protect the facade from mechanical damage;

- vapor permeable;

- provides heat and sound insulation;

- has decorative properties.

If you live near industrial facilities, the selected facade coating must be resistant to harmful radiation. The abundance of modern finishing compositions allows you to find a plaster that meets all of the above points.

thermal insulation

A layer of any facade plaster contributes to the preservation of heat inside the building. But if the walls are thin and may not provide adequate thermal insulation, a composition with a special filler is needed for exterior decoration.

The so-called "warm" plaster additionally contains expanded polystyrene, perlite, vermiculite, foam glass or sawdust. Their addition significantly increases the thermal insulation characteristics of the walls - a 3-centimeter layer of such plaster replaces 15 cm of brickwork.

Soundproofing

Plaster can also serve as a soundproofing material. This property is useful for those who live near a highway, construction site or other noise-producing objects.

But not any plaster mix will cope with sound insulation. It should contain cement with pumice or slag, or pumice and magnesite. Porous inclusions muffle the sound, partially absorbing it.

Of course, you should not rely on plaster alone, it is effective as an aid. With a high noise level, it is necessary to use additional soundproofing materials - foam boards, mineral wool.

Color and texture

Facade plaster not only protects the walls of the house, but also decorates them. With the help of this finish, you can achieve the optimal combination of the facade with other elements of the building, choose the right color and texture.

Exterior wall plaster is available in a wide range of colors. If you need to create a pronounced texture, use a mixture with the addition of stone chips or ceramic granules.

Also, the surface of the plastered layer is treated with special floats, changing the texture of the coating. Popular patterns are created in this way, such as “bark beetle”, “lamb”, etc. More about the technology of applying “bark beetle” plaster?

Which decorative plaster is better for the facade - in each case is decided individually. With it, you can create any patterns, up to imitation of brickwork and natural materials (wood, stone).

Varieties

There are 5 types of facade plaster. They differ in composition, properties and application technology.

mineral plaster

Mineral plaster consists of slaked lime, cement grade M500 and above, stone chips, colored clay or other small fillers. Additional additives may also be present to increase resistance to mold and mildew. The plaster is sold in the form of a dry mix in bags; to prepare the solution, it is required to dilute it with water.

Apply the composition with spatulas manually or mechanically. Ready solution is suitable for work about 60-90 minutes. After drying, the coating forms a durable non-combustible layer with heat and sound insulation properties. Granules and additives provide a decorative finish.

Depending on the characteristics of a particular product, mineral plaster retains its properties at temperatures up to -25 or even -50 degrees. The service life of the finish is about 15 years.

But keep in mind that this type of coating does not tolerate vibrations well. The use of mineral facade plaster is not recommended near railways, as well as in areas with seismic activity.

Acrylic plaster

In acrylic facade plaster, instead of cement, acrylic resins serve as a binder. In addition to them, the composition contains:

- modifiers that increase strength, ductility and other technical characteristics;

- dyes responsible for the color of the coating;

- filler (sand, granules, stone chips), which creates the surface structure.

Acrylic plaster is sold as a ready-made solution suitable for application. The service life of such a coating is about 15-25 years. Plaster with the addition of acrylic is resistant to temperature extremes, but easily attracts dirt. However, it is easy to clean it by pouring water from a hose.

Before applying the acrylic coating, dust and residues of the previous finish must be removed from the surface of the walls. If there are places affected by fungus and mold, they are pre-treated with a special antiseptic.

Acrylic plaster sets in 20 minutes, but it takes up to 48 hours to dry completely. At this time, the coating must be protected from direct sunlight to avoid cracking. Due to the rapid hardening, noticeable joints of the layers often form, so the work should be done by professionals.

Silicone

Silicone facade plaster contains silicone resins, filler, coloring pigments and additives that increase the durability of the material. It is available as a ready solution.

Among the advantages of silicone coating is increased moisture resistance, elasticity, self-cleaning ability, ease of application. The service life of such plaster is 20-25 years. Its only drawback is the high price.

The solution adheres well to any surfaces previously cleaned of dust and dirt. The application technology and drying conditions for silicone plaster are similar to those for acrylic mixtures.

silicate

Another expensive, but high-quality material is silicate plaster. It contains the same substances as the mineral, but there is one additional component - liquid glass.

Silicate plaster is sold in the form of a solution. Just like silicone mixtures, it has antistatic properties, that is, it repels dust. The finished coating has increased abrasion resistance, water resistance and elasticity. Service life - 25 years or more.

Of the minuses of silicate plaster, it should be noted that it hardens too quickly after application. Because of this, only a professional who can do the job without errors the first time can do plastering. In addition, silicate plaster requires the use of a special primer.

Cement

Cement plaster is a time-tested composition. This inexpensive type of finishing material has been used in Russia for cladding interior and exterior walls for decades. Its basis, as the name implies, is cement. The composition also includes lime or sand, and other additives that increase strength may be present.

The mixture is sold in powder form and is diluted with water immediately before use. Cement plaster comes in different shades, but the color range is very limited. This problem can be solved by subsequent staining.

The obvious disadvantages of cement plaster are the need to independently prepare the mortar and low decorative qualities. The coating is also inferior in terms of service life, on average it is 10 years.

Wet plaster technology

Probably, many have heard the term "wet plaster". It means plastering on top of a multi-layer "pie" of primer, insulation and reinforcing mesh. This facade decoration takes the dew point outside the house, taking on the condensate. As a result, housing is dry and warm, an optimal microclimate is created.

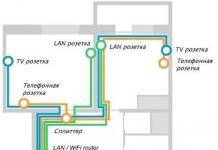

The thickness of the layers and their sequence may be different, but more often the order is as follows:

- Foundation (wall).

- Fixing primer.

- adhesive layer.

- Thermal insulation material fixed with dowels.

- reinforcing layer.

- Primer to improve adhesion.

- Decorative plaster.

It is very important to choose the right thermal insulation material. What insulation is better for a facade under plaster? A good option in this case is OSB boards, mineral wool or polystyrene foam. They are moisture resistant and reliably retain heat.

Advantages and disadvantages of facade plaster

Facade plaster, like any finishing method, has strengths and weaknesses. Its various types differ significantly from each other, but it is still possible to distinguish the qualities common to this group of facing materials.

The advantages of plaster for outdoor use include:

- fire resistance;

- thermal insulation properties;

- resistance to temperature extremes;

- the ability to perform work without special equipment;

- light weight of the material;

- fast obtaining of a decorative covering.

But there are also disadvantages. The resistance of plaster to mechanical stress is lower than that of ceramic panels, wall tiles and other similar materials.

If we are talking about a decorative coating, its creation will require professional skills. In addition, work can only be done at temperatures above +5 degrees, and complete drying with a thick layer of plaster will take a lot of time.

How to choose?

The choice of facade plaster depends on the material of the walls of the task, the operating conditions of the coating and the requirements for it. Whether to purchase a composition with granules or with a smooth texture is a matter of taste. The same applies to color design.

If you think that the house needs additional insulation, pay attention to compounds containing perlite, vermiculite, foam glass, etc. For those who wish to repair the facade less often, plaster with increased strength - silicate or silicone - is suitable.

Ready mix

In cases where you need to do the work quickly, and there is little experience in this matter, it is better to purchase ready-made compositions. With them, there is no risk of making a mistake when mixing the solution. The finished mixture has other advantages - convenient storage and transportation.

Selection of plaster for a specific surface

The answer to the question - which plaster will be better for the facade, directly depends on the material of the walls. Even a high-quality plaster composition may not live up to expectations when applied to an unsuitable base.

Optimal combinations of types of facade plaster and base material:

- Brick walls - cement or silicone mixture.

- Aerated concrete - silicate or silicone composition.

- Wooden walls - silicate plaster.

- Insulation boards - an acrylic-based composition applied over a reinforcing mesh.

- Other options are a silicate mixture.

Facing with decorative plaster is a modern, inexpensive and reliable way to decorate the facade of a house. Subject to the application technology and the compliance of the base material with the composition of the mixture, you will definitely get a durable and decorative coating. If you plan to create a complex pattern, but you don’t have the necessary skills, you should contact professional builders.

Useful video: how to choose decorative plaster?

It is necessary to plaster the facade of the house, about 250 m2. house from gas silicate blocks. Insulation with foam plastic or mineral wool is not needed. Question - which of the manufacturers of bark beetle plaster to choose and why? and it is also interesting to hear the variants of facade plastering technology. The whole process from the very beginning, the priming of the blocks - the installation of beacons - the installation of fiberglass mesh and plastering on the mesh how many times? then bark beetle. Thank you.

For aerated concrete, special mixtures with high vapor permeability are used, for example, ceresite ST 24. Work is carried out in the following order: 1) primer diluted by half with water 1 layer, 2) primer not diluted 1 layer, 3) spraying with plaster ceresite ST 24 with the addition of adhesion additive ceresite CC81, 4) application of ST 24 plaster on lighthouses (the layer must be at least 15 mm!) 5) application of ST 16 ceresite primer, 6) application of ST 174/175 silicate-silicone decorative plaster ceresite. Between points 5 and 6, it is possible to create a base reinforcing layer with a fiberglass mesh, while using CT190 ceresite glue. Why ceresitis? Because, among various manufacturers of facade materials, ceresite was selected by selection as the optimal price / quality ratio. It is clear that these works require experienced specialists or technical supervision/support.

your finishing option makes sense only if there are very even walls. if the walls are crooked, then it’s easier to install a heater and then the whole system (wet facade) there are many options for the material .... for your pocket ... I work with caparol satisfied

www.avangard-teplo.ru

Take "bark beetle" only on acrylic basis, no "silicone" ... The manufacturer is not so important, I like Veber

Dear Colleagues. We kindly ask you to give convincing arguments to your answers and advice ..))). Why only acrylic bark beetle??? Why not acrylic?

The photo shows a house finished with mineral decorative plaster, Knauf diamond and painted with acrylic paint, the facade is 5 years old.