The easiest and most practical way to make a deep metal detector with your own hands is to make a deep pulse metal detector. As a basis, you can take an existing pulse metal detector, or make an electronic unit of a pulse metal detector, etc. How to make these metal detectors is already described on our website. And then you need to make a deep coil to it.

In this article, we will explore with how to make depth coils for pulsed metal detectors. Such coils can be used with Pirate, Clone, Tracker, Koschey and other pulse metal detectors.

But it should be noted that with the same dimensions of the depth frame, with different metal detectors, different detection depths also wake up (With the Pirate, the results will be the most modest, and the best result is shown by Koschey 5IG and Koschey 4IG (trackerPI-G) because they have a separate deep firmware!

Let's start with the mechanical designs of deep frames for a metal detector.

Depth frames small sizes, are installed on the rod like a conventional coil, but there are restrictions on weight and dimensions. Therefore, this design is suitable for frames with a diameter of up to 60-70cm. The large frame becomes too heavy and uncomfortable to wear in this way.

Depth coil frame for metal detector made of plastic pipes, without the use of metal elements. You choose a pipe depending on the way in which you will connect it, and depending on the size of your frame, so that the pipe provides sufficient structural rigidity!

Small coils are usually made non-separable in the form of a ring or square.

Here are some photos of such frames:

![]()

For frames of large sizes, the non-separable design is already inconvenient for transportation, and it is already difficult to carry such a frame on the bar. The most common solution for large frames is a collapsible square frame with an overhead search loop or a loop passed inside the tube frame.

In this case, the frame frame is made of plastic pipes, and the search coil is wound with a stranded wire in insulation! THE WIRE MUST BE MANDATORY STRANDED, since when disassembling and transporting the deep coil, the wire will bend and the single-core wire may eventually break!

Such frames are usually worn together:

But there are design options for a deep metal detector for self-carrying:

But there are design options for a deep metal detector for self-carrying:

Here are some more design options for deep metal detectors and their coils:

Here are some more design options for deep metal detectors and their coils:

Depth frame winding

Table of the number of turns for depth frames of various sizes and their maximum detection depth with PIRAT and Koschey 5I metal detectors:

| 40*40cm | 60*60cm | 90*90cm | 120*120cm | 150*150cm | |

| Number of turns | 19 | 16 | 13 | 11 | 10 |

| Detection range helmets with MD PIRATE | 0.8m | 0.9m | 1m | 1.1m | 1.25m |

| Maximum range PIRATE | 1.7m | 2.3m | 2.6m | 3m | 3.5m |

| Detection range helmets with a metal detector Koschey 5IG | 1m | 1.2m | 1.25m | 1.5m | 1.6m |

| Maximum range metal detector detection Koschey 5IG | 2.3m | 3m | 3.5m | 4m | 5m |

It is advisable, after winding the frame, to tighten the turns together with electrical tape or tape, this will reduce the interturn capacity and make the loop more durable. The wire from the frame to the electronic unit can be made from the same wire with which the frame is wound, twisting it in increments of 1 turn per 1 cm. And then crimp it with heat shrink tubing or wrap it with electrical tape.

This is how you can easily make a deep frame for an impulse metal detector, and get a full-fledged deep metal detector that is not inferior in depth to branded metal detectors.

How they differ from conventional detectors and where it is best to use them, let's look at examples.

Principle of operation

Any metal detector generates a magnetic field around the coil transmitter. Due to this, a magnetic flux also appears at the target under the coil, which catches the coil receiver. This magnetic flux is then converted into visual information on the screen and into an audio signal.

Conventional ground metal detectors (VLF) generate a constant current in the transmitter coil, and changes in the phase and amplitude of the voltage at the receiver indicate the presence of metal objects. But devices with impulse induction (PI) differ in that they generate a transmitter current that turns on for a while, and then turns off abruptly. The coil field generates pulsed eddy currents in the object, which are detected by analyzing the attenuation of the pulse induced in the receiver coil. This cycle repeats continuously, perhaps hundreds of thousands of times per second.

Advantages of metal detectors with pulsed induction

1. The detection speed does not depend on the material between the metal detector and the target. This means that the search can be conducted through air, water, silt, corals, various types of soil.

2. Sensors are highly sensitive to all metals and do not react to high levels of soil mineralization, hot stones and salt water.

3. You can search for metal objects and find them at a greater depth, it works especially well on mineralized soils.

4. There will be no interference in mineralized soils, salty sand, salt water, and the performance will be higher than that of VLF detectors.

5. Pulse induction metal detectors have been specially designed to find gold objects, even very small ones (nuggets, chains).

The disadvantages of metal detectors with pulsed induction may be not very good discrimination and high price.

Where do pulse induction metal detectors perform best?

The pulse repetition rate (transmitter frequency) of a typical pulse induction metal detector is approximately 100 hertz. Different models of MD use frequencies from 22 hertz to several kilohertz. The lower the transmission frequency, the greater the radiated power. At lower frequencies, a greater depth and sensitivity of detection of objects made of silver is achieved, however, sensitivity to nickel and gold alloys decreases. Such devices have a slow response, so they require a very slow movement of the frame.

Higher frequencies increase the sensitivity to nickel and gold alloys, but are less sensitive to silver. The signal may not penetrate as deep into the ground as at lower frequencies, but you can move the coil more quickly. This allows you to check a large area for a given period of time, and also such devices are more sensitive to the main beach finds - gold items.

Thus, it is best to use PI-metal detectors for beach search on the coasts of the seas and oceans, underwater search, gold search, search in desert and mountainous areas. They are also good at cleaning up “knocked out” terrain and during geological exploration.

Top 5 best metal detectors with impulse induction:

Hello! I haven't written here for a long time. There were a lot of things to do ... It's already spring outside the window, the second day the temperature is kept at 9-10 degrees. The snow is slowly melting away. The opening of the season is just around the corner. So, one of the things that would help pass the time and bring the season closer was assembling a metal detector from scratch with your own hands. The result makes me happy :)

Who can not wait, a video with the work of this miracle:

It all started with the fact that I finally got a foil textolite without paying a penny for it)). The first step for testing this textolite) was the assembly of a metal detector.

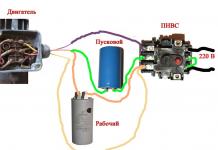

For assembly, the “Pirate” impulse metal detector scheme was chosen, because it was not a desire to make a device on beats). So, the circuit is loaded, the Sprint Layot program is installed, the printed circuit board is printed on photo paper. I start assembling.

The board was made using the laser iron method (LUT for short). I will not paint in detail, there is Google for this matter :). That's it, the textolite is cut out, the tracks are transferred to the board.

Next, I dilute the pickling solution. And then the electrolyte from the battery helped me again! The solution included table salt, hydrogen peroxide and an electrolyte (in the evening of the same day, a kitten knocked over a jar with a solution).

Well, the board is etched, the holes are drilled. Now it must be tinned. Tinning was done with a soldering iron.

It's time for the longest part of the build. Namely, the collection, search and soldering of parts. Both microcircuits and two transistors were found without difficulty. Capacitors and resistors pulled from old boards. But I did not find a few resistors. They had to go to the TV room for them. They gave it to me for FREE.

The board is assembled, the experimental coil is wound. It's time to turn on. The first inclusion was made from a twelve-volt power supply. I twisted the wires, connected the coil, rechecked the polarity, turn it on ... it doesn’t work ... it’s silent (. The transistor is heating. I soldered it. I turn it on again ... silence. Subsequent checks revealed a malfunction of the K157UD2 microcircuit. life It works!!! It was a lot of joy :)

The next day, the scheme was adjusted and received a cultural building. Connectors removed. Now I needed a normal coil. I cut it out of a piece of plywood. Then he picked up the number of turns, filled the winding with hot glue and wrapped it blue tape.

Now material for the bar was required, which was the subject of the next day. I bought 4 meters of PVC water pipe and 0.5 meters of sewer pipe. From them, the corresponding parts for the collection of the rod were cut. The pipes were soldered with hot glue and a hair dryer.

The rod is assembled, the coil is ready, the body of the device has acquired the proper form. It remains to combine everything. The block is attached to the bar with fittings. But for mounting the coil in the store there was no plastic bolt. The coil is still temporarily held on the screed.

It remains only to buy a battery with a charger. Works with a battery from a screwdriver :).

At home, the device begins to respond to a penny from 20 cm, which I think is not bad. I will also say that it does not have discrimination, so it is impossible to cut off the metal garbage so hated by all diggers.

I was completely satisfied with the assembly process and the results obtained, and I think I improved my amateur radio skills a little by applying new methods in my practice.

So, my investment (except for buying a battery) took 230 rubles. With a battery, I think it will be about 1000 rubles. This device can be easily recouped and even earned by searching for scrap metal with it. The search for coins is also possible, but due to the lack of discrimination, it will be difficult.

Let me tell you about the photos. I made them for myself, so their quality is a little watery :)

I also advise you subscribe to the channel "Old Vyatka", where you will find many videos about detecting, metal detectors, navigation, cartography and coin care:

Continuous operation at maximum depth settings can help retrieve deep targets. Otherwise, adjusting the depth is impractical. It is best to test the increase in detection depth in a specially prepared place in the field or on your own land.

Here 9 tips how to achieve maximum depth performance of a metal detector coil.

1. Sensitivity

Adjusting the sensitivity is the most popular way to increase depth. Usually, as the sensitivity increases, so does the depth. But keep in mind that there are by-effect, as setting the sensitivity too high can reduce the chance of identifying a target, as well as drive you crazy with constant erratic sounds.

2. Ground balance

Every modern metal detector usually has a ground balance function. Correctly identifying it and installing it is a direct way to increase depth. After all, a lot depends on the mineralization of the soil, including the depth at which you will detect targets.

3. Sweep the coil as close to the ground as possible

Simple calculation: if you can bring the coil closer to the ground by 1.5 cm, then the detection depth will increase by the same 1.5 cm. Sometimes this is enough to catch a weak signal from a coin. Sometimes the grass makes it difficult to move the coil closer to the ground. In this case, take a larger and heavier coil, it is easier for it to crush the vegetation. However, take care of its additional protection.

4. Reduce discrimination

Very deep targets are often detected incorrectly by a metal detector. But you will never detect these many false positives if the level of discrimination is too high, for example, as with the Coin programs. Reducing discrimination to a minimum can lead to success. Maybe you will dig up an ancient artifact, not just another nail.

5. Interference elimination

There is a lot of interference in civilized places, as well as near power lines and buried cables. Working electrical appliances also emit a lot of noise. Usually in such cases, reduce the sensitivity, and this reduces the depth. Therefore, it is better to try to work away from interference. Also turn off your cell phone and remove all metal objects from your pockets. Do not wear shoes with metal elements. Do not stack the cables from the reel onto the reel itself.

6. Special settings and devices

Study the instructions for your metal detector inside and out. Your device may have some unique features that can help you hear and see deep targets better. Some detectors are specially designed to amplify deep but weak signals, for example, recently there has been some revival among domestic search engines about the deep firmware of the AKA Signum MFT metal detector. Or the use of deep nozzles also gives a good result. XP released one recently for the Deus.

7. Large coil

Larger searchcoils provide greater detection depth and clearer readings from targets. Carefully! A large reel can carry a lot of weight. Therefore, it would be good to purchase a special unloading for the metal detector, which makes it easier to carry the device. Recall that a large coil cannot be effective on areas heavily littered with iron and on highly mineralized soils.

8. Experiment with speed

For example, moving fast with the Fisher F75 has a better chance of detecting deep targets than moving slowly. Again, refer to the user manual and tirelessly test - what speed of movement for your metal detector gives a deeper penetrating signal.

9. Wear headphones

If you use a conventional metal detector speaker, then you can quite naturally not distinguish signals from deep targets. With headphones, you are distracted from external noise and pick up fast, weak signals. If for some reason you do not want to use headphones, then try to conduct a series air tests and memorize sounds for the most distant purposes. Sometimes tiny, imperceptible changes in the audio tone do not show up on the detector's display.

Principle of operation

The search head-emitter (inductance 0.2-0.3 μH) of a pulsed metal detector is supplied with pulses with a repetition rate of 40 - 200 Hz of high current (up to 20 A) and voltage up to 200 V. If there is no metal object near the emitter, then the trailing edge of the pulse stays short. In the case of a close location of a pipe, cable or something conductive, the trailing edge is tightened.

Fig.1. Pulse Metal Detector Timing Diagram

Based on the analysis of the transient process, one can judge the presence of not only a metal object, but also the type of metal.

Structural scheme

The device is based on a circuit developed by Yu.Kolokolov, with the processing of pulse parameters using a microcontroller. This made it possible to simplify the circuitry of the device without reducing the technical characteristics.

Specifications metal detector:

Supply voltage: 7.5 - 14 V.

Current consumption: 90 mA.

Depth of detection:

- a coin with a diameter of 25 mm: 0.23 m;

- pistol: 0.40 m;

- helmet: 0.60 m.

Fig.2. Structural diagram of a metal detector

The "highlight" of this circuit is the use of a differential amplifier in the input stage. It serves to amplify the signal, the voltage of which is higher than the supply voltage. Further amplification is provided by the receiving amplifier. The first integrator is designed to measure the useful signal. During direct integration, the useful signal is accumulated, and during backward integration, the result is converted into digital form. The second integrator has a large integration constant (240 ms) and serves to balance the amplifying path with respect to direct current.

Schematic diagram of a pulsed metal detector is shown in fig. 3.

Fig.3. Schematic diagram of a metal detector

A powerful key is assembled on a field-effect transistor VT1. Since the IRF740 field effect transistor has a gate capacitance of more than 1000pF, a preliminary stage on the VT2 transistor is used to quickly close it. The opening speed of a powerful key is no longer so critical due to the fact that the current in the inductive load increases gradually. Resistors R1, R3 are designed to "quench" the energy of self-induction. Protective diodes VD1, VD2 limit the voltage drops at the input of the differential amplifier.

The differential amplifier is assembled on D1.1. Chip D1 is a quad operational amplifier TL074. Its distinguishing features are high speed, low consumption, low noise level, high input impedance, as well as the ability to work at input voltages close to the supply voltage. The gain of the differential amplifier is about 7 and is determined by the values of the resistors R3, R6, R9, R11. The receiving amplifier D1.2 is a non-inverting amplifier with a gain of 57. During the action of the high-voltage part of the self-induction pulse, this coefficient is reduced to 1 using the analog switch D2 .1 which prevents overloading of the input amplifying path and provides a quick entry into the mode for amplifying a weak signal. Transistors VT3 and VT4 are designed to match the levels of control signals supplied from the microcontroller to analog switches.

With the help of the second integrator D1.3, the input amplifying path is automatically balanced by direct current. Integration time 240 ms. is chosen large enough so that this feedback does not affect the amplification of the rapidly changing useful signal. With this integrator, the output of amplifier D1.2 is maintained at +5 V in the absence of a signal.

The measuring first integrator is made on D1.4. At the time of integration of the useful signal, the key D2.2 is opened and, accordingly, the key D2.4 is closed. A logical inverter is implemented on the D2.3 key. After the integration of the signal is completed, the key D2.2 closes and the key D2.4 opens. The storage capacitor C6 starts to discharge through the resistor R21. The discharge time will be proportional to the voltage that is established on the capacitor C6 by the end of the integration of the useful signal. This time is measured by a microcontroller that performs analog-to-digital conversion. To measure the discharge time of the capacitor C6, an analog comparator and timers are used, which are built into the D3 microcontroller.

The AT90S2313 microcontroller also includes an 8-bit RISC processor with a speed of 10 MIPS, 32 working registers, 2 kilobytes of Flash ROM, 128 bytes of RAM, and a watchdog timer.

With the help of LEDs VD3...VD8 light indication is made. Button S1 is intended for the initial reset of the microcontroller. Switches S2 and S3 set the operating modes of the device. Using a variable resistor R29, the sensitivity of the metal detector is adjusted.

Functioning algorithm

To clarify the principle of operation of the described pulse metal detector, below are oscillograms of signals at the most important points of the device (Fig. 4)

Fig.4. Instrument waveform

For the duration of interval A, the key VT1 is opened. A sawtooth current begins to flow through the sensor coil. When the current reaches about 2 A, the key closes. On the drain of the transistor VT1 there is a self-induction voltage surge. The magnitude of this surge is more than 300V and is limited by resistors R1, R3. To prevent overloading of the amplifying path, limiting diodes VD1, VD2 are used. Also for this purpose, for the time of interval A (accumulation of energy in the coil) and interval B (ejection of self-induction), key D2.1 is opened. This reduces the end-to-end gain of the path from 400 to 7. Oscillogram 3 shows the signal at the output of the amplifying path (pin 8 D1.2). Starting from the interval C, the switch D2.1 closes and the gain of the path becomes large. After the end of the guard interval C, during which the amplifying path enters the mode, the key D2.2 opens and the key D2.4 closes - the integration of the useful signal interval D begins. After this interval, the key D2.2 closes, and the key D2.4 opens - "reverse" integration begins. During this time (intervals E and F), the capacitor C6 is completely discharged. Using the built-in analog comparator, the microcontroller measures the value of the interval E, which is proportional to the level of the input signal. For firmware versions V1.0 and V1.1, the following interval values are set: A - 60...200 µs, µs, B - 12 µs, C - 8 µs, D - 50 µs, A + B + C + D + E + F (recurrence period).

The microcontroller processes the received digital data and indicates the degree of impact of the target on the sensor using the VD3...VD8 LEDs and the Y1 sound emitter. The LED indication is an analogue of a pointer indicator - in the absence of a target, the VD8 LED lights up, then, depending on the level of exposure, VD7, VD6, etc. light up sequentially.

It is recommended to set up the device in the following sequence:

- make sure the installation is correct;

Apply power and make sure that the current consumed does not exceed 100 mA;

- instead of resistor R7, install a variable resistor and rotate its rotor to achieve such balancing of the amplifying path so that the waveform at pin 7 D1.4 corresponds to waveform 4 (Fig. 4). In this case, it is necessary to ensure that the signal at the end of the interval D is unchanged, i.e. the waveform at this location should be horizontal. After that, the variable resistor must be measured and replaced with a constant of the nearest rating.

You can assemble the metal detector from the parts of the NM8042 kit, released by the MASTER KIT company and including a printed circuit board, a case, a complete set of parts and assembly instructions.

Fig.5. Assembled metal detector from NM8042 MASTER KIT

search head

The search head for a metal detector is one of its most important parts. The quality of its manufacture depends on how the device will work.

Coil data - diameter 19 cm, number of turns 27, PEV wire, PEL 0.5 mm, cable for the coil - two-wire, stranded unshielded wire in rubber insulation. This head provides the sensitivity of detecting a coin of 5 kopecks (USSR) at a distance of 19-20 cm in air.

Fig.6. Single circuit head

A single contour search head with a diameter of 19 mm does not have sufficient sensitivity to small metal objects (for example, jewelry), while a small one has a small search depth. You can combine search depth with sensitivity to small objects by making a dual-circuit search head.

Fig.7. Dual circuit head

On pieces of fiberboard we mark the contours of the future coil (outer diameter 200 mm, inner diameter 90 mm, wall thickness 18 mm). We wind coils. On sending with a diameter of 19.2 mm - 25 turns, on a mandrel with a diameter of 84 mm - 5 turns. We impregnate the coils with varnish and put them in the grooves, connecting them in series. We start the cable, solder the ends, insert the cable gland. We put the coil upside down with a groove and fill the groove with epoxy resin. After polymerization, we turn the coil over, glue the ears and cover the entire surface with epoxy in 2 layers. We unsolder the plug, wrap the cable with tape to protect it from paint and paint the coil 2-3 times.

The design of the coil allows you to localize 1 kopeck (USSR) at a distance of 100 mm. The center of the object is very easy to determine, since the sensitivity diagram for small objects is tapered (1-2 cm larger in the center).

Upper stem

For the manufacture of the upper rod of the metal detector, a piece of duralumin, copper or brass pipe with a diameter of 22 mm and a wall thickness of 2 mm is required. Its length is 120-140 cm. An S-shaped bar is bent out of the pipe using a pipe bender (see Fig. 8).

Fig.8. Rod drawing

An armrest is cut and bent from sheet metal 1.5 - 2.5 mm. The armrest is attached to the bar with an M6 bolt. Under the armrest is a container for batteries. The power wire is passed inside the rod and brought out through a hole with a diameter of 5 mm in the area of the electronic unit. The plastic tightening sleeve is taken from a retractable window cleaning brush. The inner diameter of the tightening element of the coupling is 16 mm, the outer diameter is 20 mm. The tightening element is glued into the rod for epoxy resin. The neoprene handle can be replaced with a piece of rubber hose or a foam roller.

Lower stem

The lower rod is wound on a mandrel with a diameter of 14 mm from 6 layers of fiberglass until a diameter of 16 mm is obtained. Rod length - 500-750 mm. In my version, the bar is made of 2 pieces of 370 mm each.

General form device is shown in fig. nine.

Fig.9. General view of the device