Insulation of the roof of the house is an important stage in the construction or overhaul of the roof. The choice of technology for installing a heat-insulating layer depends on the configuration of the roof, the type of insulation and the requirements that apply to the room located directly under the roof.

The need for roof insulation

How to insulate the roof to significantly reduce heat loss at home? First of all, you need to choose the right materials for insulation and strictly adhere to the installation technology. A high-quality insulated roof increases the thermal efficiency of the house by 15%, and allows you to turn the attic into a room suitable for year-round use.

The highest requirements are placed on the insulation of the roof of the residential attic of houses located in areas with cold winters. The roofing cake of summer attics or exploited attics may include a thinner layer of thermal insulation. The roof, under which an unused attic is located, is usually not insulated - thermal insulation is mounted on the floor of the attic or the ceiling of residential premises. An uninsulated non-residential attic is well ventilated, which prevents the wooden elements of the roof frame from rotting.

When installing pitched and flat roofs, different methods of roof insulation are used.

Flat roof insulation

How to make an insulated roof when installing a flat roof? It should be noted that a flat roof can be insulated both from the outside and from the inside.

The composition of the flat roof pie includes:

- vapor barrier;

- heat insulator;

- waterproofing layer of rolled material;

- bulk layer (drainage + cement-sand mixture).

External insulation is most conveniently performed using mineral basalt wool. You can also use expanded polystyrene and other rigid insulation. At the same time, it should be borne in mind that polymeric heaters cannot be used when installing roofing with high fire safety requirements.

Pitched roof insulation

The roofing pie of a pitched roof is made with insulation along the rafters. It is important to figure out how to properly insulate the roof of the house in order to prevent mistakes that will eventually lead to damage to wooden structures.

The most popular insulation in private housing construction is mineral wool. It is an easy-to-install non-combustible material that can be purchased at a low price. But the very structure of cotton wool contributes to the accumulation of moisture, which causes a significant decrease in the thermal insulation properties of the material, and also, over time, provokes decay of the elements of the truss system. Thus, when creating insulation, it is important to provide for proper ventilation and steam and waterproofing of the roofing pie.

Installation of a pitched roof heat insulator is carried out from the side of the attic during the construction or repair of the roof. If repair work is underway, before laying the insulation, it is necessary to check the condition of the rafters - rotting elements must be replaced with new ones. It is also worth treating all wooden structures with a fire-retardant composition.

Pitched Roof Pie Includes:

- finishing roofing;

- hydrobarrier (layer of waterproofing material);

- heat insulator;

- vapor barrier;

- interior decoration (optional).

Proper roof insulation requires high-quality air exchange, for which it is necessary to create air gaps between:

- roofing waterproofing and roofing;

- insulation and hydrobarrier;

- vapor barrier and inner lining (if provided).

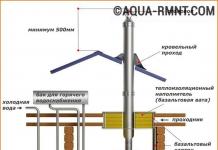

Air circulation (free inflow and removal) is provided by special air ducts, one of which must be located in the roof overhang, and the second - under the ridge.

Materials for thermal insulation of a pitched roof

Roof insulation technology involves the use of various materials. The most popular heat insulators include mineral wool and glass wool (in slabs or rolls), plate polymer materials - polyurethane foam, expanded polystyrene. The principles of their installation are similar, but it is worth noting that it is much easier and more convenient to mount plate material.

As a waterproofing, roofing material or a waterproofing membrane is usually used, impervious to water, but capable of removing moisture from the insulation. The vapor barrier can be made from:

- roofing material;

- polyethylene film;

- parchment;

- foil materials laid with foil towards the attic.

To create a roofing cake with high functional characteristics, it is recommended to use a special vapor barrier membrane to create a vapor barrier: it removes condensate outward from the insulation and does not let steam and moisture into the roofing cake.

Stages of work on the insulation of pitched roofs

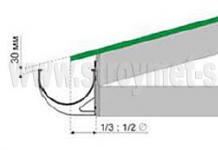

The scheme of roof insulation is quite simple. First of all, you need to measure the distance between the rafters. Cotton wool insulation boards should be cut according to the results obtained, adding 1 centimeter. This will allow you to fix the heat insulator by surprise between the rafters. This stage of work is greatly simplified if the roofing system is initially designed and installed for the use of plate heaters of a certain width.

If there is no waterproofing between the rafters and the already installed roofing, the hydro-barrier must first be fixed. The membrane should envelop the rafters, it is most convenient to fix it with a construction stapler to the rafters themselves and to the roofing sheathing in the openings between them. The waterproofing must be led under the overhang at the bottom of the roof to ensure the removal of moisture. It should be borne in mind that with this method of attaching the hydrobarrier, the insulation has to be mounted without the necessary air gap. For this reason, it is recommended to use a superdiffusion membrane as a waterproofing.

If there is a waterproofing layer under the roofing, nails are stuffed onto the rafters in increments of about 10 cm. The nails should be located at a distance of 3-5 cm from the waterproofing layer. Between the nails it is necessary to stretch the polyethylene thread or cord, knocking them to the end. This will help create an air gap between the hydrobarrier and the insulation. If the heat insulator is planned to be fixed with a cord, and not with a sheathing for the inner lining, nails must also be stuffed along the outer edge of the rafters.

If, when determining how to insulate the roof of the house, a cotton slab insulation was chosen, then the prepared elements must be slightly squeezed and inserted between the rafters. When using stiffer foam boards and similar materials, it is important that they are accurately sized so that the boards fit snugly into the opening. Warming is recommended to be carried out in two layers. If it is necessary to mount in the opening not solid sheets, but narrower fragments, joining them in length or width, it is necessary to ensure that the joints of the second layer do not coincide with the joints of the first. The heat insulator should not protrude beyond the plane of the rafter legs. If the rafters are not wide enough to mount two layers of insulation, an additional beam is nailed to them.

If, when determining how to insulate the roof of the house, a cotton slab insulation was chosen, then the prepared elements must be slightly squeezed and inserted between the rafters. When using stiffer foam boards and similar materials, it is important that they are accurately sized so that the boards fit snugly into the opening. Warming is recommended to be carried out in two layers. If it is necessary to mount in the opening not solid sheets, but narrower fragments, joining them in length or width, it is necessary to ensure that the joints of the second layer do not coincide with the joints of the first. The heat insulator should not protrude beyond the plane of the rafter legs. If the rafters are not wide enough to mount two layers of insulation, an additional beam is nailed to them.

The heat insulator is fixed between the rafters with a stretched cord fixed on pre-stuffed nails. Or, as a fastener, a crate of slats is used, designed for mounting the interior cladding of the room. The slats are nailed to the rafters in increments of 30-40 cm. In this case, the vapor barrier is fastened with a stapler to the rafters before the lathing is installed: the thickness of the slats allows you to create the necessary air gap between the vapor barrier and the sheathing.

When installing the vapor barrier, special attention is paid to the tightness of the layer. The panel is laid with an overlap of at least 10 cm, the joints should be glued with adhesive tape in two layers. It is necessary to perform the installation of a vapor barrier around the chimney and at the junctions with the walls with the highest quality. At the final stage, the cladding is installed using wood-containing or gypsum boards.

How to insulate the roof of a house correctly: video, insulation scheme, methods

Find out how to properly insulate your roof. Watch the video on how to insulate the roof of a house using various schemes, methods and types of insulation

How to insulate the roof with your own hands

When building a private house, attention should be paid not only to the thermal protection of walls and floors, but also to the insulation of roof structures. The temperature and humidity conditions of the room, and even the service life of structures, depend on the literacy of roof insulation measures. Work on the installation of thermal insulation material can be done by hand.

The need for insulation

Everyone knows from the school physics course that heated air rises. If there is no thermal insulation, nothing prevents him from leaving the building. Because of this phenomenon, a large amount of heat loss occurs precisely through the roof or attic floors. Lack of adequate protection against cold and warm air loss can lead to the following problems:

- lowering the temperature in the room;

- increased heating costs in winter;

- condensation on the inner surface of the roof;

- the appearance of mold or fungus on the elements of the roof;

- destruction or damage to load-bearing structures, and bringing the house into disrepair.

The insulation of roof structures, as well as the insulation of walls and floors during the construction of multi-apartment residential buildings, must be checked by state or private expertise at the design stage. The thermal insulation of a private cottage completely depends on the future owner, no one checks its availability and a competent choice, but this does not lose its importance.

Warming methods

Do-it-yourself roof insulation largely depends on the design of the roof. There are two types of roofs: flat and pitched. Most often, flat roofs are used for the construction of multi-storey buildings, but it is possible to use them in the construction of a private cottage. Flat roofs can be constructed in two ways:

In the inversion, the order of the layers has been changed. This technology is used in the arrangement of the exploited roof. As a material for insulation in both cases can be used:

- Styrofoam;

- extruded polystyrene foam;

- mineral wool (in slabs);

- expanded clay.

The latter is quite cheap, but has lower heat-shielding characteristics. In most cases, roof insulation is applied from the outside. This allows you to simplify the installation process and make competent protection from the cold from the point of view of thermal engineering.

The scheme of laying insulation between the rafters

The scheme of laying insulation between the rafters

It is necessary to remember the strength of the material; additional measures will also be required to protect the insulation from mechanical damage.

When building a private house, the option with a pitched roof is most often used. It allows you to equip the attic or attic and has a more attractive appearance. Insulation of the roof of a wooden house or any other can be done in several ways:

- laying material between the rafters (the most common);

- laying insulation over the rafters;

- fastening from the bottom of the rafters.

Material selection

Insulation of the roof of a wooden house or a building made of other materials is carried out using the following materials:

Rarely used materials include:

- expanded clay;

- sawdust.

Scheme of roof insulation with mineral wool

Scheme of roof insulation with mineral wool

Bulk materials are used to protect against the cold outside. They have an attractive price, but are quite difficult to install, so they are not widely used. It is better to use more modern technologies.

In general, materials for thermal protection measures must meet the following requirements:

- safety, no harmful effects on humans;

- environmental friendliness;

- small weight to prevent excessive loads on the truss system;

- resistance to crushing and sagging, sufficient strength and rigidity;

- soundproofing characteristics (especially important when using metal roofing);

- resistance to fire (especially important for wooden construction);

- if possible, good vapor permeability, which will provide additional ventilation of the room;

- good thermal performance.

One of the most important characteristics of a material is its thermal conductivity. This value must be specified by the manufacturer. The lower the value, the smaller the thickness of the insulation will be needed. In the absence of constraint in funds, it is better to choose materials such as mineral wool or polystyrene foam. The values of their thermal conductivity depend on the manufacturer and are in the range of 0.03-0.04 W / (m2*ᵒС).

Thickness calculation

It is important not only to choose the right material for insulation, but also to correctly calculate its thickness. Insufficient will lead to condensation, and excessive indicates an irrational expenditure of funds. You can select the value "by eye" based on general recommendations, for example, regardless of the type of roof (pitched or flat), for insulation with mineral wool or polystyrene foam, a layer thickness of 150-200 mm is required.

It is best to perform a full-fledged heat engineering calculation that takes into account modern comfort requirements and allows you to find the perfect balance of cost and quality. For a specialist, the implementation of such a calculation is not difficult. A person far from construction can use examples of calculations or the Teremok program, which is freely available and is quite simple and understandable.

Competent calculations at the design stage are aimed at saving the budget and ensuring the reliability of thermal protection.

Their implementation will not take a lot of time, but will avoid overspending during construction and additional repair costs during operation.

Flat roof insulation process

Depending on the type of roof, the insulation technology will be different. For flat roofs, the following order of layers is usually observed:

- load-bearing structure (most often reinforced concrete pavement);

- vapor barrier layer;

- thermal insulation material;

- cement-sand screed (reinforced for non-durable materials);

- waterproofing carpet, which acts as a topcoat.

If absolutely necessary, you can work from the inside of the room, but this method has several disadvantages:

- reducing the height of the room;

- transfer of the dew point inside the structure;

- inconvenience of work.

Thermal protection of a pitched roof

Before you properly insulate the roof of the house, you need to understand the order of the work. In the vast majority of cases, pitched roofs are insulated between the rafters. Warming the roof from the inside with your own hands is quite a feasible task. It is important to follow the correct order of laying materials from the bottom up:

- interior decoration;

- bottom crate;

- vapor barrier;

- rafters with insulation between them;

- waterproofing;

- wind protection;

- crate;

- roofing material.

If the thickness of the insulation is greater than the height of the rafter legs, counter rails are installed. It is better to use modern diffusion membranes as wind protection and waterproofing.

Competent insulation, regardless of the type of roof, requires a careful approach. To avoid problems during operation, it is necessary to choose the right thickness of the insulation, choose a reliable manufacturer and follow the installation technology. The fulfillment of these conditions will allow the roof to serve for a long time and contribute to the preservation of the normal temperature and humidity conditions in the building.

We insulate the roof correctly: how to avoid mistakes

Roof insulation will create heat in the house. How and what is better to insulate the roof of a private house, we will describe in detail in this article.

How to properly insulate the roof of a house: key points, methods

One of the main conditions affecting comfort in a house or cottage is a warm, reliable and durable roof. It should retain heat well, protect from moisture, protect from wind. When solving such a problem as insulating a roof, one should not save on the materials used. The roof is exposed to harsh conditions, experiencing large temperature fluctuations, the influence of precipitation, significant physical exertion under the influence of wind.

The main points of roof insulation

Roof insulation is one of the important stages of building insulation as a whole. It is the final structure of the building that performs the main function of protecting the interior from adverse external influences. High-quality thermal insulation of the roof will provide tangible savings in money during the further operation of the dwelling, reducing heating costs. After all, about 20-30% of heat loss occurs through the roof.

When deciding how to properly insulate the roof of a house, first of all, you should decide on the function of the attic space. If the attic is not planned to be made into a living room, then it is not necessary to insulate the roof from the inside. In this situation, only the attic floor should be well insulated in order to protect the premises of the uppermost floor from the effects of cold and heat loss. In a situation where a residential attic will be arranged in the attic, roof insulation from the inside is a must.

The method of performing work also depends on the design of the roof and the stage at which insulation is performed. The design can be pitched or flat, each of them has its own characteristics when performing work. When choosing a method, one should take into account the current stage of construction, since it is preferable to insulate the roof of the house at the design stage. The technology for performing work is the same for both a wooden building and a brick one.

It should be noted that before insulating the roof of a wooden house, you need to carefully inspect all the details of the roof, rafters for dampness, signs of decay and various damage. Wooden structures must be treated with an antiseptic, badly damaged areas must be replaced. Electrical wiring elements located under the roof also require careful checking.

Materials for warming the roof of the house

The modern market offers a huge selection of materials for insulation, the most common include fiberglass and polystyrene foam boards, foam concrete, foamed glass, mineral wool boards. Each type of insulation is characterized by different thermal conductivity, vapor permeability, strength and other properties. Mineral wool boards have been widely used, which compare favorably with other heaters in terms of their quality characteristics. Their use is acceptable for most types of roofs.

Mineral wool boards are positioned as a fire-resistant material with low thermal conductivity, good waterproofing and noise-absorbing properties. They practically do not deform during operation.

How to insulate a flat roof

To insulate a flat roof, two methods are used:

- The principle of a rolling ceiling - the insulation is laid on top;

- The principle of a false ceiling - insulation is knocked out from the inner surface of the ceiling.

Performing insulation work from the outside is a simpler and more convenient option. Several key points should be taken into account, among which it is necessary to highlight the ability of the supporting structure to withstand the weight of the roofing material and insulation. It is possible that insulation according to the principle of a rolling ceiling will be enough to achieve comfortable living conditions in the house. Priority work on this method is more appropriate under the circumstances. The operation of the premises in the cold season will allow us to conclude whether it is worth doing insulation from the inside, based on the principle of a false ceiling.

For insulation outside the roof, which has a flat shape, it is better to use basalt mineral wool. The choice of high-quality materials is especially important at this stage, since it is impossible to properly insulate the roof without this component.

Phased insulation of a flat roof occurs in the following sequence:

- With the help of a vapor barrier film, a layer is laid that serves as a vapor barrier;

- A layer of thermal insulation made of mineral wool boards is arranged on top of the film;

- Waterproofing is laid in the form of a rolled coating of roofing material, synthetic materials;

- Laying bulk material - insulation.

Important! If the work is carried out during the period of precipitation, then it should be noted that the waterproofing coating must be immediately laid on the insulation, not allowing the latter to become covered with water, snow, ice. For large areas, measures must be taken to prevent precipitation from falling onto the roof surface.

Before starting work on the insulation of the roof, it is necessary to thoroughly clean the surface of dust and debris. If there are large irregularities, it may need to be leveled. Thermal insulation boards are glued with special cold mastic or glue. To achieve uniformity of the coating, it is necessary to lay mineral wool with half-overlapping of the seams. Laying an additional layer of slabs is allowed to improve thermal insulation, while the slabs are arranged "in a run", and the joints are glued with adhesive tape. The use of this technology avoids the appearance of "cold bridges".

Recently, the fire method of laying waterproofing has become widespread. A cement-sand screed with a thickness of more than three centimeters is being laid on mineral wool slabs. After the concrete becomes strong, the working surface is cleaned of dirt and excess sagging. The waterproofing carpet is glued under short-term exposure to fire, without changing its protective properties. The laying of the material is carried out with an overlap of ten centimeters, which ensures the strength and tightness of the coating.

How to insulate a pitched structure

The pitched roof of houses or cottages often serves as the basis for creating an attic, which allows you to get additional square meters of living space. More stringent requirements are imposed on the insulation of the attic from the inside.

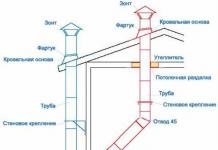

The design of the insulated roof is called the “roofing pie” due to the fact that it consists of several layers: a ventilation circuit under the coating, a waterproofing layer, another ventilation circuit (not always arranged), a heat-insulating layer and a vapor barrier.

Waterproofing helps protect your home from moisture. When water gets under the roof, the insulation begins to lose its properties, wood structures begin to rot. In addition, the air under an insulated roof and outside can differ significantly, the temperature difference causes condensation of moisture in the air on cold structures. Condensation can also occur inside the insulation, but the device of the ventilation circuits allows you to avoid this. Under the influence of supply air, water vapor is removed from under the roof without condensation. The waterproofing layer covers the construction logs and is attached to them with a stapler.

The presence of a ventilation circuit on the roof is a prerequisite for its functioning. The intake of fresh air must be arranged through a gap located on the overhang of the eaves, the exhaust is carried out through a ventilation device on the slope or ridge of the roof. It should be noted that all components of the structure must be ventilated. The ventilation device does not cause any particular problems for conventional gable roofs. For roofs with intricate geometry, this task is faced with certain difficulties, since various obstacles prevent the free movement of air: ventilation shafts, a chimney, windows and other structural elements.

The next layer is thermal insulation. The main characteristics of the material that affect the quality of insulation work are thermal conductivity and rigidity. The material must keep its shape, not deform under the influence of environmental conditions.

A vapor barrier layer attached to the rafters is laid on the thermal insulation layer. As a material for its device, a building membrane film is usually used.

The final stage in the insulation of the roof is the finishing of the "roofing cake" from the inside. The finished surface should be sheathed with drywall or chipboard for further wallpapering or other finishing work.

Roof insulation is an important component of the construction process, allowing you to achieve comfortable living conditions. Competent performance of work will ensure an increase in the period of flawless operation of the entire roof structure, eliminating unnecessary repairs.

How to properly insulate the roof of a house

Roof insulation technology. Tips and tricks on how to properly insulate flat and pitched roofs.

How to insulate the roof of a house?

- Pitched roof features

- Step-by-step instruction

- Flat roof and the nuances of working with it

Each owner is concerned about the issue of economical consumption of resources for heating a private house. You can partially solve the problem by performing the roof insulation procedure. Thus, it is possible to reduce heat loss by up to 15%. The complexity and result of the work largely depends on how to insulate the roof and what its design is.

If the attic space is not used, then ceiling insulation is a sufficient measure to insulate the room.

If the attic is not planned to be used, you can limit yourself to insulating the ceiling of the house. The roof itself is insulated if the room under it will be used.

Pitched roof features

The scheme of insulation of a pitched roof.

Before insulating the roof, it is important to find out exactly how this task is performed in accordance with the type of roof. The pitched roof is insulated from the inside. In an old house, be sure to check the crate for the presence of rotten or damp boards. Damaged boards must be replaced with fresh ones, after which all wooden frame elements should be treated with an antiseptic and fire-fighting impregnation.

To make an insulated roof follows from several layers. The presence of the following materials is mandatory: waterproofing, insulation layer and vapor barrier. On request or need, interior decoration is carried out. Between the roof and the insulation, an air “cushion” should be organized, and there should also be a space between the waterproofing and the insulation. This is necessary for the free removal of the resulting moisture. If a decorative finish is planned from lining or chipboard, it is necessary to provide an air gap in front of these layers.

Ensuring air circulation when insulating a pitched roof.

Before insulating the roof, two holes should be arranged between all layers to ensure free air circulation.

How to insulate the roof? To carry out work that is quite realistic to do on your own, you need the following materials:

- Directly insulating material. Use of mineral wool or glass wool is allowed. The second is available in slabs or in the form of a roll, however, in order to make an insulated roof, it is optimal to use slabs that do not deform. In addition, you can use foam.

- Roofing material can be taken as a waterproofing material. A film that protects the layers from water, but allows evaporation of the moisture formed inside, is also suitable for this task.

- For vapor barrier, you can choose one of the materials: roofing material, plastic film, foil, glassine. The recommended option is a special membrane that protects the insulation layer from water and steam, but allows the removal of the resulting condensate.

After choosing the material for each of the layers and preparing the roof, work can begin.

Step-by-step instruction

Between the boards of the frame, blocks of heat-insulating material cut to the width are laid.

- It is necessary to measure the distance between the rafters, as well as the thickness of the boards. Next - cut the plates of insulating material. At the same time, their width should be 1 cm more than the step between the rafters.

- If there is no insulation layer between the roof and the frame, it must be laid so that it envelops the frame beams. The material is fixed with a stapler. Having laid it around the entire perimeter, you should bring the lower edges under the bevel to organize the flow of water. Further, the thermal insulation is laid tightly to the previous layer, without forming voids.

- If there is already insulation under the roof, space should be provided between it and the insulation layer. For this purpose, nails are driven in between the rafters (after 3-5 cm from the waterproofing). Then a thread is fixed on them, after which the nails are driven in until they stop.

- Fixation of the insulating material can be carried out with a cord. In this case, nails must be hammered along the edges of the frame.

- The next step is the installation of insulation. Mineral wool is placed between the boards of the frame, while you need to lightly press it, in the future it will take the desired shape. The foam is located in the cells between the elements of the frame. If necessary, two layers can be made. When laying slabs, do not match the joints of adjacent layers. It happens that the thickness of the frame boards is not designed for a double layer of insulation. Additional bars can save the situation.

- Further, as after the previous layer, a thread or cord is pulled over the nails driven into the edges of the rafters. In addition to this method, fastening in the form of a crate of slats is used. They are nailed to the rafters with a distance of 30-40 cm.

- The next task is to fix the vapor barrier. The canvas is overlapped by 10 cm. The joints of the layers must be sealed with adhesive tape or adhesive tape, and the insulation itself must be fixed with a stapler. It is important to qualitatively fix the vapor barrier at the intersection of the roof and the pipe. The service life of the insulation layer depends on how well this area is insulated.

- In conclusion, you need to do the interior decoration of the roof in case you plan to organize an attic. Suitable chipboard, drywall or lining. It is important to maintain an air gap between the insulation and the finishing material. This can be done using not a stapler, but pressed strips for fastening.

Flat roof and the nuances of working with it

This design involves insulation both from the inside and outside. Before insulating the roof inside, it is necessary to perform external insulation and check whether it is sufficient.

The outer layer is made of mineral wool.

Such a material has properties that are indispensable for insulation - it does not burn, it passes steam well, has low thermal conductivity and lasts a long time.

The scheme of thermal insulation of a flat roof.

An alternative material is styrofoam, but it is not good enough in fire resistance.

For external insulation, the following sequence of layers is assumed: vapor barrier, insulation material, waterproofing and bulk layer. Any rolled material can be used as a waterproofing, for example, roofing material, and the bulk layer is made with expanded clay or a mixture of sand and cement.

An important criterion when choosing a material for external insulation is the strength of the supporting structure. You should make sure that the frame and floors are able to withstand the weight of both roofing materials and insulation. In this case, it is better to use a material that is not heavy in weight - polystyrene foam or mineral wool.

The execution of work involves the following sequence of actions:

- Cleaning and leveling the roof surface.

- Laying a layer of vapor barrier.

- Insulation boards are installed. Fastening is done with glue or mastic, and the seams and joints must be sealed.

- Finally, waterproofing is installed. At the same time, it is also worth taking care of sealing the seams.

In the case when the external insulation of a flat roof is not enough, the roof should be insulated from the inside. To do this, wooden planks are screwed to the ceiling in increments of 40 cm. A foam polystyrene plate is glued to these planks using mastic or glue. Then the next one is screwed to the bar, on which the next plate is glued. Upon completion of the overlap of the entire ceiling, a plastic film is attached. You can perform further surface finishing.

When performing roofing work, it is important to observe safety precautions. With the right approach and following the technology, all work can be done independently.

How to properly insulate the roof of a house: analysis of the entire technology of work from A to Z

How to insulate the roof of a house one day and forget about it for at least 30 years? To no repairs, leaks or other problems? It's real! It is only necessary to design a roofing cake correctly, choose an eco-friendly insulation and do not forget about vapor barrier. And what and how to do, we have revealed in detail in our step-by-step master classes - study and apply, everything is simple!

So, the insulation of the roof of the house in detail!

Stage I. Design

The main factor affecting the performance of the roofing cake and its durability is the humidity regime. Ideally, of course, if there is no moisture in the roofing cake at all - in any form. But in reality, it is always there, especially when it comes to a residential building where they breathe, cook and iron.

And how protected the insulation will be in such an environment depends on how competently the roofing pie was designed and how technologically the roof of the residential building was insulated, because there are no such problems with water vapor during the construction of industrial buildings or outbuildings. Just think carefully about what kind of waterproofing you need, what kind of insulation is suitable and how to close it from moisture.

Stage II. Waterproofing

The first step is to purchase high-quality waterproofing for the roof. So, in the application of conventional waterproofing films and in the laying of a diffuse membrane, the principle is far from being the same. The steam released from the insulation settles in the form of condensate and is brought out with the help of ventilation air for both insulators, only with the following difference:

- If a conventional film serves as a waterproofing, steam accumulates in the form of condensation right on it! Those. in the space between the insulation and the film.

- But when using a super-diffuse membrane, steam condenses in the form of small drops directly on the membrane, but not from the side of the insulation, but from the side of the roofing.

And now, what do you think is better for roofing insulation - so that the drops hang directly above it, or are outside the dense waterproofing? Do not forget also that the air from forced ventilation is taken simply from the street, and it is humid (for example, during rain).

Especially all this concerns fashionable metal roofs. The fact is that metal is a cold material, and condensate forms especially willingly for us. And, if you do not carefully consider the ventilation system for the evaporation of these drops, insulation from the first year of life will cease to fulfill its main functions. In general, the principle is quite simple: a "breathing" waterproofing membrane removes excess moisture from the insulation to its surface and successfully gets rid of it along with the condensate formed under the roof. Here is an example of its installation:

But what absolutely cannot be used as a waterproofing of a roofing cake of a residential building is glassine, roofing material, simple polyethylene, dense wind protection and advertising banners. And it is best to use modern membranes as waterproofing, which have additional vapor permeability. Such a film additionally removes the accumulated moisture in the insulation up, thereby maintaining its dry state.

So, the first step to a durable and problem-free roof is a high-quality "smart" vapor barrier, breathable waterproofing that can remove excess vapor from the insulation, well-thought-out ventilation. As well as additional systems such as a flow guide (special fixture from Isover) and a roofing system like Paroc Air.

Stage III. Warming

So, at this stage, we select the appropriate insulation for the roof of your house.

Mineral wool: a classic of the genre

Here are the main advantages of insulating mineral wool boards:

- Good soundproofing.

- Fire resistance.

- Relatively light weight.

- No deformation even under heavy loads.

- Durability: service life - not less than 25 years.

Their installation is also not difficult:

It is especially convenient to insulate the attic floor with mineral wool:

If you purchased too thin insulation, then lay it in several layers, always with a joint offset of 20 cm each. It is clear that the more solid flooring we lay insulation, the less possible cold bridges we will have later.

Basalt wool: high environmental friendliness

Basalt insulation (a separate type of mineral wool) for the roof is produced with a thickness of 50-150 cm. Due to their porous structure, they hold heat well, they are difficult to get wet, and even when wet, moisture easily leaves without any damage.

True, basalt slabs have considerable weight and are not easy to work with:

Styrofoam: with extreme caution!

So, polystyrene foam, or polystyrene foam, is polyethylene foam, which is produced in the form of sheets up to 20 cm thick and can be of different density.

Not a single specialist will advise to insulate the roof of a residential building, especially a wooden one, with foam plastic. After all, in such a house, if the thermal insulation was done incorrectly, styrene constantly negatively affects the human respiratory tract, blood, causes headaches and other disorders of the nervous system. For example, in production shops where block foam is packed, many workers complain of a constant dry cough and frequent sore throats. In addition, foam plastic and extruded polystyrene foam at a temperature of 80 ° C begin to melt and at the same time become toxic.

But at the same time, extruded polystyrene foam is the only type of thermal insulation that is officially recommended in the design of an inverted roof. All thanks to its resistance to moisture and valuable performance properties.

A good solution in terms of insulation can be the so-called sandwich panel, when mineral wool is placed between two steel sheets. Steam can no longer enter such a structure, and therefore there is no condensation and such a moisture-sensitive insulation retains its properties for a long time.

Backfill insulation: expanded clay, sawdust and foam ball

Infill insulation is popular to this day, although well-thought-out marketing of mineral wool boards is gradually replacing them. The main advantage of bulk insulation is that it can be mixed with almost any material, and even embedded directly into the structure. The most popular types of bulk insulation:

For a residential building, for example, expanded clay is one of the best options:

Vermiculite insulates the attic floor. It is a natural stone that is mined in quarries. In terms of its properties, it is close to expanded clay, and is also good because it absorbs odors. For the attic - a significant plus, you see! A foam ball is individually frozen pores of expanded polystyrene. Usually it is mixed with special solutions.

But how to properly insulate the inside of the roof of the house with ordinary sawdust? They often insulate the floor of a non-residential attic by mixing shavings with cement. Here is the technology:

- Step 1. We interfere with the solution: 10 buckets of sawdust per 1 bucket of cement. You do not need to add much water, the main thing is that the mixture is only slightly moist. So, for dry sawdust, take ½ bucket of water, for rotten - just one bucket. First, pour 10 buckets of sawdust into the prepared container, then gradually water them with water from a watering can and mix all the time. Then we pour a bucket of cement into the sawdust and again knead everything thoroughly. In appearance, all this will look like shavings smeared in cement, but if you squeeze a little solution into a fist, it should not disintegrate, nor should it release water.

- Step 2. Now we lift this mixture into the attic and lay it out with a simple tamping with our feet. For insulation, 20 cm of such a layer will be enough.

- Step 3. When the mixture dries, the screed will be a solid layer that will not bend underfoot - just crunch a little.

And if you mix them with dry clay and fall asleep between the lags of the attic floor, then there will no longer be a need for a vapor barrier for the roof.

Clay is also suitable as a binder for sawdust:

Ecowool: excellent vapor permeability

The heat capacity of ecowool can be compared with mineral wool, and other indicators are also pleasing:

- Fire class A. This material, due to special processing, is classified as difficult to ignite. Even in a fire, it does not support combustion and does not adversely affect the roof structure. As a result, with a strong flame, just charcoal is obtained from ecowool, which in turn does not allow fire and heat to spread further.

- The ability to "breathe", maintaining the exchange of air with the environment and withstanding any level of humidity. That is why special vapor barrier membranes are not needed for ecowool.

- Preservation of properties even at high humidity - up to 23.5%, while other heaters in such conditions lose their thermal insulation by almost half.

- biological stability. Ecowool is not affected by fungi or insects due to special processing with borax.

- soundproof qualities. Ecowool is a class 2 sound-absorbing material.

This is how the thermal insulation of an ecowool roof usually looks like:

PPU: durability and practicality

The main value of polyurethane foam is durability: 1% moisture in polyurethane foam will change the thermal conductivity of this material by less than 10%. And this is a little. Another feature of the PPU structure is that the cells have a cross-linked molecular wall structure that does not allow molecules larger than a water molecule to pass inside. For comparison: an oxygen molecule is twice as large.

But let's make a couple of points. According to the correct technology, PPU is not poured into the attic, but sprayed. Here the difference is as essential as putting out a fire or putting out a burning object. In addition, the best PPU is afraid of direct sunlight: for the experiment, you can leave a piece under the sun, covering it only with a sheet of metal, and after a few days you will find only a loose substance.

Just decide first whether you need internal thermal insulation, or external:

And the process itself is quite simple. First, the roof is covered from the inside with a 30-cm layer of low-density polyurethane foam coating, only 60-80 kg / m3, and on top - more dense, with a thickness of 5 to 15 mm. The average thickness of both layers is about 8 cm for the snowy Russian regions.

And now about safety: consider roof ventilation so that PPU particles do not enter the living space. After all, depending on many factors (temperature, UV rays, humidity), the walls of such cells are gradually expanded. Usually all this happens within 15-20 years, while according to world standards, the warranty period of thermal insulation should not be less than 25 years. The sprayed polyurethane foam is formed into cells with a temperature of 80-120C, and when cooled to normal room temperature, the cells with gas are partially discharged (and freon and a little CO2 are used as gas, the thermal conductivity of which is worse than that of air). And over the years, air diffusion in PPU continues.

Stage IV. vapor barrier

And finally, in no case do not skimp on the vapor barrier of the roofing cake in the house.

Separately, we note that the pressure of water vapor directly depends on the air temperature. So the warmer, the higher the pressure. Have you ever noticed blistering bubbles on someone's bituminous roofing? This is just the result of excess pressure, which is under the waterproofing. The same applies to heaters in a roofing cake: the more places there are accidental ingress of moisture, the worse the vapor barrier used and the higher the air temperature, the worse it is for the heater.

And fix the vapor barrier correctly:

- Step 1. Lay a vapor barrier between the rafters, at least 0.2 mm thick.

- Step 2. Fasten the vapor barrier to the rafters with a construction gun with staples, and seal the joints that we overlap with adhesive tape.

- Step 3. With the same tape, we additionally close the attachment points with brackets. Necessarily!

Have you done everything as we suggested? Now you can sleep peacefully!

How to properly insulate the roof of a house: an overview of roof insulation technology

Everything about the proper insulation of the roof of a residential building: selection of insulation, hydro and vapor barrier, useful tips. Video and photo instructions with a detailed analysis of all the work

It is necessary to insulate the roof of the house only when it is planned to make the attic premises residential. If the attic is not provided, then it is necessary to insulate not the roof, but the ceiling. The quality of roof insulation has almost no effect on the microclimate in the rooms; this is an extra waste of time and large financial resources.

Currently, the construction industry has mastered the production of a large range of products with excellent performance. Such a wide choice often puts inexperienced developers in a difficult position. They read only manufacturers' brochures, and based on this information, it is difficult to make a specific choice. All companies describe only the positive aspects of their products and do not talk about the negative ones. The article will give objective comparative characteristics of various materials used for roof insulation. This information will allow you to make an informed decision in each specific case.

According to what physical parameters are heaters classified?

| Insulation property | Short description |

|---|---|

| It is necessary to pay attention to this indicator in the first place. Heat loss occurs in two ways: infrared rays and convection. The lower the body temperature, the less rays it emits. Perceptible energy losses by infrared radiation occur at a high heating temperature of solids. For the roof, such losses can be ignored due to the low temperature. But the coefficient of thermal conductivity is crucial. The parameter is defined in W/m×K. The values of thermal conductivity for different bodies differ by several orders of magnitude. For example, the thermal conductivity of wood is approximately 0.15 W / m × K, and that of foam plastic is 0.015 W / m × K. This means that it retains heat energy ten times better than wood. |

| A very important indicator for all buildings, fire regulations have strict requirements for the safe operation of buildings. All materials are divided into several groups, from non-combustible (NG) to easily flammable (G4). The classification is carried out according to the standards of SNiP 21-01-97 and depends on several parameters: the temperature of the gases, the degree of damage in length and weight, and the duration of self-burning. The category of non-combustible includes mineral wool and expanded clay, and low-quality polystyrene foam belongs to the highly combustible category. The stability class must be indicated on the packaging. It should be noted that the most modern polystyrene foam insulation due to various additives have a reduced flammability class (G2 and G3) and are allowed for limited use in residential construction. |

| Notional value, used to classify potentially hazardous materials. It is set on the basis of changes in the amount of harmful fumes, is assigned taking into account the values of the concentration dangerous for the human body. The classification is done taking into account the provisions of GOST 12. 1. 007-76 and SanPiN 2. 1. 4. 1074-01. Building materials are subject to strict regulatory control, class III (moderately hazardous) and class IV (low-hazardous) substances are allowed to be used to a limited extent. Mineral wool, expanded clay, glass wool are completely safe. The fourth class includes only some types of foam and liquid insulation, it is recommended to use them carefully. |

| The thermal conductivity of water is much higher than that of insulating materials. Accordingly, the more water they can absorb, the lower the final heat saving performance. Another disadvantage of high water absorption is that wet materials with prolonged contact with wooden structures cause rot and fungi. As a result, the tree loses its original properties, the rafter system and sheathing have to be repaired prematurely. A particularly unpleasant situation with the truss system, its restoration not only requires a lot of time and money, but can also be carried out in warm and dry weather. And this greatly complicates the repair work. Unfortunately, mineral wool has a high water absorption, in order for it not to get wet, it is necessary to carry out a set of complex and expensive special construction measures. This is its essential shortcoming. Styrofoam-based insulation absorbs the least moisture. |

| The higher this indicator, the more heat is removed from the insulation, the lower the heat saving values. And according to this indicator, mineral wool is significantly inferior to polystyrene, it is freely blown by the wind. Even pressed mineral wool has this disadvantage, though to a lesser extent than rolled. To reduce energy losses, mineral wool insulation must be covered from the wind, while the shelter must let steam through. If the steam cannot leave, then condensation processes will begin, the cotton wool will get wet with all the negative consequences. For shelter, modern diffusion membranes are used, they are quite expensive. |

| The parameter characterizes the resistance of insulation to the effects of various active chemical compounds. Smog is always present in the city air, and it contains various chemical compounds. More stable than all mineral wool heaters, foam at certain concentrations may react negatively to some compounds. But this is possible only in cases of a critical increase in concentration; in practice, these situations happen very rarely. |

| The truss system of the house is constantly changing its linear dimensions. The reasons may be violations of construction technology and calculation, excessive snow and wind loads, changes in the relative humidity of wooden elements. Heaters must constantly compensate for the dimensions and at the same time not lose their strength. Mineral wool works best in such conditions. Styrofoam materials can compensate for fluctuations up to certain limits, when they are exceeded, the sheets are destroyed. |

| For roof insulation, this parameter does not matter much. But there is one caveat. Mineral wool in terms of strength takes the last place among the used heaters. If the angle of inclination of the slopes is large, then over time it can shrink or sag under its own weight, cracks form, the effectiveness of thermal insulation decreases, and very unpleasant cold bridges appear. If the angle of inclination of the slopes exceeds 20°, then it is recommended to take measures to fix the mineral wool. |

As can be seen from the table, there is no ideal roof insulation for all cases, each has its own strengths and weaknesses. They must be taken into account before making a final decision.

Performance characteristics of roof insulation

Consider the most used modern materials, it is not worth talking about currently rather exotic loose insulation. Not only are they almost never used, but they are much inferior to modern technologies in all respects. What is the most common roof insulation today?

Prices for mineral wool

Mineral wool has now almost completely replaced glass wool.

What are its advantages over traditional heaters?

- Below is the thermal conductivity. Mineral wool has a thermal conductivity of 0.03-0.05 W/m×K, glass wool has a thermal conductivity of 0.41 W/m×K. The higher the density of mineral wool mats, the higher the thermal conductivity. In practice, the difference in thermal conductivity can be neglected, it is leveled due to gaps at the points of contact with the truss system.

- Elasticity and manufacturability. These indicators are interconnected, so it makes sense to consider them simultaneously. Glass wool manufacturing technology assumes that the diameter of the fibers will be approximately 15 microns, the diameter of mineral wool fibers is much smaller and does not exceed 2–8 microns. This explains the difference in terms of manufacturability and elasticity. It is difficult to work with glass wool, thick glass fibers damage the skin and irritate it, you need to use gloves and a respirator. Minvata is much softer, has no such shortcomings. In addition, it is more elastic, after the removal of static loads, it completely restores its factory thickness. Glass wool cannot be completely restored, thick glass fibers break.

- Weight. It has a significant effect in the case of a large angle of inclination of a pitched roof. If there is a large slope, then the material may deform under its own weight. According to this performance indicator, mineral wool is ahead of glass wool.

With regard to environmental friendliness, fire resistance, hygroscopicity and chemical resistance, the materials are almost no different from each other. But there is one remark - the cost of mineral wool is much higher than glass wool.

The service life of mineral wool is practically unlimited, but on condition that the material will not be damaged by rodents.

Mineral wool can be rolled and pressed. How do their performance differ?

It has a thickness of 5 cm to 15 cm. The dimensions of the sheets in width are standard 60 cm, the length of each manufacturer may vary. The advantages of such cotton wool are the speed of installation. The sheets are tightly inserted between the rafters, they are kept from falling out by stretched ropes, no additional fixation is required. Cotton wool is easily cut with an ordinary mounting knife.

The material rolls tightly into rolls, after removing the packaging, the factory thickness is restored. It has two advantages: low price and the possibility of insulating truss systems with complex geometry.

Styrofoam prices

Widely used modern insulation material. Density, depending on the characteristics of the manufacturing technology, ranges from 16–30 kg / m3, the higher the density, the greater the load the insulation can withstand.

There are grades of expanded polystyrene that do not support open combustion, they melt, and ignition occurs after a strong increase in temperature. Such polystyrene foam is allowed to be used for warming flat roofs of multi-storey buildings; there are no restrictions for private houses. For example, paper ignites when heated to +2300°C, wood at +2600°C, and modified polystyrene foam ignites spontaneously at +4900°C.

Expanded polystyrene is very afraid of hard ultraviolet radiation, but this does not matter for roof insulation, the material is located under the roofing. The service life is approximately thirty years. The plates are easy to cut, all roof insulation work can be done without special expensive tools and fixtures.

To reduce the number of gaps, they need to be foamed with construction foam.

Practical advice. Professional builders strongly recommend using high-quality imported foam, it has high elasticity. Domestic materials crack when compressed - the strength of the fixation of the plates decreases, the thermal conductivity increases.

Expanded polystyrene is almost non-hygroscopic; in two days of direct contact with water, it absorbs no more than 2% of the moisture volume. These low values have no visible negative effect on performance.

Thermal conductivity depending on density 0.028–0.034 W/m×K.

polyurethane foam

One of the least flammable plastic insulation, can be used in liquid form. But such insulation of the roof of a private house has more disadvantages than advantages and is not recommended by professional builders. Warming is much more profitable to do with ready-made plates. Up to 99% of the pores are closed, which almost completely eliminates moisture absorption, thermal conductivity, depending on the type of foam, is 0.019–0.028 W / m × K. The service life is at least 20 years, if the manufacturer's recommendations are followed, it withstands frosts down to -160°C.

The material is technologically advanced, the release of harmful chemical compounds into the air does not exceed the norms controlled by state standards. Weight no more than 60 kg/m3, has excellent adhesion with all building materials, which simplifies the process of finishing the interior surfaces of attic spaces. One of the important advantages is that it is little damaged by rodents. For example, mouse styrofoam boards can completely turn to dust within one year.

Penoizol

It is characterized by very low weight (from 10 kg / m3), thermal conductivity in the range of 0.036–0.038 W / m × K. The difference between the material and other types of polymer is a large number of open pores, which increases the vapor permeability to 0.21. Vapor permeability is a positive parameter for roof insulation - excess moisture is removed without problems, and the risks of condensation are minimized. But there are also problems. Condensation not only increases thermal conductivity, but also destroys the insulation when it freezes.

It does not support open fire on its own, the service life is at least 50 years, but subject to several conditions:

- penoizol must be reliably protected from UV rays;

- relative humidity should not go beyond the valid tolerance fields.

Only 5 cm thick foam insulation provides the same thermal protection of structures as 7.5 cm thick foam, 12.5 cm mineral wool or 34 cm wood.

The material is easily cut with an ordinary hacksaw, but a lot of small chips are formed in the process. It is necessary to take measures so that it does not get into all the premises of the house.

Liquid heaters

Some polymeric materials can be sprayed onto the roof in a liquid state. This method has no advantages, but only disadvantages. Let's list just a few of them.

These are not all problems, you can add to them an increase in time and cost, a large influence of the human factor, etc.

Modern and fashionable insulation, recycled raw materials are used for manufacturing. More than 80% of the composition is secondary cellulose, the rest is fillers and binders. To insulate the roof, it is recommended to use pressed ecowool, it is easier to work with, in terms of its performance it is much superior to powder. Thermal conductivity in the range of 0.032–0.040 W / m × K, density up to 75 kg / m3, vapor permeability 0.3 mg / m × h × Pa.

A relatively large weight can create difficulties when insulating the roof, additional loads must be taken into account at the design stage of the truss system. To increase the resistance to combustion, a flame retardant is added to the material, the inhibition of the development of microorganisms is achieved by adding boric acid. As can be seen from the composition, there is no reason to call such material absolutely environmentally friendly.

A wide choice of heaters by name, unfortunately, does not mean the same wide choice in terms of operational properties. Minor differences in thermal conductivity do not play a noticeable role. They are reduced to nothing during certain deviations from the recommended insulation technology, and such deviations will always be.

Practical tips for choosing insulation for the roof of a private house

Prices for windproof membranes

Windproof membrane

There are some practical tips that will be of real help when planning work to insulate the roof of a private house.

Correctly calculate the estimated cost of work. The costs should include not only the price of the insulation, but also the cost of its delivery. If the work is done independently, then they can be ignored. But in the case of attracting construction companies, the estimated cost of insulation increases significantly. Most of them simply value their services - they are equal to at least half the cost of all materials. But these are the minimum values, there are companies whose cost of services exceeds the cost of purchasing heaters.

Roof wind protection

These are synthetic modern membranes with a rather high cost. In addition to membranes, it is necessary to make a counter-lattice for natural ventilation - add the price of lumber and hardware.

Compare the technical characteristics of various heaters. At the same time, you should not pay much attention to the thermal conductivity indicators, it does not differ much. Important for the duration of operation is the weight and elasticity of the material. Information should be taken not only from manufacturers' websites about the benefits, look for practical user reviews. Especially those who, for one reason or another, had to deal with the repair work of the roof after its insulation.

Soberly assess the complexity of the recommended technologies with your capabilities. The roof is not an element of the structure with which you can experiment. Even minor, at first glance, violations of technology can cause very big problems for the structure as a whole.

Before starting work, you need to prepare materials and tools in advance. Do not allow breaks in insulation due to lack of insulation or other materials. After the resumption of work, some previously installed structures will have to be dismantled, and this costs money.

Always try to buy insulation of the right thickness. If, taking into account the climatic zone of residence, the thickness of the insulation should be 15 cm, then it is much more profitable to buy sheets of the same thickness, and not to make three layers 5 cm thick. You can meet assurances that if three layers are laid with offset joints, then cold bridges are eliminated. This is not so, there are no cold bridges where there are no joints at all, that is, in a whole slab. In addition, one slab of expanded polystyrene or mineral wool 15 cm thick costs less than three 5 cm each. And the last. It is much faster to install one layer of insulation than three.

It is not recommended to start warming immediately after the completion of the construction of the roof. We must wait for the first rain and make sure that there are no leaks. It is much more difficult to notice and eliminate the problems that have arisen due to a violation of the tightness of the roof after its insulation and will always cost several times more.

Video - Insulation for the roof of a private house

In order to maintain an optimal microclimate in a private house, you need to take care of the presence of a reliable warm roof. It is this element that prevents moisture from entering the house and helps to keep warm. Accordingly, it is worth dealing with the question of how to insulate the roof of the house. At the same time, it is equally important to responsibly approach the choice of a suitable material.

What you need to know about roof insulation

When organizing the thermal insulation of a dwelling, it is worth paying special attention to the insulation of the roof, because it protects the interior from various external factors. Thanks to high-quality thermal insulation, it will be possible to reduce heating costs.

To properly insulate the roof, it is important to determine the purpose of the attic. If there is a non-residential premises here, then it can only be insulated from the outside. This also applies to the attic floor, thanks to which it will not be cold on the top floor.

The execution of work depends on the design of a private house, namely the type of roof. It can be flat or pitched, which affects the features of the work. Experts recommend insulating the structure at the design stage, thanks to which it will be possible to take into account all the important points. You also need to pre- inspect the details of the roof, which will help to identify rotting or damage. Such areas are replaced, and then the wood is treated with an antiseptic. It is equally important to check the wiring.

Materials that can be used to insulate the roof of a house

On the modern market there is a large selection of heaters, which differ in their characteristics and features of use.

Mineral wool. This material, which has a fibrous structure, is supplied in slabs or rolls. When choosing, you need to pay attention to the density and thickness. The main advantages of mineral wool are increased thermal insulation, affordable price, environmental friendliness, incombustibility, vapor permeability, biostability, and ease of installation. To insulate the roof from the outside, it is worth choosing basalt slabs, and stone wool will provide fire protection. It is important to take care of the presence of a ventilation gap, as well as reliable vapor and waterproofing, so that water will not accumulate in the insulation. Otherwise, rotting of wooden elements and deterioration of the properties of mineral wool is possible.

Mineral wool. This material, which has a fibrous structure, is supplied in slabs or rolls. When choosing, you need to pay attention to the density and thickness. The main advantages of mineral wool are increased thermal insulation, affordable price, environmental friendliness, incombustibility, vapor permeability, biostability, and ease of installation. To insulate the roof from the outside, it is worth choosing basalt slabs, and stone wool will provide fire protection. It is important to take care of the presence of a ventilation gap, as well as reliable vapor and waterproofing, so that water will not accumulate in the insulation. Otherwise, rotting of wooden elements and deterioration of the properties of mineral wool is possible.- glass wool. This is a popular material that is often used to insulate roofs. Its characteristics are close to those of mineral wool. In this case, glass melt is used, thanks to which the material is environmentally friendly, incombustible and soundproof. When installing glass wool, you must follow the safety regulations and use protective equipment. To simplify the installation, it is worth giving preference to plates, the outer side of which has a foil coating.

- Styrofoam. Such a popular material is used to insulate the roofs of private houses. Expanded polystyrene is resistant to moisture, so you can not create a ventilation gap. If we are talking about a flat soft roof, it is worth refusing to use such a heater because of its vapor tightness and flammability. When insulating the pitched roof of a private house, the slabs are laid in one layer, making sure that the edges fit as tightly as possible to the rafters. At the same time, all joints are sealed with mounting foam, and later the structure is trimmed with reinforced tape.

- polyurethane foam. Its advantages are light weight, biostability, excellent soundproofing and waterproofing characteristics, as well as low thermal conductivity. Polyurethane foam can be applied by spraying or purchased rigid boards. The latter can be cut or drilled, while during operation the shape will remain the same. For spraying, you will need the appropriate equipment, thanks to which it will be possible to create a truly monolithic layer.

- Penoizol. The characteristics of this material resemble the properties of foam. Its advantages include affordable price and good quality, as well as environmental friendliness. The material is sprayed using a foaming machine. The frozen thermofoam does not weigh down the roof of a private house, however, the need for a vapor barrier layer is considered a disadvantage of using such a material.

- foam concrete. To create this material, concrete and cement are used, as well as a blowing agent and sand. The finished insulation will make the thermal insulation of the roof of a private house really reliable and durable, and due to its low density, the supporting structure will not be subjected to significant load. The advantages of foam concrete are non-toxicity and vapor permeability. It is also worth noting fire safety.

- Expanded clay. Such insulation is used in the process of installing flat roofs. In fact, it is customary to lay this bulk material on the outer surface or floor slabs after the screed, while maintaining the required slope angle. Naturally, when using expanded clay, the load on the structure will increase, so it is important to take into account the use of this material at the design stage.

- foamed glass. This material is recognized as an environmentally friendly insulation. To create it, the foamed glass mass is combined with carbon. The finished material is resistant to decay and deformation, water and steam. It is also non-flammable and durable. This insulation is suitable for thermal insulation of any type of roof. When performing such work, it is important to use exclusively polymer acetate glue, which will provide increased adhesion.

- Ecowool. To create such a heater, waste paper is used, thanks to which the material is really environmentally friendly. It is worth noting its excellent sound and heat insulating characteristics. Ecowool is additionally treated with protective agents, as well as flame retardants, which will help get rid of the shortcomings of cellulose, including its biological instability and flammability. When performing installation, it is important to follow a few rules. So, a special closed box is created, where ecowool is blown.

- Sawdust. Previously, the material was widely used to insulate the roofs of private houses. Today, this is no longer relevant, since sawdust is subject to rotting and burning. They are used for insulation of ceilings. To improve thermal insulation characteristics, the material is mixed with clay.

Flat roof insulation

To perform thermal insulation of a flat roof at home, you can use two methods:

To perform thermal insulation of a flat roof at home, you can use two methods:

- rolling ceiling, when the material is laid on top;

- hemmed ceiling, that is, there is a padding of heat-insulating materials from the inner surface.

It is worth noting that external insulation considered to be the easier option. However, it is important to make sure that the supporting structure of a private house can support the weight of the insulation. Experts recommend giving preference to basalt mineral wool for external insulation of a flat roof.

Features of the installation of insulation

In order for an insulated flat roof to really help avoid heat loss, it is important adhere to the stages of work.

- First of all, it is necessary to organize a vapor barrier layer using a special film.

- A layer of mineral wool slabs is laid out on top.

- Next, you need to arrange the roofing material or prepare a coating from other synthetic materials.

- The last stage involves laying insulation.

Naturally, before starting work, it is important to properly prepare the roof surface. To do this, it is cleaned of debris and dust, and significant irregularities must be eliminated.

To fix the heat-insulating plates, glue or cold mastic is used. In order for the coating to turn out to be homogeneous, it is necessary to take care of the semi-overlapping of the seams. To improve thermal insulation, laying mineral wool in 2 layers will help. In this case, it is worth gluing the joints with tape. Thanks to this technology, there will be no cold bridges.

Some experts prefer fired waterproofing. To do this, after fixing the mineral wool slabs, a cement-sand screed with a minimum thickness of 3 cm is made. After that, it is necessary to glue the waterproofing layer under the influence of fire, so that the coating will be durable, tight and reliable.

In most cases, a pitched roof is the basis for creating an attic, so there are quite a few requirements for thermal insulation. strict requirements. The design itself must be made of several layers:

- ventilation circuit;

- waterproofing layer;

- ventilation circuit;

- thermal insulation layer;

- vapor barrier.

Since water ingress can lead to loss of insulation properties and rotting of wooden structures, it is important to take care of waterproofing. The device of ventilation circuits prevents the formation of condensate inside the material, which is also very important.

Since water ingress can lead to loss of insulation properties and rotting of wooden structures, it is important to take care of waterproofing. The device of ventilation circuits prevents the formation of condensate inside the material, which is also very important.

It should be noted the need for fresh air, for which a gap is organized on the overhang of the eaves. It is important to make sure that all components of the structure are ventilated. This can cause certain difficulties in the presence of intricate roof geometry. For thermal insulation of a pitched structure, a rigid material is suitable that will not deform due to any external factors.

The final stage of warming involves finishing from the inside. Most often, surfaces are sheathed with sheets of drywall or chipboard, and then wallpaper is glued or paint is applied.

During the repair of any private house, it is important to insulate the roof. Thanks to this, it will be possible to organize a comfortable microclimate in the room. In order not to have to redo everything anew, it is worth responsibly approaching the choice of material and its installation.

Country living in a private house has ceased to be the prerogative of a single number of citizens. Individual construction of dwellings is developing rapidly, and people have to solve issues of improvement, in particular, with insulation. It is quite easy to insulate walls from heat leakage, but it is much more difficult to properly insulate the roof of a house. However, we are solving the issue - it is enough to carefully approach the choice of material and competently carry out thermal insulation work with your own hands.

Depending on the side of the roof from which the insulation is laid, there are two methods of thermal insulation:

- from the inside (otherwise called the "principle of a false ceiling");

- outside ("rolling ceiling principle").

Most often, residents have to insulate the top of the house in the first way, since most moves to a new place of residence occur during the warm season. When the first frosts begin, the problem makes itself felt. This is due to the arrangement of houses - a large amount of heat leaves the room not only through doors and windows, but also through the roof. To minimize losses without dismantling the roof, the thermal insulation of the roof is made from inside the house.

Features of the choice of materials

The urgency of the problem is established; now you need to choose the right material. The question of saving money should not be brought to the fore here. It is better to take into account three important factors, information about which is usually indicated on the packaging:

- thermal conductivity of the insulating material (the value should be minimal; optimally - up to 0.04 W / m ⁰С);

- resistance to mechanical and climatic influences, which, in turn, depend on the region of residence;

- the weight of the insulation (the heavier it is, the greater the load on the roof elements, and this is undesirable).

To achieve the desired effect, it is recommended to choose a sufficiently soft and elastic material so that it fills the free space between the rafters. You will also need vapor and waterproofing. The best materials to prevent moisture from entering the insulation are:

- ruberoid;

- glassine;

- polyethylene film;

- special vapor barrier membrane.

It is necessary to take into account the features of the area; if precipitation is often observed, it is worth choosing a denser material to insulate the roof from the inside.

There are several ways to ensure the proper quality of thermal insulation. The most common are:

- glass wool installation;

- internal lining with mineral wool boards;

- installation of polystyrene panels;

- pouring PPU (polyurethane foam).