Fashion does not stand still. Once upon a time, wicker furniture was unrivaled, then soft corners and armchairs forced it out of regular use, but not for long. Already today, rattan furniture is returning to its position, occupying an important place in the interior of modern cottages and houses. Such products can not only replace modern furniture, they also have many advantages over it. Rattan is a high-quality, strong and durable material. In addition, it has unique aesthetic properties. This is why there is high demand for it. And if someone wants to purchase rattan wicker furniture, others, who are more enterprising, launch small production in this area. This direction is suitable for those who are looking for a way.

What is artificial rattan?

Rattan is a polymer thread that is produced by extrusion. The plastic is melted to a certain temperature, then passed through a specialized mold. Depending on the type and nozzle of this shape, it is possible to obtain a synthetic thread in the form of a rod, a crescent, an imitation of wooden bark and much more. The result is raw material for further weaving of different textures and colors. The plastic components must meet all specified criteria and ISO 9001 standards, be pleasant to the touch and odorless.

Features and advantages of artificial rattan:

- aesthetic appeal;

- high degree of material strength;

- moisture resistance;

- lightness of the material, which makes it easy to move around the house and during transportation;

- ease of assembly;

- duration of operation;

- does not require special care - just wipe with a damp cloth to remove dirt.

Rattan has many advantages for manufacturers as well. It is easy to work with the resulting raw material (plastic thread); due to the flexibility of the material, you can make products of any shape, even extraordinary ones (which is now popular in the interior design of houses). In addition, rattan plastic thread is very long (some manufacturers produce it up to 200 meters), so it is easy to work with. And you don’t need to think about connecting the lashes, which is important for natural materials.

Equipment for making artificial rattan furniture

The production and weaving process can be done manually (suitable for beginners). It is based on the purchase of ready-made rattan, which is supplied in reels. This option does not require large investments and consists of purchasing raw materials and hand tools.

A more professional approach is to install a production line that not only makes furniture, but also makes polymer tapes, which minimizes the cost of raw materials. Professional equipment costs from 1.5 million rubles, but having such a “factory”, you can produce furniture of any shape and size.

Equipment for making furniture from artificial rattan:

|

Manual for machining and weaving |

Wickerwork Production Line |

| set of files | extruder |

| shmol (tape sharpening) | winder |

| plows | cooling system |

| bit | crusher (for processing secondary raw materials) |

| iser (a cone-shaped steel plate for leveling rows when weaving) | granule mixer |

| welding machine | |

| drill | |

| screwdriver | |

| knives, scissors | |

| keys | |

| consumables – dyes, frame base, furniture fittings | |

This equipment allows us to produce a wide range of products - chairs, armchairs, sofas, chaise lounges, beds, cribs, tables, shelves, cabinets.

Advice: The final price of the finished rattan furniture production line is not limited to the above cost. Depending on the planned scale of production, the volume of investment can reach up to 3.5 million rubles. But in practice, a high-power extruder and other professional machines are not needed in the workshop of a novice entrepreneur.

Search for markets

The demand for do-it-yourself wicker furniture made of artificial rattan does not depend on seasonality. You can organize a business in two directions:

- select certain models of furniture and produce them for individuals, try to expand sales channels through cooperation with furniture showrooms;

- conduct an advertising campaign and work to order, fulfilling the wishes of clients.

New entrepreneurs who do DIY production still need to spend a small amount of money to attract customers. The first orders can be completed for your friends and relatives, but in the future you will need:

- advertise in local newspapers;

- post information on the Internet, on city portals, forums;

- Post advertisements around the city, leave your business cards in places where potential clients gather.

In this business, as in business, it is important to provide quality services. We need to make sure that customers are satisfied with the completed order and tell their friends about it. There are masters who do not spend a penny on advertising, while they are provided with orders through word of mouth.

When entering larger-scale production, it is necessary to enter into contracts with specialized stores that sell furniture, or organize a sales point yourself.

Advice: An excellent option for expanding sales channels is to create your own website. By collaborating with different delivery services, you can go beyond the domestic market and sell throughout the country or even abroad.

Save the article in 2 clicks:

The production of wicker furniture from artificial rattan is. It can develop into a profitable business that is in high demand, although the market is not sufficiently saturated with such offers and has great prospects for beginners.

In contact with

Fashion goes in circles. And now, once replaced by upholstered furniture, wicker interior items are returning to homes. Wicker furniture and rattan products can not only replace any ultra-modern furniture, but also have many advantages over it. After all, the material itself is extremely versatile, high-quality, durable and lightweight. Therefore, the demand for wickerwork is growing again. And many people want to not only order or buy them, but even make rattan furniture with their own hands. After all, then one more thing will be added to all the known advantages - pride in yourself and your creation.

Rattan furniture is high-quality, durable and lightweight products, the production of which can be used to organize a profitable business.

Wicker furniture: what should you know about it?

You can learn any business if you have the desire. And with the right approach, such a hobby can turn into a well-paid occupation. You will need skills that are acquired in the process of work, as well as knowledge of certain nuances.

What, from what and how to weave?

First of all, you should know that wicker furniture is divided into soft and semi-hard. There are several types of products:

- stick products - the sticks you use will serve as a supporting structure;

- frameless products - sticks are needed to act as stiffening ribs for the structure, you will need a lot of them, and they must be very strong;

- frame (compositing) and joinery-frame products, here a ready-made frame in the form of steel rods or duralumin tubes will be used, and weaving will be carried out between them.

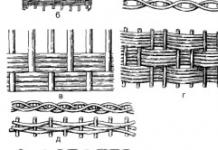

Weaving methods are also different. You can use simple single weaving, openwork or even combined (for several twigs). In the process, you can stick to one continuous weave for the entire product, or you can try to create some patterns and combine them later.

It's worth paying attention to how you connect all the parts of your product. After all, you want the furniture to last a long time and be of high quality. To do this, all nodes and elements must be securely and firmly connected. Be sure to ensure that there is the necessary rigidity. Choose the way you will connect the parts. It can be detachable. Then you will be able to assemble and disassemble furniture without any obstacles in the future. But there are restrictions on using this type of connection, because the nature of this furniture is quite specific. The second method is one-piece. You will need nails, a hammer, glue and self-tapping screws. With it, your furniture will really last a long time and reliably, but keep in mind the lack of mobility (in case of moving or transportation).

You can weave furniture from a wide variety of materials. For these purposes, they use willow, alder, bamboo, bird cherry, hazel and even nettle and raspberries. Apart from the fact that, in parallel with them, rattan material is also widely used for making furniture. It can be either natural or artificial. What to choose?

Wicker furniture or rattan furniture?

Each material has its own advantages and disadvantages. True, the shortcomings are mostly small and they pale in comparison to the many advantages.

Vine is a universal material. You can weave anything from it. Any furniture made of wicker and various decorative elements look incredibly beautiful, stylish and elegant. It is also important that products made from it are natural and environmentally friendly. To weave, you will have to prepare the rods (boil them in boiling water), peel them from the bark, then soak them until maximum elasticity, and prepare additional cut strips. Usually they work with willow. Willow furniture is a very suitable option for decorating a yard and garden. The vine is resistant to moisture, so you can safely place the products outside.

Rattan furniture can be made from natural material. This process is quite labor-intensive, since the rods also need to be carefully processed before the weaving process. As in preparing the vines with your own hands, rattan also needs to be cleared of bark. But the material also needs to be ranked by thickness, steamed, and straightened. Even rattan bark is used. Various rugs, mats, backs of chairs and sofas are woven from it. Thin stems are well suited for decorating corners or weaving a pattern, and thick ones will be used to make the frame itself.

To do this, you will need to give the stem the desired shape (before this it must be well steamed). Then the stem is fixed on a special machine to secure the necessary structure. After a day you can remove it and make grooves and notches on the parts, drill holes. All elements are also connected with rattan. If the product is treated with varnish or wax, it will retain its natural shade and texture for a long time.

Rattan furniture is made using a virtually waste-free method. It is environmentally friendly, has high strength, relative moisture resistance, is easy to assemble and transport, weighs little and can serve for a long time. But among its disadvantages is that natural rattan is very expensive. It also does not tolerate sudden temperature fluctuations or close proximity to heating devices or open fire. Such products require careful care.

Artificial, or technorattan, does not require such a labor-intensive and complex process as natural one. All you need is to find a ready-made frame. It can be made of metal, plastic or wood. Next, you will need to attach guides to its base in order to later create a specific rattan pattern. This can be done using a furniture stapler, screws, and bolts. The rods that protrude beyond the frame must be cut off with a knife or sharp scissors. Then start weaving the frame. You can simply weave in a checkerboard pattern or choose some interesting and complex openwork when you have practiced enough. If you try a combination of several varieties of rattan, you will get a very original and beautiful pattern. Anything that is superfluous and extends beyond the frame must be cut off, and the ends of the finished product must be masked.

If you make rattan furniture using artificial material, the product will be very functional and practical.

The advantages of technorattan include the fact that products made from it are non-toxic, light in weight, moisture and ultraviolet resistant, they do not deform due to sudden temperature changes, are easy to care for, and have no synthetic odor. When handling them, you can use detergents and apply heavy loads. Such furniture has no joints, it is reliable and durable. Prices for finished products and the material itself are more than acceptable. The downside is that due to the rigidity of artificial rattan, a plastic or iron frame is required. And when the weaving is damaged, the product may lose strength and even fall apart completely.

From study to art

Making wicker furniture yourself is not difficult, but how much joy it will bring to you and your loved ones. Try to start small, gradually moving to more complex shapes, patterns, and products. You can weave for yourself, or you can turn weaving into an entire art and organize a profitable business.

Wicker furniture has always been in demand and testified to the wealth and refined taste of the owners. Its cost is quite high, since the products are made by hand and are original in their design. Natural rattan is considered the most popular material for its manufacture, but it is quite expensive and not everyone can afford it. To make rattan furniture more affordable, an artificial analogue was invented, which turned out to be much cheaper and stronger than natural rattan.

Wicker furniture has always been in demand and testified to the wealth and refined taste of the owners.

Amazing structures are also made from artificial rattan: houses for cats and indoor dogs, flower stands and other products.

After its invention, specialists began to quickly master it, and in a short time, artificial rattan products appeared on the furniture market, characterized by elegance, comfort and durability.

To make rattan furniture more affordable, an artificial analogue was invented, which turned out to be much cheaper and stronger than natural rattan.

Home craftsmen immediately appreciated the advantages of the new material, and those who did not yet have weaving skills looked with envy at the amazingly noble and beautiful products. But there is nothing in our life that cannot be mastered. Therefore, more and more often there are beginning home craftsmen who want to learn how to weave furniture on their own. Practice shows that the science of weaving is within the capabilities of everyone, especially since such a durable and comfortable material as artificial rattan, which is most often used in weaving furniture, can be purchased relatively inexpensively today.

Home craftsmen immediately appreciated the advantages of the new material, and those who did not yet have weaving skills.

To make artificial rattan furniture with your own hands, you will need the material itself for the work.

Making wicker furniture from artificial rattan at home has its advantages:

- significantly saves the family budget;

- has a long service life;

- low weight of products;

- with external lightness and delicacy, it retains strength and reliability with careful handling;

- not subject to temperature changes and exposure to sunlight;

- does not contain harmful or toxic components;

- hypoallergenic;

- easy care.

But there is nothing in our life that cannot be mastered.

Important! The material itself is lightweight, easy to transport, attractive from an aesthetic point of view, has high strength, and is not subject to deformation from moisture.

Therefore, more and more often there are beginning home craftsmen who want to learn how to weave furniture on their own.

It must be taken into account that the material has different lengths and differs in material thickness and width.

It is convenient to work with artificial rattan, as it is flexible and comes in the form of long threads, which does not require constant gluing or other methods of connecting small parts of the material.

Making wicker furniture from artificial rattan at home has its advantages.

Deciding on design and construction

The material provides ample opportunities for the implementation of design ideas. It can be used to make products of varying complexity, including relaxation sets consisting of wicker chairs, a sofa, and a table of an original shape. Interesting bookcases, bedside tables, chests, ottomans. Amazing structures are also made from artificial rattan: houses for cats and indoor dogs, flower stands and other products.

Significantly saves the family budget.

It is available with a smooth and ribbed surface and is available in a variety of colors and textures.

Attention! With all the breadth of choice, a novice craftsman should start with the simplest products that allow him to master weaving skills. The easiest way to start is by making an ottoman: an elementary design, the opportunity to master weaving skills, and in case of failure, it is easy to remake the defect, which turns out to be preferable in the first stages of mastering the skills of weaving from artificial rattan.

With external lightness and delicacy, it retains strength and reliability with careful handling.

In addition, you cannot overdo it so as not to overtighten one of the sides, otherwise the result will not be satisfactory.

Necessary materials

To make artificial rattan furniture with your own hands, you will need the material itself for the work. In this case, you can select the desired configuration, taking into account the fact that it is available in the form

- long stripes

- braids

- rod

- imitation tree bark.

Not subject to temperature changes and exposure to sunlight.

At the initial stage of work, when a simple product is selected for manufacturing, a minimum of equipment will be required for weaving.

It must be taken into account that the material has different lengths and differs in material thickness and width. It is available with a smooth and ribbed surface and is available in a variety of colors and textures.

The material itself is lightweight, easy to transport, and attractive from an aesthetic point of view.

But if you want to make it even more elegant, you can use bright soft blankets and pillows as decoration.

Required Tools

At the initial stage of work, when a simple product is selected for manufacturing, a minimum of equipment will be required for weaving. To get started, you will need:

- stapler - for attaching rattan to the base if a wooden base is used;

- small pliers;

- small hammer;

- a convenient sharp knife or cutter;

- soldering iron for soldering connecting elements of the material or glue.

It is convenient to work with artificial rattan, as it is flexible and comes in the form of long threads.

In order for the manufacturing process to proceed without unexpected interruptions, it is necessary to take into account the recommendations of experienced craftsmen.

Manufacturing process: step-by-step instructions

In order for the manufacturing process to proceed without unexpected interruptions, it is necessary to take into account the recommendations of experienced craftsmen who suggest organizing it in a certain order:

- Prepare the structure chosen as the base, wooden or metal. It can be made with your own hands, but you can also use a ready-made one.

- To make it convenient to work, install the guides on the base and secure them with self-tapping screws, a stapler or bolts.

- Level the surface of the frame by cutting off the protruding rods with scissors.

- The next step is weaving on the frame. Its type is chosen according to your taste and depending on the selected raw materials.

| Weaving type | Peculiarities |

| Simple | It is easy to perform. Perfect for those just learning to work with rattan. |

| Rope | Produces a dense weave with a pattern similar to a twisted rope. You can start working with this type after mastering the simple one. |

| Three rods | A more complex type of work that requires skill and ensures the strength and stability of the product. |

| In four rods | This is done in two ways. At first, the drawing looks the same from the outside and inside. The second is a rope; with its help weak strips of other types of weaving are secured or separated. |

| Openwork (simple and complex) | A variety of loose weaves with open cells. The complex openwork is similar to lace patterns. Simple openwork includes rhombuses, columns, rosettes, spirals, rings, and also chessboard. |

- Excess material is removed after completion of the work, and the ends are “masked” on the finished product.

The material provides ample opportunities for the implementation of design ideas.

In order for the product to be smooth, durable and neat, when weaving, it is necessary to constantly check how the rows of rattan “lay down”.

Attention! In order for the product to be smooth, durable and neat, when weaving, it is necessary to constantly check how the rows of rattan “lay down”. In addition, you cannot overdo it so as not to overtighten one of the sides, otherwise the result will not be satisfactory: the product will turn out to be lopsided and it will be impossible to use it.

Interesting bookcases, bedside tables, chests, ottomans.

Wicker furniture made from artificial rattan looks rich, it is elegant and graceful.

The final stage is decoration

Wicker furniture made from artificial rattan looks rich, it is elegant and graceful. But if you want to make it even more elegant, you can use bright soft blankets and pillows as decoration.

With all the breadth of choice, a novice craftsman should start with the simplest products that allow him to master weaving skills.

The product will be lopsided and will be impossible to use.

VIDEO: Making artificial rattan furniture

If you master the technology of weaving from natural or artificial materials, you can decorate your home, apartment, or summer cottage with stylish original furniture and interior items at no extra cost. It is not difficult to make artificial rattan furniture with your own hands; the prepared frame is braided with rattan cord or ribbons, and a pattern is created according to the chosen pattern.

What materials are used for wicker furniture?

In our region, willow vines are traditionally used for weaving; in tropical latitudes, rattan palm stems (calamus) are used. Vine is an affordable raw material, but harvesting it yourself is a rather labor-intensive process. Wicker furniture is less strong and durable compared to rattan. Natural rattan, like vines, is harvested and subjected to multi-stage processing - the stems are cleared of bark, sorted by thickness, steamed, acquired elasticity and straightened. Thick stems after this treatment can be bent, giving the shape necessary for the frame elements, and dried. Thin stems and bark are used for weaving; they are cut into fragments of the required length. It will not be possible to prepare natural rattan with your own hands - it does not grow here, and purchasing prepared raw materials, taking into account transportation costs, will be very expensive.

Natural rattan has a synthetic analogue - polyrottan or technorattan. It is made by extruding a soft polymer through holes of different diameters and cross-sections. The material has many modifications:

- flat strip with a textured surface, ribbed surface, possible imitation of tree bark;

- tape, braid with a smooth surface;

- round or oval cord;

- cord with a crescent-shaped cross-section;

- rattan rod.

Artificial rattan is more popular compared to natural rattan for a number of reasons:

- the price is significantly more affordable;

- synthetic rattan is superior to its natural counterpart in flexibility and elasticity;

- environmental friendliness and safety are not inferior to natural raw materials, does not have a specific odor characteristic of some polymers;

- Polyrattan is more durable, furniture made from it can withstand significant loads without deformation;

- the furniture is moisture-resistant and frost-resistant, not afraid of changes in temperature and humidity conditions;

- the furniture is easy to care for and can be cleaned of dirt using various detergents;

- rattan strips and cords are available in any length, which allows you to weave furniture without joints;

- the raw materials are completely ready for use;

- A large selection of modifications of different shapes, colors and textures allows you to create attractive furniture that will fit into any interior.

The disadvantages of technorattan include its relatively low rigidity, so furniture made from it necessarily needs a rigid frame. There is a risk of damaging the weave during use, and it will begin to unravel.

For lightweight furniture that will be used in conditions of high humidity, for example, in a bathroom or outdoors, it is better to use a plastic or aluminum frame rather than a wooden frame. If the furniture will be subject to significant loads, a frame made of metal or wood is preferable.

Furniture making technique

To weave artificial rattan furniture with your own hands, you need to choose a model, decide on the frame configuration and weaving pattern, draw up a project and draw a sketch of the product, and calculate the amount of material. To make a chair, 2 kg of poly rattan is enough, for a small two-seater sofa it will take 5-7 kg, for a large sofa - up to 10 kg.

It is better for beginning craftsmen to stick to regular checkerboard weaving; if you combine rattan of different colors or textures, even a simple pattern will look impressive. If you have experience, you can choose a more complex pattern, openwork weaving.

To create furniture you will need:

- a frame that you can assemble with your own hands or order a blank from a carpentry workshop or a hardware workshop;

- tape or rod for guides that are attached to the frame; a pattern will be created on them;

- ribbon, braid or cord for weaving;

- fasteners for fixing the guides to the frame;

- pins, bolts or thin strips of leather to connect parts of the finished product (if it is assembled from separate elements).

Sequence of work:

- Assemble or buy a ready-made frame (frame elements).

- Fix a number of guides on the base. A rod or tape is wrapped around the frame; as a rule, one turn is enough, but for reliability, several turns can be made with overlap, after which the end is attached to the base. For high-quality weaving, strong tension and density of the guides are important; it is better to connect 2-3 strips of tape and use them as one guide.

Depending on the frame material and the thickness of the rattan rod, it can be fastened with self-tapping screws, using a regular furniture stapler (to wood), or a pneumatic stapler with narrow short staples (to an aluminum frame). The most difficult thing is to fix the guides to the steel frame made of furniture pipes. There is a way out - the frame is wrapped with rattan tape, the end is braided with an overlap, the touching fragments of the tape or rod are welded with a soldering iron with a point tip. Then the guides are welded to the base with the same soldering iron.

- The ends of the rods extending beyond the frame are cut off with a construction knife, scissors or wire cutters.

- A pattern is created on the basis of the guides in accordance with the selected pattern.

- The weaving is constantly trimmed to ensure a neat pattern without distortions, and at the end the final alignment is carried out. The cord (tape) can be moved, compacting the rows as necessary or increasing the gaps between them; during the weaving process, alignment is done by hand; when the fabric is finished, you can use a sharpened pencil to move the tightly closed rows apart in some places.

- The ends of the cord are fixed with a stapler or soldering iron to the base from the inside out, the excess is cut off.

- The frame itself, legs and similar elements are braided; a special tool with a curved tip is useful for pulling the tape.

- If the product consists of several elements, they are connected after each is braided with rattan; after final assembly, the ends are masked.

- If desired, finished furniture can be painted with acrylic spray paint, but a sufficient selection of technorattan colors allows you to do without additional painting.

You can make it easier to pull the tape or cord between the guides and avoid scratches and abrasions by wiping the weaving material with a piece of rag soaked in vegetable oil.

It is better to create complex rattan furniture (for example, a sofa) in the following sequence: first, the frames of individual elements are braided - the back, the seat, the sides and armrests, and then they are connected to each other with bolts or another method. To seat a large area, it is necessary to attach longitudinal and transverse rigidity strands made of dense nylon tape to the frame before starting weaving.

Since ancient times, people have made their own household items with their own hands. Furniture was made from wood, and also woven from willow, wicker, rattan and other suitable materials. Such interior items are functional, elegant, unique, and you can make them yourself. Do-it-yourself wicker furniture made from wicker will look much more original than purchased furniture. Manufacturing will not take much time.

- 1 Life history of wicker furniture

- 2 Pros and cons of wicker furniture

- 3 Preparation for manufacturing

- 4 Types of weaving

- 5 Tools

- 6 How to weave furniture from twigs: step-by-step instructions

- 7 Product finishing

- 8 How to care for and repair wicker furniture

Life history of wicker furniture

Weaving furniture is a fascinating and rewarding process. Not everyone can afford to buy such products, but making an effort and weaving extraordinary and functional interior items is accessible to every person who loves creativity and does not know how to be lazy.

Archaeologists find wickerwork in various parts of the world - Egypt, the Middle East, Europe. Items made of wicker, willow, rattan, reed, papyrus and other suitable materials have always been in demand in everyday life: baskets, laundry boxes, strollers, fishing tools, vases.

This is what a bed woven in ancient Egypt looked like

The spread and popularization of this type of needlework in Russia was facilitated by the location of villages near reservoirs, where the main types of natural material for weaving grew. True masters of their craft lived and worked in different provinces. The Moscow, Nizhny Novgorod, Kostroma, Ivanovo, Vladimir, and Yaroslavl regions were famous for such products.

Gradually, wickerwork from ordinary homes migrated to the interiors of wealthy people, becoming beautiful, elegant furniture. Many wicker products were in demand by the Russian nobility in the 20th century. They began to be produced not only by single artisans, but also by entire artels, whose participants studied in specially opened weaving schools.

In the houses of aristocrats, entire sets were made of wicker

The passion for wicker furniture came from Prince Golitsyn, who, having seen similar products abroad, introduced this type of applied creativity to his estate, creating a specialized workshop.

Masters of this type of needlework wove:

- furniture (couches, sofas, chairs, tables, chaise lounges, armchairs, rocking chairs, cradles, screens, shelves);

- travel accessories (suitcases, suitcases, bags, chests);

- household items (baskets of different sizes, vases, bread bins, plates, candy bowls);

- toys (rattles, cars, dishes and furniture for dolls).

Hanging furniture was also made from wicker.

Most often, furniture is woven from rattan, wicker and willow.

Nowadays, this craft is also not forgotten. Wicker furniture can be purchased in specialized stores or from craftsmen. But you can test yourself, try your hand at this type of applied art. By making furniture from wicker for a summer house, country house or loggia, you can become the owner of a unique interior element.

Wickerwork can be seen on the canvases of world-famous artists: a cradle in Rembrandt’s painting “The Holy Family”, baskets in Pieter Bruegel the Elder’s “Haymaking”, a basket in the hands of a maid depicted by Pieter de Hooch (“Mistress and Maid”), household items in Jan’s painting Vermeer's "Thrush" and others.

Pros and cons of wicker furniture

Making wicker furniture with your own hands is a rather lengthy and labor-intensive process, but the result will delight everyone.

Wicker furniture has a number of advantages:

But there is one significant drawback - instability to certain climatic conditions (it can get wet under heavy rain or dry out under prolonged exposure to heat). In addition, even with the highest quality weaving, over the years, some parts of the product may become unraveled. However, it is very difficult to repair them.

You can weave furniture yourself if you carefully study the technology of this process and strictly follow the step-by-step instructions.

Photo gallery: various items of wicker furniture

This sofa looks elegant in an outdoor interior.

This daybed perfectly combines wicker elements with decorative upholstery.

Entire furniture sets can be made with your own hands from natural materials.

How nice it is to sit and rock in such a chair made of wicker

A bed made of wicker looks stylish and original

Preparation for production

The process of weaving furniture cannot be called fast; preparation for it also takes a lot of time.

What can wicker furniture be made from?

To weave furniture, you can use various materials, the choice of which is limited by the climatic conditions of a particular country. The main thing is that the raw material is strong, flexible and elastic.

All material used can be divided into main and auxiliary.

For weaving you can use:

- birch bark;

- bast;

- pine shavings;

- cattail;

- processed reed core (peddig);

- palm leaves (coconut and Moorish);

- rattan (liana);

- loofa (plant sponge from Greece);

- cane;

- bamboo;

- banana leaves;

- willow;

- bird cherry;

- hazel;

- outer shell of coconut tree, etc.

Not all of the listed materials are suitable for weaving large amounts of furniture, since they do not have sufficient strength to withstand the weight of a person.

willow vine

Traditionally, willow twigs are used for weaving, which are called a miracle material. Willow “gives” raw materials that combine flexibility and elasticity. It is these qualities that are especially valued in weaving.

Cleaned willow twigs are ready for use

There are many varieties of this tree, each with its own characteristics of use. Since ancient times, willow vines have been used for handicrafts, creating both household items and interior decoration elements. Red flower (willow), goat willow (willow), bay willow (broom), almond and other shrub species are the most suitable material for weaving.

Swamps, grass swamps, mixed forests are places where willow trees grow. Masters of their craft use them selectively - some varieties are purchased for rough weaving, others - for creating elegant little things.

Furniture made from willow wicker is very elegant

Willow vines are harvested in autumn, winter and early spring. During these periods, you can stock up on suitable twigs, since the growing season has ended in the plant.

It is difficult to remove bark from twigs harvested in autumn and winter, but material stored at the very beginning of spring (when sap flow just begins) is the best for weaving.

Additional soaking or boiling will help remove the top layer from the rods.

Branches of bird cherry, hazel, rowan can also be used for wicker furniture, but their use is not as common. Bird cherry rods are more suitable for beginners, those who are just learning the basics of weaving. They are more pliable, easier to cut, bend and perform other manipulations when weaving.

Reed

One type of this plant material is used in weaving - lake material. Reeds that grow in the southern regions are more suitable.

Reeds are collected in late June - early July and dried in shady places. Long thin rods 1 mm thick are made from it - peddig, which is in demand when creating “openwork” furniture elements (seat backs, decorative elements).

Reeds are stacked in sheaves for storage

Bamboo

This type of wood is very durable. For weaving, you can take whole stems or split ribbons. It bends well after treatment with an alcohol lamp. This raw material is used in the Caucasus region.

Bamboo furniture has a special pattern

Rattan

The vine, which can be found in Asian countries and the Pacific Islands, is very suitable for weaving a strong frame.

Rattan products (very popular among consumers) are most often made using a monolithic method. This technology allows rattan stems to be bent into desired configurations. Do-it-yourself rattan wicker furniture is characterized by durability and strength. An example of this is the rare Viennese chairs.

Rattan rods are dyed and bleached before use

Auxiliary materials for the frame

To ensure that wicker furniture does not fall apart the first time it is used, but lasts for many years, many craftsmen use alternative materials that add strength to such products.

Use of metal structures (frames of chairs, tables, sofas):

- helps save the consumption of basic materials;

- speeds up and facilitates the weaving process;

- adds strength to the product;

- increases the service life of furniture.

Modern life dictates its own conditions, so it is quite justified for some craftsmen to use furniture elements made of polyurethane foam, expanded polystyrene, and polyvinyl chloride. Backrests, seats and other parts in combination with wicker elements look quite organic; such furniture is also in demand on the market.

Soft upholstery will make the furniture very comfortable

When starting to prepare material, it is useful to listen to the advice of experienced specialists:

You can prepare the material yourself. If you don’t have the time or desire, you can always buy it in specialized stores.

The list of requirements that wicker weaving experts place on the material:

For weaving furniture, rods with and without bark are used: the so-called green and white rods. The top layer is removed using a special device - a pinch.

Green twigs can be recommended for beginning dows weavers, as they are more flexible and do not require time-consuming cleaning of bark. Products made from such material do not look as beautiful as objects woven from white rod.

Cleaned rods turn white

The color of the bark-cleaned twigs can be adjusted using various means to obtain the following material:

- snow-white (hydrogen peroxide);

- brown (potassium permanganate solution);

- grayish (iron sulfate):

- different shades (aniline dyes).

Types of weaving

You can weave in different ways, and each of them carries not only a decorative, but also a functional load. To weave in one way or another is to fill the voids between the posts in a certain way.

Before you start weaving any voluminous items, practice on samples.

In these ways you can weave any product from wicker, rattan and other materials.

| Weave name | Method of execution | |

| Simple | Solid thick | Single rods are woven between the posts, alternating the position of the rod in front or behind the post. |

| Rope | Weaving is done with at least two rods, which go around each post on both sides, forming strong cells. | |

| Checkers | The working rod (or several rods) braids in a checkerboard pattern two posts at a time to the desired height (first strip). The same movements are repeated with the next rod, weaving it between the resulting rows of the first strip (second strip). The third and fourth stripes are woven like the first and second. | |

| Diamond-shaped | Openwork | More complex weaving with the implementation of certain geometric shapes and patterns from open cells. |

| In the form of pillars | ||

| Chess | ||

| Rosette | ||

| Ring | ||

| Spiral | ||

| Pigtail | This type is used as weaving decorative elements, as well as for edging - from the ends of posts. | |

| Bending | In this way the edges of the product are decorated (from the protruding parts of the racks) | |

Photo gallery: types of weaving

Openwork weaving is suitable for making decorative elements

Rope weaving refers to openwork

The braid is called so because of its appearance

Simple weaving suitable for beginners

Checker weaving allows you to create a pattern on furniture

Tools

Like any creativity, weaving requires special tools:

- special knives and garden shears (for cutting and trimming twigs);

- ladder (for sorting raw materials);

- large container, tank (for soaking the rod);

- boiler (for cooking and bleaching preparations);

- squeezers (for cleaning twigs from bark);

- splitters (for dividing the rods into parts);

- shof (for obtaining planed strips);

- shmyg (for curly processing, notching);

- iser (for aligning rows);

- clamps (for straightening frame blanks).

All these tools are highly specialized; not a single weaving master can do his work without them. Household aids familiar to many are also used: pliers, round-nose pliers, awls, pliers, saws, planes, etc.

The driver requires special skills from the master

How to weave furniture from twigs: step-by-step instructions

A step-by-step description of the process of weaving furniture is a good help for people just starting to master this type of needlework.

How to weave a chair from willow or rattan

First of all, we need a chair frame. It is made from sticks, the thickness of which varies between 15–20 mm. The frame can be reinforced with plates, rods or weaving.

Ready-made wooden frames are also available for sale.

The use of a ready-made wooden frame will significantly simplify and speed up the work

The weaving process itself takes place in several stages:

The chair can be made on a ready-made frame

An armchair is woven like a chair, only armrests are added to it.

Video: DIY chair weaving

Product finishing

A piece of furniture woven by hand must be “brought to mind.” Here's what's included in the finishing work:

Several layers of varnish will help make the product more durable.

How to care for and repair wicker furniture

Wicker furniture requires special care:

- Wipe the dust with a damp cloth at least once a week;

- If a large amount of liquid gets on the furniture, dry it immediately (preferably naturally - in the air);

- vacuum products using soft attachments;

- When the material from which the furniture is made dries, cover it with a thin layer of linseed oil (preferably from a spray bottle).

Repairing such products is almost never done, since this process is so complex that not every master is ready to take on it.

The well-known expression “eyes are afraid - hands are doing” fully applies to furniture weaving. Having studied the information on this issue, prepared the necessary material and pattern, you can independently weave any piece of furniture.