Round rolled O10, square #10. Cut out petal blanks from the sheet.

We heat the rod O 10 and, stepping back from the edge by about 40 mm, we forge a transition to O8.

Then we clamp the workpiece in a vice and press the remaining end to O 12-13. Let's trim the boss and use a backing chisel to make an undercut at a distance of 5-10 mm from the edge - this will be the rod for the rivet.

Pull the rod back to #6-7mm.

When crimping, we roll the rod to Ø 6mm.

Now let's move on to the spikes. To forge a thorn, the stem is forged to 8, leaving part of the rod (l = 10mm).

Then, on the edge of the anvil, with two or three sharp blows of the hammer, we delay the protrusion. You have to hit very accurately.

Then we clamp the workpiece in a vice and install the protrusion through the guide (bar).

The thorn is ready. We forge others (as many as planned) and complete the stem.

It's the petals' turn. On the petals you need to lower (make thinner) the edges and mark the veins. Well, it’s possible without veins, but I’ll do it.

Let's form the petals.

And also the lower petals.

And the middle of the corolla.

The time has come to “grow” the leaves. To do this, heat #10, pull the end onto a cone and leaving about 45mm, make a neck for the handle.

We break the workpiece, giving it the shape of a sheet.

We apply veins on the leaf.

And we pull back the stalk.

You can collect "to the heap".

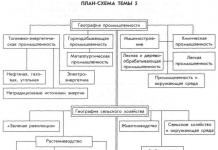

Assembly procedure for a forged rose

Let's start assembling the flower. We clamp the stem in a vice, put the rims on the rivet rod and seal them. Let's rivet st.

From rough metal, if you wish and have the right materials, you can make an elegant flower, for example, a rose like this. Its bud turns out lush, textured and closely resembles its natural prototype. This flower even has metal spikes, which are very easy to make if you know some tricks of working with steel.

Materials

To create a metal rose with your own hands, you will need:

- thin steel sheets;

- steel rod, 0.6 mm, length 38 cm;

- tig for manual arc welding;

- hammer;

- pliers;

- acetylene torch;

- a hammer with a well-sharpened edge;

- manual coffee grinder.

Step 1. Before creating a rose, you need to make a template of all its constituent parts from paper.

- The very first layer of a rose is a small bud with three petals, 7 cm in diameter.

- The second layer consists of five petals, the diameter of which is 9.6 cm.

- The third layer of petals consists of five units with a total diameter of 12 cm.

- The fourth and fifth layers consist of six petals with a circle diameter of 14.4 cm.

- The final layer of petals is five identical petals with a diameter of 9.6 cm.

Cut all these blanks out of thick paper.

Step 2. The prepared templates should be attached to a sheet of metal and transferred using soap or chalk. To use material as economically as possible, apply the templates close to each other.

Step 3. Cut out each tier of rose flowers. Don’t throw away any remaining scraps you have at this stage. They will be needed for the formation of leaves. In the center of each of the resulting blanks, make holes with a diameter of 0.6 cm. They are necessary to string the blanks onto the stem.

Step 4. After plasma cutting, scale may remain on the edges of the workpieces; it must be removed. To do this, pass the components of the flower through a small section of a hand-held coffee grinder.

Step 5. Now you can start forming the flower. You will just need to bend the first two tiers without giving them a particularly realistic texture. This will be extra work, since the petals of the bud will be closed and not visible. String the first tier of petals onto the rod. Slide it to the edge. Heat the petals to a red metallic color and bend them with a hammer and pliers to form a tight center of the bud. In order to heat a steel workpiece, you can use an oxygen torch clamped in a vice. In this case, you will need a lot of time. If you want to do the job faster, use a foundry furnace.

Similarly, attach a second layer of petals to the stem, which also form a dense central bud.

Step 6. Continue to string all other layers of petals in the same way, but make their ends more textured. Their wavy curves should be shaped like a real rose flower.

Step 7. Fold the layer with rose sepals downwards.

Step 8. Having thus collected the flower, make a weld along the stem, which will strengthen this elegant metal sculpture.

Step 9. Cut rose leaves from the remaining scraps, shape them into the desired shape and weld them to the stem.

Step 10. You need to make thorns on the stem. To do this, you need to turn off the gas on the welding machine for a moment. Without shielding gas, the metal will begin to bulge outward on its own. Similar passes need to be made throughout the entire stem. The advantage of these metal spikes is that they are not sharp. In some places it will be necessary to heat up the rod itself in order to give it the bends characteristic of a living flower.

The metal rose is ready!

I am with you again and will please you new articles about homemade products every day!

This work was done with a minimum of tools and can be repeated by almost anyone.

Tool

I also forgot to add a hammer and a soldering iron (torch), but metal scissors turned out to be superfluous.

The round thing with a thread :) is part of the ball joint of the Lada.

Let's start with the petals, cut out the following blanks from tin:

We anneal it, put it in a spoon and begin to slowly roll it with the ball, giving it the shape we need.

In the photo, the original version with already curved petals, later I made uncurved ones and first polished them, and only then folded them.

Then we make a hole in the tail, collect several pieces and see how it turns out

In total, 7 petals were made.

And then I ran into a problem: I can’t make the petal smaller than the ball one...

It was a two-day plug. Ultimately, a solution was found. Let's cut out this strip of metal.

We make such cutouts on it

Then we take the bolt and cut it with a hacksaw.

Solder

and roll it up :)

We push it out a little and begin to bend the petals.

Then we solder the tip so that the circle becomes rigid.

Now let's move on to the sepals.

We take the ball joint and PUNCH it with a hammer so that the necessary depression is formed in the wood.

We burn a strip of copper tin.

Let's hit it with all our might. Cut it out as we need it, then I think it's clear from the photo

Drill a hole and collect the flower.

Now we make the receptacle.

I didn't have the necessary copper blank... so I had to do this:

We solder it (don’t forget to solder a nut into the wide end :)), clamp it into a drill, process it

in the narrow part we cut a thread (or also solder a nut)

The stem is a copper tube (from a refrigerator, I think).

Let’s roll it all up :)

Now the twigs and leaves.

The twigs are just ordinary wire, drill a hole in the stem and solder it there:

The original version of the leaves

I had to abandon it, because when punching the recesses (under the rhinestones) they were very

warped. Therefore, they were made using the LUT method.

Well, a few words about fixing the stones

We grind two such punches into a cone, with cones equal to the cones of the stones

Metal jewelry has never gone out of style. Of course, you can easily buy them from folk craftsmen. But what could be more beautiful than a handmade metal rose as a gift to your beloved woman, or a hand-made candlestick presented to friends on the occasion of a family celebration?

How to make a metal flower?

The technology for making a metal rose is not difficult to master. You just need to show patience and practical savvy.

To make metal jewelry by doing the work yourself, you will need a sheet of roofing iron, which is best annealed to give it plasticity and softness. Next, you need to mark five star-shaped figures on the metal. Four stars have pointed petals, and the fifth has straight petals. The diameters of the circumscribed circles of pointed stars: 12 cm, 10 cm, two 6 cm each. The figure with straight petals has a diameter of 8 cm.

Rose

The next step is to make three cylindrical mandrels with base diameters of 1, 1.5, 2 cm. The mandrel material can be hard wood or metal. The cut out star is placed on a slab of hard wood or lead. The mandrel is placed along the line connecting the center and tip of the petal. With light blows of a hammer, bend the metal of the petal around the mandrel. All petals are processed in this way. The smaller the diameter of the sprocket, the smaller the diameter of the mandrel you need to take for processing it.

Next, the mandrel with its end rounded end is placed in turn in the center of each sprocket and hit with a hammer. The stars should take a neat cup shape. Using pliers, you need to bend the tips of the flower petals outward at your discretion and desire. For the inner sprocket of the smallest diameter, leave the tips straight. The processing must be carried out in such a way that after its completion all the stars easily fold into each other. Metal flowers, skillfully created with your own hands, can be made not only in the form of a rose, but also any other flower. It all depends on your desire and imagination.

Next step. Cut leaves with embossed veins from metal. As a stem

you can take thick wire. Attach the blanks to the end of the stem and grab them for strength.

To give a flower a complete color scheme, it must be heated until red, cooled in oil and washed in gasoline. After all these procedures, the product will have a beautiful, very dark shade.

DIY metal candlesticks

A unique candlestick can be made using simple materials and tools:

- a metal strip made of sheet 3 mm thick, 40 mm wide, 400 mm long and a strip of the same metal 20 mm wide and about 500 mm long;

- a piece of metal sheet 2 mm thick, dimensions 100 x 100 mm;

- green paint;

- hacksaw;

- files – flat and round;

- hammer;

- drill with 6 mm drill bit;

- ruler, needle and core for marking;

- for assembling parts.

Candlestick – sketch

Candlestick – sketch Bracket part No. 1, which will be attached to the wall, is made from a strip with a cross-section of 3 mm x 40 mm and a length of 400 mm. The ornament of your choice is applied along the edge of the workpiece using a round file. A hole is drilled in the strip for hanging on a wall mount. The upper end of the strip can be bent using a hammer, holding the part in a vice.

A piece in the form of a circle is cut out of a sheet 2 mm thick to install a candle. This detail can be decorated with a flower, which is cup-shaped in the manner described in the previous section. A hole with a diameter of 6 mm is drilled in the center of the round part. Souvenirs made with soul and with your own hands require imagination and some skills when working with plumbing tools.

Next, bracket No. 2 is made with a cross-section of 3 mm x 20 mm and a length of about 50 cm. One of its ends will then be attached by welding to bracket No. 1. The second end is cut lengthwise into 100-150 mm. The ends are bent in different directions, they are given an arched shape. The resulting candle bowl is placed on the resulting stand and spot welded to the strips.

Now you need to think about how to attach the candle to the candlestick. For this purpose, you need to take a piece of rod with a diameter of 8 mm and a length of 35-40 mm. One end of the 10 mm rod is machined to a diameter of 6 mm. At the second end, a point is created on a lathe or using a file. The end with a diameter of 6 mm is inserted into the hole in the bowl of the candlestick.

After assembling all the parts, the candlestick is painted with metal enamel in a dark green color or patinated. If you like hand-made metal engraving as a decoration, then the easiest way is the electro-chemical method, which is accessible to everyone.

Curved gratings produced by cold forging

How can you decorate your site with imagination with your own hands? Curly bars, gates, wickets. But if you use products obtained by hot forging, then such improvement can result in a very decent amount. You can, of course, make all these structures from a 4 mm thick strip, bent using primitive devices. However, the appearance of such grilles, as well as their reliability, leave much more to be desired.

The most optimal is to use equipment that allows you to create parts from a rod with a cross-section of 1 cm x 1 cm and 1.2 cm x 1.2 cm that imitate hot forging products. The resulting products are much cheaper than hot-forged ones, but are also beautiful and reliable.

Various devices in combination with welding work make it possible to make real metal patterns using your own hands: multi-point spiral curls, a rod or strip twisted along the vertical axis, three-dimensional parts that are used in the production of “three-dimensional” gratings.

Particularly impressive is the figure obtained from square rods 6 mm x 6 mm welded together. It's called a "flashlight". Using welding, it is possible to obtain periodic “boyar” and “wave” patterns from parts bent using the “ ” method.

Using metal patterned parts obtained by cold forging and assembled, you can make gazebos, pergolas, decorations for porches, stairs and canopies. Such shaped metal products are perfectly combined with all architectural styles and can decorate any premises and garden plots.

A metal rose is a stylish decoration for any interior. Such a flower will never lose its attractiveness, and if made with your own hands, it will become an original gift for a loved one. Making such an unusual flower is quite simple. You just need to be patient and have the necessary tools.

What you need to make a rose from metal

To create a metal flower, you need to prepare the following materials:

- a smooth metal sheet, the thickness of which will be approximately 5 mm;

- a steel rod for a rose stem with a diameter of about 10 mm;

- anti-corrosion agent or motor oil for processing crafts.

Necessary tools to create decoration:

- grinder or grinding machine with two types of discs - for grinding and for cutting;

- drill for working on metal with drills up to 1 cm in diameter;

- pliers and pliers;

- wire cutters;

- welding machine;

- gas-burner;

- hammer and anvil.

It is better to make a flower outdoors or in a ventilated area. It is important to follow safety precautions when working with tools and metal. Having provided all the necessary conditions, you can begin making roses.

The process of making petals for a metal rose

To make a flower bud, we cut out at least four 10x10 cm squares from a sheet of metal. The more petals there are, the more magnificent and luxurious our rose will be. Using a regular felt-tip pen, we draw sketches of the petals on the blanks, according to which we cut them out with a grinder or a grinder. There is no need to cut them until the very end.

Next, you need to give the workpieces the necessary texture. To do this we use a hammer and an anvil. Using gentle blows of a hammer, flatten the edges of the petals on one side. The same must then be done with future leaves of the stem.

To place our petals on the stem, you need to make a special hole in their center. To do this, you can use a drill or welding. When using a drill, drill a hole in the center of each petal equal in diameter to the flower stem. The use of welding involves burning holes of the required diameter using the electrode of a welding machine. We do this carefully so as not to make holes larger than necessary.

After the petal blanks are ready, we put them on a metal rod one by one and weld them to it. We put the first blank for the petal on the rod, leaving about 2 cm from its end. We arrange the petals crosswise. When connecting the petals to the flower stem, try to melt the rod more, since the metal of the petals is thin and can burn out. We bend the lower petals down, forming a sepal of a flower.

To give our petals the desired shape, we use a gas burner, with which we heat the products. Next, using pliers, bend the central petals inward and the rest around them. Having connected the petals, you need to slightly bend their edges.

Making metal rose leaves

In addition to the bud itself, it is necessary to supplement the flower stem with leaves. To do this, draw a sketch of future leaves on a metal sheet and cut them out using a grinder. We make small notches along the edges of the leaves and make them slightly wavy, so that it looks natural. We connect the finished leaves to the stem by welding.

In the same way, you can weld metal spikes to the stem of the flower, which are cut in the shape of small triangles. If the stem is too long, it can be trimmed with a grinder. The average length of such a stem is usually 40 - 50 cm.

Treatment of roses against corrosion

The final stages of creating a metal flower will be anti-corrosion treatment. If this is not done, the craft will lose its appeal over time. For these purposes, you can use varnish or spray paint. It is very convenient to purchase special paint in a can, which can be silver or golden in color. It is convenient and evenly applied to the product and dries quickly.

Another treatment method is to use unused motor oil. It is applied to a pre-heated product, processing all its elements. After this, the rose is heated again to remove excess oil. Using this method will give the flower a noble dark shade. An elegant souvenir is ready.