Frame technology for the construction of suburban private real estate is becoming increasingly popular. Mainly due to the low cost, when compared with other types of construction of objects. Besides, it doesn't take much time. Nevertheless, such buildings are fire hazardous, especially when using wood. Therefore, electrical wiring in a frame house should be carried out with the utmost care.

When the house is built, it is necessary to conduct electricity. But before you start, you need to understand a number of important points. This will allow you to get a reliable, safe, and, no less important, aesthetic result.

Main cable connection

First of all, the main power cable from the common electrical main must be connected to the newly built mansion. There are two ways to connect to power lines:

- air;

- underground.

In the first case, poles and an air type of cable are used, and only a special conductor is suitable for the second method. At the same time, underground laying is more expensive due to earthmoving and protecting the cable underground. Nevertheless, this method has high reliability during wiring in a frame house.

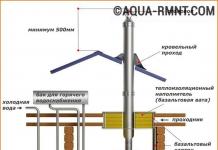

For underground cable laying, a trench is dug a meter deep, after which its bottom is covered with sand. Then an electric cable is laid, which has an armored protective sheath, and everything is covered with rubble from above. Then the wire is marked with a special signal material, and everything is finally buried underground.

It is worth noting that before connecting to the power line, you must first obtain permission from the local network company. In this case, you will need a project for the power supply of the building and the site.

In no case should you try to connect to power lines on your own, as this is not only life-threatening, but also leads to penalties. This work is the prerogative of specialists.

Wiring Options

After the main power cable is connected, you can choose which of the two types of wiring is preferable:

- Hidden (internal).

- External (external).

Moreover, both hidden and open wiring in a frame house has its advantages and disadvantages, which you should be aware of. And to begin with, we will analyze what are the strengths and weaknesses of hidden wiring.

pros. Its main advantage is that it is securely hidden from view, which is important for owners with a high aesthetic taste. Another advantage is that the works are final. That is, all sockets and switches cannot subsequently be moved from place to place. Although for some this may seem rather a disadvantage.

Minuses. The total cost of internal wiring significantly exceeds the cost of the external power grid. It is impossible to connect additional points in the general electrical network over time. In addition, not every insurance company undertakes the design of a house in which hidden wiring appears. In addition, it is not possible to periodically assess the physical condition of the wires.

What about the external version?

pros. Everything in the frame house is in the public domain, which allows you to identify flaws in a timely manner. If necessary, replacing any elements is not a problem. In addition, it will be possible to launch an additional line in order to add connection points for new electrical appliances.

Minuses. Here the main difficulty is connected with the harmony of the combination of wires with the interior of the premises. There are also some special requirements.

Features of internal wiring

With all its advantages in terms of aesthetics, concealed wiring poses a certain risk of fire. And here certain difficulties arise, since, according to the Rules for Electrical Installations, frame houses are equated with wooden buildings. Therefore, with hidden wiring, it is necessary to use metal pipes. At the same time, their inner part must be treated with something (painting, galvanizing). In addition, they must be grounded.

At the same time, another document (SP), which is followed by the builders of frame houses, allows the use of boxes, PVC corrugations, metal hoses for hidden wiring in a frame house. Only if they are covered with fireproof material along the entire length of the wiring.

It is equally important to consider that hidden wiring must be carried out even at the stage of building a house. Choosing this option, you should prepare in advance for inflated material costs. Less time and effort will be required.

Features of external wiring

External wiring, in turn, can be done in several ways:

- Using non-combustible corrugated pipe.

- In special channels made of special PVC.

- Open cable.

A lot of dust usually accumulates on the corrugated pipe, which is not so easy to remove. In addition, the appearance is far from perfect.

As for the channels, due to the natural shrinkage of a wooden house, the boxes may crack, which leads to the need to redo the wiring. Among other shortcomings, it is worth highlighting a meager assortment of accessories, an unattractive look. But in the external wiring diagram in a frame house there are also advantages - low labor intensity, coupled with low costs, and also the fact that it is easy to make appropriate changes later.

Aluminum or copper?

The age-old question that worries any electrician: what is better for wiring - aluminum or copper? It is these metals that are predominantly used in the conductive cores of all electrical cables, due to their good conductivity. If we take a wire with a cross section of 1 mm 2 and a length of 1 km, then the resistance of metals will be as follows:

- for aluminum - 28.5 ohms

- copper has 17.5 ohms.

At the physical and chemical level, their differences are more significant. But at the same time, both varieties belong to reactive metals and are easily oxidized under the influence of ambient air. However, the conductivity of aluminum film is much worse.

The silvery metal is very fragile - just a few bends and extensions are enough to break the conductor. Copper does not have such a drawback, and therefore this option is more preferable for wiring in a frame house with your own hands.

Aluminum has another unpleasant property - over time, being under load, it shrinks. As a result, this leads to a weakening of the contact, and the connection will begin to spark. And if a gap appears, then an electric arc of several thousand degrees will occur. It is for this reason that all connections must be periodically tightened.

Thus, it is clear that copper wins in many respects, and the strength of aluminum is only in its low cost. This factor became decisive in the mass construction of residential buildings during the Soviet era.

Electrical network diagram

In fact, there are practically no differences between a private house and an apartment in terms of functionality. Therefore, the first step is to draw up a clear diagram of all electrical wiring with the inclusion of all used consumers. It is best to connect to the work of a professional electrician. He can tell you how to do the wiring in a frame house in the best way.

But you can do everything yourself. To do this, armed with a tape measure, measure the dimensions of all the premises of the house. After that, a drawing is drawn up indicating all dimensions. You should also indicate how the wiring will go and where all consumers (sockets, chandeliers, etc.) will be located, not forgetting the shield. Russia has adopted the European standard for switches and sockets. The first should be located at a height of 90 cm from the floor, and the second - 30 cm.

You should immediately determine the number of electrical appliances and the place of their installation, which will allow you to identify how many sockets you need. At the same time, calculate the required number of wires. This will determine the total length of the cable. It is worth considering that in 2 years several more pieces of equipment may be added to the existing devices. That is, the power grid should be performed with a certain load margin.

Correct load distribution

When wiring in a frame house with your own hands, it should be noted that at least on each floor, in the case of multi-storey construction (2 or 3), there must be one junction box. However, for large buildings, several of them will be required. Moreover, the less load falls on one box, the better and safer.

For example, if wires from sockets supplying both the split system and the refrigerator are led to one box, then it will not be able to withstand such a load and will turn off. If there is no other choice, electrical appliances should be connected to stabilizers. This is especially true in the event of periodic power outages or power surges.

During the course in rooms with a high level of humidity, special vigilance should be exercised. If possible, all wires and sockets should be located as far as possible from moisture.

Must be made with special fasteners. Simply nailing them with nails is categorically not welcome. In order to be able to conduct wiring in a frame house without kinks, it is worth using insulating corner elements at the joints of the walls.

All it takes

To do the wiring in the house yourself, you will need a certain list of materials. For electrical wiring, it is worth taking a cable with a cross section of 14 mm and with some margin in length. If it is necessary to use insulating material, its quantity is also based on the entire length of the wiring. You will also need:

- distribution boxes.

- Sockets.

- Switches.

- Fasteners.

- Adapters.

Boxes should be taken at the rate of one per floor. You should not buy too complicated sockets and switches, it is better to take simple designs, but with grounding. This will make it easy to replace them if necessary. Adapters and fasteners should be taken with a large margin so that you do not have to screw in again.

You can't do without tools either. Helpers are:

- drill;

- hammer;

- pliers;

- screwdrivers (preferably a whole set).

Also, during the arrangement of wiring in a frame house, a screwdriver-indicator will be useful to detect voltage. There will be a use for a construction knife.

Electrical network switching

Junction boxes are needed for wiring, in order to conduct electricity to all areas of the house. They are made from different materials and can have different shapes.

Some of them are surface mounted and suitable for external wiring. Others are relevant for hidden wiring.

During self-assembly, it is important to consider the colors of the wires:

- phase (L) - white;

- at zero (N) - blue;

- at ground (PE) - green and blue stripes.

Part of the insulation is removed from the wires, and the freed ends are inserted into the terminals, where they are firmly fixed with a spring. The connection is of high quality, and the contacts themselves do not heat up.

It is not difficult to distinguish sockets with grounding - on the outside they have two springy contacts. That is, during the installation of the plug, it is they who are first involved, and then the phase with zero is already connected. This will allow you to safely connect devices in case of wiring damage.

As many experts advise, electrical wiring in a frame house is best done using copper wires. Yes, it costs a lot, but your own security has no price! In addition, it is recommended to install a power distributor in the electrical panel, which allows you to turn off unused consumers.

In order to save money, it does not hurt to put motion sensors, which are more convenient to place on the stairs or in the pantry. If there is any movement near them, the light will turn on. Kind of know-how.

And finally, the most important advice is to follow safety precautions in order to avoid electrical injuries.

Finally

Usually, anyone who has planned the construction of a house using frame technology begins to be intimidated by a fire hazard. Yes, there is a certain risk, but it all depends on what materials are used. Therefore, when wiring the electrical network in your home, you need to approach the matter with all responsibility. Also, do not forget about state standards.

It is best to consult with a specialist on a number of important issues before wiring in a frame house. Drawing up a clear scheme and using only high-quality materials will allow you to do all the work at the proper level. As a result, you can live in your own home not only comfortably, but also safely.

Every year there are more and more new and perfect frame technologies in construction. And even if you did not graduate from special institutes and did not study the profession of a builder, it will be possible to build a house yourself using a frame-frame or frame-panel method. Wiring in a frame house, first of all, must be safe and reliable. And in terms of aesthetics, it is desirable that it does not spoil the whole overall look, design and style inside the building. Therefore, we will consider all possible options for electricians for a frame house.

layout

As with any other building, everything must first be carefully planned and schematically displayed on paper. Consider where the switchboard will be located, the entrance doors to the rooms, since switches must be mounted near them. Decide on the location of lighting fixtures and household appliances so that sockets are nearby, and then you don’t have to throw carriers through the entire room.

Calculate the loads in order to correctly select conductors by cross section and switching devices by rated current. Also, such a layout will help you determine the amount of materials needed.

Entering the house

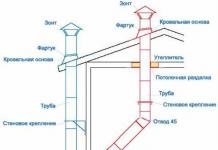

From the main power line, a branch is made to your home. Its installation is carried out by air or underground. Depending on the required voltage (single-phase 220 V or three-phase 380 V), the cable is selected, it will be three-core (for 220 V) or five-core (for 380 V).

The input cable goes to the electric energy meter, which, according to the new requirements, must be installed on the outside of the house so that the controller can easily take readings at any time.

The meter must be located in a sealed shield or box to protect it from the effects of precipitation.

From the meter, the cable must be brought inside the house. To do this, a hole is drilled in the wall, if the house is two-story, then it is best to do this at the level of the floor. The cable is laid in a corrugated pipe, pulled through the hole made, fastened in the interfloor ceiling and then laid to the inlet switchboard.

Note! After the meter, there must be an automatic machine in the circuit, which will serve as protection for the cable going from the meter to the switchboard in the house. If there is a damage to this cable or a short circuit, then the protection will work - the machine will turn off. Otherwise (if there is no machine), the meter may burn out, and the entire trunk line will be turned off somewhere in the transformer substation or at the substation.

Distribution board

The input cable enters the switchboard and is connected to the input machine, which must be the same in power as the one that stands on the street after the meter.

After the introductory machine, all switching in the switchboard is carried out according to the scheme. Outgoing circuit breakers, RCD protection devices, differential circuit breakers are connected. Ideally, two machines should be assigned to each room of a frame house (one for lighting, the second for connecting sockets). For rooms such as a bathroom or kitchen, it is necessary to install additional machines for energy-intensive household appliances.

What type of wiring to choose?

Electrical wiring in such buildings can be performed, as in ordinary houses, in two ways - external (or open) and internal (hidden).

The option of external wiring involves the installation of wires on wall and ceiling surfaces using special cable channels, electrical pipes or in an open way. The wiring is carried out when the main construction stages have already been completed.

Hidden wiring in a frame house involves the placement of conductors inside walls and ceilings. Outside there will be only switches, sockets and wire ends for connecting lighting fixtures.

The installation of such a wiring is combined with construction, while the walls inside the house are not sheathed with anything.

Video example:

Each method has its positive and negative sides.

The main advantage of internal wiring is that it is aesthetic, all conductors and connections are hidden, nothing spoils the appearance of the room. It has many more cons:

- Any switching device (socket or switch) is installed completely, you can no longer move it somewhere to a new place.

- It is not possible to periodically inspect and assess the state of the power grid.

- In material terms, internal wiring is more expensive than external wiring, and it also requires considerable physical costs.

- Insurance companies do not risk drawing up contracts for wooden frame houses with internal wiring.

- There is no possibility to install additional points (for example, if you need another socket in some room).

The main advantage of outdoor wiring is its accessibility, that is, it is in plain sight and you can control its condition. Accordingly, there is the possibility of repair, at the right time you can replace not only the switch or socket, but also the wires.

Outdoor wiring can be branched, adding points for connecting new household appliances.

The disadvantages of the outdoor wiring option include the fact that it does not always organically fit into the overall interior of the premises. Also, when the wires are in plain sight, the risk of damage increases.

As you can see, all arguments tend to suggest that an outdoor electrician in a frame house is preferable. In addition, statistics show that fires are more likely to occur in buildings with hidden wiring.

External wiring

Do-it-yourself external wiring in a frame house is done without any problems, there are several options for it.

open cable

You can use a rigid cable with a double or triple insulating layer made of non-combustible materials. Such a conductor is attached to wall surfaces with special brackets. Between the wall and the cable, it is necessary to lay an asbestos or metal substrate, which should be 1 cm wider than the conductor on both sides. This is a reliable and economical way of laying, but not quite aesthetically pleasing, especially if you need to place several cables side by side.

When the design of the premises is made in a retro style, then twisted wires on ceramic or porcelain rollers (insulators) will look nice and original.

Electrical pipes

It is possible, when laying wires externally, to place them in electrical corrugated pipes, for the manufacture of which special non-combustible materials are used. Several conductors can be placed in the pipes at the same time; they are attached to the walls with the help of special clips. Such wiring looks compact, in addition, the pipe isolates the cable from flammable wall surfaces and protects against possible external damage. But the pipe does not look presentable at all, besides, it collects dust too well, which is practically impossible to clean.

Cable channels

Cable channels will look much neater than corrugated pipes. Moreover, now in the market of electrical goods you can pick them up for any interior (they are available in different colors).

The disadvantage of cable channels is that they make the curvature of the wall surfaces noticeable.

But since it is hardly possible to find curved plastered walls in a frame house (gypsum boards or lining are most often used), laying wires in cable channels is considered a good option.

Cable channels are plastic boxes that are attached to walls and ceilings with glue or self-tapping screws. For their manufacture, high-quality refractory plastic is used. They come in different widths depending on how many cables and what section are laid in them at the same time. When the conductors are laid in the boxes, they are closed from above with locking covers. An example of such wiring in the video:

Another disadvantage of using cable channels is that over time, the frame house shrinks, and plastic boxes can crack. In this case, the electrical wiring will have to be redone. But at the same time, there are advantages of this laying method - it is cheap and easy to install.

Internal wiring

The most important regulatory document for an electrician is PUE (rules for electrical installations). According to these rules, internal wiring (also called hidden) in wooden houses must be carried out in metal pipes. Since frame housing constructions are made of wood, this requirement must be observed for them as well. Can you imagine what financial costs such a number of pipes and their installation can result in?

You can use metal sleeves or boxes, but if money allows, still use pipes. These aids must have a wall thickness of 2.5 to 4 mm (depending on the cross-section of the conductors) so that in the event of a short circuit the metal structure does not burn out. It is desirable that the pipes inside be painted or galvanized, this will protect the walls from rust. Video example:

Naturally, bends and turns will occur along the cable laying path; in these places, pipes should be connected by welding or threading. It is very convenient to use copper pipes, they bend easily, but it is too expensive.

In order not to damage the insulating layer of the cable, plastic bushings are mounted at the ends of the pipe.

Such installation is carried out even at the construction stage, besides, as you can see, it is quite costly both in terms of finances and in terms of labor, time and effort. Therefore, the most correct choice for a frame house is still external wiring.

Quality materials

Before you make the wiring, you still have to choose and buy materials. Remember that the reliability and safety of the power supply of your home directly depends on their quality.

If in order to bring electricity to the house, a rigid aluminum wire (such as SIP) is quite suitable, then it is recommended to carry out all the wiring inside the building with a flexible copper cable.

The best option would be a NYM cable. It is marked 3x1.5 mm 2, where the first digit "3" means that this conductor consists of three cores, one of which is a phase, the second is zero, the third is grounding (most often it is yellow in color).

The number "1.5" means the cross section of each core. A cable of this section is just right for making all the lighting wiring. To connect sockets, you will need a larger conductor (2.5 mm 2), and for energy-intensive household appliances, such as an oven, a water heater, it is better to take a cable with a cross section of 4-6 mm 2.

To install sockets and switches in a frame house, you should choose metal mounting boxes.

If you have the time, effort, experience and knowledge for such a responsible decision, how to build a house yourself, then you will be able to handle the wiring in a frame house. But in case of the slightest question, consult with experts. Still, you can never switch to “you” with electricity, the safety of human life depends on it.

Usually in a frame house, wiring is open. However, laying and concealed wiring options are quite possible. In this case, it is necessary to strictly adhere to the existing safety standards, which entails considerable costs. Consider how electrical wiring is laid in a frame house with your own hands.

Laying open wiring

With this method, rigid cables are used, enclosed in double or even triple insulation. The insulation must be made of refractory materials. The cable is fastened with open wiring directly to the surface using electrical brackets.

When using a wire with conventional insulation, a spacer must be installed under the cable, which is made of refractory material, expecting it to protrude 10 mm on both sides. Asbestos or metal is perfect for this.

Variants using ceramic rollers and twisted wires are also possible. However, the latter option is quite "ancient" and is practically not used today. The use of electrical brackets and refractory wire is a fairly reliable method and at the same time very economical financially. The disadvantage of the open method of installing electrical wiring is not very aesthetic appearance, especially in places where several cables are laid.

Back to index

Laying electrical wiring in a corrugated pipe

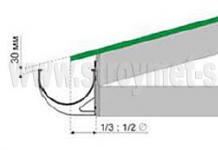

Scheme of a plastic corrugated pipe for electrical wiring.

Corrugated conduit wiring is very similar to open wiring. The difference is that the cable is laid in a corrugated pipe. This tube must be made of heat-resistant material and comply with all existing standards. Fastening of corrugated tubes is carried out using special clips. One tube is designed to install two or more cables. In this case, the laying of electrical wiring looks more neat, but still resembles some kind of technical room.

With this method, inconvenience can occur when the cable is pulled. In this case, you will have to remove the wiring in large pieces. This method of laying electrical wiring is still safer, as protection against mechanical damage increases. In addition, an air gap is formed from the combustible surface. One of the varieties of this wiring is the use of rigid plastic pipes.

Back to index

Laying electrical wiring in electrical boxes and cable channels

In this case, the wiring is placed in special plastic boxes, which are called cable channels, they must be made of refractory plastic.

To accurately install cable channels, you need to spend a lot of patience and time.

In this case, you need to have some skills and a good tool.

a - straight; b- tee; c - angular for measuring the route in the horizontal plane; d - angular for changing the route in the vertical plane.

The use of boxes makes it possible to change the configuration of the wiring and additionally place switches and sockets.

On the market you can meet boxes of various colors and sizes. The set includes various additional elements: corners, both external and internal, plugs, joints. This makes it possible to greatly simplify the process of installing electrical wiring in a frame house.

But this method also has a number of disadvantages, among which the most common is the placement of boxes on a wet wooden lining. Over time, the tree warps, and the box begins to deform.

Laying in the cable channels of the wiring should be carried out only after the wood has completely dried. In this case, it will be possible to avoid damage to the wiring as a result of its deformation.

Of the above methods of laying electrical wiring, the use of cable channels leads to an increase in the cost of the process. But if we compare all the disadvantages and advantages, this is the most preferred way of laying electrical wiring.

Installation of electrical wiring of a two-story cottage

Below is a step-by-step instruction for conducting electrics in a frame house. The instruction is written as a guide to action with all the details and pictures.

Here is how the layout of the site and the house itself look like

Step one - input, input shield and grounding

We do power input at a distance of 1 meter from the wall from the side of the window.

Indicated by a turquoise arrow

We use VVG 2x6 or VRG 2x6 cable to perform the input (it will need 5m (with a margin))

With this cable we lead from the input to the main machine

We also connect the main machine, from it the counter, and further,

drawer block. The block has as many clamps as we have automatic machines

at the output plus one (input comes to it). The box itself is double sided.

These pads are plastic and brass. We need brass (then no

you don't have to make a switch). Be sure to mount it in the shield so that

there was no contact with the body, if the body of the shield is metal, if it is plastic,

then in any free space of the case. For "zero" wires, a second such block is required.

Instead of an introductory block, you can use a little trick.

It consists in this:

The phase (phases) from the counter come to the first machine, and all the rest are connected to it using a “comb”.

We choose sockets of the European standard, with grounding knives.

To do this, in parallel with all the wires going to the sockets, we pass another single wire, with which we connect the grounding knives of the sockets into one line, which will connect to the ground loop.

The contour is performed in different ways:

1. Triangle

2. rectangle

The best of them, of course, is the triangle.

It is carried out in the form of an equilateral triangle with a side of at least 1.5 meters, at the tops of which pins are driven in (preferably from a corner or a square pipe), interconnected by steel strips. A strip of steel should also be brought into the house and, with a bolt and nut with washers, the wire that connects the grounding knives of the sockets should be screwed to it.

The "triangle" itself is laid no closer than a meter from the foundation of the house.

For good, the assembly diagram of the introductory shield looks like this

True, there is an error in the picture. It consists in this: it is necessary to run a 3x2.5mm2 wire on the sockets. PE, it is also a protective conductor, and there is a ground electrode.

The shield itself might look like this:

Its size depends on the number of machines that are in it (they can be located in 2 rows).

Inside, it looks something like this:

Since, in the light of the latest "instructions from above", the counter must be placed outside the building, the din rail of its fastening can be used for the second row of machines

Here is an approximate layout for the premises of the house (where to put which machines):

1) Introductory machine - 64 A

2) Lighting of the room and living room - 16A

3) Lighting of corridors, boiler room and vestibule - 10A

4) Kitchen lighting - 10A

5) Kitchen sockets - 16A (dif.automatic)

6) Oven - 16A

7) Electric boiler - 20A

8) Washing machine - 20A

9) Dishwasher - 16A

10) Sockets of the room on the first floor and corridor 16A (diff.automatic)

11) Living room sockets 16A (diff.automatic)

12) Sockets of the bathroom 16A (differential automatic)

13) Sockets of the boiler room and vestibule 20A

14) lighting of children's rooms and wardrobe - 10A

15) lighting of the pantry, bedroom - 10A

16) toilet and bath lighting - 10A

17) sockets on the 2nd floor - 16A (difavtomat)

The figure below shows (using the lighting of the 1st floor as an example) which room is powered by which machine:

If desired, you can install a socket in the input shield, as shown in the figure (you can connect it directly to the central machine).

Since we, thanks to the removal of the meter to the outside of the house, have freed up the lower din rail, we can easily install the shield in two rows without changing its size.

Therefore, we divide the automata into 2 equal parts: we put the first 8 in the top row, and the second in the bottom.

I recommend wiring the “phase” wire using a “comb”, that is, it comes to the first machine with a piece of wire (a piece of wire with a section of 6 squares), and from it to all the others - with a “comb”. Naturally, the wire from the cable and the contact from the "comb" sit "on top of each other." We need two combs, the fact is that we have two rows of machines and we cannot connect them with one “comb”. From the last automaton of the first row, we start up the same segment of the core with which the first automaton was powered, to the nearest automaton of the second row (naturally, the extreme contact of the second “comb” connecting all the automata of the second row into a line sits there).

We begin the installation of wiring with the selection of tools and materials

We will need the following tool (it will also be needed later):

1. Drill for making through holes in the wall

Of course, it can be different, but personally I use this one.

2. Good electric drill

3. Screwdriver (amateurs can use a regular screwdriver)

4. Screwdrivers

5. Pliers

6. Insulating tape

7. PPE (connecting insulating clips)

They may look like this

8. Self-tapping screws

10. Plywood socket boxes (you can make them yourself)

11. Glasses

True, if the entire installation is carried out between the wall and the sheathing, then plywood sockets are not needed (sockets and indoor switches, which also need to be stocked up, are mounted in glasses, while junction boxes are mounted instead of glasses so that only their cover sticks out).

12. VVG cable 3x2.5 (bay (may not be enough))

13. VVG cable 3x1.5 also

14. Corrugated tube for both cable sizes (the same as the cable)

15. Fasteners for corrugation

16. For drilling in the casing for the "glasses" you will need a "crown", for the junction boxes you will have to cut it out with a knife (it is better to use a wide FIT stationery)

Started!

We install the shield in the corridor on the wall adjacent to the vestibule from the side of the boiler room. We do this in order to pull fewer wires from the shield to the meter. We choose the height of the shield installation 1.5 meters (for convenience).

First, we will perform all the internal installation, and only then we will connect the meter. Therefore, we insert the first “comb”, and do not tighten the contact on the introductory machine, but we stretch it well on the rest.

First, we will perform all the internal installation, and only then we will connect the meter. Therefore, we insert the first “comb”, and do not tighten the contact on the introductory machine, but we stretch it well on the rest.

Since the first machine after the introductory one is responsible for the lighting in the room and living room, we will start with it. We measure 15 meters of cable VVG 2x1.5 and 14.8 meters of corrugated pipes of the appropriate size. For the convenience of retracting the cable, the corrugated tube is equipped with thin steel (to which we tie the end of the cable and pull it into the tube).

In the wall separating the corridor from the room (as close as possible to the outer wall), we make 2 through holes. We need one now, and the second - for laying the cable to the sockets. In the room, in the place where the switch is planned (which is closer to the entrance), under the ceiling, we fix the junction box.

The installation schemes of the corridors, the room and the living room are fully consistent with the drawing. The only exceptions are the kitchen, boiler room and bathroom, where lighting wires are laid "directly" through the ceiling. This is implemented as follows: the wire from the junction box is led up to the ceiling, where it is laid in a straight line to the installation site of the lamp (that is, if the figure shows a gasket with turns, then in fact the gasket is carried out along the shortest distance). This applies to all premises where it is necessary.

From there we will start laying the cable. We put the end of the cable (5-7 centimeters) into the box, we lead the rest to the hole in the wall, where we bring it out so that between the junction box and the hole in the wall there is a cable sag of 1-3 cm. Further, we lead the cable to introductory box (fixed with special fasteners above the entrance).

the fastening of the corrugations to the ceiling is performed in the same way.

We also fasten the “corrugation” above the introductory shield with special fasteners, after which we lower it down and put it into the shield, where we connect the phase wire to machine No. 2 (the wires in the cable are painted in different colors for convenience), we clamp the zero one in a metal terminal block, intended for this.

Now we are installing the lighting wiring inside the room.

Since this room assumes independent switching on of light from two points, we use 2 pass-through switches, connecting them with a two-wire line from the same VVG 2x1.5 cable. Here is a wiring diagram for lighting a room using such a system:

The "zero" wire goes directly to the side contact of the lamp. The phase comes to the central contact of the first pass-through switch, after which, bifurcating from a pair of its output contacts, a second such switch goes into two wires, deployed by the output contacts towards the first one and is connected to them. From the remaining contact, the phase wire goes to the central contact of the lamp.

We connect the remaining free zero and phase in the junction box to the cable that was previously laid there (but we do not isolate, because we need to connect another lamp and living room lighting there). We connect the second lamp in the usual way (zero directly to the side contact of the lamp, phase - through the switch to the middle one).

Here according to this scheme

Now we forward the cable (exactly the same) into the living room. We take its length at the rate of 4-5 meters (up to the first junction box, which we put under the ceiling right next to the door). When the connection of the lighting cables is completed, it is necessary to isolate the connections with PPE. All cables must first be tightened into corrugated tubes. The first lighting box is ready, it can be closed and signed.

Living room lighting installation.

The first is the simplest, since we connect a lamp that has a single switch. This is done in the same way as in the room. No need to isolate just yet. Next, we install the second pair of walk-through switches and lamps controlled by them. Installation according to the same system, with the difference that instead of one lamp, this pair controls two connected in parallel. But, since the first of the pair of walk-through switches is located on the other side of the door, then you need to mount another junction box above it and run a cable between the boxes, after which we isolate the wires in the second box with PPE, close and sign the box. The third box does not need to be closed yet (it will come in handy for laying kitchen lighting). Accordingly, on the opposite wall, above the place where the second kitchen switch will be, we mount another box under the ceiling. A wire (3 cores) goes to it from the “pass through” at the entrance to the kitchen-living room. Two of these cores are a bifurcated “phase”, and the third is “zero”, which will return from the lamps. “Phases” are hooked to the opposite ends of the second “through”, “zero” is led to the side outputs of the lamps. We connect the central conclusions to the remaining conclusion of the switch. After all this, we close the box above the lamps and sign it, having previously insulated the connections with PPE.

For laying between the last pair of boxes, approximately 5.5 meters of cable will be required (we lay along the shortest distance, since all this will be hidden behind the false ceiling). It will take another 1.6 meters from the box to the switch.

light in the kitchen

The third machine, for now, we skip and work with the fourth. This is due to the fact that we need to make a kitchen and close the remaining open box. This will require a cable (again with a margin) of 8.3 meters. We tighten the cable into the "corrugation" and start laying. We put one end of it into the shield and connect the phase to the fourth machine, and zero to the “common wire” block. Next, we lead the cable up, where, under the ceiling, we fasten it with a pair of clamps for the corrugation (one to the wall, and the other to the ceiling, thereby forming an angle). After that, you can drive the cable along the shortest distance into the corner between the toilet and the kitchen wall (then it will take less). There, in the wall, we make a through hole, where we put the corrugation with the cable. In the kitchen, the corrugation turns towards the entrance and is again attached to the wall with a clamp. Further, this cable goes to the remaining open box, where it is connected to the switch and fixtures. We install a three-pole switch in the kitchen. From it we lead cables to all kitchen lamps (having previously tightened them into corrugations).

Now, after all the connections in this box are made, we isolate them with PPE, close the box and sign it.

Wiring for which the 3rd machine is responsible

We hang the lamps in the vestibule and in front of the entrance and connect them in parallel (not forgetting to mark the phase wire). On the same wall where the inlet shield is, only on the side of the jamb where the boiler room is, we mount the junction box under the ceiling. We lead a cable from the third machine to it. This will require 3.2 meters of cable. Since the light in front of the entrance and in the vestibule, according to the project, is controlled from two points, we mount the control of the walk-through switches by installing one of them in the corridor, and the second one in front of the entrance to the house and connecting them in the same way as connected the "pass-throughs" in the room. We connect the wires from them to the parallel-connected lamps mounted earlier (not forgetting the phasing). To these lamps, in parallel, we connect a lamp mounted under the ceiling in the center of the corridor of the 1st floor. From this box we lead the cable to the second floor to the box, which we mount under the ceiling on the wall between the children's rooms. We mount a switch on the same wall, and a lamp in the center of the corridor on the ceiling. Then, having connected everything into a circuit, we close and sign the box, not forgetting about the insulation of the connections. On the wall, between the boiler room and the vestibule under the ceiling, we mount the junction box. On the same wall we install the boiler room light switch. After all this, we lead the cable from the previous box to the last one and make the necessary connections. Having done all this, we close and sign the penultimate box, not forgetting about the insulation (the last one, for now, does not need to be closed, it will still be useful to us).

To finish with the lighting of the 1st floor, we go straight to the 16th machine (it is responsible for the light in the bathroom). From it we lead the cable up and, through the ceiling, to the box between the toilet and the boiler room. In it, we carry out the cable routing down the wall to the switch, then to the toilet lamp and up to the bathroom, where we mount a two-pole switch and a pair of lamps (naturally, by mounting a junction box under the ceiling). Having finished the installation of the bathroom and toilet lighting, we isolate the connections with PPE, close and sign the boxes. We are done with the lighting of the first floor.

2nd floor lighting

The red dotted line shows the passage of the lighting cable from the junction boxes to the fixtures (between the ceiling and the “false ceiling”).

Light in nurseries and wardrobe (14th machine).

We take 10 meters of the VVG (or VRG) 2x1.5 cable and tighten it into the corrugation. After that, we make through holes in the interfloor ceiling above the introductory shield, in the walls between the corridor and the first nursery, and in the wall between the nurseries. After that, we connect the “phase” to the machine, and the “zero” to the block and pass the cable up, through the ceiling, to the ceiling of the second floor, fixing it with clamps before and after the ceiling and a couple of times on the wall of the 2nd floor. Under the ceiling of the 2nd floor, we turn the cable (with the help of clamps) towards the nursery. After entering the nursery, we fix the cable on the wall under the ceiling and lead it to the pre-installed junction box (we install it under the ceiling in the place where there will be a switch on the wall and a lamp on the ceiling). The split is done like this:

We lead “zero” directly to the lamp and connect it to the side contact

We lead the phase to the switch and connect it to the input contact

We lead from the output contact to the lamp, where we connect to the side contact

After that, we install junction boxes in the second nursery and wardrobe (under the ceiling in those places where switches and lighting shades will be mounted). Now we lead the cable from the box in the first nursery to the box in the second nursery, where we install the lighting scheme in the same way as in the first nursery. Now the box in the first nursery can be closed and signed (not forgetting about the insulation of the connections). Then we lead the cable to the wardrobe. We install the wardrobe light switch outside the room, for which we make a through hole in the place where the switch will be installed. We mount the switch and carry out the installation of the entire lighting scheme in the same way as for both children. Now we close and sign the boxes, insulating the connections with PPE.

Storage room and bedroom lighting

Now we mount the light in the bedroom and pantry. To do this, we install junction boxes under the ceiling in those places where switches and ceiling lights will later be. Since the light in the pantry is turned off from the outside, we also install the box outside. We lead the cable from the box to the switch.

In the bedroom, we connect according to the standard scheme (the same as in children's rooms). In the pantry, we do the installation like this:

1. We have already installed the cable from the box to the switch

2. Above the box we make a through hole in the wall

3. From the box we lead the cable to the lamp

4. The connection itself is carried out in the usual way, with the difference that the switch is located outside the room.

We begin the installation of sockets

With the lighting completed, we proceed to the installation of the wiring of sockets and start from the kitchen (machine No. 5).

Laying cables to sockets is fully consistent with the scheme that is indicated on the plans of the house.

We need a cable (to the first junction box) 9.2 meters. We connect the “phase” to the machine, “zero” to the common wire block, the third cable core must be connected to the ground block. The cable itself is led through the ceiling towards the kitchen (to the place where we install the junction box). This machine is responsible for 5 sockets in the kitchen: a socket under the switches, a kettle, a microwave, a toaster and a socket on the wall opposite the switches. First, install the sockets and connect them in parallel (we use all three contacts). We connect the sockets using a VVG (or VRG) 3x2.5 cable (we also supply power to the sockets with it). From each of the sockets we lead the cable up, where we mount the junction box. Boxes are connected in parallel. From the junction box, with the same cable, we connect the sockets, not forgetting the phasing and the fact that the ground knives must be connected to a wire connected to the ground block.

Power for the oven, dishwasher, electric boiler and washing machine

The oven and dishwasher are powered by separate machines (machines 6 and 9, respectively). Since the installation of their sockets is the same, I will describe the installation of only one. In this case, we do without junction boxes, because we run the cable directly from the machines to the sockets (we use the VVG (or VRG) 3x4 cable). The cable for this will need approximately 10 meters (do not forget to tighten it into the corrugation). We connect the cable in the shield to the machine and the common wire and ground blocks, after which we lead the cable to the outlet, where we make the connection, not forgetting where to connect which wire.

Machines 7 and 8 are responsible for the electric boiler and the washing machine. The installation of these sockets is no different from the installation of the sockets of the previous paragraph, with the difference that the cable will need less.

Other machines

The 10th machine is responsible for the sockets of the room on the 1st floor and the corridor, so let's do this.

At the top, above the shield under the ceiling, we mount the junction box, and under the shield - a socket. We lead the cable from the machine directly to this outlet. We lead another cable from the same machine to the junction box. We lead 2 cables from the box: one from the box to the socket on the opposite wall, and the other to the junction box pre-installed in the room. We close the box above the shield and sign it (not forgetting about the insulation of the connections). On the wall, under the junction box, we mount a pair of double sockets connected in parallel, and on the wall opposite the entrance to the room - a single socket. We select the cable for mounting these sockets VVG (or VRG) 3x2.5. we lead 2 cables from the box: one to the sockets on the same wall as the box, and the other to the socket on the wall opposite the entrance. After that, we isolate the connections, close and sign the box.

We proceed to the installation of sockets in the living room (machine No. 11). In the living room itself, we mount 3 junction boxes (above the places where the sockets will be mounted). On the wall bordering the room, we mount 2 double sockets, in two other places - single. We lead 3 cables from the box: one to double sockets, pre-connected in parallel, and the other two to single sockets through the ceiling. Now we are connecting the junction box in the living room and the machine. After that, we isolate, close and sign the box.

In the same way, we mount and connect the sockets in the rest of the house, not forgetting to connect the grounding knives of the sockets into one circuit and connect it all to the ground bus in the input panel.

The final stage - connecting the meter and power

Now it's time to connect the meter to the wiring system.

We do it like this:

1. From the introductory machine, we bring the cable out to the shield in which the meter is installed

2. We connect the meter input according to the diagram indicated on its cover

3. We connect the cable to the output of the meter, which we lead back to the input shield, where we connect it to the rest of the machines (“phase” to a pre-prepared place in the first machine, and “zero” to the common wire block)

4. We extend all contacts

Now you can apply voltage to the input machine from the input cable. By the way, for the last connections it is necessary to use a cable with a cross section of 6mm2.

If you have any questions please use the form below and I will answer.

Building a house, making a roof and erecting walls is not a cheap pleasure financially. Therefore, some owners are tempted to do the wiring of the building with their own hands. Such a process requires compliance with electrical safety requirements when performing this kind of work, failure to comply with at least one rule can lead to a wiring short circuit. Therefore, it is worthwhile to carefully weigh the pros and cons, and only then do the installation and wiring do it yourself.

Important! Since the frame and all the materials of the house will be made of wood, which remains a fire hazard even after impregnation, we advise you to make external electrical wiring.

First, prepare the necessary tools and materials:

- Copper electrodes will be needed for grounding.

- Clips for fastening the corrugation and the cable in it.

- Self-tapping screws for fastening clips and other devices.

- Electric cables of three types, SIP cable for connecting from power lines to a pole, copper PVA cable, VVG cable.

- Marker or pencil

- Ladder or stepladder

- Laser level

- Roulette

- Drill or power screwdriver

- wire cutters

- Insulating tape

Before starting work, make sure that all these tools and supplies are available, this will save you time!

Do-it-yourself wiring in a wooden building requires more attention and caution, due to the increased fire hazard of such a structure. The result of a short circuit or heating from poor-quality fasteners of wiring parts can lead to more disastrous consequences than in a stone structure. From this and a more stringent approach to fire safety requirements.

Important!

- The distance from the floor to the socket is 30 cm.

- The distance from the floor to the switch is 90 cm.

According to all fire safety requirements, rules, building codes, electrical wiring in a frame house is laid in a shell that excludes possible fire. As such a shell, a corrugated metal hose, a steel pipe or a PVC box (not supporting combustion) is used.

It is recommended to mount a corrugated metal hose at a certain slope, this is done to drain condensate (if any). Junction boxes are either metal or flame retardant PVC. Installation of switches, sockets in a frame house is also carried out in metal and PVC mounting boxes.

Which wiring to choose: hidden or outdoor

Installation of electrical wiring in wooden and frame houses can be carried out in two ways: hidden and external wiring.

The most common option is outdoor wiring. This method is easy to install. This method uses wire with reinforced, double insulation. It is placed inside a plastic corrugation or box, which serves to protect against mechanical damage. You can also consider wiring with the help of a designer, make it on ceramic insulators mounted on the wall (as was done in the 50s of the last century).

Wiring laid in this way is more practical than hidden. You can, if necessary, connect an additional outlet to it or inspect it in case of a malfunction.

The disadvantages of this method include the ease of damage to the wiring by pets, when rearranging furniture or cleaning.

Laying electrical wiring in a plastic box will not improve the aesthetics of the interior, but this method is safer. Such boxes are clearly visible on the walls, ceilings. Some manufacturers have gotten used to making accessories in light brown or brown shades. This hid the design a little, but not completely. It is worth noting that in addition to cables, there should be about 40% free space in the box. This prevents the wires from heating up.

In addition, with an external version of the wiring, the wires can be fastened with special brackets. However, this technique is also quite noticeable, especially when connecting five cables at the same time. Therefore, camouflaged hands are still the best option in this case.

The main rule of electrical wiring still remains the determination of the maximum allowable load, respectively, the selection of the type and section of the cable for electrical wiring. This rule applies regardless of the design of the house or the material from which it is made. However, when wiring a wooden structure, it is necessary to choose a cable with good insulation.

A prerequisite is the presence in the house of an automatic RCD shutdown system (the so-called differential machine). This device is activated during a short circuit, thereby preventing the fire of household appliances and electric shock to any of the residents.

In addition, an important point is the grounding of the box filled with wiring. This method is called "armored sleeve". In this case, mechanical impact, any pressure on the wiring must be completely excluded.

Installation of electrical wiring is carried out simultaneously throughout the house, entirely, according to a pre-thought-out scheme. It is not recommended to change a specialist until the wiring is completed. In addition, it is not recommended to do the wiring of a frame house with your own hands; it is better to entrust this to a qualified worker who knows all the rules for electrifying a building and has an appropriate document. It is recommended to make a preliminary contract for the performance of work, so that in case of any malfunctions, you can make a claim.

Let's say you decide to do the wiring yourself. Any installation of electrical wiring consists of two stages:

- Wiring of power lines from a power source (switchboard, pole), direct cabling according to the agreed scheme. The scheme must be prepared in advance and checked by a specialist. At this stage, the assembly and installation of grounding, special equipment (junction box, electric meter) is carried out. Openings for sockets are determined and drilled.

- The final stage is the plastering of cable laying places, the installation of frames, the installation of doors. In addition, sockets, switches are installed, lamps and chandeliers are connected. The final stage is not particularly difficult and, in order to save money, can be done by hand.

Simple rules for electrifying a house:

- The wiring diagram, installation of sockets and switches should be well thought out in advance. It is extremely difficult to change their location with your own hands in a frame house, unlike a stone structure.

- Junction boxes should be located so that their inspection and repair does not cause access difficulties.

- Open wiring is carried out only if there is an air gap between the wire and the wooden wall, it is mounted on insulators.

- First you need to do all the work on the electrification of the house, and only then begin the installation of doors and windows.

Automation selection

To install protection, you need to purchase automatic machines from DEKraft, LEGRAND and ABB manufacturers. All protection units are installed according to the DIN system (mounting is done on DIN rails using an ordinary snap-in). All three machines are equipped with 10-63 Amp fuses. There are also for greater current strength, but they are not needed for residential premises. The circuit breakers are distinguished by the time of disconnection from the load and the coating of the clamp contacts.

- DECraft machines have metal clips, the turn-off time is several milliseconds longer than that of LEGRAND and ABB

- ABB automations are equipped with copper clips, making them the fastest to shut down.

- LEGRAND devices have copper-plated terminals, which also makes the disconnection time minimal

Power calculation

As a rule, the maximum current power in residential premises is not higher than 6.6 kW; there is no need to buy wires with a thickness of more than 2.5 mm2. Power is calculated by adding the power of all electrical appliances that are available (iron, kettle, microwave, etc.). As a result, the number is quite large. It is for this that several separate branches are made during installation, for example, in each room. A separate branch has its own automatic protection. Therefore, no overload is allowed.

Correct installation of connections

Connections of aluminum and copper cables are made using special electrical terminals.

Connections of cables with stranded conductors are carried out with special sleeves for special. equipment.

What cable do you need

For new wiring in a residential area, a cable with three copper cores and double insulation is required. It would be better if the cores themselves are single-wire.

Breaking the scheme into groups

- The breakdown of wiring into groups is carried out in two ways: a star or looping.

- In the first method, all devices are divided into groups, and a separate branch from the apartment electrical panel is connected to each. Usually, this is one branch per room or a particularly powerful electrical appliance, such as an electric stove.

- When looping, sockets located in the same wall, but on different sides, are combined into a group.