A water seal for mash is a device without which the process of preparing an alcoholic drink can occur uncontrollably. This may result in apple cider vinegar ending up in the fermentation tank instead of the expected drink.

Purpose of the water seal

To understand why a water seal is needed, you should know what the fermentation process is. Fermentation is a set of complex biological and chemical processes. The main one for winemakers is the breakdown of sugar, which is part of organic substances. This produces alcohol. Yeast and bacteria play a major role in the wine fermentation process. Bacteria can carry out their activities both in the air and without atmospheric oxygen. In the first case, the decomposition product is apple cider vinegar, in the second - alcohols and carbon dioxide.

Winemakers are interested in producing alcohol, so their task is to provide fermentation conditions without air access. It will not be possible to simply seal the fermentation container hermetically. For every liter of alcohol produced, about 4 m³ of carbon dioxide is released. The pressure created by carbon dioxide is so great that it can rupture the fermentation tank.

To ensure normal pressure in the container, a water seal is used. This is a valve that releases excess carbon dioxide from the container and prevents atmospheric oxygen from entering it.

Homemade water seals

You can purchase a ready-made water seal, but it’s easy to make it yourself.

Medical glove

This is the simplest and cheapest type of water seal. The glove can be purchased at any store. Due to its elasticity, it fits tightly onto the neck of any glass container. If the neck is narrow, the glove must be secured with tape or tape. Some winemakers leave the glove intact, others puncture a hole in one of its fingers.

In the first case, it is possible that the glove will burst. In the second case, carbon dioxide formed during fermentation creates excess pressure and prevents atmospheric oxygen from penetrating into the container.

But it is preferable to insert a tube into the hole to drain carbon dioxide into a container of water.

During the fermentation process, the glove is inflated and by its appearance one can judge the degree of readiness of the mash.

Classic way

If the bottle has a narrow neck and is equipped with a plastic, rubber or wooden stopper, you need to drill a hole in it for a glass or metal tube onto which the hose fits. You can do without the tube by inserting the hose into the drilled hole. The connection between the tube and the plug must be sealed. If the neck of the bottle is designed for a plastic cap, you can use it. But you need to think about how to secure the lid so that excess gas pressure does not rip it off.

The free end of the hose is lowered into a bottle of water.

During the fermentation process, gas bubbles come out of the hose into the water. If their formation has stopped, then fermentation is over.

In all cases, the length of the hose must be selected so that it does not get tangled or kinked. The diameter of the hose does not play a special role, but you should not take less than 5 mm, it can become clogged with mash. The hose can be purchased at a hardware store or auto parts market.

Disadvantages of homemade water seals:

- at any inopportune moment, a rubber glove can burst;

- not everyone likes the sound (gurgling) of escaping air;

- There may be an unpleasant odor in the room where fermentation occurs.

You can get rid of an unpleasant odor. As a container with water, you need to take a jar with a plastic lid in which 2 holes are drilled. The hose from the fermentation tank passes through one and its end is in the water. The second hose passes through the other. One end of it is located in a jar above the surface of the water, and the second is attached to the ventilation grille or window. The gases removed from the fermentation tank are collected under the lid and removed outside the room. Unpleasant odors disappear.

Alcohols are bacterial waste products. When their content in the mash reaches 15%, the living conditions for bacteria will become unfavorable, they will stop their activity and fermentation will stop.

A water seal is a device for carbon dioxide removal from the fermentation tank, as well as lack of oxygen inside this container. It allows you to maintain the mash in optimal condition, creating conditions for fermentation and preventing it from souring. There are many options for implementing it at home, which we will consider below.

A water seal is used in the vast majority of cases when mash is installed for moonshine. In some situations, fermentation products, on the contrary, are allowed to breathe, leaving the container open, but this is the exception rather than the rule. Every self-respecting moonshiner should know what a water seal is, what it can be made of and how to install it correctly.

Classic approach to water seal for fermentation

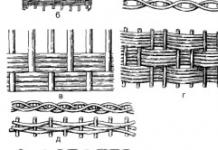

The diagram below shows the principle of operation of the simplest water seal, which consists of a tube lowered into a container of water.

During fermentation, carbon dioxide is released, which creates pressure inside the fermentation tank. It goes through a tube into the water, from which it enters the environment in bubbles. At the same time, air from the external environment does not enter the fermentation tank, since water prevents its passage.

This principle allows the mash to calmly “play” and process sugar into alcohol, reducing the risk of souring and spoilage.

What types of water seals are there and which one is better?

When used correctly everything water the shutters work the same way. It is impossible to say which one is better, since they perform their task perfectly. It is best to choose the most convenient option for you, which will perform its function and not strain you during moonshine brewing.

Two-chamber (75-200 rubles)

This type is the most popular among moonshiners. It is simple, clear and difficult to turn over, break or disturb. A two-chamber shutter is installed on top of the container and perfectly shows the presence or absence of carbon dioxide emissions from the mash.

You won’t be able to make it on your own, so you will need to go to a specialized distillery store or order it online (it sells on AliExpress for 75 rubles).

Double chamber

Collapsible with two flasks (100-150 rubles)

Another purchased option that can be disassembled and cleaned. In terms of price, it can be purchased even cheaper than a two-chamber one.

Some moonshiners are bothered by the height of this device, which does not allow placing the container in a limited space. Therefore, it is quite possible that a simpler and home-made option will suit you.

Collapsible

Tube lowered into water

The principle is as follows: a hole is cut in the lid of the container for the tube. Using plasticine, the cracks are sealed and the tube is attached. Next, it is lowered into a container of water. As a result of fermentation, carbon dioxide accumulates in the container, exits through a tube into the water and is removed through bubbles. Due to water, air does not penetrate inside.

The most versatile, simple and effective way to install a water seal. Completely fulfills its task. Definitely recommended for use.

With an additional straw for odor removal

A slightly improved method compared to the previous one, which allows you to rid the room of the smell of mash. The fact is that many people distill moonshine in apartments, which results in an unpleasant odor that disturbs both the residents of the apartment and the rest of the house. To avoid this, you can make a special outlet.

Taking a universal water seal with a tube, we additionally close the container with water with a lid and install another tube there, which we take outside. The air accumulates in the jar of water (you haven’t completely filled it, right?) and escapes under pressure through the second tube.

With air exhaust

Medical glove with a punctured finger

A classic for mash of wine, moonshine, beer and other alcoholic drinks of own production. The glove is pierced with a needle on one of the fingers, after which it is pulled over the neck of the fermentation tank and secured with an elastic band.

During fermentation, the glove inflates and air gradually escapes through the hole. When the process ends, the glove deflates.

This option appeared more out of despair and misunderstanding of chemical processes, rather than out of ingenuity. In this case there is no water seal at all, but some of the oxygen penetrates inside, causing oxidation to occur faster.

From syringes

Another option related to the medical topic. It can be done using two syringes tied with insulating tape. The syringes are connected by a tube and water is poured into one of them, which acts as a seal.

In my opinion, the method is quite complicated and unreliable. In any case, a silicone tube is used, which can be used for a universal seal with a water container.

From syringes

Cotton wool is packed quite tightly into the neck, which allows carbon dioxide from fermentation to pass through. There are many disadvantages here, for example, oxygen actively enters the container after fermentation, cotton wool can simply fall into the mash, and gurgling is also hard to hear.

Silent water seal

To create it, you will need a syringe, the neck of a plastic bottle, a thin silicone tube and, ideally, sealant. Its production is best shown in the video from Olga and Sergei on Youtube. The author describes step by step the process of creating a water seal from scrap materials.

However, apart from the absence of noise, this device cannot boast of anything else.

Fermentation is a complex process of decomposition of organic substances, the stable occurrence of which is impossible without a water seal. Ready-made devices are available for sale, but they do not always fit the container used. Making a water seal from improvised materials takes just a few minutes, and the cost of the product is pennies.

The process of processing sugar into ethyl alcohol is accompanied by abundant release of carbon dioxide. Accumulating inside a hermetically sealed container, it creates high pressure, which will inevitably lead to its rupture. To avoid this, the gas must be vented, but simply opening the lid will not solve the problem.

While the container is hermetically sealed, the bacteria in the mash are not active. But as soon as oxygen gets inside, they begin to multiply and convert alcohol into acetic acid. The result is not wine, but an acidic, unfit for consumption liquid.

To prevent this from happening, a one-way valve is installed on the container, which is called a water seal - it removes carbon dioxide, but at the same time prevents the access of oxygen. In addition, the device allows you to control the fermentation process and determine the degree of readiness of the mash.

Watch the video that explains what a water seal is, why it is needed, and how to make it yourself:

Making a device from improvised materials

Making a water seal yourself is not difficult; it does not require expensive tools and materials - you just need to choose the most suitable model for the given situation. There are several popular designs whose effectiveness has been tested by time.

Classical

The most common design, characterized by simplicity and reliability.

To make it you will need:

- cap or stopper;

- flexible tube;

- glass jar with a capacity of 0.5 l.

Manufacturing process:

- A hole is made in the center of the lid to match the diameter of the tube.

- The tube is inserted into the hole.

- The joint is sealed with plasticine, wax or silicone glue.

- The lid with the tube is placed on the container with the mash.

- The second end of the tube is lowered into a jar of water so that it does not rest against the bottom.

The disadvantage of this device is the possibility of an unpleasant odor appearing in the room. This problem can be solved by putting a lid with two holes on the jar. A tube from the fermentation tank is inserted into one and lowered into the water. Another tube is passed into the second hole so that its end is above the water level. The free end is discharged to a window or sewer, thereby ensuring the removal of carbon dioxide outside the room.

Attention! The classic water seal allows you to determine the readiness of raw materials with maximum accuracy. If there are no bubbles in the liquid for a day, then the active fermentation phase has ended and the mash is ready for further processing.

For a classic water seal, it is advisable to use a silicone tube - when in contact with alcohol-containing liquids, it does not change its characteristics and does not emit an odor. The easiest option is to purchase a dropper at the pharmacy. It has a rubber tip at the end, which does not require sealing when installed in the lid hole.

Medical glove

The fastest and most affordable option, but not the most successful.

This method is mainly used by women, since making a water seal from a glove does not require any male skills:

- The glove is put on a container with mash and tied at the base with a strong thread.

- Punctures are made in one or more fingers with a sewing needle to allow gas to escape.

- The carbon dioxide released will inflate the glove. When the fermentation process is over, it will deflate and hang on the container.

The medical glove is suitable for use on wide-necked containers. It copes with the task no worse than more complex water seals, but it is advisable to use it on containers less than 20 liters - a large volume of gas released will simply burst it. Another drawback is the unpleasant smell of mash in the room, and nothing can be done about it.

Attention! You can use a condom or an inflatable balloon as a water seal for containers with a narrow neck.

Cotton plug

To block the access of oxygen to the mash, the neck of the container is plugged with a piece of cotton wool or other porous material. Not a very reliable method, but for use in emergency cases when there are no other materials at hand, it is quite suitable.

The structure of the wool allows carbon dioxide to escape, but does not provide complete tightness. Especially when the intensity of fermentation drops and the gas pressure decreases, at this moment oxygen gradually begins to penetrate into the bottle. The disadvantage of using cotton wool is also the inability to visually determine the degree of readiness of the mash and the unpleasant odor in the room.

"Quiet"

When using a classic water seal, the release of gases is accompanied by gurgling sounds. During the day it is practically not noticeable, but at night it causes irritation for some people.

You can make a silent water seal from a transparent silicone tube with a diameter of 12-14 mm and a length of 40-60 cm:

- One end of the tube is inserted into the hole in the bottle cap and sealed with a plastic material.

- The tube is folded so that a loop is formed on it, and the other end sticks up and is fixed with tape.

- A small amount of water is poured into the tube, which forms a water seal in the loop.

The carbon dioxide will pass through the water loop in small bubbles without making any sound. The disadvantage of this method is the evaporation and splashing of liquid during strong fermentation. To eliminate it, a cap is inserted into the free end of the tube, which allows gas to pass through but retains liquid.

From a syringe and dropper

To make such a water seal it will take literally 5 minutes. and minimum materials:

- 2 syringes of 10 ml and 50 ml;

- dropper;

- tape or rubber band.

Manufacturing process:

- The fittings are removed from the syringes.

- A syringe of a smaller volume is hermetically sealed with the spout facing up in the hole in the lid of the fermentation tank.

- The second syringe is secured to it with tape or an elastic band, with the spout down.

- A tube of the required length is cut from the dropper and the internal filter is removed.

- Connect the nozzles of the syringes with a tube so that there are no kinks on it.

The result is a design in which a small syringe serves to collect gas, and a second one filled with water prevents oxygen from entering the bottle.

Wine magazine

Store-bought water seals, unlike homemade ones, are compact and do not require assembly.

There are two main types of devices commercially available:

- dual chamber shutter;

- glass type shutter.

The two-chamber shutter is made of food-grade plastic. It has a monolithic design and consists of two flasks connected in series. A similar device has a device made of two syringes and a dropper.

The tightness of the connection with the fermentation tank is ensured by a special rubber stopper, which is mainly sold separately. The device significantly increases the height of the container, which is not always convenient when stored in a closet.

A water seal is needed to remove carbon dioxide from the container where fermentation occurs. Along with oxygen, bacteria enter the mash. It is necessary to limit the access of air and close the container. How to make a water seal for mash with your own hands to get a high-quality product?

The process of preparing moonshine must be controlled and monitored at all stages. Preparation of raw materials, setting for fermentation is an incomplete cycle of product preparation. This is a complex process of interaction between components. At all stages of preparation, certain rules are followed.

Water seal for mash

Winemakers monitor fermentation temperatures. When using fruit and berry raw materials, a water seal is installed - it prevents contact of the liquid with air and removes carbon dioxide.

The resulting alcohol, upon contact with oxygen, forms acetaldehyde, methane, ethanol and other harmful oxidation products. It is important to exclude the interaction of mash with air. This applies to the preparation of cognac alcohol and fruit and berry raw materials.

After the end of the active fermentation phase, water seals are installed, which are:

- industrial;

- homemade.

They assemble the following structures with their own hands:

- Classic.

- Medical glove.

- Cotton plug.

- "Quiet" shutter.

- From a plastic bottle.

The water seal is installed depending on the temperature conditions. When fermenting wine, the juice is drained on the 6th–7th day. A rubber tube 40 cm long is installed on the cylinder. The diameter of the hose is 8–10 mm. One end of the tube must be hermetically mounted in the lid of the cylinder, the other is lowered into a glass of water.

Fermentation under a water seal lasts from 12 to 20 days. The duration of the process depends on the temperature and the method used.

Water seal designs

1) The simplest water seal is made as follows. They put a medical glove on the jar and pierce it at the tip of the finger. As it ferments, it puffs up. Carbon dioxide escapes through a hole in the glove. You can also put a rubber ball on the jar.

The fermentation process stops when the glove is lowered.

2) To make a glass-type water seal, you must use:

- test jar;

- 2 syringes - 10 and 20 ml;

- container lid;

- gun or glue “Moment”;

- drill.

In a 10 ml syringe, cut off the top and bottom. Before this, the needle is first removed. A hole is made in the lid and the plunger from the syringe is fixed.

A hole (16 mm) is drilled in the test jar. All irregularities are sanded with a file. Make holes in the cap and piston of the syringe.

Cut off the top and bottom of a 20 ml syringe. The outlet hole is sealed, and then the structure is assembled. The glass is glued to the syringe (10 ml). The upper part of the 20 ml syringe is placed on the plunger of the smaller syringe.

The structure is closed with a lid, a tube is attached and tested.

3) A “quiet” water seal can be made from a jar with a metal lid. 2 holes (14 mm) are drilled in the upper part. Automotive nipples and tubes are inserted into them. For reliability, use sealant for high temperatures. Carbon dioxide goes through a hose into the water and enters the atmosphere through another tube.

4) The distillers created a design - a heated water seal. The mobile system is used for different containers. To make the closure of a 100 liter barrel, use:

- union;

- nut;

- hose.

A hole is made in the lid, a fitting is inserted, the entire structure is mounted and the nut is tightened. Pass the cable through the tube and put it on the fitting. Then the hose is twisted and secured with electrical tape.

The water seal can be used for other vessels. The hose, accordingly, is taken in a smaller size. The level of lift must be high so that the liquid does not splash out. The system is mobile and can be moved to any location.

5) The simplest design is a dropper valve. The jar of mash is closed with a plastic lid, which is pierced with a needle. The free end of the system is lowered into a vessel with water. Thanks to this simple design, oxygen does not enter the mash, and carbon dioxide leaves.

Fighting odor

During the active fermentation phase, the smell spreads throughout the house. How to get rid of odors? To do this, lower the temperature or move the container to a cooler room. When vigorous fermentation ends, the vessel should be returned to its original place. The room temperature should be optimal.

Some distillers say that the shutter is also made to combat unpleasant odors. It is recommended to fill the tube with water. They recommend special nozzles that absorb odor, but this does not always help.

The smell from the apartment can be removed as follows. A water seal is installed directly into the sewer system, where gases are removed during fermentation. They cannot overcome the liquid column and remain in the sewer.

The water seal is an indicator of the intensity of the process in the mash. If no bubbles appear on the surface of the liquid, anaerobic digestion is complete. The mash acquires a specific smell and taste. The end of the process can be determined using a wine meter.

A water seal is needed to obtain a quality product. This design is necessary when the fermentation process is slow.

Making wine involves fermenting the must, turning the sugar it contains into alcohol. The reaction is accompanied by the release of carbon dioxide, which must be constantly removed, for which a fermentation water seal is used.

Operating principle of the water seal

The process proceeds normally only in the absence of air. The oxygen and bacteria present in it oxidize the alcohol, which decomposes into acetic acid and water.

During fermentation, a large amount of carbon dioxide is formed, which must be constantly removed from the container, maintain tightness and prevent the danger of the contents of the container being released when the cap is knocked out by gas pressure. To do this, a water seal is created in the form of a water castle. The device is sold in many varieties, but it can be made from improvised materials that cost nothing.

The simplest design for creating a tight seal is a rubber glove tightly placed on the neck of the bottle. A hole is pierced in it, through which carbon dioxide comes out of the bottle. It creates excess pressure inside, preventing the passage of air from outside.

It is important to catch the end of the fermentation process so that air does not get into the bottle due to rarefaction. Here you need to seal the exit hole in the glove in time.

In the same way, you can use a children's ball with a hole, nipples from bicycle inner tubes, or a valve with a ball from a vodka bottle.

Requirements for water seals and containers

When making a water seal for fermentation with your own hands, it must meet the following requirements:

- Resistance to mechanical stress and temperature changes.

- The presence of a transparent body through which you can monitor the activity of the fermentation process.

- No materials that affect the taste of drinks.

- Durability under cyclic load during mash preparation.

- Tightness and ease of use.

The industrial fermentation water seal contains everything you need. When working with it, you only need to observe the proportions of the components, holding time and temperature conditions.

Fermentation containers

The selected containers must have the following characteristics:

- convenience and reusability;

- exclusion of explosions accompanied by the release of the lid and contents of the container by accumulating gases;

- availability of the entire kit so that you can immediately prepare the solution;

- the ability to select the required volume;

- use of chemically neutral materials (glass, wood, special plastic, stainless steel);

- correspondence between cost and quality.

Selecting a water seal

A water seal for wine fermentation can be purchased at a specialty store. It is also easy to find and can be purchased at an affordable price online. There are many types of devices on the market, including meters, drain valves, heaters, and more. The fermentation water seal is sold at a reasonable price. A three-chamber collapsible device costs only 150 rubles. Even simpler is a two-chamber design in the form of a coil, which sells for 140 rubles.

For home wine preparation, preference is given to glass containers, since they are more suitable in volume than barrels and are cheaper than stainless steel. Plastic is also starting to find its way, but winemakers still prefer glass.

Additional attributes allow you to better organize the wort fermentation process.

Simple water seal (classic)

You can make a reliable water seal for fermentation with your own hands as follows:

- A glass or plastic bottle is filled with wort no higher than the hanger.

- A through hole is made in the plug or lid.

- A rubber or plastic hose fits tightly through the hole into the container without touching the surface of the liquid. As the volume of the bottle increases, a larger diameter hose should be used.

- The fermentation bottle with a water seal is closed and additionally sealed with coating (wax, paraffin, alabaster, gypsum). The connection between the hose and the plug should be done using glue.

- The free end of the hose is lowered into a jar of water placed next to the bottle at the same level.

Fermentation begins when bubbles of carbon dioxide are continuously released in the liquid. By their number one can judge how intensively the process occurs. In warmth, the reaction occurs more actively. The water in the jar is maintained at the same level and changed periodically.

The reaction ends when carbon dioxide bubbles stop being released. But this does not mean the end of the process. The reason may be a decrease in room temperature and a lack of sugar in the wort. The process can be continued by eliminating negative factors until the alcohol concentration in the wine reaches the desired level. Winemakers determine this through tasting.

To obtain good wine, the system must be airtight. This is especially true for connecting the tube to the container lid. The use of putty does not ensure its reliability. A high-quality connection is obtained by inserting an elastic tube into the hole in the cover and then wedging it from the inside using a nylon fitting. It is made from a car windshield washer tee, which is cut into 2 parts, after first removing the side pipe. The tightness can be improved by first applying PVA glue to the contact areas.

A similar water seal design is made as follows:

- A hole is made in the lid of the fermentation container.

- A plastic dropper needle is tightly inserted into the hole.

- The free end of the flexible hose is placed into a bottle of water through a hole in the cap.

For large production volumes, each container is a barrel or fermentation tank with a water seal. A lot of gas is formed in them, and special metal inserts, for example made of bronze, are used to remove it. For private users they are offered in hardware stores.

A hole of the required diameter is made in the body of the wine fermentation container with a water seal, and an insert is mounted in it. A flexible hose is connected to it, the free end of which is lowered into a jar of water.

How to eliminate an unpleasant odor?

The gas released in the fermentation container with a water seal has an unpleasant odor. You can eliminate it using a special device. To do this, close the jar of water with a lid with two holes. 2 hoses are tightly inserted into them. One of them comes from the bottle and is immersed in water by 2-3 cm. One end of the other hose does not reach the liquid level, and the other goes into the sewer, into a window or exhaust ventilation. There will be little odor if the pipe is just sitting in the sink.

Quiet water seal

The use of a classic water seal is accompanied by noise from the released bubbles. It can be reduced by making a water seal for fermentation with your own hands. To do this you will need a plastic bottle and a syringe. A plastic bottle with a cut bottom is attached to the lid of a large container with a hole and a tube inserted into it. A syringe with holes at the bottom is placed inside it and water is poured in from above, thereby creating a water seal. The top cut part of the bottle can be closed with a non-tight lid.

The gas comes out of a large container into a tube with a syringe and passes through the water in the form of bubbles, entering the atmosphere.

Silenced bolt

The muffler can be installed for a classic water seal. To do this, a porous material, such as a sponge or foam rubber, is put on the end of a hose lowered into a glass jar. To prevent it from flying off, it is placed in a plastic bottle without a bottom, fixed in the hole in the lid of the jar and partially immersed in water.

Gas from the hose enters the porous material, which is in the water, and then flows upward through it and exits through the holes of the bottle. The lid must have a side opening for exit. At the same time, no gurgling is heard.

The muffler should be placed lightly on the hose so that when foam from a can gets into it, it does not clog, but flies off under the influence of excess pressure. Otherwise, the pressure inside the container may cause the glass container to break.

Conclusion

Fermentation containers with a water seal can be purchased individually or as a set. Some elements of the fermentation device can be made with your own hands, but the safety of the process and the production of a high-quality product must be ensured.