Many radio amateurs dream of making a metal detector with their own hands. It can be used to detect metal objects in the ground at different depths. On the Internet you can find many photos of metal detector circuits that are simple to use. Any beginning radio amateur can make them.

Easy assembly

For example, let's take the circuit of a simple metal detector. It is of the pulse type, but due to the simplicity of its design it is not able to distinguish between types of metals. Therefore, it will not be possible to operate such a device in areas where objects made of non-ferrous metal are found.

How to assemble the device

To assemble a simple metal detector circuit with your own hands, you will need the following tools and parts:

- Presence of KR1006VI1 microcircuit and IRF740 transistor;

- Presence of K157UD2 microcircuit and VS547 transistor;

- Copper conductor 0.5mm (PEV);

- NPN transistor;

- Housing, and various materials for it;

- Solder, flux, soldering iron.

Other details are shown in the diagram. In order for the assembled circuit to be securely fastened, a plastic case should be prepared for it.

The bar can be made using a small diameter plastic tube. A metal detecting coil will be installed in its lower part.

Beginning of work

The circuit diagram of a metal detector using transistors is a common option for many models. Assembly begins with the manufacture of a printed circuit board. Next, all radio elements are mounted on it exactly as shown in the diagram.

To ensure stable operation of the device, film capacitors are used in the circuit. This will allow you to use it in cold weather without any problems.

Power type for device

The device can operate on a voltage of 9-12 V. Due to its sufficient power, energy is intensively consumed. It is recommended to install up to 3 batteries and connect them in a parallel circuit. You can use a small battery that has a charger. Thanks to its capacity, the metal detector will work longer.

Coil installation

There are different types and schemes for the manufacture of metal detectors, but in the pulsed version, inaccuracies are allowed in the installation of the coil. When making a mandrel, the winding should be up to 25 turns, and the diameter of the ring should be 1900-200mm.

All turns of the coil must be insulated with electrical tape. Reducing the number of turns to 22, and the mandrel diameter of 270 mm will allow you to detect objects at a deeper location. The wire cross-section on the coil is 0.5 mm.

When the winding is ready, it is attached to a durable housing with sufficient rigidity, on which there should be no metal parts. Otherwise, they are able to shield the magnetic field, and the operation of the metal detector will be disrupted. The body can be made of wood or plastic, but so that it can withstand various impacts that can damage the coil.

The leads on it should be soldered to a conductor of several cores. The best option is a two-core wire.

The installation of a non-ferrous metal detector circuit is a little more complicated, and high precision must be observed in the manufacture of the coil. The number of turns reaches 100pcs, and a vinyl tube is used as the core. Foil is wound on top of the winding, which forms an electrostatic screen.

Device setup

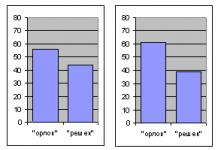

If the installation of the circuit is done exactly, then the metal detector will not need additional settings. Its sensitivity indicators will be maximum, but fine adjustment is possible through variable resistance R13. It must be performed until rare clicks begin in the headphones.

If the adjustment fails, then the resistances must be replaced with R12. When the resistor adjustment is in the middle, this will be considered normal.

An oscilloscope is suitable for checking the device. The frequency of transistor T2 is measured on it, and the pulse should last up to 150 ms. The optimal operating frequency is up to 150 Hz.

How to use the device

You should not rush and start working immediately after turning on the metal detector. It should stabilize, so you need to wait up to 20 seconds. After adjusting the resistor appropriately, you can start looking for metal.

Note!

Photo of the metal detector circuit

Note!

Note!

Today there are a large number of ways to make a metal detector at home completely independently, without the help of specialists. Some of them require certain knowledge of physics, as well as skills in working with electrical and radio devices. Others do not require any special skills, and any beginner can assemble a metal detector at home with their own hands.

How to make your own metal detector from disks

It’s quite easy to make a metal detector at home with your own hands. using two discs - CD and DVD. This method is very simple and does not require any complex components. All you need for this is:

- CD and DVD disc. It is advisable to take double-sided ones, then the sensitivity of the metal detector will be much higher.

- Any calculator you have at hand, you can take the simplest and cheapest one

- headphones

- crown size battery

- glue and tape

Sequencing

The metal detector is ready you can start testing it. For ease of use, you can attach a comfortable handle to the metal detector. To search for coins and metal in the ground, the power of such a device will not be enough, but in the house it can always be useful. For example, to search for hidden wiring, a walled-up wall, or to find a metal profile under a sheet of drywall.

Metal detector made from a radio and calculator

In order to make such a metal detector, the following things are needed:

- Empty CD box

- The simplest and cheapest calculator

- Radio receiver operating on AM frequency

- Double-sided tape or tape

- Nails

- Wooden mop stick

Assembly order

Device assembly sequence next.

Thus, you can assemble a metal detector at home with your own hands, even without special knowledge and skills. But it should be borne in mind that such metal detectors not suitable for serious searches metal objects underground, because their range of action is small. For complex tasks, you should try to assemble a “butterfly” or “terminator” type device. On the one hand, if everything works out, you can save a good amount of money, but on the other hand, according to experts, such homemade metal detectors don't always work as intended.

Not everyone can afford to buy a metal detector. And to search for iron, it is not at all necessary to purchase an expensive device. It is enough to assemble it yourself. And he will find it too.

By the way, I will say that I saw a report on TV about how a man who had assembled a metal detector and was looking for scrap metal with it found a box of ammunition from the Civil War in the forest.

I myself have been trying to assemble such a device for a long time and it even worked! But you won’t be able to search for coins with it, since it reacts mainly to large metal objects.

And so, to assemble a simple metal detector we need:

~ two KT315 transistors or similar;

~ two 1000 pf capacitors;

~ two capacitors 10000 pf;

~ two 100 kOhm resistors.

In addition, the following will be useful: a 3.7-5 volt battery, headphones, enamel-insulated wire with a diameter of 0.5-0.7 mm.

The assembly diagram is simple!

The coils can be wound on a regular pan. After ten turns, a loop is made and the winding of the remaining twenty turns continues.

The body is made of any material, preferably sealed. The bar can be made from pipes. The coils are placed on the same plane at a distance of 10 cm.

If, when you turn on the device, a squeak appears in the headphones, then it means that you need to adjust the device - change the distance between the coils. Or customize with ferrite.

Thus, you can make money by searching for scrap metal for a good branded device. And a good deed will be done - the earth will be cleansed. Well, the metal will be reused.

The photos in the article are mine, taken back in 2014. And the first picture with the diagram is taken from open sources.

How to make a simple metal detector for searching on the beach

In this article I will tell you how to build a simple metal detector for searching for coins and jewelry on the beach. It consists of one chip - the NE555N timer, a coil and several other radio components.

Expect to spend up to 300 rubles to build this metal detector!

Required materials

To assemble the metal detector you will need:

- NE555N timer chip, in DIP package;

- resistor 47 kOhm;

- two capacitors 2.2 µF, 16 V;

- piece of contact breadboard;

- 9 volt battery, switch, battery socket;

- electromechanical sound emitter;

- 100 meters of copper wire with a diameter of 0.2 millimeters;

- some thick cardboard and glue.

Instead of an electromechanical sound emitter, you can use a 10 µF capacitor and any speaker with an 8 Ohm impedance, connected in series.

Metal detector circuit

The idea of a metal detector was taken from the book " 499 circuits on NE555 timer" I just added a switch between the battery and the chip, and I also use an electromechanical sound emitter from an old electronic alarm clock instead of a speaker.

Search coil

The most difficult part of a metal detector is its coil. I calculated that a 90mm diameter coil would have approximately 260 turns of 0.2mm diameter varnished copper wire. In this case, its inductance will be approximately 10 millihenry.

I wound the coil carefully, turn to turn. To prevent the wires from unraveling, I wrapped the winding with white electrical tape on top.

If you want to make a larger diameter coil to increase the target detection range, then there are several online calculators on the Internet with which you can calculate it.

Circuit board

I placed all the electronic components on a piece of breadboard. The connections were made using the most ordinary wire that was at hand. Soldering the board itself took no more than 15 minutes.

The size of the board turned out to be approximately equal to the size of a matchbox.

Frame

To simplify things, I decided to make the handle of the metal detector out of cardboard. The handle contains a circuit board, a switch and a battery.

All this was cut out of thick cardboard and glued together with PVA glue. After the glue had dried, I made holes in the cardboard for the board and wires.

Next, I glued the search coil to the handle with hot glue. The last step, also using hot glue, I glued the board and battery inside the handle.

Conclusion

The metal detector works as follows: as long as there are no metal objects near the coil, the sound emitter beeps at the same frequency; when a metal object is brought up, the tone of the sound changes towards a higher one.

The detection range of a large coin through the air, according to my measurements, was 5 – 7 centimeters!

Simple metal detector baby FM-2 improved

I present to your attention a diagram of a more improved metal detector Malysh FM-2. The baby fm2 metal detector is not so difficult to assemble with your own hands, despite its significant changes. This is perhaps the simplest selective metal detector that even a novice radio amateur can assemble.

You have probably heard of, and perhaps collected, such metal detectors as “Malysh” and “Malysh FM-2”. But progress does not stand still and therefore we have a diagram of a more improved metal detector Malysh FM-2. The new version adds LED indication of metals, a power-on notification function is added, the notification sound is enhanced, and the device has become much more stable in operation.

Diagram of the improved metal detector Malysh FM-2

Specifications and features:

- Supply voltage - 9 Volts

- Metal detection depth is about 15 cm.

- Selection of metals - black, non-ferrous

- LED indication of metals - black, color

- Power-on indicator

So, this printed circuit board of the Malysh FM-2 metal detector is designed to use DIP components, which would be convenient for everyone, since many novice radio amateurs have not yet encountered SMD components.

Capacitors C5-22nF and C1-100nF must be film

Voltage stabilizer AMS1117 -3.3v

This is what the finished board of the “Malysh FM-2” metal detector looks like:

View from the paths

After assembling the board, we proceed to making the coil.

A standard coil contains 150 turns, wire diameter 0.3, and wound on a frame of 150 mm. But I decided to slightly reduce the diameter to 10-11 cm so that the metal detector could better see small objects; the detection depth decreases but the sensitivity increases. I didn’t have 0.3 wire, so I wound 0.4 on a 10 cm frame, 130 turns.

So, after the coil is wound, it is necessary to tighten it very tightly with tape.

Now it is imperative to shield the coil so that the metal detector does not react to interference and there are no false alarms. Take food foil and wrap the coil tightly. Please note that the ends of the foil should not touch each other!

Then we take the wire, strip the end and wrap the coil to one edge of the screen, then tighten it and wrap it tightly with tape again.

We connect the coil to the board. The wire from the screen needs to be soldered to the minus of the board.

Now all that remains is to flash the microcontroller and that’s it, you can use it)

If you do everything correctly, the device should work without problems the first time you turn it on. Carefully check the ratings of the parts and do not forget that the capacitors C2-22nF and C6-100nF must be film, NOT ceramic!

When turned on, the device should make a characteristic sound similar to a “peep-fang”, this means that the device has turned on and is working correctly.

IMPORTANT! “According to the diagram there are 8 resistances, but in the photo there are 9” - the 9th resistor (100 Ohm) I myself installed additionally on the second LED, although it doesn’t have to be installed! The 1N4007 diode can also be omitted, as I did!

The printed circuit board, firmware, as well as a list of parts that can be bought very cheaply on AliExpress with free shipping are located below the video!

Video of the metal detector baby FM-2 v2

Good DIY metal detector

This happened several years ago. I wanted to keep my hands busy and while away the evenings as the treasure hunting season approached. It was decided to assemble a metal detector. For assembly I chose the “Pirate” metal detector circuit. Since it is not complicated, but the device itself is quite interesting. The assembly began with the search for parts. I even had to go to the workshop to get some resistors. When everything was found, it was necessary to prepare the printed circuit board, namely, etch it using the LUT method. Then it was just a matter of small things: soldering all the parts. Well, check the finished board. The first time it didn't turn on. The K157UD2 chip turned out to be faulty. After changing it, the scheme worked!  Now you can work on the body. The body from Koschey 5I was taken as its quality, and a new front panel was made. It's up to the coil. For the coil, a frame was cut out with a jigsaw and a groove was machined along the side edge, where the coil winding was wound, and a cable with a connector was soldered. The rod was made of plastic pipes and fittings. The armrest is cut from a sewer pipe. It all turned out quite culturally. The device turned out to be light, but not rigid enough.

Now you can work on the body. The body from Koschey 5I was taken as its quality, and a new front panel was made. It's up to the coil. For the coil, a frame was cut out with a jigsaw and a groove was machined along the side edge, where the coil winding was wound, and a cable with a connector was soldered. The rod was made of plastic pipes and fittings. The armrest is cut from a sewer pipe. It all turned out quite culturally. The device turned out to be light, but not rigid enough.  The result was a working, high-quality device. Its only drawback is the lack of metal discrimination. Therefore, it can be said that it is not suitable for searching for coins. After all, both nails and coins ring the same way.

The result was a working, high-quality device. Its only drawback is the lack of metal discrimination. Therefore, it can be said that it is not suitable for searching for coins. After all, both nails and coins ring the same way.  But with its help, you can successfully dig scrap metal and hand it over to collection points, thereby earning money! There is a video with a test of this device. It was filmed by me in the spring of 2015.

But with its help, you can successfully dig scrap metal and hand it over to collection points, thereby earning money! There is a video with a test of this device. It was filmed by me in the spring of 2015.

Source

Devices called metal detectors or metal detectors will help detect metal objects (ferromagnetic or non-magnetic) in a weakly conducting or neutral environment. The difference in these definitions lies in the functional purpose of the devices. Both a metal detector and a metal detector indicate the location of a metal object, but only the first device also has a function that allows you to recognize the type of metal. Such products are used for work purposes by archaeologists, geologists, builders, military personnel, and treasure hunters. They use expensive devices that are produced specifically for such purposes by Russian and foreign companies using different technologies. Industrial designs differ in their construction schemes, technical characteristics and the presence of additional options. This could be the depth, type of metal, shape of the object, etc. Is it possible to make a metal detector with your own hands at home? Fans of search work will get the answer to this question in this article.

Note! An electronic metal detector can detect coins at a depth of up to 0.5 m and large objects at a depth of up to 3.0 m.

Operating principle and components

The operating principle of a metal detector depends on the design type:

- induction;

- working on beats;

- in transmit-receive mode;

- designed according to an electronic frequency meter circuit;

- impulsive.

Induction devices contain a sensor. It contains a specially designed coil. It is excited by an alternating signal. If there is a metal object under the sensor, an electric signal appears. a signal that is recorded in a certain way.

A metal detector operating on beats records the difference in operating frequencies of 2 generators. One operates at a frequency that is known, the second has structural elements operating in a frequency-setting circuit. In the ground, walls, wood, etc., where there are no metal objects, the frequencies of the generators are the same; if present, they differ. These changes are recorded by appropriate means - by listening or digitally.

The principle of operation of devices operating in transmitting and receiving modes is to register a signal that is reflected from an object made of non-ferrous or ferrous metal. The device design has at least 2 coils, one of which operates in transmitting mode, the second in receiving mode. The signal arises from the transmitting coil, because it is affected by an alternating magnetic field. The best results are obtained by sensors whose coils are coplanar.

Frequency meter metal detectors are devices with built-in microprocessor technology. They are characterized by compact dimensions, and their sensitivity is an order of magnitude higher. They can estimate the frequency increment, which makes it possible to use such devices to recognize the type of metal.

Pulse metal detectors use a phenomenon called self-induction in a conductive object. It is customary to distinguish the following components in the design:

- current pulse generator;

- receiving and emitting coils;

- a block used to process the received signal;

- switching devices.

A switching device is necessary to separate the emitted and reflected signals according to such an indicator as time, i.e. For some time, a current pulse of a damped type is maintained, which is recorded.

You can assemble a metal detector at home using any of the above schemes. The main thing is to select all the necessary parts and components, without deviating from the parameters indicated in the diagram. It is very important to follow the technology of the work performed.

Main settings

The operating principle of the simplest metal detectors is based on the properties of electromagnetic induction. The main technical characteristics of the product are:

- search depth;

- selectivity;

- sensitivity;

- coverage area;

- noise immunity.

In addition, the amount of electricity consumed and the time for which the electricity supply is calculated are taken into account. A simple metal detector is made with your own hands, taking into account all these factors.

Transistor metal detector

Such a homemade metal detector with a 12 V power supply is manufactured according to the diagram shown in Fig. below.

Assembling a metal detector with your own hands is preceded by preparatory work: a list of necessary components is compiled. Then they are purchased in a retail chain or are found among the parts available to the radio amateur. Next, making a metal detector with your own hands will help the correct sequence of work performed. They are performed according to the following algorithm:

- the board is made;

- installation of parts and elements on the board is carried out;

- a coil is made;

- the functionality of the board is checked;

- the frame of the metal detector is being made;

- The operation of the metal detector is checked.

Board manufacturing stages:

- the dimensions of the PCB are determined (in this case you will need a piece 84 cm long and 31 cm wide);

- preparing the PCB for transferring the circuit (sanded and cleaned of contaminants);

- The board is printed using a laser printer on low-density photo paper;

- transferring the circuit onto PCB (using a heated iron);

- soaking in a solution of ferric chloride or copper sulfate;

- removing toner with acetone;

- drilling holes for installing elements;

- production of board tracks (using LTI-120 solution and solder).

The elements on the board are installed in the following order: microcircuit, amplifier, 2 SMD capacitors, MLT S2-23 type resistor, transistors and capacitors.

The coil is made on a Ø 200 m mandrel using PEV wire Ø 0.5 mm. The number of turns is 25. The speaker is taken from any portable radio.

The device is configured using potentiometers with a power of 10 and 100 kOhm.

A barbell for a metal detector can be made by using a crutch with an armrest or plastic or light metal pipes, giving them the required configuration. This is up to the manufacturer's taste. The device, which was assembled according to this scheme, will see objects at a depth of 1.0 m, if they are large, and coins up to 0.4 m.

The design of the metal detector may be different, it all depends on what the DIY enthusiast has on hand and what kind of result he wants to get.

The nuances of making a deep metal detector are presented in the video https://youtu.be/0WnD4UZCmcU.

Homemade underwater metal detector

How to make a metal detector to work underwater? The main difference from devices for working on land is the creation of a coil, which must be sealed, and when creating a circuit, it is necessary to take into account the specifics of the device’s operation under water. As a rule, such a do-it-yourself underwater metal detector is used to find small items made of non-ferrous metals (rings, earrings, pendants, chains, etc.) in water at different depths. Therefore, the product must be configured for gold or searching for other non-ferrous metals. And one more thing - during operation, the device is in water for a long time, so metal detectors are subject to increased requirements for the material from which the rod is made; it is also necessary to protect electronic components from exposure to water. On the Internet you can find diagrams of all 5 types of metal detectors and descriptions for them. It is not difficult to choose according to your liking or technical characteristics, as well as to make a metal detector at home. The main desire.

The video at https://youtu.be/XGVeqdTYVzk shows in detail the manufacture of an underwater metal detector, as well as the nuances of its configuration.

What the board with components looks like can be clearly seen in Fig. below.

The manufacturing steps are the same as for the device for working on land, but only the control unit board is placed in the housing, which is additionally treated with silicone sealant. For these purposes, you can use a tube from the sealant itself or another hermetically sealing device.

With the onset of spring, more and more often you can see people with metal detectors on the banks of rivers. Most of them are engaged in “gold mining” purely out of curiosity and passion. But a certain percentage actually earn a lot of money from searching for rare things. The secret to the success of such research is not only in experience, information and intuition, but also in the quality of the equipment with which they are equipped. A professional instrument is expensive, and if you have a basic knowledge of radio mechanics, you have probably thought more than once about how to make a metal detector with your own hands. The editors of the site will come to your aid and tell you today how to assemble the device yourself using diagrams.

Read in the article:

Metal detector and its structure

This model costs more than 32,000 rubles, and, of course, non-professionals will not be able to afford such a device. Therefore, we suggest studying the design of a metal detector in order to assemble a variation of such a device yourself. So, the simplest metal detector consists of the following elements.

The operating principle of such metal detectors is based on the transmission and reception of electromagnetic waves. The main elements of a device of this type are two coils: one is transmitting, and the second is receiving.

The metal detector works like this: the magnetic field lines of the primary field (A) of red color pass through the metal object (B) and create a secondary field (green lines) in it. This secondary field is picked up by the receiver and the detector sends an audible signal to the operator. Based on the principle of operation of emitters, electronic devices of this type can be divided into:

- Simple, working on the “receive-transmit” principle.

- Induction.

- Pulse.

- Generating.

The cheapest devices belong to the first type.

An induction metal detector has one coil that sends and receives a signal simultaneously. But devices with pulse induction differ in that they generate a transmitter current, which turns on for a while and then turns off abruptly. The coil field generates pulsed eddy currents in the object, which are detected by analyzing the attenuation of the pulse induced in the receiver coil. This cycle repeats continuously, perhaps hundreds of thousands of times per second.

How does a metal detector work depending on its purpose and technical device?

The operating principle of a metal detector varies depending on the type of device. Let's consider the main ones:

- Dynamic type devices. The simplest type of device that continuously scans the field. The main feature of working with such a device is that you must be in motion all the time, otherwise the signal will disappear. Such devices are easy to use, however, they are poorly sensitive.

- Pulse type devices. They have great sensitivity. Often, such a device comes with several additional coils for adjustment to different types of soils and metals. Requires certain skills to set up. Among the devices of this class we can distinguish electronic devices operating at low frequencies - no higher than 3 kHz.

- Electronic devices, on the one hand, do not give a reaction (or give a weak one) to unwanted signals: wet sand, small pieces of metal, shot, for example, and, on the other hand, they provide good sensitivity when searching for hidden water pipes and central heating routes, as well as coins and other metal objects.

- Depth detectors designed to search for objects located at impressive depths. They can detect metal objects at a depth of up to 6 meters, while other models “pierce” only up to 3. For example, the Jeohunter 3D depth detector is capable of searching and detecting voids and metals, while showing objects found in the ground in 3- measured form.

Depth detectors operate on two coils, one is parallel to the ground surface, the other is perpendicular.

- Stationary detectors- these are frames established at particularly important protected sites. They detect any metal objects in people's bags and pockets that pass through the circuit.

Which metal detectors are suitable for making yourself at home?

The simplest devices that you can assemble yourself include devices that operate on the principle of reception and transmission. There are schemes that even a novice radio amateur can do; for this you just need to select a certain set of parts.

There are many video instructions on the Internet with detailed explanations of how to make a simple metal detector with your own hands. Here are the most popular ones:

- Metal detector "Pirate".

- Metal detector - butterfly.

- Emitter without microcircuits (IC).

- Series of metal detectors "Terminator".

However, despite the fact that some entertainers are trying to offer systems for assembling a metal detector from a phone, such designs will not pass the battle test. It’s easier to buy a children’s metal detector toy, it will be more useful.

And now more about how to make a simple metal detector with your own hands using the example of the “Pirate” design.

Homemade metal detector “Pirate”: diagram and detailed description of the assembly

Homemade products based on the “Pirate” series metal detector are among the most popular among radio amateurs. Thanks to the good performance of the device, it can “detect” an object at a depth of 200 mm (for small items) and 1500 mm (large items).

Parts for assembling a metal detector

The Pirate metal detector is a pulse type device. To make the device you will need to purchase:

- Materials for making the body, rod (you can use a plastic pipe), holder, and so on.

- Wires and electrical tape.

- Headphones (suitable for the player).

- Transistors – 3 pieces: BC557, IRF740, BC547.

- Microcircuits: K157UD2 and NE

- Ceramic capacitor - 1 nF.

- 2 film capacitors - 100 nF.

- Electrolytic capacitors: 10 μF (16 V) – 2 pieces, 2200 μF (16 V) – 1 piece, 1 μF (16 V) – 2 pieces, 220 μF (16 V) – 1 piece.

- Resistors – 7 pieces per 1; 1.6; 47; 62; 100; 120; 470 kOhm and 6 pieces for 10, 100, 150, 220, 470, 390 Ohm, 2 pieces for 2 Ohm.

- 2 diodes 1N148.

DIY metal detector circuits

The classic circuit of the “Pirate” series metal detector is built using the NE555 microcircuit. The operation of the device depends on a comparator, one output of which is connected to the IC pulse generator, the second to the coil, and the output to the speaker. If metal objects are detected, the signal from the coil is sent to the comparator, and then to the speaker, which notifies the operator of the presence of the desired objects.

The board can be placed in a simple junction box, which can be purchased at an electrical store. If such a tool is not enough for you, you can try to make a more advanced device; a diagram for making a gold-oriented metal detector will help you.

How to assemble a metal detector without using microcircuits

This device uses Soviet-style transistors KT-361 and KT-315 to generate signals (you can use similar radio components).

How to assemble a metal detector circuit board with your own hands

The pulse generator is assembled on the NE555 chip. By selecting C1 and 2 and R2 and 3, the frequency is adjusted. The pulses obtained as a result of scanning are transmitted to transistor T1, and it transmits the signal to transistor T2. The audio frequency is amplified using the BC547 transistor to the collector, and headphones are connected.

To place radio components, a printed circuit is used, which can be easily made independently. To do this, we use a piece of sheet getinax covered with copper electrical foil. We transfer the connecting parts onto it, mark the fastening points, and drill holes. We cover the tracks with a protective varnish, and after drying, we lower the future board into ferric chloride for etching. This is necessary to remove unprotected areas of copper foil.

How to make a metal detector coil with your own hands

For the base you will need a ring with a diameter of about 200 mm (ordinary wooden hoops can be used as the base), on which 0.5 mm wire is wound. To increase the depth of metal detection, the coil frame should be in the range of 260−270 mm, and the number of turns should be 21−22 vol. If you don't have anything suitable on hand, you can wind a reel on a wooden base.

Copper wire spool on wooden base

| Illustration | Description of action |

| For winding, prepare a board with guides. The distance between them is equal to the diameter of the base on which you will attach the reel. |

| Wind the wire around the perimeter of the fastenings in 20-30 turns. Secure the winding with electrical tape in several places. |

| Remove the winding from the base and give it a rounded shape; if necessary, additionally fasten the winding in several more places. |

| Connect the circuit to the device and test its operation. |

Twisted pair coil in 5 minutes

We will need: 1 twisted pair 5 cat 24 AVG (2.5 mm), knife, soldering iron, solder and multitester.

| Illustration | Description of action |

| Twist the wire into two skeins. Leave 10 cm on each side. |

| Strip the winding and free the wires for connection. |

| We connect the wires according to the diagram. |

| For better fastening, solder them with a soldering iron. |

| Test the coil in the same manner as the copper wire device. The winding terminals must be soldered to a stranded wire with a diameter in the range of 0.5-0.7 mm. |

Brief instructions for setting up a DIY metal detector “Pirate”

Once the main elements of the metal detector are ready, we proceed to assembly. We attach all the components to the metal detector rod: the body with the coil, the receiving and transmitting unit and the handle. If you did everything correctly, then additional manipulations with the device will not be required, since it initially has maximum sensitivity. Fine tuning is performed using variable resistor R13. Normal operation of the detector should be ensured with the regulator in the middle position. If you have an oscilloscope, then use it to measure the frequency at the gate of transistor T2, which should be 120−150 Hz, and the pulse duration should be 130−150 μs.

Is it possible to make an underwater metal detector with your own hands?

The principle of assembling an underwater metal detector is no different from a conventional one, with the only difference being that you will have to work hard to create an impenetrable shell using sealant, as well as to place special light indicators that can report a find from under water. An example of how this will work is in the video:

Do-it-yourself metal detector “Terminator 3”: detailed diagram and video instructions for assembly

The Terminator 3 metal detector has occupied an honorable place among homemade metal detectors for many years. The two-tone device operates on the principle of induction balance.

Its main features are: low power consumption, metal discrimination, non-ferrous metals mode, gold only mode and very good search depth characteristics, compared to semi-professional branded metal detectors. We offer you the most detailed description of the assembly of such a device from folk craftsman Viktor Goncharov.

How to make a metal detector with your own hands with metal discrimination

Metal discrimination is the ability of the device to distinguish between the detected material and classify it. Discrimination is based on different electrical conductivities of metals. The simplest methods for determining the types of metals were implemented in old instruments and entry-level devices and had two modes - “all metals” and “non-ferrous”. The discrimination function allows the operator to respond to a phase shift of a certain magnitude, compared to a configured (reference) level. In this case, the device cannot distinguish between non-ferrous metals.

Learn how to make a homemade professional metal detector using improvised materials in this video:

Features of deep metal detectors

Metal detectors of this type can detect objects at great depths. A good metal detector, made by yourself, looks to a depth of 6 meters. However, in this case the size of the find must be substantial. These detectors work best for detecting old shells or large enough debris.

There are two types of deep metal detectors: frame and transceiver on a rod. The first type of device is capable of covering a large area of land for scanning, however, in this case, the efficiency and focus of the search is reduced. The second version of the detector is a point detector; it works directed inward over a small diameter. You need to work with it slowly and carefully. If your goal is to build such a metal detector, the following video can tell you how to do it.

If you have experience in assembling such a device and using it, tell others about it!