- Recruitment

The mineral water production business has always been considered highly profitable. An endless raw material base, coupled with a wide selection of water bottling equipment (both domestic and foreign), makes this business very attractive to investors. However, due to the saturation of the market for such products, starting a business for new players is becoming more and more difficult. In this case, the sales issue always comes first.

Mineral water bottling business

From year to year, new companies and mini-productions appear in the drinking water production market. So how profitable is the mineral water production business? We invite you to familiarize yourself with the feasibility study (business plan) for the production of mineral water at a mini-enterprise with a capacity of 12 thousand liters. water per shift.

Mineral water production technology

To begin with, let us briefly introduce the technological chain of mineral water production:

- Accumulation of water in receiving tanks. Mineral water from wells (300-400m) is lifted using a deep pump and supplied through pipelines to storage tanks.

- Filtration. Water filtration is carried out on a filter block filled with sand and filtration material.

- Disinfection. Water disinfection is carried out with ultraviolet rays in a UV installation.

- Cooling. Cooling of water occurs on a plate heat exchanger.

- Carbon dioxide saturation.

- Blowing PET bottles (1.5 l) on a special blow molding machine.

- Bottling and supply of finished water to the warehouse. Mineral water is bottled in PET bottles with a capacity of 1.5 liters, sealed with corks, and labels marked on the printer are glued to the bottles. Bottles are packed in shrink film in 6 pieces, placed on pallets and wrapped with stretch on a polyizer. Then the finished products are sent to the warehouse.

Where to start a mineral production business

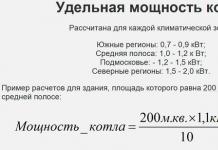

Let us calculate the main indicators of economic efficiency of a mini-enterprise for the production of mineral water.

Initial data:

- Production area: 400m2

- Type of property: rent (120 thousand rubles/month);

- Number of shifts: 1 shift (8 hours);

- Line capacity per shift: 12,000 liters (8,000 1.5 liter bottles);

- Number of working days in a month: 22 days.

- Capital costs for bottling equipment

What equipment to choose for the production of mineral water

Capital costs for the purchase of equipment for the production of mineral water will amount to 1,100,000 rubles.

Recruitment

The monthly cost of paying wages to employees will amount to 1,272,000 rubles.

How much money does it take to produce mineral water?

The cost of production of one liter of mineral water is 8.94 rubles. Total monthly expenses will be 2,363,600 rubles.

How much can you earn from producing mineral water?

Let's calculate the main indicators of economic efficiency of mineral water production, including the payback period of equipment.

Conclusion: The net profit of the enterprise for the production of mineral water will amount to 686.7 thousand rubles per month. The profitability of production with such indicators is 29%, and the payback period for equipment (not business) is only 1.5 months. It is worth considering that such indicators are possible only if 100% of the sale of all manufactured products, which is 264,000 liters of mineral water per month.

- Privacy.

- Summary.

- Project implementation stages.

- Characteristics of the object.

- Marketing plan.

- Technical and economic data of equipment.

- Financial plan.

- Risk assessment.

- Financial and economic justification for investments.

- Conclusions.

Today drinking water is purchased not only for home use. It is ordered to offices, catering establishments, hospitals, children's institutions, production shops. There will always be a demand for this product, because at any time of the year a person simply cannot live without it. Of course, such an important product cannot be left without the attention of modern entrepreneurs. The production of mineral water is one of the promising and inexpensive business ideas.

It may seem that there is no simpler product than drinking water. However, there are many types of it. The main groups are mineral table species, natural table and medicinal. The first type contains at least 1-2 g of salts per liter. In addition, the composition contains pharmacologically active components. Medicinal table waters contain more salts. They contain biologically active components. Medicinal types are products in which the total mineralization is not less than 12 g per liter. They can only be used as prescribed by a doctor. Based on the amount of anion and cation exchange resins contained in the product, table waters are divided into 19 groups, and medicinal table waters into 28 classes. There are about 160 species of the former, and no more than a hundred of the latter.

What equipment to choose for the production of drinking water?

The production line for bottled drinking mineral water costs about 1 million rubles. The equipment set includes:

| Saturator or carbonation plant | It resembles a cylinder in which a certain pressure is created. It is controlled by a valve; the level is shown by a pressure gauge installed on it. Before saturation with carbon dioxide, the water is cooled to 6 °C. |

| Filling and capping machine | It rinses and fills soft drinks into PET containers or glass bottles with volumes from 0.33 to 19 liters. The equipment can be sealed with a plastic cap, crown cap or aluminum cap. |

| Well pump | Mineral water is considered to be water obtained from a depth of 100 meters or more. The equipment must be powerful enough to pump it out and send it to the production line. |

| Water containers | Used to store drinking water before and during processing. |

| Block for the production of PET bottles | Forms a container into which the product will be poured in the future. |

| Equipment for packing | Serves for packing bottles into briquettes, convenient for further transportation and storage. |

Drinking water production technology

The production of bottled and draft drinking water occurs using this technology. Water from wells flows into special containers. It rises through pipes using special deep-well pumps. Such drinking water always contains mechanical impurities. To get rid of them, the water is carefully filtered. If this is not done, the product will sooner or later become cloudy and spoil. Industrial filters are made from well-known materials: coal, sand, and others. At the next stage, the water is purified from biologically active organisms. Ultraviolet radiation is used for this.

Not all mineral water is carbonated. As practice shows, the product without gases is in less demand. Therefore, in order to achieve the desired level of sales, water must be passed through a saturator. It will saturate it with carbon dioxide. The water is cooled in a heat exchanger. Carbon dioxide is also dissolved there.

In modern factories, containers for the product are made themselves. Installations for its production do not take up much space, and production does not depend on suppliers. Branded stickers and special design are another important feature that affects sales and the success of an enterprise’s marketing policy.

Container for mineral water.

Ozonation of bottled drinking water

Saturation of water with oxygen (ozonation) removes harmful microorganisms from the liquid, disinfects it and even imparts some healing properties. The oxygen that gets into the water does not affect its mineral properties, but it improves the taste and makes the product useful for humans. It has been proven that the cellular structure of water that has undergone ozonation is similar to the structure of human blood. The body processes it more easily.

The installation in which ozonation occurs (saturation of water with oxygen) can be purchased for 260 thousand rubles. It has a certificate of conformity ROSS RU.AB67.H00706 No. 0276073. The water passed through it complies with domestic standards and regulations. In the installation you can:

Such equipment is capable of ozonizing from 50 to 500 liters of drinking water per hour. It is a single housing that does not require special installation. The technology does not consist of carbonation, but of filling drinking water with oxygen at the ionic level. The output is a liquid that contains 40 mg per 1 liter of dissolved oxygen.

Ozonation of mineral bottled drinking water in production is carried out immediately before bottling. The ozone level in such liquids is 0.2-0.3 mg/l. They can be usable for quite a long time.

Ozonation occurs in a very short time, but nevertheless, it allows you to disinfect the product and container. Ozone also affects the filling system itself, the cap, the neck of the bottle and other elements involved in the process. Once the bottle is sealed, the ozone molecules are converted into oxygen. This process makes the product virtually sterile until it is consumed. Ozonation is mainly used at the last technological stage.

In the end, it should be noted that on average in the industry, the production of drinking mineral bottled water has a profitability of about 30%. With this indicator and provided that the products are fully sold, the investment promises to pay off within 12 months. The period will accordingly increase if more expensive equipment is purchased and production premises are purchased.

What equipment to choose for the production of mineral water

To organize a small production of mineral water, a novice entrepreneur needs to purchase special equipment. Depending on the available finances, this may be new or used equipment. There is also an option to purchase each machine separately or purchase a ready-made automated production line.

To produce mineral water you need to buy the following elements:

- well pump;

- coarse and fine filter units or automatic system;

- bottle production equipment;

- reservoirs and tanks for water;

- automatic bottle filling and capping machine;

- apparatus for producing labels.

Mineral water production technology

The technology for producing mineral water consists of several stages. During the production process, water undergoes some processing. Mineral water is pumped out by special pumps from wells 300-400 meters deep and lifted into storage tanks. Then the water enters the filter unit, where it is cleaned with filtration materials in two stages - coarse and fine cleaning, and is also disinfected with ultraviolet rays. Before filling the mineral water with CO², it is pre-cooled on a plate heat exchanger. After that, on a special production line, carbon dioxide is saturated, the solubility of which in water depends on temperature and pressure.

Pre-prepared preforms are fed into a bottle making machine, where they are heated and pressurized into the finished shape of the containers. At the last stage, mineral water is poured into PET bottles, sealed with plastic caps, and a marked label is attached. Finished products are placed in shrink film in 6 pieces, stored or immediately delivered to customers.

Why is the production of mineral water an idea for a promising business with high profits? The popularity of bottled water has grown significantly in recent years. They buy it not only in the heat, but also at home, in the office, in the gym and on the road. We tell you what types of mineral waters exist and what their benefits are, how to produce bottled water, how much costs will be required and how quickly they will pay off.

Mineral water has a high content of salts, trace elements and biologically active components. They are extracted from aquifers or complexes isolated from human influence. It should be understood that not all water from underground sources, and especially not all drinking water, can be considered mineral, although in speech it is often called that way.

The composition of mineral waters makes them a medicinal and prophylactic agent, the use of which is strictly dosed. Often the most intense ones are drunk in courses. All mineral water is usually divided into:

- Dining room. The lowest salt content is up to 1 gram per liter. Suitable for regular use. It is harmless to most people, its effect is preventive.

- Medical canteen. It has a high salt content, from 1 to 10 grams of salt per liter. It can have a healing effect, but especially saturated formulations should be consumed in accordance with the dosage, and in case of diseases of the stomach and kidneys - only as prescribed by a doctor.

- Medicinal. The salt content exceeds 10 grams in 1 liter. Sold only in pharmacies and used as prescribed by a doctor.

Depending on the composition, mineral water can be table water, medicinal table water, or medicinal water.

There is another classification based on ionic composition:

- Hydrocarbonate. The healing effect is to reduce the acidity of gastric juice. Useful for urolithiasis. Using the dosage and method of use, you can accelerate or inhibit secretion.

- Chloride. It has a beneficial effect on the pancreas and intestines. Speeds up metabolism.

- Sulfate. Helps improve the functioning of the gastrointestinal tract. Useful for diabetes, excess weight, chronic hepatitis.

- Hydrocarbonate-chloride-sulfate. Helps soften chronic gastritis, reduces the amount of gastric juice.

- Bicarbonate-sulfate calcium. Useful for chronic gastrointestinal diseases.

- Chloride-sulfate. Indicated for use by those who are overweight, with diabetes, gout and diseases of the biliary tract.

- Mineral-organic. Helps treat chronic kidney disease.

- Glandular. Treatment of thyroid diseases, iron deficiency anemia.

The benefits of mineral water

Mineral water is useful and can demonstrate a therapeutic effect only if the method of its intake is followed. To achieve maximum effect, it is not drunk like water, but taken hourly, in certain dosages at a certain temperature. For example, when cold it can enhance the peristalsis of the stomach and intestines, and when warm it can relieve spasms.

The general therapeutic effect on the body of a healthy person is to strengthen the skin, bones, hair and nails, increase immunity, regulate the acid-base balance, increase hemoglobin and replenish fluid balance.

The effect of water on the body directly depends on its composition, therefore, in case of specific diseases, you should drink mineral water with a salt content of more than 1 gram as prescribed by a doctor.

Technology for the production of drinking and mineral bottled water

Due to high demand, the water business promises to be promising. In simple terms, then There are 2 technologies:

- production of natural mineral water (extraction from wells, processing and packaging);

- production of artificial mineral water (salt and microelements are added to purified water).

The first type is the most in demand and is rightly considered more useful. In this article, we will look at the production and sale of natural mineral water.

The process begins with pumping water out of wells using industrial pumps. Freshly extracted water necessarily contains foreign impurities; it may have a cloudy tint, so it is sent for filtration. Coal and sand are usually used for this. But such purification is not enough, because microorganisms live in water. They get rid of them using ultraviolet radiation.

The production of carbonated water seems to be more promising - the demand for it is higher. Therefore, after purification and ultraviolet treatment, the water is passed through a saturator, in which it is saturated with carbon dioxide and becomes carbonated. Next, the final stage is bottling into plastic or glass containers. Most of these companies prefer to produce their own bottles: this allows the use of a corporate design and, in the end, turns out to be more cost-effective than buying containers from another manufacturer.

The depth of a mineral water well can reach 1500 meters

Features of mineral water extraction

A business plan for the production of drinking water must take into account some features of the extraction of this product. Mineral water is pumped out from wells, the depth of which can reach 1500 meters. It is believed that suitable water already lies at a depth of 100 meters, but You can get truly unique and healing compounds from a depth of 300 meters. The depth and composition of the water depend on the region.

It is not enough to simply drill a deep well, install a pump and pump out water. With this approach, it will not be possible to preserve the unique composition of the water, and the sad consequence of this approach will be the depletion of the well. Water extraction begins with the preparation of a well design, which provides for a certain volume of production, self-flow (needs to be calculated to prevent depletion of the well) and conservation. Only specialists with specialized education can develop and implement such a project.

Equipment for the production of

The production of drinking water requires the following lines of machinery and equipment:

- Well pump operating at a depth of 100 meters. Pumps out water and directs it to the production line.

- Filter for water purification for production. Groundwater is not suitable for consumption without filtration. To clean it, coal, sand and special multi-stage filtration systems are used. It is better to choose multifunctional devices that simultaneously perform several water treatment options.

- Saturator, installation for carbonation. The water is cooled and saturated with carbon dioxide. Carbonated drinks not only sell better, but also retain their healing properties better.

- Reservoirs and tanks. Used to store liquids at intermediate production stages.

- Equipment for a water bottling line. Most enterprises purchase a block for the production of plastic bottles; this turns out to be more profitable than purchasing containers from other manufacturers. More expensive water is usually bottled in glass.

- Packaging equipment and label machine. The bottles are placed in briquettes and covered with polyethylene for ease of transportation.

The total cost of equipment for the water bottling line will be approximately 1.5 million rubles. This amount does not include drilling and construction of a well. Sometimes the water is additionally saturated with oxygen. This process is called ozonation and is carried out using special equipment. Its approximate cost is 260 thousand rubles. This machine is also used to disinfect containers.

Premises for organizing production

To fit all the necessary equipment in one room, you will need an area of 300 square meters. The location of the workshop should be as close as possible to the well. All communications will be required - electricity, gas supply - and convenient access roads. Most equipment runs on electricity, so you need a reliable connection and a backup generator.

Before launching the line, you will have to pass an inspection by the sanitary and epidemiological service. The main requirement of this regulatory body is the absence of harmful materials in the finishing of the workshop that could get into the water during filtration and bottling. The fire inspectorate will check emergency exits and the reliability of the electrical network.

Pay special attention to the warehouse. If the water is properly treated and hermetically sealed, no special storage conditions are needed. A fairly large area with a flat floor where packaged products can be stored. Temperature about 15 degrees, low humidity (high moisture content in the air will damage the labels).

Plastic and glass containers are used for mineral water

Selection of containers

Mineral water is poured into 2 types of containers:

- glass;

- plastic.

Glass containers are considered more beneficial from an environmental point of view, as they do not pollute the environment and can be recycled. Many buyers are confident that glass containers are safe for them because they do not release any harmful substances into the water. However, making such containers is more difficult; it will cost the manufacturer many times more. In the future, these expenses will definitely pay off. Water on tap in glass containers is perceived by consumers as more elite, so they are willing to pay more for it.

Plastic bottles are more economical for the manufacturer, because the equipment for plastic containers can be located in their own workshop. It is not as expensive, and the work on it is not as labor-intensive as the manufacture of glass vessels. The price of a turnkey PET water bottling line will be approximately 900 thousand rubles.

Costs and payback

Organizing the production of bottled water with its own well with a depth of 300 meters is quite expensive. All expenses are divided into 4 directions:

- well (project, drilling, maintenance) - the cost is negotiable, but not less than 500 thousand rubles;

- production line - from 3 million rubles;

- container production line - from 500 thousand rubles;

- workshop rental/construction, transport and other expenses.

You should not expect less than 3 million rubles to launch such an enterprise; a more realistic amount is 5 million. Add to this payment for utilities and payroll.

How quickly the investment will pay off depends on the level of sales. Medium-capacity equipment will produce approximately 10 thousand liters of mineral water per shift. It will be sold in different containers: from 0.33 to 1.5 liters. The average cost of a liter of such water is higher than that of ordinary drinking water - 35–40 rubles. For a shift it turns out to be 400 thousand rubles, for a month - about 11 million rubles. The trade margin will be about 30%, that is, approximately 3 million rubles will be the net profit of the enterprise.

Conclusion

The production of mineral water is quite promising and has a quick payback. You will have to invest approximately 5 million rubles in organizing the enterprise. The exact cost is determined by the depth of the well, the power of the equipment, and the type of container. With proper organization, you will be able to earn 2-3 million rubles in the first month, and in the first year of work you will be able to recoup 100% of all starting investments.

It seems like a very easy task. And at first glance it may seem so. After all, nature itself took care of the quality and benefits of the product. All the entrepreneur needs to do is drill a well and install a tap so that water flows into the bottles immediately. This is only a superficial knowledge of the process. If we take a deeper look at the issue of mineral water production, a lot of nuances will appear, without which it is impossible to set up the high-quality operation of a plant for bottling medicinal drinks.

Mineral water

In order to understand how complex the process of producing bottled medicinal water is, let’s figure out what mineral waters are. Firstly, it is a mineral that is formed in the depths of the earth and flows to the surface or is mined using drilling rigs. But where does water come from in the earth? There are several hypotheses for the formation of mineral waters:

- Water that has entered the earth as a result of the process of infiltration (seepage) from the surface.

- Water released from mineral rocks by metamorphic and volcanic processes.

- Water from buried reservoirs during the accumulation of sedimentary rocks.

Subsequently, the water circulates in the thickness of geological rocks and undergoes various changes: it is saturated with salts, gases, radioactive elements and organic components. As a result of a long time, under the influence of external factors, underground waters with a unique composition are formed, which people have learned to use for medicinal purposes.

The healing properties of mineral waters have been known since ancient times. Many rulers organized places near the springs flowing to the surface where they could improve their health. Mineral waters were used for baths, inhalations or simply ingestion. Depending on the composition of dissolved components and their concentration, mineral waters have different purposes. This article will only consider waters used for food purposes.

Types of mineral waters

Depending on what defining characteristics are used for separation, mineral waters are differentiated into different types. Let's consider the most popular classification based on the concentration of dissolved elements:

- Table mineral waters. The concentration of dissolved substances is less than 1 g/l. Such natural drinks can be freely used in everyday life without restrictions, like drinking water.

- Therapeutic dining rooms. The concentration ranges from 1 to 10 g/l. These waters have healing properties due to the higher salt content in the solution or the presence of biological components. Can be used without restrictions.

- Medicinal waters with a salt content of more than 10 g/l. The intake of such waters takes place only under the supervision of a doctor according to a strictly planned plan.

The first two types of water are freely sold in any supermarket or pharmacy, and in order to drink an ion-cation cocktail, you do not need to ask your doctor for permission. The situation is different with medicinal mineral waters. Their consumption is possible only according to a certain scheme drawn up by a doctor. You won’t find a bottle labeled “medicinal mineral water” in supermarkets. In order for the effect of taking it to be positive, it is recommended to drink medicinal waters only in balneological sanatoriums or mineral resorts.

Useful effect of mineral waters

Everyone knows that, first of all, mineral water, when taken orally, has a beneficial effect on the gastrointestinal tract. Treatment of kidney diseases can occur with the help of healing drinks. Also, table and medicinal table waters can be used for inhalation to help the upper respiratory tract in case of diseases.

Extraction of mineral waters

It is known that mineral waters are extracted from the earth by drilling wells. Sometimes their depth is more than one and a half thousand meters (for example, the well for the extraction of Borjomi mineral waters). It happens that water itself finds its way to the surface of the earth through cracks in rock layers.

To preserve the uniqueness of natural deep waters, it is necessary to ensure the isolation of the mining process. Mixing mineral waters from different aquifers is strictly prohibited. For this purpose, specialists carefully develop a project for drilling a future well. It must include a clause on the abandonment or conservation of the well. And so that the extraction of mineral waters is not considered barbaric, it is necessary to take into account how much water will flow during self-flow. After all, only in this way will the healing liquid pumped out of the depths be restored again.

Technology for the production of mineral and drinking water

Before bottled mineral water, which has risen through wells to the surface, it is necessary to go through several more production stages. About each in order:

- Water spilled from the well first falls into a special container, in which it is accumulated for further use in production.

- The next stage is cooling. Firstly, many mineral waters have a specific odor that disappears when cooled. Secondly, the low water temperature is comfortable for bottling.

- Afterwards, the water is purified from various impurities using filters. Natural environmental materials are used as cleaning substances: coal, sand, etc.

- The bacteriological safety of water is ensured by the stage of ultraviolet exposure to water. It is the spectrum of light that can destroy harmful microorganisms without disturbing the structure of water.

- Carbon dioxide enrichment. This event is carried out in order to preserve the beneficial properties of mineral waters for a long time. Plus it tastes better to drink.

- Blowing plastic bottles from special blanks.

- Filling of products into containers and transportation to the warehouse. After forwarding to the point of sale.

Equipment

In order for a mineral water production plant to operate, it must be equipped with special equipment:

- Special reservoirs (large tanks) where water from the well will accumulate.

- Pumps that will pump water through pipes.

- Filters for purifying water from unwanted mechanical impurities.

- Ultraviolet lamps for water disinfection.

- A device designed to saturate water with carbon dioxide.

- Automatic machine for pouring water into containers.

- A device that will blow plastic bottles from blanks.

- Label gluing machine.

- A device that automatically or semi-automatically closes bottles hermetically.

- Large volume sterile containers in which purified water will be stored for bottling.

To control quality at the plant, it is necessary to organize a laboratory in which the chemical composition of the source waters and their safety, as well as compliance with the standards of the finished product, will be checked. It is advisable to have a warehouse on the territory of the enterprise for storing manufactured goods.

Mineral water production business

Despite the fact that today there are many factories in the country and abroad that are engaged in the extraction and bottling of mineral waters, this area remains promising. Firstly, this is due to the fact that the resource base is limitless, because with proper operation of the well, the supply of mineral water is restored. To create a full production cycle of special units, little is required; the technology for producing mineral water does not contain complex schemes and steps. Secondly, the equipment varies in price: from inexpensive to exclusive. Thirdly, the damage caused to nature is minimal (unlike, for example, wastewater from the production of mineral fertilizers). The profitability of such an enterprise is about 30%. The equipment will be able to pay for itself within a year.

Please note that the material presented below contains only a typical business plan. The figures given here can only be regarded as indicative, since the market and prices are constantly changing. However, the business plan provided provides a clear understanding of the steps that will need to be taken to successfully launch the described business, and can serve as a good template for preparing your own business plan.

Since this business plan is quite lengthy, we invite you to download the text for further reference.

Mineral water production business plan

download business plan

*The article is over 8 years old. May contain outdated information

Calculator for calculating the profitability of this business

Ready ideas for your business

Kono-pizza is a type of pizza in a cup adapted to the requirements of street trading, which is convenient to take with you and eat on the run. Let's analyze what you need to make money on this type of street food. ...

Furniture made from natural, environmentally friendly materials is always in great demand, despite the relatively high price. It is strong and durable, does not require special care and...

The amount for opening a small law firm is unlikely to exceed 200-300 thousand rubles, although it can increase significantly depending on its size. A private lawyer usually...

A car wash brings in 100 thousand rubles. profits per month The Yekaterinburg administration has calculated that the city lacks 43 car washes. The shortage is clearly confirmed by the queues that line up in front of the car washes...

The task of industrial mountaineering is to qualitatively perform the work that would be time-consuming and expensive to do using traditional methods, or even impossible. For example, we did a major overhaul of the chimney of an LLC...

With low competition, the cost of entry into the household waste processing market is quite high - from 2 million euros to open a waste sorting complex and from 20 million dollars to build a waste...