Modern country house equipped with many technological benefits that were unavailable even a couple of decades ago and which require water to function. In addition to preparing food and washing hands, there is at least a shower, washing machine, and maybe also dishwasher. For all these devices, it is necessary to establish not only the supply of clean water, but also the drainage of the resulting wastewater. This means that the usual level of convenience cannot be imagined without a modern device for cleaning household waste water. When it is impossible to connect a house to a central collector, a septic tank made of reinforced concrete rings can be one of the few ways that allows you to properly process waste and prevent soil contamination.

View of a septic tank made of concrete rings in the courtyard of a private house Source mirhat.ru

How does a septic tank work?

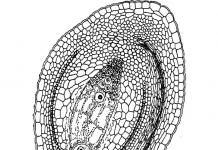

For a small private house, a septic tank made of concrete rings is installed according to classic scheme, including two tanks. If a significant volume of wastewater is expected, three tanks (wells) are installed, different in design and functionality. The first two wells are made hermetically sealed; in the third, a crushed stone filter is installed, through which the water flows into the soil.

The principle of constructing a septic tank made of concrete rings Source admiral-oz.ru

Purpose and design of cameras

- The first septic well serves to receive and settle wastewater. Here, thanks to the work of anaerobic bacteria, sedimentation occurs and partial treatment of wastewater occurs (Anaerobic bacteria are able to decompose complex organic matter into simple substances without access to oxygen). The initially clarified water flows into the second section. The volume of the chamber should be equal to half of the total planned volume of the system; its base is concreted.

- In the second well (drainage) with sealed walls and bottom, additional filtration occurs. Additional filters made of gravel can be installed here.

- In the third well, final filtration occurs. The bottom here is not concreted; a sand-crushed stone (or sand) mixture is poured in for final filtration.

Advantages and disadvantages of a septic tank made of concrete rings

Due to the features of use, design and installation, such a system is the optimal solution in many cases.

Let's consider all the pros and cons of septic tanks made of concrete rings:

Its advantages include:

- simple installation and use technology. No need to let us down electrical power, arrange additional drainage, install a pump;

- reliable autonomous design with high mechanical strength;

- complete freedom in choosing the dimensions of the structure;

- long service life;

- large useful volume and easy maintenance;

- resistance to aggressive wastewater environment;

- the weight of the rings is a guarantee that groundwater will not displace the septic tank from the soil;

- available materials and reasonable price for building a septic tank.

Video description

Additionally, the septic tank can be improved - example in the video:

Disadvantages of concrete septic tanks:

- Weight building material. During installation it is difficult to do without construction equipment.

- The need for high-quality sealing of seams between rings and joints with pipes.

- Hygroscopicity of concrete, which does not allow the method to be used in flooded areas.

- The need for regular cleaning of containers and pumping out wastewater.

Making the right calculations: capacity and design

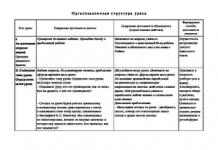

At the design stage, a septic tank diagram is created from concrete rings, then the volume of the future device is determined:

Number of cameras

The number of cameras depends on the number of people using the sewer system. If the family actively uses the shower, bathtub and household appliances, the discharge into the sewer will be significant. The drains will require thorough cleaning, for which you will need a septic tank of three wells, two of which will be settling chambers.

Diagram of a septic tank made of concrete rings Source tolkobeton.ru

Capacity

To determine the volume of wastewater entering the septic tank from the kitchen, bathhouse and toilet, you need to calculate the daily water consumption. Knowing that the daily rate of domestic water consumption for one resident is equal to 200 liters, it is easy to calculate that a family of 4 people will fill the septic tank at a rate of 800 liters per day.

The quality of the septic tank improves if wastewater lingers in the chambers for a long enough time. By increasing the volume, you can improve the quality of the wastewater and protect the system from clogging with difficult-to-decompose fat.

According to building codes, the installation must accommodate wastewater that is generated over three days (the daily flow rate must be multiplied by 3). This number determines the volume of the septic tank and the number of chambers:

- a single-chamber septic tank is installed if daily waste does not exceed 1 cubic meter;

- two-chamber – up to 5 cubic meters;

- three-chamber – 8 or more cubic meters.

In a septic tank with two chambers, the first sump occupies the volume of 2/3 of the entire septic tank, in a three-chamber septic tank - half.

What to pay attention to before starting work

If the area has a high aquifer:

- The seams of the septic tank are carefully sealed, otherwise it will constantly be recharged with groundwater and overflow. There will be additional costs for calling a sewage disposal truck.

- The installation of a filtration well becomes meaningless; For additional treatment and drainage of water from the septic tank, another option is needed.

Video description

About septic tanks on high groundwater in the video:

Increased structural strength:

- To protect the building from possible ground movements and shifting of the rings, they are additionally secured with metal ties.

- To reduce the subsidence of the septic tank and improve its thermal insulation and drainage, during installation a cushion of sand, crushed stone or gravel is placed around it.

How much will the rings cost?

Concrete rings are selected based on calculations of the volume of the septic tank. The dimensions of concrete rings for a septic tank are indicated on the marking. They are characterized by the height, diameter and thickness of the walls of the structure, as well as the type of product:

- KS – wall ring, suitable for erecting walls;

- PP – floor slabs;

- PD – road slabs, installed at the bottom of the pit.

The cost of concrete rings is affected by their size and location of production. Reinforced concrete rings with low surface permeability, resistant to aggressive environments, are suitable for sewerage.

The height can be 290, 590, 800, 900 mm. A typical product with a height of 900 mm can have a diameter of 700, 800, 1000, 1500 and 2000 mm. The average price for it varies from 1200 to 1800 rubles. Rings with other parameters can cost from 680-1050 to 1500-2400 rubles.

Rings for septic tank Source humphrey.alpvd.ru

It should be remembered that some rings are marked with an internal (useful) diameter, while others have an external diameter, which is important for selecting caps. Average cost of reinforced concrete cover or polymer hatch ranges from 1700 to 2000 rubles.

When drawing up an estimate for a septic tank made of concrete rings, the price is based on additional materials: pipes, cement, sealant, as well as the cost of work (digging, installing rings). The final average price of a turnkey septic tank is in the range from 38,000 to 69,000 rubles.

What other materials will you need?

In addition to the required number of reinforced concrete well rings and slabs with a hole for the hatch, additional materials are needed:

- sand, gravel, cement, crushed stone for the “pillow”;

- cement, liquid glass for sealing seams between rings;

- sealed (polymer) hatches;

- shovels, hammer drill;

- pipes and fittings.

Construction stages

Installation is carried out in the following order:

- A location is selected, an installation diagram is drawn up, and the parameters of the septic tank are calculated.

- A hole is dug.

- Rings are installed, pipes are supplied.

- Sealing and waterproofing work is being carried out.

- Floors are being installed.

- Backfilling is in progress.

Video description

The work procedure and installation of a septic tank made of concrete rings in the video:

How to choose the optimal location for a septic tank

The structure is mounted above the groundwater level. The best location is at the maximum distance from the house (at least 7 meters, but no more than 20, so as not to increase the cost of pipeline construction). It is logical to place the septic tank on the border of the site, next to the road. This will reduce operating costs, since the cost of leaving a sewage tank is affected by access to the system and the length of the hose. In addition, with the correct location, the sewage disposal truck does not need to enter the yard, and the hoses will not lie on the beds or paths (otherwise, when the hose is rolled up, waste may end up in the garden).

Distance to nearest source drinking water(well, well) - at least 30 (and if possible more) meters.

Pit preparation

Ground work using an excavator takes 2-3 hours. The size of the pit should be slightly larger than the dimensions of the wells. This is necessary for the smooth installation of the rings and their waterproofing. The bottom is covered with crushed stone and concreted.

Preparing a pit for a septic tank made of concrete rings Source rostovgruz.ru

Installation of rings and sewer pipes

Rings for a septic tank are installed using lifting equipment, which significantly saves time (when compared with manual installation). Fixation of the seams is ensured with cement mortar; additionally, metal ties (staples, plates) are installed.

Holes are punched in the rings and plastic overflow pipes are installed. They have a curved shape and work on the principle of a water seal.

The crucial moment is the process of installing rings Source remoskop.ru

Sealing and waterproofing

The seams of a septic tank made of concrete rings are sealed on both sides of the structure. For this purpose, cement and coating protective solutions are used. You can install ready-made plastic cylinders inside the well. This additional cost will make the system 100% sealed.

In the process of waterproofing concrete rings for a septic tank, the connections are treated with liquid glass, bitumen or polymer-based mastic, and concrete mixture. To prevent freezing (and destruction) of the structure in winter, it is recommended to insulate it with a layer of polystyrene foam.

Sealing joints and waterproofing septic tanks made of concrete rings Source zen.yandex.ru

Hatch installation and backfilling

The wells are covered with concrete slabs, with holes for hatches. In the first two wells, ventilation is installed, which is necessary for the removal of methane (gas appears as a result of the activity of anaerobic bacteria). To backfill the installed floors, use soil taken from the pit (backfill).

Backfilling of finished wells Source lanshaft.com

How to put a septic tank into operation

In order for the system to begin to function effectively, the constructed septic tank must be saturated with anaerobic microflora. The natural accumulation process takes several months, so it is accelerated by saturating the septic tank with imported microflora. You can do this in two ways:

- The new septic tank is filled with wastewater and left for 10-14 days. Then sludge sludge from an existing anaerobic septic tank is loaded into it (2 buckets per cubic meter).

- You can purchase ready-made bioactivators (bacterial strains) in the store (the main thing here is not to confuse them with aerobes, which are intended for other treatment systems).

Ready-to-start septic tank made of rings Source remont-book.com

What rules must be followed when servicing a septic tank?

There are simple rules, supporting high-quality operation of the system.

- Cleaning. Twice a year, in addition to cleaning the drains, the septic tank must be inspected and the pipelines cleaned. Once every 5 years (or better, every 2-3 years) the bottom heavy fats are removed. The sludge volume should not exceed 25% of the tank volume. When cleaning, part of the sludge is left to restore the microflora.

- Quality of work. The wastewater leaving the system must be 70% purified. Analysis of wastewater in the laboratory will determine the acidity indicator, which will allow you to find out the quality of the drainage system.

- Security measures:

- Work inside the septic tank is permitted only after intensive ventilation and using a safety belt (gases formed inside can be dangerous to human life).

- Increased safety measures are required when working with power tools (humid environments).

A septic tank made of concrete rings makes private housing more autonomous and, despite its shortcomings, it is one of the most reliable and durable options for treatment facilities for suburban real estate.

According to the principle of operation, septic tanks made of concrete rings are divided into two types - single-chamber and multi-chamber (septic tanks for 2-3 wells).

- Single-chamber ones perform the function of simple drives, from which contents are periodically pumped out.

- Multi-chamber septic tanks are a kind of treatment facilities, since they separate wastewater into fractions.

The principle of operation of a septic tank for 2 wells

- First, a solid fraction settles at the bottom of the first chamber.

- As it fills, the liquid fraction is poured into the second chamber.

- There, heavy particles that penetrated from the first chamber settle, and completely clarified wastewater, devoid of solid impurities, flows into the third chamber. This chamber contains filters through which the liquid passes before going into the ground.

The design and layout of a septic tank made of concrete rings for two or more wells will be discussed in more detail below.

Any structure takes up space and requires resources, so, first of all, you need to think about the scale of construction and the location of the septic tank.

Single chamber septic tank

If you are going to limit yourself to single-chamber treatment plant, then you need to place it where it is more convenient, namely:

- closer to the outlet of the autonomous sewer system (but not less than 5 m from the foundation of the house), which will save on pipes and minimize the risk of freezing;

- within accessibility for sewage trucks;

- in aesthetically less significant areas of the estate.

Two-chamber septic tank

If you plan to build a two- or three-chamber structure, then you must take into account the following:

- relief of individual sections of the estate;

- the presence of groundwater and its level;

- depth and duration of soil freezing;

- the presence of reservoirs and groundwater intake sites.

- There must be at least 30 m from the place of wastewater concentration to the place of drinking water intake.

- If there is a slope, then the septic tank should be located at its lowest point, or much lower than other structures.

- The head of the septic tank must rise above the ground so that flowing water cannot get inside.

Thus, the septic well should be located where its installation will require a minimum of costs and eliminate the possibility of contamination of drinking water.

DIY septic tank made of concrete rings

A septic tank is needed to accumulate wastewater and isolate it from the environment, so the most attention should be paid to the distance from groundwater - the deeper the groundwater, the better. This will avoid contamination with fecal water due to possible depressurization of concrete rings.

Ensuring the tightness of the joints is also necessary in order to prevent groundwater from penetrating into the septic tank, which in this case will quickly overflow.

To minimize risks, it is necessary to create an above-ground filtration platform in the form of a mound of soil.

1. Selecting a location and digging holes for concrete rings and trenches for a sewer pipe.

2. Installation of concrete rings.

3. Carrying out waterproofing work.

4. Backfilling pits and trenches.

5. Installation of the cover.

There is a special requirement for the placement of the wastewater pipe - it must be at a depth of about 1 m from the surface and must have a slope of 25 cm from the house to the septic tank every meter.

For more information about the process of installing a septic tank with your own hands, watch the video at the end of the article.

Construction and layout of a septic tank made of concrete rings

The easiest way to install a single-chamber septic tank. This is just a container for collecting sewage, so when installing it, it is not necessary to insulate the bottom.

Waterproofing of the day

It is impossible to know everything about the groundwater on the site, so no one can guarantee that water from the septic tank will not leak into the groundwater, and from there into the well and into the house. In addition, groundwater can change its location depending on the season.

If the septic tank is located correctly, then soon a natural layer of sludge and settled heavy fractions of wastewater will form below. As a result, a layer of self-insulation will appear that prevents wastewater from penetrating into the ground and groundwater. However, it is better not to hope for this and concrete the base of the septic tank, install rings and waterproof all joints.

Saving on waterproofing can be costly not only for owners land plot, but also to their neighbors.

Sealing joints

A particular danger arises during floods, when the soil under and around the septic tank can be washed away, which will open the way for sewerage into groundwater, soil and even open water bodies.

The joints are sealed with a special cement mortar, for example, “Aquabarrier”. In addition to greasing the joints, the outer shell of the concrete rings is treated with a special compound.

Thus, waterproofing is carried out from below in the form of a concrete base, from the sides - at the joints between the lower ring and the base and between the rings themselves, as well as along the entire outer perimeter of the rings. Maximum sealing can be achieved by installing plastic cylinders inside concrete rings.

This will increase the cost of the construction, but it will make your sewer system 100% sealed.

Ventilation

Any septic tank must be equipped with a ventilation hole. This is usually a pipe connecting its airspace to the air on the surface. The pipe is installed above the ground surface at least a meter and is equipped with a lid to prevent precipitation from penetrating deep into the septic tank.

Ventilation is necessary to protect the system from the accumulation of flammable gases, as well as to accelerate the decomposition of organic matter.

Septic tank made of concrete rings for two or more wells

When determining the size and number of concrete rings of a septic well, one must proceed from the daily water consumption, which, of course, depends on the number of people living.

Calculation of the number of rings

The required number of wells can be determined by the number of people living multiplied by 200 liters (this is how much water the average person spends). The result will be the volume of the required septic tank, to which you need to add 20% and divide it by the cubic capacity of one concrete ring (usually 1.062 m3). As a result, we will get the number of required concrete rings.

As a rule, for a family of 4 people, two or three rings per well will be enough.

Well depth

One feature should be taken into account - the level of wastewater in the septic tank should not be higher than the sewer pipe. Otherwise, backwater may occur, making it difficult for wastewater to move, and the smell of sewage will appear in the house.

To concrete septic tank performed its functions in full, constant fermentation is necessary, which is ensured by the correct location of tanks and ventilation.

Ventilation

Ventilation should work only on the second well, the first should be isolated from atmospheric air. Of course, the processes of decomposition of organic matter occur wherever it is. However, with a lack of oxygen, decomposition occurs less intensely.

In an oxygen environment, dozens of microorganisms are involved in the decomposition processes, due to which the wastewater is quickly purified, the remainder of the solid fractions is precipitated, and water, which has lost most of its toxicity, goes into the ground.

Filtration

Only the second well is used for cleaning. The third, if present, only performs additional cleaning functions in the form of filtration. If you equip the second well with a good filtration system, then the third one will be superfluous.

However, if it is technically possible, then it is better to install three tanks and not worry about the cleanliness of the land around the house.

Additionally

To speed up cleaning, the second tank is equipped with forced ventilation using a compressor with a timer. Air penetrating into the second chamber under pressure not only delivers oxygen, but also mixes the contents, accelerating the decomposition processes. In addition, additional aeration helps convert ammonia into nitrates.

It is highly advisable to place the second and third chambers of a septic tank made of concrete rings above a layer of sand or gravel. They will become an excellent filter, and the water will not stagnate. It is better to avoid a clay bottom, because clay is a waterproofing agent, and all waste water will stagnate near the septic tank.

The cost of a septic tank made of concrete rings on a turnkey basis

The term “turnkey” includes the following types of work and equipment.

- Concrete ring: 1 piece - 2000 rub.

- Floor slab: 1 pc. - 1700 rub.

- Hatch: 1pc. - 1000 rub.

- Ring with bottom: 1pc. - 3000 rubles or filling the bottom 2000 rubles.

- Construction and consumables: 2000-3000 rub.

- Pipes: 150-200 rub. for 1 m.

- Excavation work and pipe installation: RUB 1,000. for 1 m.

- Installation of hatch and ceilings: from 800 rub.

- Making holes in concrete: from 250 rubles.

- Filter: 1 pc. from 1500 rub.

- : 150 rub.

On average, a turnkey septic tank made of concrete rings for three tanks will cost 40,000 - 45,000 rubles. You can also save money by doing some of the work yourself, reducing costs by 40-50%.

Conclusions

Provided that the installation is done efficiently, a septic tank made of concrete rings will last for decades, and simple operation will save you from unnecessary hassle.

The only disadvantages include the complexity of installation and the large volume of dug up soil.

Sometimes connecting a private house to a centralized sewerage system is impossible, and in this case the only alternative to connecting is a septic tank or treatment station, as it is called. From this article you will learn how to properly make a septic tank from concrete rings with your own hands, without involving a contractor, about the work scheme and purpose of the treatment plant.

The need for septic tanks in the absence of a centralized sewage system is due to the fact that wastewater contains various kinds of organic substances, the ingress of which into food or drinking water entails serious problems.

Before wastewater penetrates into the ground, it must be cleaned and neutralized. This is the purpose of the treatment plant.

Here, the organic component of fecal and sewage accumulations is separated into safe sludge and water suitable for irrigation of the territory. The septic tank as such does not affect its contents, but it creates conditions in which bacteria develop, decomposing organic matter into safe elements.

The choice of location for a septic tank is regulated mainly by SNiP 2.04.03-85 “Sewerage. External networks and structures."

In addition to compliance with the regulations of this document, you must obtain a hygienic certificate, which gives the right to install a treatment plant in the selected location, as mentioned in SanPiN 2.1.5.980-00.

Here: V is the volume of a separate section of the septic tank, Y is the rate of water consumption by one person (conditional), Z is the maximum number of people living in the house.

Septic tanks installed in accordance with this formula are very large, but they provide maximum purification of fecal and sewage wastewater, turning it into water suitable for irrigation of the site and sludge that serves as fertilizer. The rate of water consumption is determined by many parameters.

Indoor water supply and sewerage systems in buildings meet the conventional norm of 95–300 liters per person per day.

You can calculate on your own how much water you consume, or use the SNiP table.

When thinking about installing a septic tank made of concrete rings, it is better to stick to the maximum values and increase the number of residents by 50%. Although this will increase the cost of building a septic tank, you will eliminate the risks: if guests arrive, the septic tank will not overflow and the ground near the building will not be flooded with feces.

Some experts use the formula mentioned above, but it is used to calculate the total volume of a station consisting of several sections, for example, a two-chamber septic tank made of concrete rings.

With this approach, construction costs are significantly reduced, and the degree of wastewater treatment becomes worse as the number of residents increases.

If purified water is supposed to be discharged close to buildings and water intake points (up to 50 m), use the formula in relation to the volume of one section.

If the distance is greater than 50m, you can use the formula for the total volume. Untreated wastewater removed at such a distance will not be dangerous.

Types of septic tanks made of concrete rings

Several types of septic tanks are built from reinforced concrete rings, and the stations differ:

- depth level;

- ring diameter;

- insulation.

The depth of the septic tank is determined both by its dimensions and winter temperatures, more precisely, by the depth of soil freezing.

The lower it is, the lower the septic tank must be installed, since a strong drop in temperature (less than zero degrees) slows down or even stops the processes occurring in each section. Therefore, it is necessary to either deeply bury the septic tank - all its sections, or insulate each section with polystyrene foam or similar insulation.

You can reduce the cost of installing concrete rings under a septic tank when the station is deeper, if you install not reinforced concrete rings above the freezing depth of the soil, but brick well, since above the freezing depth of the soil, processes in the septic tank are greatly inhibited even with high-quality insulation.

Septic tanks are also classified according to the number of their elements. Single-element ones are called cesspools and are considered ineffective.

The most effective designs are made of three elements. A larger number of sections does not affect the quality of wastewater treatment. Three sections can be placed in the longitudinal direction, in which case the installation is very long, or in a triangle, when the area of the pit for the septic tank is reduced by almost a third, and with it the volume of soil that needs to be dug.

If you need a small-volume septic tank, make a single-chamber septic tank from concrete rings. A wall with an overflow hole is placed inside the rings. It divides the space into a pair of chambers.

Construction of septic tanks from concrete rings

Although you'll have to take it construction equipment for rent for manipulating concrete rings for a septic tank; if you build the structure yourself, you will be able to save money.

The construction of a sewage treatment plant is a fairly simple task for someone who has at least some knowledge of construction, plumbing and reinforced concrete work.

The necessary calculations are extremely simple and approximate; they can be performed even by a schoolchild. The key condition for installing a septic tank is the flow of waste into it by gravity.

That is why the optimal slope between the sewer exit from the building and the entrance of the septic tank is considered to be from 1 to 3 cm/m. You can build a septic tank on a hill, but in this case you cannot do without installing a pump and valves that block the movement of wastewater in the opposite direction.

Preparing a pit for a septic tank with concrete rings

Having determined the volume of the treatment plant, think about how the treated water will be discharged. You can supply it to the site using a pump, or by pouring it directly onto the ground.

In the second case, digging septic tanks from concrete rings requires digging not only a foundation pit, but also trenches for laying drainage pipes that carry wastewater 10–20 m from the foundation of the treatment plant. Discharging water near the foundation will cause it to subsidence and cause damage to the septic tank.

It is necessary for the water to flow by gravity through the pipes, and in the place where the wastewater is discharged, it is necessary to dig a hole (below the pipe) with a length, width and depth of 1 m.

The hole should be filled with sand or fine crushed stone, after which a pipe must be laid, filling it at least 1 m above its level, to the top.

After you have managed to select and buy concrete rings for the septic tank, you begin to dig a pit. Concrete rings are selected based on the area sufficient for the septic tank and allowing deep digging.

If the site has rocky soil, it is better to lay the widest rings. Products of the KS-30-1 brand with an internal diameter of 3 m are suitable.

If there is little free space, if the soil is sandy, loamy or clayey, it is better to dig a pit as deep as possible, choose rings of the KS-10-9 brand with an internal diameter of 1 m.

It is necessary to determine in advance the location of each column, taking into account the distance between adjacent ones of 50 cm, which is required to protect the septic tank and insulate it during soil shifts.

To the calculated depth of the well, it is necessary to add the depth of freezing (to maximally protect the treatment station from heaving in frost) and the concrete-crushed stone cushion (approximately 0.2 and 0.3 m). The result will be the depth of the pit for digging.

Digging a pit for the subsequent installation of a septic tank from concrete rings on your own is too difficult and time-consuming. It’s easier to rent an excavator - such a machine will cope with the job in a maximum of 3 hours.

If it is not possible to hire an excavator, you can seek help from a team that carries out earthworks. The cost of services in this case is comparable to the cost of hiring an excavator, but it will take more time.

After constructing the pit and leveling the walls, the bottom of the septic tank should be compacted from concrete rings. If the soil is not rocky, then this stage of work is required so that the foundation of the treatment plant can become strong enough. For compaction, you can use a vibrating plate or a hand tamper.

It is important to fill the hole evenly - do it in small portions of soil on each side so that the rings do not move.

After leveling the surface of the resulting backfill with the nearby soil, wait 2–3 weeks. After the ground has subsided, add soil around the perimeter of the septic tank. The next addition is carried out after the rainy season.

Using, cleaning and repairing a septic tank made of concrete rings

You can use the treatment station immediately after the construction of wells. Septic tanks do not require special maintenance. It is only necessary to monitor the sludge level in the first two chambers once every 3–5 years.

When lowering into the hatch for inspection purposes, use a gas mask. The smell from a septic tank made of concrete rings is very strong and gas accumulates under the hatch, so without a gas mask you can suffocate.

If the sludge level exceeds half the distance to the outlet pipe, you need to call a sewage disposal machine or scoop out the sludge with buckets.

The sludge obtained from a septic tank is used as fertilizer for non-food plants.

If everything is clear with sewerage in the city, then what about its arrangement in the private sector or on summer cottage? Fortunately, there is a solution. You can build a septic tank. Moreover, it can be made from various materials. And concrete rings are considered one of the most popular technologies for creating this structure.

Design and principle of operation

A septic tank is a structure designed to clean sewage that is formed as a result of the use of a bathtub, dishwasher and, of course, toilet. It is a structure made of several tanks connected by pipes at a certain height so that water entering the septic tank can flow from one chamber to another. Typically this structure has two or three chambers - their number often depends on the volume of drainage. In this case, as a rule, one of the sections of the septic tank is a filtration well, where an additional cleaning process takes place and the liquid is released into the environment.

The principle of operation of a three-chamber septic tank is as follows: waste water flows through the drain sewer pipe, enters the first chamber, where the primary stage of purification occurs - large inclusions, according to the laws of gravity, begin to settle to the bottom of the container. Further, as the chamber is filled, partially purified water passes through a pipe located at a certain level (but located lower than the inlet pipe) into the next chamber - the secondary settling tank. There it settles further, and some of the lighter particles also have time to settle to the bottom.

Note! Additionally, anaerobic bacteria can work to purify the water in the second purification chamber, which process pollutants. For them, this is their favorite “delicacy.”

The third chamber is a filtration well, which, unlike the previous two, has a bottom that is not sealed, but through, but covered with sand and crushed stone. The liquid begins to seep and go into the ground, further purifying itself in this layer. Such a septic tank, one might say, does not need, since the water goes into the soil layers on its own. But still, every few years it is necessary to remove sediment deposited at the bottom from it. Vacuum trucks are called for this purpose.

A septic tank consisting of two compartments works on the same principle, only the water after the first chamber immediately enters the drainage well and goes into the ground. By the way, soil purification can also be carried out on filtration fields or using biofilters, and not only in filter wells.

What are the benefits of septic tanks made from concrete rings?

One of the most common and inexpensive ways to build a septic tank with your own hands is to make it from concrete rings. Such rings come in different sizes, and can also have additional parameters - a certain thickness, the presence of holes in the walls, etc. In addition to these products, round bottoms and covers are also produced, in which a hole is provided for installing a hatch.

Table. Types of concrete rings.

| View | Characteristic |

|---|---|

| Such rings are also called additional rings. They are used only in situations where standard parameter rings are not suitable. Such designs are made to order. |

| Ideal for use when installing wells and other various communications. For example, they make excellent drainage wells, water canals, gas pipelines and others. |

| A neck can be formed from such rings during the construction of a septic tank. They are used for the manufacture of the upper part of any types of communications and wells. |

| Prefabricated, closed with a bottom, with ceilings, with a lock, etc. |

A septic tank made of concrete rings is a time-tested design. But during installation you will have to work hard. Most likely, to install the rings in the pit prepared for the septic tank, you will have to call in special equipment - a truck crane. It is very difficult to move such structures on your own - they have considerable weight. There are, of course, options for installing and digging reinforced concrete rings into the ground without the use of machinery, but the problem is that the ring itself is, nevertheless, quite fragile. If such an element is dropped even from a small height, it can easily break.

The disadvantage of using concrete rings as the basis for a septic tank is the need for a large space. In a small area, it is unlikely that such a design will be implemented in compliance with all rules and regulations. Also, when building a septic tank from concrete rings, great attention should be paid to sealing seams and joints. "How does it happen? , you can look in our article.” The advantages of a septic tank made of reinforced concrete rings are as follows:

- these structures are not afraid of exposure to aggressive chemicals that enter the drain. And the waste water itself is far from having the most harmless composition;

- such a septic tank will not be afraid of temperature changes;

- the structure will cope perfectly with the unexpected influx of large volumes of water.

Note! When choosing rings for a septic tank, it is best to choose those that have fittings inside. Such rings are much stronger than ordinary concrete ones and will last as long as possible.

We calculate the sizes

Calculating the dimensions of the future structure is an important point in the design of a structure. The parameters of the occupied space, as well as the amount necessary materials. The first step is to calculate the volume of the septic tank, which depends on the volume of wastewater, which, in turn, depends on water consumption. On average, a person uses about 200 liters of water during the day. This means that a family of three will spend 600 liters per day. However, according to the standards, the septic tank must be three times larger in volume. This means that it must contain at least 1800 m 3 of liquid.

Now we need to calculate the internal volume of one concrete ring. It is easier to figure it out using the formula for the volume of a cylinder. This V = 3.14*D 3 *H/4, where H is the height of the structure, D is its internal diameter, and V is the volume required for further calculations. Let's say the ring has a diameter of 1 m. Then its volume will be equal to 0.79 m 3. In this case, the height of the ring does not need to be measured - this is a standard value and is equal to 1 m. Although sometimes there are rings with a height of 0.9 m on sale. Additional rings can have very small dimensions.

Attention! When making calculations, it is important to remember that the last, upper ring should never be filled entirely with liquid, but only 1/3. Thus, the working volume of the upper ring is 0.79/3 = 0.26.

Based on the calculations described above, you can deduce the number of rings that need to be purchased. Thus, one section of the septic tank will need 3 rings. To build a structure of three chambers, 9 reinforced concrete rings will be required.

The rings that are sold in stores usually have standard sizes and can be of different diameters - 70, 100, 120, 150, 200 cm. If the sewer system will be built for a house where many people live, then it is better to use structures with a diameter of at least 100 cm For small families, you can purchase 70 cm rings. The larger the ring, the heavier it is, and therefore to install a septic tank made of products 100 cm or more in diameter, you will definitely have to call a truck crane, since the weight of these rings varies between 700-900 kg.

Advice! When making calculations, it is worth remembering that the upper ring should protrude above the ground by about 20-30 cm.

Before building a private house, it is advisable to design a sewer system. An excellent solution to this problem is to build a septic tank from concrete rings with your own hands.

Septic tank made of reinforced concrete rings - advantages and disadvantages

The use of reinforced concrete rings as the basis for a septic tank has the following advantages:

- possibility of long-term operation (50-100 years);

- increased resistance to negative impact environment;

- high strength comparable to natural stone. The design can withstand strong pressure, it is able to function even with large water discharges;

- when installing additional waterproofing, the septic tank made of reinforced concrete rings becomes completely sealed, groundwater cannot damage the structure;

- low cost, allowing you to significantly save on building a sewer system with your own hands. Installing a septic tank made of concrete rings will cost much less than installing an analogue made of polypropylene material.

However, there are certain disadvantages of such a system, which it is advisable to know about before starting construction. These include:

- the need to use special mechanisms or equipment for installation, because concrete is a fairly heavy material, which affects the weight of the structure;

- there is a possibility of runoff liquids entering the soil under the system. This happens due to the appearance of cracks in the concrete or a violation of the tightness of the joints after long-term operation of the sewer system or poor-quality sealing.

The principle of operation of a reinforced concrete septic tank

For not very large areas, a chamber type of design with a drainage or closed bottom is most often used. In the second option, an ordinary storage tank for waste liquids is obtained, and in the first, a cesspool system with drainage is obtained.

The principle of operation of a drainage septic tank with 3 compartments:

- The waste liquids enter the initial compartment, where they are clarified, i.e. elimination of sediment of heavy elements.

- Then the clarified sewage water penetrates into the next chamber. Fermentation occurs in it.

- After this, the wastewater flows into the last compartment, where it is drained into the soil.

The processing efficiency in such a facility reaches 90%. The remaining 10% includes sludge residue, which will need to be removed several times a year using sewage disposal. A similar septic tank made of concrete rings, built with your own hands, is capable of treating a large volume of liquid. As a rule, if up to 5 people live in a building (2-story private house), then such a system will be sufficient.

When installing an additional compressor for a septic tank with a timer in the second chamber, the process of decomposition of biowaste will be significantly accelerated. Such a compressor provides a regular supply of air. Also, a pipe is installed in compartment 2 for ventilation; it should extend 70 cm above ground level.

Diagram, design structure

The most effective design is one with 3 separate chambers. Externally, the system is similar to VOC, which has separate compartments for storing wastewater and its subsequent filtration. Before we start installation work you should know how a septic tank made of concrete rings works.

A sewer system with a sealed bottom without drainage fills up quite quickly, so the owner of the site will often need to call a sludge pump for sewage removal. An installed septic tank made of concrete rings with a drainage base does not have this disadvantage.

Watch video

Most of the incoming liquids are filtered into the ground on their own. Therefore, the need for sewerage services arises on average only 2 times a year to eliminate residual sludge.

Calculation of septic tank volume

Choosing a location for installation

To determine a suitable installation location, it is necessary to study the regulations and legislative framework. It is prohibited to install a concrete septic tank or lay sewer branches in the immediate vicinity of residential buildings.

Watch the video - a septic tank made of concrete rings from A to Z

Before you start designing a septic tank, it is advisable to remember these rules:

- the presence of a driveway for a sewer truck;

- The septic tank should be placed at least 50 meters from a water source (for example, a well). This is necessary in order to reduce the likelihood of contamination of drinking water with waste;

- The sewer system should be located 5 meters from buildings. However, you should not make the distance more than 20 meters, because... because of this, additional costs will be required for laying sewer pipes;

- the pipe location scheme must be accompanied by a low groundwater level.

When designing a sewer system, it is also advisable to take care of creating ventilation for the septic tank.

What materials and tools will be needed

When selecting concrete rings for a septic tank, it is advisable to pay attention to options with locks. Such rings significantly simplify the installation process and also prevent displacement when freezing and increasing the volume of soil. When purchasing, it is advisable to check that the seats are level and also make sure that the locks are intact.

Trenches are also dug for laying the sewer pipeline; it must be located below the layer of freezing soil. Trench dimensions depend on the size of the reinforced concrete rings. In most cases they are about 1.5 m deep and 50 cm wide.

To ensure gravity flow of wastewater, the bottom must have a slope of 2-3 cm per linear meter. It is advisable to first calculate the distance between the end points; for this it is necessary to multiply the distance by the slope coefficient (it is determined by regulations).

After digging, the bottom should be well compacted and covered with sand 10 cm. Then it is concreted to a depth of 30 cm using cement mortar (3:1). There is no need to make a concrete bottom if a lower bottom ring is installed. Then it will be enough to pour a 20-centimeter cushion of crushed stone.

Installation of rings, installation of overflow pipes

First of all, install the bottom ring so that its walls are perpendicular to the bottom. Level installation will increase the strength, reliability and stability of the structure. When using a reinforced concrete ring without a bottom, a concrete screed is created. Its dimensions must exceed the annular diameter by 20 cm. The final formation of the screed may take up to 14 days.

Then install the first ring. This work cannot be done on your own, so you will need several people to help. After installation, the next ring is installed. To improve the fixation properties on the outside, special metal staples are used. Entry points are covered with concrete and insulation for safety.

Watch video

Concrete rings for the septic tank are immersed into the pit using a construction crane. External voids are then filled with soil and sand. There is no need to rush; it is important to compact the soil evenly and alternate this with pouring water. Such backfill has shock-absorbing properties and is capable of draining storm and groundwater.

However, treated wastewater can leave not only through the bottom, but also through the side walls. If such a design option is planned, then the reinforced concrete ring at the base should be perforated. The installation procedure for such a ring does not differ from conventional technology. The “pocket” between the outer walls and the ground is filled with crushed stone.

To create a filtration field, perforated pipes are used. They are placed on a layer of gravel and sand, which ensures penetration clean waters into the ground. The top of the pipe must be covered with geological textiles and covered with soil.

Waste disposal

A filtration well is used to dispose of wastewater. If it is installed in places where there are pebbles, sand or gravel under the base of the structure, then the infiltration process will proceed without problems.

When deciding to make a septic tank with your own hands, it is better to install a three-chamber version. Then the last compartment will dispose of pre-purified waste liquids.

Thus, the construction of an autonomous sewer system You can do it yourself quite quickly.

However, most likely, it will not be possible to carry out the construction completely independently, because... You will need to call workers to dig a trench or craftsmen with special equipment, and also find assistants to lay the rings. The large dimensions of the products will not allow you to install them yourself.

Watch video

The procedure for installing a filtration well and laying pipes for overflow is not complicated and does not require professional equipment. Therefore, you can do it yourself.