GOST 14918-80

Group B23

INTERSTATE STANDARD

GALVANIZED THIN SHEET STEEL WITH CONTINUOUS LINES

Specifications

Continuously galvanized sheet steel. Specifications

MKS 77.140.50

OKP 11 1110

Date of introduction 1981-07-01

By Decree of the USSR State Committee on Standards dated March 31, 1980 N 1465, the implementation date was set to 07/01/81

The validity period was lifted according to Protocol No. 3-93 of the Interstate Council for Standardization, Metrology and Certification (IUS 5-6-93)

INSTEAD GOST 14918-69

Edition (August 2007) with Amendments No. 1, 2, approved in September 1981, June 1986 (IUS 11-81, 9-86).

This standard applies to sheet and coil cold-rolled steel, hot-dip galvanized in continuous galvanizing units, intended for cold profiling, for painting, production of stamped parts, utensils, containers and other metal products.

The technical level indicators established by this standard meet the requirements of the highest and first quality categories.

1. CLASSIFICATION

1. CLASSIFICATION

1.1. Galvanized thin sheet steel (GTS) is divided into:

by appointment to groups

for cold stamping - ХШ,

for cold profiling - HP,

for painting (trained) - PC,

general purpose - OH;

by drawing ability (steel group XSh) into category

normal hood - N,

deep drawing - G,

very deep drawing - VG;

by uniformity of zinc coating thickness

with normal thickness variation - HP,

with reduced thickness variation - UR.

1.2. By agreement between the consumer and the manufacturer, galvanized steel can be produced:

with crystallization pattern - KR,

without crystallization pattern - MT.

1.3. Depending on the thickness of the coating, galvanized steel is divided into three classes in accordance with those indicated in Table 1.

Table 1

Thickness class | Weight of 1 m of coating layer applied on both sides, g | Coating thickness, microns |

P (increased) | St. 570 to 855 inclusive. | Over 40 to 60 incl. |

From 142.5" to 258" | From 10" 18" |

When producing steel with a differentiated coating, its thickness on one side of the sheet must correspond to class 2, and on the other side to class P (for sheets) or class 1.

(Changed edition, Amendment No. 2).

2. ASSORTMENT

2.1. Galvanized steel is manufactured with a width from 710 to 1800 mm inclusive, and a thickness from 0.5 to 2.5 mm inclusive.

2.2. Dimensions, maximum deviations and other requirements for the assortment must comply with the requirements of GOST 19904-90.

Galvanized steel of the highest quality category is produced:

with crescent shape of rolled steel no more than 6 mm per 3 m length;

with flatness PV and PU and permissible thickness deviations according to the standards of increased rolling accuracy;

with telescopic rolls with a steel width of up to 1000 mm no more than 30 mm.

Examples of symbols

Galvanized steel 0.8 thick, 1000 wide, 2000 mm long, normal rolling accuracy B, normal flatness PN, with unedged edge NO group OH, with crystallization pattern KR, first class zinc coating according to GOST 14918-80:

Galvanized rolled steel 1.2 thick, 1000 mm wide, increased rolling accuracy A, with cut edge O, grade 08kp, very deep drawing VG, without MT crystallization pattern, with reduced thickness variation UR, second class coating according to GOST 14918-80:

Galvanized rolled steel with a differentiated coating 0.5 thick, 710 mm wide, increased rolling accuracy A, with a cut edge O, grade BSt3kp, for PC painting, without a crystallization pattern MT with a reduced thickness difference UR, with a coating on one side of the first, and on the other other second class according to GOST 14918-80:

3. TECHNICAL REQUIREMENTS

3.1. Galvanized steel must be manufactured in accordance with the requirements of this standard according to technical documentation approved in the prescribed manner.

3.2. Galvanized steel is made from carbon cold-rolled coiled steel with a surface quality in accordance with GOST 16523-97. Steel grades must correspond to those given in Table 1a.

Table 1a

Cink Steel | Cold rolled steel grade for making galvanized steel |

|||

GOST 380-2005, GOST 9045-93 and GOST 1050-88 | Steel grades with a chemical composition in accordance with GOST 9045-93, as well as GOST 1050-88 with a sulfur content of no more than 0.035% and phosphorus - no more than 0.020% and GOST 380-2005 with a mass fraction of sulfur no more than 0.035% and phosphorus - no more than 0.025 % |

|||

08ps according to GOST 9045-93 |

||||

Steel grades with chemical composition according to GOST 380-2005, GOST 9045-93 and GOST 1050-88 | Steel grades with a chemical composition in accordance with GOST 9045-93, GOST 1050-88, GOST 380-2005 with a mass fraction of sulfur of no more than 0.045% and phosphorus - no more than 0.040% |

|||

(Changed edition, Amendment No. 2).

3.3. For galvanizing, zinc grades Ts0 and Ts1 are used according to GOST 3640-94 with the addition of aluminum, lead and other metals to the bath. Alloying with lead through the introduction of zinc grade Ts2 is allowed.

3.4. The surface of galvanized steel must be clean and completely coated.

3.4.1. Violations of the continuity of the coating in the form of cracking on small sagging located on defects in the steel base, the classification and dimensions of which are provided for by GOST 16523-97, are not allowed.

3.4.2. On sheets and strips with unedged edges, edge flaws with a depth exceeding the maximum deviations in width are not allowed.

3.4-3.4.2. (Changed edition, Amendment No. 2).

3.5. For galvanized steel of groups XSh, HP and OH, small sagging (sagging, layering), grains and uneven crystallization of zinc, traces from bends of the strip and control rollers, local roughness of the coating (rash), light scratches and abrasions that do not violate the continuity of the zinc coating are allowed. light and dull spots, uneven coloring of the passive film.

3.6. For galvanized steel of the PC group, dark dots and tracks (traces) from deformed small deposits (sagging, layering), grains and local roughness of the coating (rash), a matte and blurred zinc crystallization pattern, traces from strip bends, light scratches and abrasions, not violating the continuity of the zinc coating, light and dull spots, uneven coloring of the passive film.

3.7. At the consumer's request, the passive film must have a uniform color.

(Changed edition, Amendment No. 2).

3.8. The reduced thickness difference of the UR zinc coating should be no more than 16 for class P, no more than 10 for class 1, no more than 4 microns for class 2. Galvanized steel of normal thickness HP must have a coating thickness within the limits specified in Table 1.

Galvanized steel of the highest quality category is manufactured with varying thicknesses of the zinc coating for steel groups XIII, HP and PC of class P - no more than 12, class 1 - no more than 8 and class 2 - no more than 3 microns.

(Changed edition, Amendment No. 1, 2).

3.9. At the point of bending of galvanized steel up to 1.0 mm thick inclusive, when testing the adhesion strength of the coating to the base metal when bending 180°, there should be no peeling of the zinc coating exposing the steel surface. A network of small cracks along the entire length of the bend and peeling of the coating at a distance of up to 6 mm from the edges of the sample are allowed.

3.10. The mechanical properties of galvanized steel must comply with the standards specified in Table 1b.

Table 1b

Cink Steel | Tensile strength, MPa | Yield strength, MPa, not less | Relative elongation, %, not less, |

||||

St. 0.7 to 1.5 | St. 1.5 to 2.0 | ||||||

Note. The values of temporary tensile strength and relative elongation for galvanized steel of the XSh group of drawing categories N and G, relative elongation for steel of the KhP and PK groups were optional until 07/01/89. When calculating the tensile strength and yield strength, the thickness of the zinc coating is not taken into account. |

|||||||

3.10.1. The depth of the spherical hole of galvanized steel of group XSh must comply with the standards given in Table 1c.

Table 1c

Thickness of galvanized steel | Depth of spherical hole for hood categories, not less |

||

Notes: 1. For galvanized steel of intermediate thicknesses, the depth of the spherical hole must correspond to the standards established for the next smaller thickness. 2. The depth of the spherical hole for galvanized steel with a thickness of over 1.5 mm was optional until 07/01/89. 3. When tested on devices such as MTL-10 g, the norms for the depth of a spherical hole are reduced by 0.3 mm. |

|||

3.10.2. For galvanized steel of group XIII of the highest quality category, the relative elongation should be 1 unit. more than the norms of table 1b, and the depth of the spherical hole is 0.2 mm more than the norms of table 1c.

3.10-3.10.2. (Changed edition, Amendment No. 2).

3.11. Galvanized steel of the XSh group is produced with a ferrite grain size of points 7, 8, 9, 10 according to GOST 5639-82 for exhaust category VG and not lower than point 6 for exhaust category G.

For galvanized steel of category VG, grain unevenness is allowed within two adjacent numbers, for sheets of category G - within three adjacent numbers.

3.12. For galvanized steel of group XIII, category hood VG, the presence of structurally free cementite is allowed within points 0, 1, 2 and 4 of scale 1 according to GOST 5640-68. For hood categories G and N, the presence of structurally free cementite is not standardized.

3.13. The number of bends without fracture of galvanized steel of the HP, PK, OH groups must comply with the standards established in Table 1d.

Table 1d

Thickness of galvanized steel, mm | Number of bends |

Up to 0.8 incl. | |

St. 0.8" 1.2" | |

Note. The norms for bending galvanized steel with a thickness of more than 1.5 mm were optional until 07/01/89. |

|

(Changed edition, Amendment No. 2).

3.14. (Deleted, Amendment No. 2).

4. ACCEPTANCE RULES

4.1. Galvanized steel is accepted in batches. The batch must consist of sheets or rolls of one group of galvanized steel, one size, one type and class of coating thickness, type of preservation, one grade and melt (steel of groups XSh, XP and PK) and drawing category (steel of group XSh), must be registered and be accompanied by a quality document in accordance with GOST 7566-94 with the addition of values of optional quality indicators.

The batch weight should not exceed the shift production of the unit.

(Changed edition, Amendment No. 2).

4.2. In the quality document, test results and chemical composition data are indicated at the request of the consumer.

For galvanized steel that has been awarded the state Quality Mark, the designation of the state Quality Mark is affixed to the quality document.

4.3. To control the size and quality of the surface, 6% of the sheets or one roll from the batch are selected.

4.4. To control the adhesion strength of the coating, mechanical properties, and microstructure, one sheet or one roll from the batch is selected.

4.5. If unsatisfactory test results are obtained for at least one of the indicators, a re-check is carried out in accordance with GOST 7566-94.

5. TEST METHODS

5.1. The quality of the surface of sheets and rolls is checked by external inspection without the use of magnifying devices.

5.2. To conduct tests, samples are cut from each selected sheet or roll in accordance with the requirements of the drawing and Table 2.

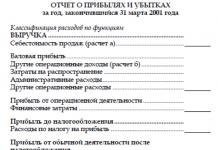

Scheme of cutting samples for testing

Scheme of cutting samples for testing (- sheet width)

table 2

Sample number | Sample dimensions, mm | Test method |

|

On the adhesion strength of the zinc coating to the base metal |

|||

To determine the mass of zinc coating and thickness variations |

|||

To the bend |

|||

To extract a spherical hole ( - test site) |

|||

Tensile |

|||

Microstructure assessment |

|||

Note. Samples are cut with maximum size deviations of ±3 mm. |

|||

(Changed edition, Amendment No. 1).

5.3. To determine the mass of the zinc coating, the test sample is degreased, weighed, immersed in a solution of antimony oxide () or antimony chloride () in hydrochloric acid and kept until the violent gas evolution stops, then the sample is removed from the solution, thoroughly washed with cold and then hot water, and dried with filtration paper and weighed. Degreasing is carried out with synthetic technical ethyl alcohol.

A solution of antimony oxide or antimony chloride is prepared in the following way: 20 g of antimony oxide (or 32 g of antimony chloride) is dissolved in 1000 ml of concentrated hydrochloric acid (GOST 3118-77) for the second and first classes or 50 g of antimony oxides of class P.

The mass of zinc coating applied on both sides of the sheet, in grams () per 1 m2, is calculated using the formula

where is the mass of three samples ( 3, 4 And 5 ) until the zinc coating dissolves, with an error of 0.01 g, g;

Weight of three samples ( 3, 4

And 5

) after dissolving the zinc coating, with an error of 0.01 g, g;

- actual surface area of the samples with an error of 1·10 m, m.

To determine the mass of zinc coating, it is allowed to use other methods that provide the necessary accuracy.

The method specified in this standard is used when there is disagreement in assessment.

(Changed edition, Amendment No. 1, 2).

5.4. The difference in thickness of the coating in the transverse direction of the sheet is determined as the absolute difference between the maximum and minimum values of the coating thickness on the samples 3, 4

And 5

according to the formula

for which purpose, first calculate the thickness of the zinc coating on each of the samples using the formula

where is the coating thickness of the corresponding sample, μm;

- mass of the sample before removing zinc, g;

- mass of the sample after removal of zinc, g;

- zinc density, g/cm;

- surface area of the zinc coating, cm.

(Changed edition, Amendment No. 1).

5.4.1. The average thickness and variation in thickness of the zinc coating on the surface of a sheet with a differentiated coating are determined and calculated for each side. To do this, after degreasing the sample, one side is covered with a dense layer of rubber glue or paraffin and zinc is removed from the opposite side, as indicated above. After re-weighing, the glue or paraffin is removed mechanically or in hot water. Removal of the zinc coating on the other side of the sample is carried out in the same way.

.

5.9. Bending testing of galvanized steel with a thickness of up to 1 mm inclusive at an angle of 180° is carried out according to GOST 14019-2003. A sample of galvanized steel is tested on a mandrel equal to the thickness of the rolled product.

Galvanized steel of the highest quality category must withstand 180° bending tests without mandrel until the sides touch.

By agreement between the consumer and the manufacturer, the bending test can be replaced by a double roof lock test in accordance with OST 1411-196-86, and for galvanized steel of the PK group, by testing on the U-1A device in accordance with GOST 4765-73.

Galvanized steel with a thickness of over 1.0 mm is tested at the request of the consumer according to a method agreed upon in the prescribed manner.

5.10. To control the quality of galvanized steel, it is allowed to use non-destructive control methods.

(Changed edition, Amendment No. 2).

6. LABELING, PACKAGING, TRANSPORTATION AND STORAGE

6.1. Labeling, packaging, transportation and storage - in accordance with GOST 7566-94 with additions.

6.2. To protect the surface of galvanized steel from corrosion, preservation is carried out: passivation, oiling or passivation and oiling.

At the request of the consumer, galvanized steel is not preserved.

When shipped to regions of the Far North and equivalent areas, conservation is required.

6.3. Sheets of galvanized steel are formed into a stack, placing one sheet on top of another. For sheets with a differentiated coating, the side with the 2nd class of coating thickness should be facing the bottom of the pack.

The end and side surfaces of the bundle are covered with channels made of annealed steel sheet with a thickness of at least 0.4 mm according to the regulatory and technical documentation.

Wooden bars in accordance with GOST 2695-83 and GOST 8486-86 with a cross-section of at least 80x80 mm or metal bars in accordance with regulatory and technical documentation must be attached to the bottom of the pack. The number of wooden and metal bars for a pack width up to 1200 mm is 2 pcs.; over 1200 mm - respectively 3 pcs. and 2 pcs.

6.4. Rolls of galvanized steel with differential coating are rolled so that the side with the 2nd class of zinc coating thickness is located inside the roll.

6.5. Packs and rolls must be tightly tied. The number of strappings must comply with the requirements of GOST 7566-94.

When shipping to the Far North and hard-to-reach areas, the minimum number of strappings must be one more than the norms established by GOST 7566-94.

For strapping, a metal tape with a thickness of 1.2-2.0 mm and a width of 30 to 40 mm is used in accordance with GOST 3560-73, GOST 6009-74 or other regulatory and technical documentation.

The outer diameter and width of the rolls should not exceed 2 mm, the length, width and height of the bundles, respectively, should be 6.2 and 1 m.

6.6. The weight of one package must be at least 3 tons and must not exceed 10 tons.

Until 01/01/88, at the request of the consumer, the weight of a pack of galvanized steel sheets should not exceed 5 tons.

6.7. Transport marking of packages must be applied in accordance with GOST 14192-96 with dark paint on the end surface of the pack and the side surface of the roll and contain basic, additional and informational inscriptions.

6.8. Transportation of galvanized steel by rail is carried out by open rolling stock in accordance with the rules for the transportation of goods in force for transport of this type and the conditions for loading and securing cargo, approved by the Ministry of Railways.

6.9. Storage of galvanized steel must comply with the conditions of ZhZ in accordance with GOST 15150-69, excluding joint presence with chemically active substances.

Section 6. (Changed edition, Amendment No. 2).

Electronic document text

prepared by Kodeks JSC and verified against:

official publication

M.: Standartinform, 2007

Requirements for galvanized sheet steel are regulated by GOST 14918-80. The standard specifies the classification, assortment, technical requirements for raw materials and protective coating material, as well as the mechanical properties of galvanized steel. GOST 14918 also regulates test methods, requirements for labeling, packaging, transportation and storage of finished products.

Galvanized steel in standard rolls according to GOST 14918-80

14918 GOST “Galvanized sheet”

Today, many types of products are manufactured by enterprises according to their own specifications. But this does not apply to materials that can be used for the manufacture of load-bearing structures and other products, the strength of which is subject to special requirements. Such materials must necessarily comply with the requirements of state standards, including GOST 14918-80.

This standard replaced the previously existing GOST 14918-69 and came into force on 07/01/81 by Decree of the USSR State Committee on Standards dated March 31, 1980 No. 1465. Today, GOST 14918-80 has the status of an interstate standard, and its validity period is limited removed by protocol No. 3-93 (IUS5-6-93) of the Interstate Council for Standardization, Metrology and Certification. Therefore, at present, GOST 14918, the status of which applies to all states included in the CIS, is valid over a vast territory with a population of almost 200 million people.

You can download GOST 14918 for free using the link. In order to download GOST 14918-80, right-click on the link and select “Save as...” or “Save link as...” from the menu that appears. After this, indicate where you want to download GOST 14918, change the name of the document if necessary, and then click the “Save” button.

How sheet steel is classified (GOST 14918-80)

The correct name of this regulatory document is: “GALVANIZED THIN SHEET STEEL WITH CONTINUOUS LINES.” The standard applies to coils and sheets of cold-rolled steel, galvanized by hot-dip galvanizing and intended for the manufacture of stamped parts, cold forming and the manufacture of other metal products.

According to GOST 14918-80, galvanized steel is classified according to several criteria.

By purpose:

- galvanized steel for general purpose (OH);

- for cold profiling (CP);

- for cold stamping (XIII);

- for painting (PC).

In turn, steel of group XIII is divided into the following categories: normal drawing (N), deep drawing (D) and very deep drawing (VD).

According to the uniformity of the thickness of the protective zinc coating:

- galvanized sheet with normal thickness variation (NR);

- galvanized sheet with reduced thickness variation (UR).

According to the thickness of the protective layer of zinc there are three classes:

- increased (P) with a mass of 570 to 855 g per 1 m² of double-sided coating;

- the first with a mass of 258 to 570 g per 1 m² of double-sided coating

- the second with a mass of 142 to 258 g per 1 m² of double-sided coating.

For the manufacture of corrugated sheets in accordance with GOST 24045-94, a galvanized sheet GOST 14918-80 with a protective coating thickness of at least first class must be used.

Galvanization GOST 14918-80, assortment and symbols

Galvanization is made from cold-rolled steel, with a thickness of 0.5 to 2.5 mm and a width of 710 to 1800 mm. Galvanized steel can be produced in the form of separate sheets, up to 6 m long, and products of small thickness can be wound in rolls. Sheet steel GOST 14918-80 is produced in significantly smaller quantities, since its transportation is more expensive than transportation of metal coils.

The crescent shape of rolled steel cannot be more than 6 mm per 3 m of length, and the telescopicity of the coil cannot be more than 30 mm for a width of up to 1000 mm. The flatness of galvanized steel must be of classes PV, PN or PU with thickness deviations in accordance with the standards of increased rolling accuracy.

About the range of galvanized steel

The requirements for the range of galvanized steel are not detailed in the standard, since the range of the steel sheet from which it is made is regulated by GOST 19904-90. Therefore, the symbol for galvanized steel indicates the characteristics of the assortment according to two standards, the numerator indicates the assortment of the original workpiece according to GOST 19904-90, and the denominator indicates the characteristics of the protective coating according to GOST 14918-80.

Example of designation for galvanized steel sheets

Above is an example of the designation of galvanized steel sheet with a thickness of 0.8 mm, a width of 1000 mm, a length of 2000 mm, with normal rolling accuracy B, normal flatness PN, uncut edge NO according to GOST 19904-90, group OH with a crystallization pattern KR first class zinc coating according to GOST 14918-80. The designation of steel group XSh immediately indicates the index of drawing ability (VG, G or N).

Technical requirements for galvanized steel according to GOST 14918-80

Galvanized steel in accordance with GOST 14918-80 is made from carbon cold-rolled steel with a surface quality corresponding to GOST 16523-97. Table 1a of GOST 14918-80 shows steel grades for the manufacture of each group and category of galvanized steel.

To apply a protective coating, zinc grades Ts0 and Ts1 according to GOST 3640-94 are used with the addition of other metals, such as aluminum or lead. The coating must be continuous, without cracking, and the surface of the galvanized steel must be clean. At the 180° bend point, galvanized steel up to 1.0 mm thick should not have any delamination exposing the steel surface. At the same time, for all groups of galvanized steel, minor roughness, scratches and abrasions are allowed, without disturbing the continuity of the coating, as well as the presence of light and matte spots. The reduced thickness difference for different classes of galvanized steel should be from 4 to 16 microns.

Table 1b of the standard shows technical characteristics such as tensile strength, yield strength and relative elongation for different groups, categories and thicknesses of galvanized steel.

GOST 14918-80 also regulates the characteristics of the crystal structure of the feedstock and the permissible number of bends without breaks. So for galvanized steel, up to 0.8 mm thick, the number of such bends should be at least 8.

The table below shows the characteristics of galvanized sheet.

| Sheet size, mm |

Sheet group according to GOST 14918-80 |

Brand become |

GOST 14918-80, sheet weight, kg |

| 0.4x1000x2000 | ON, VG | 08ps3sp | 6.95 |

| 0.4x1250x2500 | ON, VG | 08ps3sp | 8.64 |

| 0.45x1000x2000 | ON, VG | 08ps3sp | 7.42 |

| 0.5x1000x2000 | ON, VG | 08ps3sp | 8.25 |

| 0.5x1250x2500 | ON, VG | 08ps3sp | 12.89 |

| 0.55x1000x2000 | ON, VG | 08ps3sp | 9.8 |

| 0.55x1250x2500 | ON, VG | 08ps3sp | 15.3 |

| 0.6x1000x2000 | ON, VG | 08ps3sp | 9.89 |

| 0.6x1250x2500 | ON, VG | 08ps3sp | 15.45 |

| 0.7x1000x2000 | ON, VG | 08ps3sp | 11.39 |

| 0.7x1250x2500 | ON, VG | 08ps3sp | 19 |

| 0.78x1250x2500 | ON, VG | 08ps3sp | 21.1 |

| 0.8x1250x2500 | ON, VG | 08ps3sp | 21.4 |

| 0.9x1250x2500 | ON, VG | 08ps3sp | 22.71 |

| 1.0x1250x2500 | ON, VG | 08ps3sp | 26.3 |

| 1.2x1250x2500 | ON, VG | 08ps3sp | 31.2 |

The influence of GOST on the quality of galvanized steel

The standard strictly regulates the requirements for the quality of galvanized steel, the scope of testing and the methodology for checking the quality of finished products by enterprises. Each batch of galvanized steel must have a document drawn up in accordance with GOST 7566-94, confirming the compliance of this batch with the requirements of GOST 14918-80, a certificate of conformity received by the buyer of the metal, which guarantees that the products have passed all the necessary tests at the manufacturer.

The surface quality of the sheets is checked by external inspection. To test the tensile strength, the adhesion strength of the protective coating to the metal base and to evaluate the microstructure, as well as the thickness of the coating and variation in thickness, samples are cut from the roll.

All this practically eliminates the exit of low-quality finished products outside the territory of the manufacturer.

Galvanized sheets are used in many areas of the economy. This product belongs to sheet metal products. Its peculiarity is that it contains zinc.

Composition and characteristics of galvanized sheet

This sheet basically contains metal and zinc. The latter element covers the product on all sides to protect it from corrosion, which occurs as a result of metal oxidation in the environment.

But there are varieties of the product that are coated with zinc on only one side. This is necessary for further actions with the sheet, for example, bending, cutting, drawing and others.

There are several types of galvanized sheet:

- corrugation;

- corrugated sheeting;

- smooth sheet.

When processing this product, its qualities and technical characteristics are not lost. These include: mechanical strength, flexibility, rolling, corrosion resistance and deep drawing stamping.

Where is galvanized sheet used?

Its use is not limited to specialized, highly targeted plants or factories. Galvanized sheets are actively used in construction, mechanical engineering, industrial enterprises, engraving, instrument making, and as roofing.

If you use a low-quality product, it will not be able to resist corrosion, withstand various loads, or be used in any climatic conditions.

Types of zinc coated sheet

This product has its own areas of use, so there are different types.

Depending on the goals and objectives, it is carried out:

- for general purpose;

- for the production of corrugated sheets (cold profiling);

- for cold stamping;

- for subsequent painting (trained group).

Quality requirements

Galvanized sheets differ in length, width and thickness. But they must strictly comply with production standards (GOST). Such rolled metal products are produced in accordance with GOST 14918-80 (galvanized steel is made from carbon coil material with a certain surface quality as a result of cold rolling; aluminum, lead and other metals are added during the galvanizing process). For the production of high-quality surfaces, there are standards that comply with GOST 16523-89.

Depending on the purpose, galvanized sheets are made:

- with normal thickness variation;

- reduced thickness variation.

To produce high-quality rolled metal products, zinc TsO, Ts1, Ts2 is used in accordance with GOST 3640-79. It can be presented to the buyer in sheets and rolls.

Where to buy

The Metal-Magnit company has established itself as a reliable organization for the sale of rolled metal products. The sizes, types and technical characteristics of these products can be found on the company’s website. The company enjoys a good reputation as a supplier of rolled metal products and has many positive reviews from customers.

Metal-Magnit cooperates only with reliable and trusted suppliers, so all rolled metal products are of high quality in accordance with generally accepted production standards. The company's employees use an individual approach to the requirements and requests of each client, guaranteeing the quality of the product, ease of handling, resistance to aggressive environments and durability.

This is not at all surprising, because the possibilities of this material are really great. This steel is perfect for making cable trays intended for laying wires and cables with voltages up to 1000 Volts, installing floors, making corrugated sheets from it, using it to create roofing, as well as in the process of creating stamped products. Galvanized cable trays not only protect electrical wires from mechanical damage, but also ensure the safety of the cable route. Trays are installed indoors, and to protect street electrical wiring they are installed outside buildings and structures.

Before the metal turns into galvanized sheet, which has anti-corrosion properties, it goes through a zinc alloying process. Preference is given to this metal due to the fact that it is highly resistant to corrosion. When compared to other metals that are rust resistant, it is the cheapest.

Before the metal turns into galvanized sheet, which has anti-corrosion properties, it goes through a zinc alloying process. Preference is given to this metal due to the fact that it is highly resistant to corrosion. When compared to other metals that are rust resistant, it is the cheapest.

Steel receives galvanized protection after it is immersed in molten zinc, and as a result of a chemical reaction, zinc and iron molecules are bonded. The end result is galvanized steel, of which zinc is an integral part. The outer layer of this steel is zinc, followed by mixed layers, the proportion of zinc in which gradually decreases, and steel acts as the core. As a rule, this material is called galvanizing.

Galvanized rolls are divided according to their purpose into several different groups: general purpose group, cold forming group, painting group and cold stamping group. Cold-formed steel, due to its drawing quality, is divided into subgroups: normal, deep and very deep drawing. Also, galvanizing thickness can be normal or reduced. Such material may or may not have crystallization patterns.

The intensity of galvanizing can be determined based on the mass of zinc that was spent on processing one square meter of steel. Thus, you can understand how much zinc was spent on protecting the metal. Based on this, three classes of galvanized steel can be distinguished:

. Higher class, having a mass of one square meter with coating applied on both sides from 570 to 855 grams. The thickness of this coating is from 40 to 60 microns.

. The first class, having a mass of no more than 258, the coating on both sides reaches 570 grams, thickness from 18 to 40 microns.

. The second class has a coating weight from 142.5 to 258 grams, its thickness is from 10-18 microns. This class of steel is used in the manufacture of galvanized cable trays (ducts).

A mandatory quality of galvanized steel is cleanliness: for example, there should be no sagging or cracks on the surface of the sheet. It is acceptable to have small deposits or slight deposits on the surface; uneven crystallization of the coating and the presence of small particles are possible. When creating galvanized steel, the norm is considered to be a width from 710 to 1500 mm and a thickness from 0.5 to 3.0 mm.

Advantages of galvanized steel

Metal products have many advantages over their competitors - stone and wood. A sheet of iron has almost the same lightness when compared to wood, but it is much stronger (its strength is comparable to stone, while metal is much lighter). The main disadvantage of metal is corrosion. For example, an untreated car body can last only ten years, after which it will be susceptible to corrosion and after a few years the metal will be completely rusty.

Metal products have many advantages over their competitors - stone and wood. A sheet of iron has almost the same lightness when compared to wood, but it is much stronger (its strength is comparable to stone, while metal is much lighter). The main disadvantage of metal is corrosion. For example, an untreated car body can last only ten years, after which it will be susceptible to corrosion and after a few years the metal will be completely rusty.

There are many ways you can combat corrosion. One of these methods is anti-corrosion treatment with various compounds. The main disadvantage of such compositions is that if it is erased, the open area will become completely defenseless against corrosion. Nowadays, one of the most effective methods of preventing corrosion is galvanizing the metal.

Depending on the area of application of galvanized metal, its thickness may vary: for example, the thinnest coating has a thickness of 10 microns. Steel of this thickness is used for simple working conditions. Galvanized steel with a 50-micron coating has increased resistance to various heavy-duty work; such a coating can completely protect the metal from hazardous chemicals and corrosion for many years.

This standard applies to sheet and coil cold-rolled steel, hot-dip galvanized in continuous galvanizing units, intended for cold profiling, for painting, production of stamped parts, utensils, containers and other metal products.The technical level indicators established by this standard meet the requirements of the highest and first quality categories.

Subdivided:

- by appointment to groups

- for cold stamping - ХШ,

- for cold profiling - HP,

- for painting (trained) - PC,

- general purpose - OH;

- by drawing ability (steel group XSh) into categories:

- normal hood - N,

- deep drawing - G,

- very deep drawing - VG;

- according to the uniformity of the thickness of the zinc coating:

- with normal thickness variation - HP,

- with reduced thickness variation - UR.

- with crystallization pattern - KR,

- without crystallization pattern - MT.

Galvanized steel is made with a width from 710 to 1800 mm inclusive, a thickness from 0.5 to 2.5 mm inclusive from carbon cold-rolled coiled steel. For galvanizing, zinc grades Ts0 and Ts1 are used with the addition of aluminum, lead and other metals to the bath. Alloying with lead through the introduction of zinc grade Ts2 is allowed. To protect the surface from corrosion, preservation is carried out: passivation, oiling or passivation and oiling. At the request of the consumer, galvanized steel is not preserved.

Example of a symbol: galvanized coiled steel 1.2 thick, 1000 mm wide, increased rolling accuracy A, with cut edge O, grade 08kp, very deep drawing VG, without crystallization pattern MT, with reduced thickness variation UR, second class coating according to GOST 14918 -80:

OTs A - O - 1.2x1000 GOST 19904-74

08kp VG - MT - UR - 2 GOST 14918-80

Galvanized steel sheet is manufactured according to GOST 14918 - 80 .

Galvanized steel is made from carbon cold-rolled steel coils with a surface quality of GOST 16523-89, width from 710 before 1800mm inclusive, thickness from 0,5 before 2.5mm inclusive.

The range of galvanized steel must correspond GOST 19904-74 .

Depending on the thickness of the coating, galvanized steel is divided into three classes:

- P - with a coating thickness exceeding 40µm before 60µm on;

- 1 - with a coating thickness exceeding 18 before 40µm on;

- 2 - with a coating thickness of 10 before 18µm on

Depending on the purpose, galvanized sheet steel is divided into:

- ХШ - for cold stamping;

Galvanized sheet steel for cold stamping is divided into:

N - normal hood;

G - deep drawing;

VG - very deep drawing;

- HP - for cold profiling;

- PC - for painting (trained);

- OH - general purpose.

Profiled steel sheet (corrugated sheet) is manufactured according to GOST 24045-94 .

Cold-formed steel sheet profiles with a trapezoidal corrugation shape (corrugated sheeting) are manufactured on profile bending machines and are intended for use in construction and other industries.

Corrugated sheets are classified according to:

- purpose;

- material of the original workpiece;

- the presence of a decorative paint coating.

According to their purpose, corrugated sheets are divided into types:

- for flooring - N;

- for flooring and wall fences - NS;

- for wall fences - S.