Cable lines are divided into on-site, local, intrazonal, main, international.

- on-site- networks on the territory of one facility (factory, oil depot...), purpose - providing technological and production communications within the facility. Example - there is a collection of tanks for storing liquid chemicals. The tanks have sensors for temperature, level, etc. The cable through which signals from the sensors are transmitted to the server room for monitoring and processing will be part of the on-site networks.

- local- cable lines between buildings in the city (different enterprises) or nearby settlements (towns, villages...), purpose - providing communications at the local level, for example, telephone communication channels for connecting a departmental telephone exchange to a city telephone exchange.

- intrazonal- cable lines within one edge, area, purpose - providing communications within a given zone.

- main- cable lines passing (connecting) more than one entity, the purpose is to provide communication between entities.

- international- cable lines passing across the border of a state(s), purpose - providing communications between countries (Internet).

Compound

Cable lines consist of communication centers, unattended regeneration (reinforcement) points - NRP, NUP, cable route.

- communication center- communication structure in which transmission system equipment is installed. There are serviced, semi-serviced and unserviced. The serviced communication centers are manned 24 hours a day; engineering and technical personnel may be present during the day. In semi-serviced nodes in working hours there will be staff present; the site is closed during non-working hours. Maintenance of communication equipment in an unattended communication center is carried out according to a schedule or as needed. Physically looks like a building or block container.

- unattended regeneration (reinforcement) points- points at which regeneration (digital transmission system) or amplification (analog or digital transmission system) of the signal is carried out. Physically represents a container (for example, a barrel) buried in the ground at a shallow depth, in which a regenerator or amplifier is placed. A buried container usually has a superstructure (wooden, brick, iron or reinforced concrete). The location of the regenerator or amplifier in the upper part of the superstructure is also common. Within the city limits, it is possible to locate the NRP/NUP in a building, in an underground metro station or in a distribution cabinet.

In addition to regeneration/amplifier equipment, the NRP/NUP may contain power supply equipment (external or remote), batteries, heating, ventilation and air conditioning devices, lighting devices, telecontrol devices (control of air pressure in the cable and in the cylinder, control of closing doors and covers, control of the presence of water in the chamber, temperature control, humidity control, power control), equipment for maintaining cables under excess air pressure, electric compressor units, compressed air cylinders.

- cable route (route)- cable laid in the ground (most often outside settlement), in the sewer system (most often in the territory of a large populated area). This also includes cable wells, pits, signal posts and signs, cable input rooms and other linear structures.

If we install a transmission system on a cable line, we get a communication network.

Links

- Telephone Network User's Guide (Russian)

- Guidelines for drawing up work projects (WPP) for the construction of linear structures of trunk and intra-zonal cable communication lines (Russian)

Wikimedia Foundation. 2010.

See what “Cable communication lines” are in other dictionaries:

communication lines- communication lines: Transmission lines, physical circuits and linear cable communication structures. [Federal Law “On Communications”, Article 2, paragraph 7]. Source: GOST R 53111 2008: Stability of communication network operation public use. Requirements and methods... ...

Communication lines- 1. Transmission lines, physical circuits and linear cable communication structures Used in the document: dated 07.07.2003 No. 126 Federal Law 2. Transmission lines, physical circuits and linear cable communication structures Used in the document: Order of the Ministry of the Russian Federation on ... Telecommunications dictionary

Power transmission lines (PTL) and overhead communication lines and technical control equipment (TC)- 7.3.30. Power transmission lines (PTLs) and overhead communication and technical control lines (TC) in undeveloped areas are recognized by dark parallel aerial images of shadows from supports*. Usually the farms themselves are clearly visible in the photographs... ... Dictionary-reference book of terms of normative and technical documentation

Communication lines- 7) communication lines, transmission lines, physical circuits and linear cable communication structures;... Source: Federal Law of 07.07.2003 N 126 Federal Law (as amended on 07.28.2012) On communications... Official terminology

COMMUNICATION LINES- according to Federal law“On Communications” dated 07/07/2003 No. 126 Federal Law, - transmission lines, physical circuits and linear cable communication structures... Record keeping and archiving in terms and definitions

Radio communication lines formed by a chain of transceiver stations, allowing the transmission of information over distances exceeding the reliable transmission distance of one pair of transceiver stations. Successfully complement cable communication lines in cases where... Encyclopedia of technology

dispatch lines- 3.3 dispatch communication lines: Communication lines (cable, wireless) designed for the exchange of information between dispatch control devices and the dispatch console. Source … Dictionary-reference book of terms of normative and technical documentation

STO 70238424.29.240.20.011-2011: Power cable lines with voltage 110 - 500 kV. Organization of operation and maintenance. Norms and requirements- Terminology STO 70238424.29.240.20.011 2011: Power cable lines with a voltage of 110,500 kV. Organization of operation and maintenance. Standards and requirements: 3.1.1 long-term permissible current load of the cable line: Maximum... ... Dictionary-reference book of terms of normative and technical documentation

Coaxial transformers (transforming lines, serial cable transformers, impedance transformers) sections of coaxial lines with characteristic properties, intended for matching resistance in microwave... ... Wikipedia

NUP

maintenance-free amplification point;

uncontrolled amplifier point

NUP

low level programming

program

NUP

natural penis enlargement

without surgery

honey.

Source: http://www.gratis.pp.ru/index.php?act=ST&f=99&t=9538&s=

NUP

tax accounting policy

Finnish

NUP

initial management training

discipline

education and science

Source: http://www.peo.ru/navigator/?articleId=679&print=1

Dictionary of abbreviations and abbreviations. Academician 2015.

See what “NUP” is in other dictionaries:

NUP- unattended amplification point [OST 45.121 97] Topics of lines, connections and telecommunication circuits Synonyms unattended amplification point ... Technical Translator's Guide

NUP- maintenance-free amplification point... Dictionary of Russian abbreviations

Nuptse- (7861), view from the south. The numbers indicate 7 heads of the array: 7742, 7784, 7861, 7827, 7804, 7776 and 7695. Photo from here. Nuptse (7861) (Nuptse), sometimes written Nuptse is a peak in the Khumbu region, Mahalangur Himalayas. Located in Nepal in western... Encyclopedia of tourists

Dream Stone (cartoon)- Tie? Dream stone ... Wikipedia

Chukhung- The style of this article is non-encyclopedic or violates the norms of the Russian language. The article should be corrected according to the stylistic rules of Wikipedia... Wikipedia

The Dreamstone- The Dreamstone (English) Genres comedy, family Animated series ... Wikipedia

Dream Stone- The Dreamstone Still from the intro of the animated series... Wikipedia

Cable communication lines- Cable communication lines communication lines consisting of directional transmission media (cables), designed together with wire transmission systems to organize communication. The organization of communications here means the organization of channels: ... ... Wikipedia

Linear cable structures of trunk and intrazonal transmission lines- 1) part of the transport communication network; 2) a set of linear paths of transmission systems or standard physical circuits that have common linear structures, devices for their maintenance and the same propagation medium within the range of the devices... ... Environmental law of Russia: dictionary of legal terms

Unattended amplification and regeneration points (NUP and NRP) are components of the transmission systems K-3600, K-1920P, IKM-30 and others.

The NUP houses signal amplification equipment that does not require the constant presence of people for maintenance. Unattended NUP and NRP points are usually located under; earth. NUP equipment is located in special thermal chambers, NRP equipment is located in cable wells.

NUP tanks can be made of reinforced concrete or metal. Metal tanks must be grounded. The floors in NUP are covered with dielectric mats, and the walls are painted with paints that do not contain toxic or flammable substances (zinc, benzene, acetone, etc.). The NUP necks are closed with lids that are locked with a lock. Equipment in NUP is installed using lifting devices (truck cranes, hoists, etc.). You can go down into the chamber only after placing the load on the floor.

Work in the NUP is carried out by a team of at least two people, and the foreman must have at least IV qualification group and ensure the safe execution of work. Each worker descending into the NUP must put on a hat and button up his sleeves. You should go down to the cell using a securely installed ladder with handrails. The removable ladder must be secured to the neck of the chamber. All work must be carried out with the chamber neck cover open. When carrying out work, the chamber must be ventilated, for which purpose ventilation devices are provided in some NUPs. If there is no constant ventilation, then the room is ventilated using a hand fan or a fan powered by a car engine. To create optimal air flow, the end of the fan hose is placed at a distance of 20-30 cm from the floor.

The NUP room is particularly dangerous, therefore, when working with power tools, low voltage sources are used. You should use an electric soldering iron, electric drill,

designed for a voltage not exceeding 42 V, portable lamps - 12 V. Portable lamps are equipped with reflectors and covered with metal mesh to protect them from impacts.

Sources of low voltages are step-down transformers. The use of autotransformers is prohibited, since their use does not exclude the possibility of the voltage of the primary circuit transferring to the secondary circuit and damaging the working electric shock.

When working in the LUP chamber with a power tool, workers must wear dielectric gloves or sit on a rubber mat.

Work in the NUP can be carried out without removing, with complete or partial stress relief. Cleaning the LUP room, wiping casings and equipment, replacing compressed air cylinders can be carried out without removing the voltage, and repairing faulty amplification equipment and soldering adjustment jumpers can only be done with complete voltage removal. As stated above, the withdrawal of DP is carried out at the POU or OP. The work manager must receive confirmation of the removal of the DP using the official telephone communication, which is organized between NUP and PMO. To ensure the safety of installers performing work with complete voltage relief, additional breaks are made in the DP receiving circuits.

When the voltage is partially removed, the spark gaps on the high-frequency and signal conductors of the cable are replaced and adjusted. You must first remove the voltage from those cable cores on which you are going to work, and make sure that there is no voltage using a voltmeter. Adjacent arresters that remain energized are fenced, and the cable cores on which work is to be worked are grounded.

The amplification and switching equipment of the NUP system K-1920U is placed on blocks that are installed on racks. Power is supplied to the blocks through cut-in blocks. If the block is removed from the rack, the contacts of the pads open and the voltage is removed from the block. However, the mating terminals located inside the rack compartment remain live and touching them presents a risk of electric shock. Blocks from the NUP racks can be removed without removing the DP. The exception is the filter board; when removing it, the couplings can be disconnected after disconnecting the DP at the POU.

The remote power board (RPP) is removed only after first turning off the three high-voltage connectors located on it. The connectors are removed using dielectric gloves.

The K-1920U system is equipped with telemechanics equipment (TM), which ensures the appearance of notification signals on the control unit when the internal cover of the control unit hatch, the appearance of water in the control unit, air leakage from the cable containment device under pressure (UCSD), malfunction of amplifier lamps, short circuit or open circuit DP. The voltage of the linear circuits of telemechanics in relation to the ground is more than 200 V and is considered dangerous for the premises of the NUP. Therefore, cleaning the contacts, checking the adjustment of individual relays located on the board, repairing the “Hatch” and “Water” alarm sensors, and repairing the control system are carried out with complete removal of voltage. The voltage is turned off by removing the arms from the sockets of the linear circuits of the telemechanics on the auxiliary rack (SV) boxes.

When carrying out main checks of the operation of TM devices, in particular when checking the passage of notification signals “DP short circuit” or “DP circuit open”, you should use dielectric gloves.

IN recent years The experience of limiting repair work in the NUP premises has spread. Faulty units are removed and replaced with spare ones. The removed blocks are repaired in special workshops. This organization of work allows not only to more efficiently repair and check equipment, but also to significantly improve and protect working conditions.

LABORATORY WORK No. 8

MAINTENANCE-FREE REGENERATION POINT

NRP-K12 TRANSMISSION SYSTEMS IKM-30.

8.1. Purpose of the work.

Study of the design and structural diagram of an unattended regeneration point.

8.2. Exercise.

8.2.1. Familiarize yourself with the composition of the equipment and the design of the NRP-K12 IKM-30.

8.2.2. Study the structural diagram of the NRP.

8.3. NRP equipment.

NRP equipment is located in NRP-12 containers, each of which contains from one to 12 blocks of double-sided linear regenerators (RL) and one linear regenerator control block (CR). NRP-K12 containers are installed, as a rule, in large-type telephone sewer wells.

Structurally, NRP-K12 is made in the form of a sealed cast-iron container, consisting of a body and a lid, equipped with a rubber seal and attached to the body with specialized bolts. On the lid of the container there are niches in which an air valve is installed, used for pumping the container with air (the “Pressure” niche/, and the service communication connector/ “Communication” niche/ for connecting the AO-30 lineman’s apparatus. Both niches are protected by sealed lids rubber seals. On the inside of the lid there are two compartments for storing silica cable; the silica cable is changed after each opening of the container.

To connect the NRP-K12 to the main cable, the housing has an input made in the form of a sealed coupling. The connection of the coupling to the container body is a flange bolted connection, covered with a paronite gasket.

The presence of an introductory removable sealed coupling makes it possible not to use gas-tight couplings when installing the container, replacing the container body with the equipment placed in it without violating the tightness of the main cable, and repairing stub cables without violating the tightness of the container. Repair and replacement of the cable sleeve is possible without disturbing the electrical installation of the container. For connection to the ground electrode, a stainless steel bolt with appropriate markings is provided on the container body.

According to operating conditions, the container can be submerged for up to 6 months at a depth of up to 2 meters. Therefore, the container lid bolts are made of stainless steel and have an anti-corrosion coating, and the coupling connecting bolts are filled with sealant.

To control the tightness, the container is kept under excess air pressure, pumped through an air valve. When opening the container, excess pressure is first released.

A steel frame is placed inside the container, on which the RL and KR blocks are installed. Switching of the block circuits with the electrical installation of the container is carried out by rectangular detachable connectors with gold-plated contacts. A switching field is mounted on the frame for connecting regenerators to selected cable pairs and connecting telecontrol pairs to service communications; A low pressure alarm, a locking button and a contact strip with control resistors, connected by jumpers, are installed.

The weight of NRP-K12 without stabilizing bars is no more than 120 kg, overall dimensions are 1000 x 380 x 355 mm.

8.4. Structural diagram of the NRP.

The block diagram of the NRP is shown in Fig. 8.1.

The digital signal, weakened and distorted during its passage along the cable line, is fed through the balun transformer Tr1 to the input of the linear corrector LC, which corrects the shape of the received pulses and their amplification. The amplitude-frequency response of the linear corrector was selected based on the requirement to maximize the signal-to-noise ratio at its output.

The LC includes a correction amplifier KUS, which corrects the shape of the received pulses at maximum attenuation of the cable line and an adjustable artificial line RIL, which complements the attenuation of the regeneration section to the maximum value. The attenuation of the RIL is set by a device for automatically adjusting the AGC level, so that when the attenuation of the cable line changes, the amplitude of the pulses at the LC output remains unchanged.

The corrected bipolar digital signal is generated at the output of the LC and is divided in the UR separation device into unipolar sequences of positive inverted negative pulses.

These sequences are fed to the inputs of two identical decision devices RU1 and RU2, where the transmitted code symbols corresponding to the pulses and spaces included in the sequences are identified, and the pulses are restored by shape, duration and time position. Regeneration sequences of positive and inverted negative pulses are combined in the output pulse shaper FVI and, through the balun transformer Tr2, are supplied to the input of the next regeneration section. The set of decision devices (RU1 and RU2) and the output pulse shaper (OPF) is a regeneration device R.

The operation of the decision devices RU1 and RU2 is controlled using two sequences of rectangular pulses P1 and P2 /timing sequences/. The pulse repetition rate of the timing sequences is equal to clock frequency digital signal, and their duty cycle is two.

The time position of the leading edge of the P1 pulses determines the moments of recognition of code signals in the regenerator, and the time position of the trailing edge of the P1 pulses fixes the duration and determines the time position of the trailing edge of the regenerated pulses. Pulses of the timing sequence P2 block the input of the switchgear after a short period of time compared to the clock interval after the moment of identification, which limits the identification time and increases the noise immunity of the decision devices.

Timing sequences P1 and P2 are formed from the output signals of the separation device in the timing device UH, consisting of a coincidence circuit C, an impact excitation circuit K, a phase shifter PV, and a timing sequence generator FHP. Sequences of positive and inverted negative pulses from the output of the UR arrive at the input of the coincidence circuit, from the output signal of which a quasi-garonic oscillation of the clock frequency is extracted using a shock excitation circuit. Using a timing sequence generator, chronic sequences P1 and P2 are generated from the resulting quasi-garonic oscillation, phased with the regenerated signal for correct establishment of the moment of recognition in the phase shifter FV. In the output transformer Tr2 of the linear regenerator there is a control winding connected by the measuring socket Gn on the front panel and connected through a matching resistor to the KR block.

The regenerator is powered from two stabilized voltage sources 4.7V 10% V. In RL units, the supply voltages are generated in the remote power receiver to the zener diode. Combined connection of regenerator nodes of directions A and B to a remote power source up to 110 mA.

In order to reduce the overall dimensions of the equipment and increase the reliability, the power supply of station regenerators is organized directly from the station battery using zener diodes, and to increase the efficiency of the power supply device, all regenerators of one DPR panel are powered in series. Zener diodes are protective and allow you to remove any of the PC blocks from the panel without disturbing the operation of others. In operating condition, the protective zener diodes are bypassed by the zener diodes supplying the station regenerators, i.e. they are locked.

To reduce the level of interference induced at the input of the regenerators, the common point of the regenerator power circuit and the cable sheath, grounded to the housing of the rack or NRP container, are connected through a capacitor.

8.4. Contents of the report.

8.4.1. Block diagram of the regenerator.

8.5. Test questions.

8.5.1. How is NRP-K12 constructed?

8.5.2. How many RL units are placed in NRP-K12?

8.5.3. How is NRP-K12 connected to the main cable?

8.5.4. Where is NRP-K12 installed?

8.5.5. How is NRP-K12 powered on balanced cables?

L I T E R A T U R A.

1. Multi-channel transmission systems. Ed. N.N.Baeva and V.N.Gordienko, M.: Radio and Communications, 1997. - 559 p.

2. Digital and analog transmission systems. Ed. V.I. Ivanova: Radio and communications. - 231 p.

Rice. 8.1. Block diagram of the regenerator.

UR

RU

FVI

RU 1

RU 2

KUS

RIL

FHP

FV

Tr 1

line

OK

UH

line

To the reception. dist. Pete.

Tr 2

Gn

To the reception. dist. Pete.

to the KR block

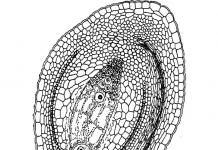

For symmetrical cables MKS 4X4 and 7X4, sealed with lamp equipment of the K-60 and K-24 systems, the NUP is an underground vertical steel chamber (Figure 3). Thermal insulation made of mipore is placed between the steel walls of the chamber, due to which the heat generated by the lamps maintains a positive temperature in the NUP throughout the year.

Figure 3 – Underground LUP with a vertical thermal chamber for lamp systems: a) section; b) general view; 1 - layer of bitumen; 2 - magnesium electrode; 3 - tank; 4 - anti-corrosion layer; 5-ground part

The entrance to the chamber is through a hatch closed with two lids, one of which is thermally insulated. The outer side of the walls and the bottom of the chamber are protected by a multi-layer anti-corrosion coating. The inside of the camera is primed and painted.

The camera is installed in a pit about 4 m deep on a concrete foundation. A brick or prefabricated concrete booth is constructed above the chamber, in which equipment for maintaining the cable under pressure, gas-tight and insulating couplings of alarm devices, protection panels, etc. are placed. To stabilize the temperature in the chamber, the ground part of the NUP, if necessary, is embanked with soil, which is reinforced with turf or sowed with grass.

Cables are introduced into the ground part of the NUP through two input blocks of three asbestos-cement pipes. From the ground part, the cables are introduced into the LUP chambers through special steel pipes. To seal the input, the cable sheath and the ends of the input pipes are soldered (Figure 4). If cables are introduced without a metal sheath (from grounding loops), then the input holes are sealed using bitumen-rubber mastic.

Inside the chamber, the main cables are routed to the VKSh cabinet on which the boxes are installed.

Figure 4 – Soldering the cable to the inlet pipe (o) and fastening the cable inside the heat chamber (b); 1 - flange of the introductory cartridge; 2 - cable; 3 - liner; 4 - soldering; 5 - introductory cartridge; 6 - camera; 7 - compression sleeve; « - clamp; 9 - clamp; "0 - soft gasket; // - bolt; 12 - chamber stiffener

Figure 5 – Horizontal LUP for the K-60P system (semiconductor) and cable entry: 1 - branching coupling on the AGC cable; 2 - PVChS wires: 3 - tank neck; 4 - stairs; 5 - VKSh introductory cabinet; 6 - gas-tight couplings; 7 - trunk cables; 8- grounding cables; 9 - lineman service communication cable: (O-cables AGC; 11-cylinder; 12 - air ducts: II AKOU

Rice. 8.6. Section of the NUP for single-quadruple cables (K-60P-4 system): 1 - NUP housing; 2 - protective concrete well; 3 - hatch; 4 - deboning; 5 - load-bearing plate; 6 - blind area; 7 - inlet pipes; " - asbestos-cement pipe: 9-cable

Figure 7 – Installation of LUP with a horizontal chamber

Figure 8 – Sealing the cable entry into the horizontal LUP: 1 - cable without jute cover; 2 - bitumen mass; 3 - soldering; 4 - end wall of the tank; 5 - stiffener; 6 - cable without armor; 7 - cable in jute cover

To transmit telecontrol and alarm signals, a connecting cable is laid between the camera and the ground part of the NUP, which ends in a box in the chamber, and in the ground part it is soldered into a splitter mounted on the wall.

For symmetrical cables of the MKS 4x4 type, sealed with K-6OP semiconductor transmission equipment, the NUP is a horizontal steel single-wall underground chamber (Figure 5). The entrance to the chamber is through a hatch and neck, above which there is a ground booth. The cables are inserted through metal inlet pipes located at the end of the chamber directly into the underground part of the NUP. To protect against corrosion, the joint area is carefully covered with bitumen mass.

For symmetrical single-four cables MKS, MKSA, ZKP, ZKPA, etc., sealed with semiconductor transmission equipment K-24P and K-6OP, small-sized NUPs are used (Figure 6). The NUP housing consists of an underground vinyl plastic shell, which houses the amplification equipment, and an above-ground metal housing, where the input and cable devices are located. In the lower part of the ground housing there are two pipes through which the ends of single-quad cables 3.5 m long are brought out from the LUP. Inside the housing, these ends end in gas-tight connectors, with the help of which the linear cable is connected to station devices. The inlet pipes with the outgoing cables are carefully sealed to protect the LUP from moisture penetration into it. In this form, the NUP is transported to the main line, where, after its installation, the main cables are connected to the outer ends of the input cables in conventional straight couplings. To protect against mechanical damage, the NUP body is placed in a brick or reinforced concrete well with cast iron hatch.

For coaxial standardized cables KMB-4, sealed with K-1920 equipment, underground horizontal single-walled metal chambers are used as LUP (Figure 7). The chamber has the shape of a cylinder 4 m long with convex (spherical) bottoms. The entrance to the NUP is through a hatch and a vertical neck. The outer part of the chamber is covered with waterproofing. The cables are inserted through metal pipes located at the end of the chamber. The place where the cable sheath is soldered to the inlet pipes (Figure 8) is protected from corrosion with bitumen mass.

Inside the chamber, each main cable is soldered in a branching coupling into single-coaxial distribution cables of the KRK type (according to the number of coaxial pairs in the cable), one symmetrical cable with a capacity of 7x4 and one air duct. KRK distribution cables are laid on an air chute and terminated with OGKM type termination couplings. The symmetrical cable is soldered into a box.

Figure 9 – Cable entry and placement of terminal devices in the horizontal NUP for K-1920 systems: 1 - OGKM; 2- distribution cables KRK; 3- balloon; 4 - branching couplings; 5 - main cables; 6 - AGC cable; 7 - grounding bus; S - place where the grounding cable is soldered to the tank; 9 - grounding cable; 10 - AKOU; 11 - air duct; 12 - gas-tight couplings GMS

A gas-tight coupling is connected between the branch coupling and the box. The air duct is connected to the cable maintenance system under excess pressure (AKOU, USKD, ShchPV). Equipment for maintaining the cable under pressure is located in the chamber. The input arrangement is shown in Figure 9. A small prefabricated reinforced concrete, metal or wooden booth covered with slate is installed above the entrance hatch. Similar, but elongated (6 m) horizontal chambers are used for KM-8/6 cables, sealed with K-1920 and K-300 equipment.

Currently, a universal metal horizontal chamber NUP with a length of 2.4 m is being introduced, intended for cables KM-4 and KM-8/6, sealed with semiconductor equipment K-3600, K-1920P, K-1020, K-300. A container with such equipment has a stub cable 3-4 m long, which is spliced with a linear cable in a straight or branching coupling. Terminal and gas-tight devices are assembled and placed directly in the container by the manufacturer.

For small-sized coaxial cables MKT-4, sealed with K-300 equipment, small-sized semi-recessed NUPs are used, which are a steel single-walled vertical cylindrical housing with a welded bottom and a tightly closing lid (Fig. 8.10). The part of the body buried in the ground is covered with waterproofing on the outside, and the above-ground part is painted with water-resistant paint. The ends of the input cables, 4 m long, are brought out through the branch pipes in the housing. Inside the housing, the input cable is divided into distribution cables, the ends of which end with coaxial or symmetrical connectors. With the help of the latter, the line is connected to the station equipment. The outer ends of the input cables after installing the NUP are connected to the main cable in a straight or transition coupling, and when the cable is kept under constant overpressure - through a gas-tight coupling KGS.

Electrical measurements of the mounted cable are carried out with the LUP cover open from the terminal connectors. To protect against precipitation, a wooden, slate-covered or metal booth is installed above the NUP.

Figure 10 – NUP for small-sized cable MKT-4 (K-300 system)