Reading time ≈ 15 minutes

Every summer resident should know that a homemade chicken feeder will be useful on the farm, and its production will not break the bank. We will present you photos and original ideas below, and the chickens will be satisfied with the product. After all, they provide a very important product from our diet - eggs. And their meat is also famous for its taste. And self-grown birds have not only tasty, but also healthy meat. Such a bird is unpretentious, but still, you will have to work hard on arranging a chicken coop for breeding it.

Homemade chicken feeder

In order for chickens to give a lot of eggs, you need to follow some rules for their maintenance. For example, they are very fussy birds, so place them in a quiet and calm place. Plus, proper nutrition is important. And to make it convenient and comfortable for them to eat, they need a chicken feeder. Of course, buying such an item is not difficult. But such a purchase is not always possible due to the high cost of the product. And the one made personally will best suit your requirements. There can be many options. But let's talk about the most accessible and popular ones.

Experts distinguish three types of structures:

- tray feeder - consist of flat containers that have small sides. They are needed to prevent birds from scattering food. This option is best used for feeding small chickens;

- groove feeder – a turntable is also attached to the tray. It can be replaced with a restrictive grille, which is easy to remove. Also, the tray itself can be divided into several compartments. This separation is convenient when feeding different types of feed. Often these types of products are taken outside the cage. So they are quite easy to maintain;

- bunker feeder - used for feeding dry food. This design consists of a bunker, which contains enough feed or grain to provide a complete ration for a certain time (for example, a day) and a tray. The feed enters the tray evenly, depending on how the food is eaten. When used this way, the food will always be clean and dry, because the hopper itself is securely closed.

Feeding chickens

Preparatory work

For manufacturing, you can take various materials, including those that are easy to find in every yard. All available materials will do - boxes, wooden boards, pipes and even plastic bottles. But farmers will always be faced with the question of how to mix feed? After all, using several for separate feeds will take up a lot of free space. But everything is much simpler, as it seems. This secret will be revealed a little later.

Location of the feeder on the street

The structure must cope with the main function - delivering grain. For full functionality, it is necessary to properly prepare before construction itself. The first step is to outline the parameters of the future design. The choice of location is also important. This is important for both indoor and outdoor feeders. The main criterion is freedom of approach and access to food for each bird. It is important that the chickens do not crowd or disturb during feeding. Therefore, when calculating parameters, take into account the number of animals.

When choosing an option for construction, do not forget about the correct diet. The fact is that chickens should receive both dry and wet food (mash). The best option for dry food is a bunker feeder. It is most often made in a cylindrical shape, and grain replenishment occurs automatically. But for wet types of food it is better to choose trough or tray feeders.

Of course, the construction of the tray and the bunker have different technologies and the use of materials will be different. But thanks to today's tools, the process has become much easier. So even a beginner in this matter can easily build a simple feeder on his own. The main thing is to adhere to the given recommendations. Consider the main options that are easy to execute and most popular among farmers. Detailed instructions for each type are included.

Important! When creating a structure for feeding chickens, you need to follow this principle: create maximum stability and the feed should not spill out of it. In case of non-compliance with this rule, there will be an extra waste of food and a lack of sanitation standards.

Option 1. Feeder made from cutting boards

To get an unusual do-it-yourself chicken feeder, look at the photo. And this and other original ideas will help you create your own unique version. For equipment of this type of grain supply, you need to take the following materials and tools:

- cutting board;

- small plastic cup;

- funnel;

- transparent rubber hose;

- electric drill.

We make the feeder as follows.

- You need to take a plastic funnel and circle its outer contour on the board itself in the center.

- Using an electric drill, make a lot of holes along the intended circle. But you don’t need too much so that the feed comes in a little at a time.

- The diameter of the hose must match the spout of the funnel. They need to be connected to each other. To make the connection as strong and reliable as possible, you can take suitable fastening elements (clamp).

- You need to make a hole closer to the bottom of the plastic container. Its size must match the hose so that it can enter and hold firmly.

- The free end of the rubber hose must be passed through the hole made in the cup. If the joint is not tight enough, use sealant. Just apply it to the edges of the hole and the hose, or rather its outer part.

- After everything has dried, you need to attach the bell of the funnel to the board itself. Here also use sealant along the contour.

- The funnel should lie exactly along the contour made. Hold it until the sealant is completely dry.

- The hose must be connected at one end to a plastic cup, and at the other end to the spout of the funnel. It should be on the bottom side of the board. The feeder is ready!

Important: The feed will be supplied from the watering can through the hose into the cup itself. Pay special attention to the stability of such a feeder, because the birds will sit on the board and can turn it over.

Cutting board feeder

Option 2. Design based on plastic bottles

Many people store water in case of outages or for other household needs. Storage most often occurs in accessible plastic containers. We can say that such containers already exist in every home. It is plastic bottles that can be taken as the basis for creating a bird feeder.

Finished product for feeding

Creating such an option for feeding chickens involves the use of two containers and is carried out according to the following algorithm:

- You need to cut the bottle into two parts. After this, make holes at the bottom, see the photo for exactly how to do this. The size of such holes should be made slightly larger than the head of the chicken. This way they can easily stick it in and eat it.

- In the second container, you need to cut out the bottom and place it with the neck down so that it fits inside the cut made earlier. The result should be a small gap of a few centimeters between the bottom itself and the inserted neck.

- Grain is poured inside. It needs to be covered with something on top. The feeder is ready for use.

Bottle cut in half

The only caveat is that if it rains or there are other adverse conditions outside, the feeder must be moved indoors. But if you use it indoors, then this type will be very successful.

Such a chicken feeder can also be built with your own hands, but from ordinary plastic bottles. So the whole structure will have smaller dimensions, as in the photo. But there are other original ideas for feathered babies.

Chicken feeder

Option 3. Wooden feeder with drawings

The option below is very convenient, because you do not need to constantly monitor the amount of feed and add it. This is one of the varieties of bunker feeder. See below for how to make such a feeder. The process is not complicated. The main thing is to follow the recommendations and sequence of work.

To build a wooden feeder you will need the following building materials and equipment:

- high-strength plywood (pieces can be used) or wooden sheet;

- drills and electric drill;

- hand saw or electric jigsaw;

- loops (pair);

- sandpaper;

- screwdriver;

- tape measure and marker.

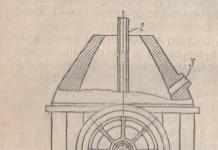

Drawing of a wooden version

- After you have decided on the drawing, you need to transfer the necessary markings of future parts onto the tree. In our case, the element parameters are as follows:

- bottom – 290 x 170 mm;

- side walls (2 pcs.) – height 400 mm, while the width of the upper edge is 240 mm, and the bottom – 290 mm;

- front wall (rectangle - 2 pcs.) - 280 x 290 mm and 700 x 290 mm;

- rear wall – 400 x 290 mm;

- cover – 260 x 290 mm.

- It is necessary to cut out the parts according to the drawn markings.

- Using an electric drill, make holes to secure with fasteners.

- The entire surface must be sanded. This way you will make the feeder not only smooth, but also safe for the birds themselves.

- Using screws, you need to assemble the entire structure together. To make the fastenings secure, you can use a screwdriver. When assembling, you need to position the walls and attach them at an angle of 15 degrees.

- Using the hinges, install the cover to the side walls.

Wooden feeder

- After this, the feeder should be treated with a special agent with an antiseptic effect.

It is worth refraining from using paint and varnish materials because it may repel birds.

Important: The whole building has impressive dimensions, but at the same time very comfortable. With such a feeder, the grain will always be dry and clean. We can say that this option is an automatic feeder, because dry food will be fed gradually. The disadvantages include high labor costs. But the result will please you.

Option 4. Hopper-type feeder made from a plastic bucket

Such a feeder also belongs to the category of automatic ones, because you almost do not have to intervene in the process of feeding your farm. It's pretty easy to make, so don't pay big bucks at the store and try to make it yourself.

Hopper feeder

Consumables for construction:

- plastic bucket;

- animal bowl divided into sections.

Sectional bowl

- Initially, you need to make holes in the bottom of the bucket for the feed to enter.

- Using self-tapping screws, you need to attach the bucket to the bowl.

- Fill the bucket with dry food to the top and close the lid.

Finished feeder from a plastic bucket

The undeniable advantage of this option is its versatility and simplicity. This feeder can be installed anywhere. You can even hang it up. The grain will come as it is eaten. So that the excess will not spill out of the feeder, which ensures cleanliness in the yard or chicken coop. The feed supply is provided by pressure, which is formed from its own weight.

Hopper feeder for small chicks

Option 5. Pipe feeders (PVC)

This type of product is quite simple to manufacture. And the cost of such construction is minimal. PVC pipes are very common and their price is low, so everyone can afford it. But, despite the simplicity, there are several design options for such feeders. Which one should you choose? Assess your actual conditions for keeping birds and their numbers.

Method 1. With the creation of cutouts.

For such a product you will need:

- PVC pipes (2 pcs.) 400 and 600 mm long;

- plug (2 pcs.);

- elbow for connection.

Plastic pipe construction with cutouts

The long pipe will be horizontal. Its function is to directly feed the birds. The short plastic pipe will be installed in a vertical position. It will feed feed into a horizontal pipe.

First you need to make holes in the long pipe. Often one large hole is made so that the chickens have full access to the feed.

- Take a pipe 600 mm long and mark the holes. Each has a diameter of 70 mm. Maintain a distance of 7 cm between them. After this, you need to make holes in accordance with the markings. If the farm is large, then you can place holes on both sides of the pipe. This way, more birds can approach at one time. Also, the holes may not be round, but oval.

- The plug must be placed on one end of the pipe.

- On the reverse side you need to insert the pipe into the connecting elbow. And after that another pipe is inserted into the elbow.

Feeder inside the chicken coop

The feeder needs to be secured in the house so that it does not tip over. It is better to place fasteners in several places.

You need to install another plug on top after filling the feed. This will prevent debris and dirt from getting into the grain. This design allows backfilling to be done every couple of days.

Method 2. Using a tee.

In this case, you need to stock up on the following materials:

- plastic pipe (3 pcs.) 700, 200 and 100 mm long;

- plugs (2 pcs.);

- tee at 45 degrees.

PVC feeder with tee

- Place a plug on a 200 mm pipe. This pipe will be the bottom of the entire structure.

- Place a tee on the other side of the same pipe. The side knee should face up.

- The 100 mm pipe must be inserted into the third elbow of the installed tee.

- The longest pipe is installed in the free elbow of the tee.

The feeder is assembled according to the drawing

Drawing of a feeder with a tee

As with the option described above, you need to constantly cover the top of the feeder to ensure cleanliness of food for the chickens.

Any household requires investment: physical and financial. When raising chickens, the main concern is feeding the birds. The factory products offered are not cheap, but are easy to use. It is not difficult to make a chicken feeder with your own hands, and you can use various materials for this.

A well-designed feeder saves the time and effort of the poultry owner, which is especially important when keeping a large flock. A properly made container for drinking and feed helps improve the productivity of chickens, and you can also take care of the health of birds, since various pathogens can enter the animals’ bodies through contaminated food and water.

What kind of chicken feeder is there?

A container for feeding birds can be made from any material and given almost any shape and size. But the convenience of feeding poultry depends on the feed supply process, since it is more convenient to pour food to the chickens once a day than to run to the poultry house several times a day (Figure 1).

According to the method of serving food, containers for dry and wet food are divided into the following types:

- Tray: They are excellent for feeding chickens, as the containers are made with sides that prevent the feed from spilling.

- Grooved models with additional stops: The inside of the container is equipped with dividing partitions that will serve as compartments for different types of feed. Such models can be made both floor-mounted and wall-mounted.

- Bunker: This type of feeder is intended for dry feed and grain. They are intended to be refilled infrequently with food that will remain dry and clean and can be dispensed.

Figure 1. Types of containers (from left to right): tray, trough and hopper

Figure 1. Types of containers (from left to right): tray, trough and hopper Homemade automatic feeders only look complex in design. In fact, it is quite possible to make such containers for chickens with your own hands, if you know how to do it correctly. We will cover all the necessary nuances in the following sections.

Requirements for structures

There are few requirements for chicken feeders, which are mainly aimed at economical use of feed and ease of use (Figure 2).

The main requirements for feed containers are the following:

- Rational use of feed: the entire structure must be such that chickens cannot climb into it and scatter food or spoil it with their waste products. This effect can be achieved using various elements of the feeder (sides, turntables, jumpers, meshes), which will protect the bulk of the grain inside the container.

- Ease of daily use: The structure must be freely cleaned and filled with food. In addition, it should be comfortable for birds, for example, it should be installed at the optimal height relative to the floor level.

- Optimal feeder sizes and feed volume: The volume of the container should be enough for at least one daily feeding of the birds, and the dimensions of the structure are selected so that all the livestock in the poultry house have free access to food.

- Feasibility of use: Each type of structure made from a specific material should be used for a specific type of food. For example, it is better to use metal feeders for dry grain mixtures, since upon contact with certain liquids, the metal can begin to produce components harmful to the health of birds.

- Safety: the strength and stability of the structure also plays an important role. The material for the feeder must be durable and not deform during use, and also be non-toxic for birds. The structure must be stable upon contact and not tip over or fall on its side. You can use wooden, polypropylene or metal models. The main thing is that they do not have sharp corners or parts that could damage the bird.

Figure 2. All containers must be functional and absolutely safe for birds

Figure 2. All containers must be functional and absolutely safe for birds Making a feeder with your own hands is quite simple. To do this, it is enough to decide on its type (floor-mounted, suspended, bunker, etc.), select a suitable diagram or drawing for manufacturing, and also prepare tools and materials for the work.

Types of materials used

Structures for bird feed can be made from various materials. When choosing material for a feeder, you need to consider what type of food it is intended for (Figure 3).

Note: In fact, the container can be made from any available material: from scraps of plywood, wood, sewer or plastic pipes.

The differences in materials are:

- Wooden: the most common type of design, which is intended for pouring dry food. The wood is best suited for grain, feed and mineral supplements.

- Plastic: Feeders made from this material are ideal for wet food, which is then easier to wash in a container. Steel structures are also suitable, but ferrous metal is susceptible to corrosion when exposed to moisture, and stainless steel is not a cheap material.

- Metal: The use of metal would be appropriate when making grass bunkers. In this case, a V-shaped container is made with a blank back wall made of tin, and the front part is covered with rods or mesh.

Figure 3. The feeder can be made from any available materials: wood, metal or plastic

Figure 3. The feeder can be made from any available materials: wood, metal or plastic Simple models can also be made from scraps of PVC pipes, especially since this material is very convenient and practical to use.

Feeder options

There are a wide variety of chicken feeders on the market for agricultural implements, but you can save money and make a similar one with your own hands.

You can use almost all materials that are at hand (boxes, boards, pipes, plastic bottles, etc.). The main condition for the manufacture of structures for chicken feed is safety for the health of the birds. Next, we will consider possible options for feeders that can be installed on paddocks and in cages.

Bunker made from pieces of wood

The bunker feeder option for chickens is suitable for those who do not have the opportunity to frequently add feed to the container. The operating principle of this model is based on dosed distribution of food to the birds as they eat the previous portion. It is not difficult to make such a container with your own hands (Figure 4).

The beginning of the manufacturing process of such a structure is at the stage of preparing the necessary materials and equipment:

- Wood or a piece of strong, thick plywood.

- Electric drill, set of drills.

- Saw.

- Sandpaper.

- A couple of loops.

- Pencil.

- Screwdriver.

- Roulette.

Making a bunker feeder from wood begins with drawing up a working drawing.

After which the dimensions from the diagram are transferred to the wood and all the elements of the required dimensions are drawn:

- Bottom 29x17 cm.

- Two side walls are 40 cm high, with an upper edge of 24 and a lower edge of 29 centimeters.

- Top cover 26x29 cm.

- Two rectangles for the front wall 70x29 and 28x29 cm.

- Back wall 40x29cm.

All elements of a wooden feeder for laying hens can be assembled in the following sequence:

- After cutting out all the parts of the bunker feeder, we make holes for the screws in the required places using an electric drill.

- We sand all surfaces to make them smooth and safe for birds.

- We assemble all the elements into a single structure and fasten them with screws. If you need to achieve maximum density, then you can use a clamp. It is also worth fixing the front and back walls at an angle of 15 degrees.

- Using hinges, we mount the cover to the rear parts of the side walls.

Figure 4. Drawing and photo for making a bunker model

Figure 4. Drawing and photo for making a bunker model At the final stage, you need to treat the product with an antiseptic. It is prohibited to use varnishes and paints on the surfaces of the feeder, as they can be toxic to chickens.

In the form of a trough

A trough-shaped feeder is the simplest option, which is suitable for owners of a large number of birds who have a canopy for walking in case of precipitation (Figure 5).

Note: To create such a design you will need a hammer, thick boards or plywood, screws and nails, a saw, a pencil, a ruler and a tape measure.

Making a chicken feeder in the form of a trough with your own hands begins with preparing the necessary elements according to a drawing drawn up in advance.

- Bottom - 15x100 cm;

- Two side walls - 8x100 cm;

- One beam - 2x3100 cm;

- Small end walls 15 cm wide and a height corresponding to the long side walls and the thickness of the bottom.

Figure 5. A simple trough model can be easily made from scrap materials

Figure 5. A simple trough model can be easily made from scrap materials The assembly of the feeder parts should be carried out after cutting out all the necessary structural elements. All elements can be connected to each other using self-tapping screws or nails. It is recommended not to leave gaps, as food may spill out through them. The bottom of the feeder should be heavy and thick enough to prevent birds from knocking over the trough inside the cage or on the run.

Bunk

This type of feeder is most often filled with dry food, but you can also fill it with various mash. Due to the presence of a second tier, this option is suitable for a small poultry house, as it saves free space (Figure 6).

To manufacture the structure, the following materials and tools are required:

- Wooden bars.

- Boards.

- Self-tapping screws.

- Loops.

- Saw.

- Screwdriver.

- Pencil.

- Roulette.

Figure 6. Two-tier model helps save space in the poultry house

Figure 6. Two-tier model helps save space in the poultry house Making a two-tier wooden chicken feeder begins with preparing the necessary parts. The main element in this design will be the lower tier with a height of 25 cm and a width of 26 centimeters. The length of the container will depend on the number of birds. Next, you should make special grooves into which the damper will be inserted.

The second tier of the device will be a small volume trough with a side height of 10 cm. The second tier must be installed on the ends of the first, and then attached with hinges.

Detailed instructions for making a feeder from plastic pipes are given in the video.

To effectively provide food for poultry, farmers use special feeders. Let's consider what feeders for chickens should be, their varieties, and also how to make various devices for feeding young animals and adults.

Basic requirements for chicken feeders

The following is required from chicken feeders:

- Provide chickens with food. They must contain a daily portion of food and provide each bird with quick access to food.

- Convenience and ease of maintenance. The feeder should be easy to fill with food, move, clean and wash.

- Ensure cleanliness and dryness. It is necessary to take closed devices so that precipitation and debris cannot get inside. It is optimal if the design does not allow birds to climb into it with their feet, scatter and dirty food.

- Safety. The feeder is made from bird-safe materials. There should be no sharp protrusions or protruding nails that could cause injury or places where the bird could get stuck.

- Sustainability. The structure must stand firmly or be securely fastened so that laying hens cannot knock it over.

Did you know? Most chicken feeders sold are red or yellow. These colors attract babies well and help increase food intake. It should be noted that there should be a sharp contrast in color between the gender and color of the feeder and drinker.

Types of chicken feeders

Feeders are produced in different designs and using different raw materials.

Depending on the type of feed

In different devices, feed may be supplied in a different way from others.

Bunker

Closed type, keeping the feed clean. Only dry food is poured into it. Its design features allow you to immediately place the daily dose of food into it - food will flow into the trays as the bird consumes it.

Grooved

The tray of this design has a spinner or a removable grid-limiter. This feeder is equipped with several sections for food.

Tray

It is a shallow container with sides that prevent food from scattering. Typically used to feed chickens.

Important! Such trays are installed at the rate of 10–15 cm for each laying hen and 5 cm for each chicken. The circular tray provides only 2.5 cm per head.

Depending on the material used

Feeders are divided according to the raw materials used for their production:

- Wooden. They are optimal for dry food and supplements.

- Metal. Good for moisture-rich foods.

- Plastic. They are used in the same way as iron devices.

- Made of mesh or thin rods. They are usually filled with herbal mass.

Depending on location

The feeder can be located in different places of the chicken coop and can be:

- Floor-standing. It is located directly on the floor of the chicken coop and must have good stability so that it does not fall over. At the same time, the bird has the opportunity to climb with its feet into the food and bring in garbage.

- Wall. Reliably attached to a wall or other stable structure (partitions, fences). The bird will not be able to climb into the hanging devices with its legs. Such feeders should be mounted at a level that is comfortable for food consumption.

- Hanging. They are attached at the height of the chickens' backs, and they are inaccessible for climbing.

How to make a chicken feeder with your own hands

You can buy an industrial product, or you can make it yourself. There are ways to make these devices even from waste material such as plastic bottles.

Bunker

This type of homemade feeder is made from PVC pipe.

For this you need to have:

- sewer PVC pipe of the required diameter and length to the height of the chicken coop - 1 pc.;

- tee for PVC pipes - 1 pc.;

- thick wire;

- measuring meter;

- marker;

- jigsaw

For this homemade device, take a PVC pipe of 7–6 cm for ordinary chickens, and 11 cm for broilers.

Did you know? Laying hens constantly need calcium in their bodies, since a lot of this element is spent on the formation of eggshells. They lay eggs only in the light.

When making it, you need to do the following:

- Cut off the PVC pipe with a jigsaw or grinder - you need a piece the size of the floor to the ceiling of the chicken coop minus 30 cm. Cut off the piece of pipe where there is no thread.

- At the top of the pipe, at a distance of about 20 cm from the cut, burn holes on the sides for the wire that will secure the pipe.

- Connect the bottom of the pipe with a thread to a tee.

- Secure the structure with wire to the hook. There should be 20 cm between the bottom of the device and the floor.

- The pipe is filled with food from above. It lingers in the bends of the tee, and when the birds eat away part of it, under its own weight the food again enters the tee.

Video: how to make a bunker feeder for chickens with your own hands

A simple option from a plastic bottle

Very little time and budget will be spent on a feeder for young animals from a 5 liter plastic bottle.

To do this you need to stock up on the following:

- 5 l plastic bottle - 1 pc.;

- a piece of wire;

- liter glass jar with a lid - 1 pc.;

- scissors or a knife;

- marker.

Did you know? In Ancient Rus', chickens appeared aroundIV century BC. They were brought by traders from Greece.

During the manufacturing process you need to perform the following steps:

- Cut off the top of the bottle where the narrowing begins, but not all the way - leave 5 cm of plastic.

- Mark with a marker and cut holes with a diameter of 3 cm at a distance of 2 cm from each other in the bottom of the bottle. A chicken's head will easily fit into such holes, but its body will not be able to squeeze through. It is necessary that the holes are smooth, without sharp edges.

- To prevent the chickens from knocking over the feeder, you need to place a liter jar of water or sand inside it. If the bottom is uneven, then first you need to pour 1 cm of food into a plastic bottle for a more stable position of the weight jar.

- Make holes in the lid at the edge, and under it, on the wall of the container. They should be opposite the uncut part. Thread a wire through them to close the lid.

- Pour food up to the holes, close the bottle with a lid and secure with wire.

Video: DIY chicken feeder made from a plastic bottle

tray type made of wood

You can make a wooden device in the shape of a tray.

To do this you need to have the following:

- a wooden board with a smooth surface 12–15 cm wide and 1 m long for the bottom of the tray;

- 2 narrow long boards of wood with a smooth surface, no more than 5 cm wide and 1 m long - for the sides along the feeder;

- 2 small wooden planks for the cross sides, 15–20 cm in height (the width must exactly match the width of the product);

- a narrow smooth board 3–4 cm wide and length corresponding to the size of the tray. It will be used as a handle for moving and will serve as a barrier for chickens when they try to climb into the feeder with their paws;

- metal nails and screws - 20–30 pcs.;

- sandpaper - at least 20 cm;

- marker;

- ruler 1 m for measurements;

- hammer;

- plane;

- saw.

Important! Any feed equipment must be carefully looked after. Routine cleaning should be carried out regularly. Remains of wet food (mash) should be removed in a timely manner so that the food does not become acidic. Feeders are washed as needed, as it depends on the type of food.

Manufacturing instructions:

- Process the boards with a planer until a smooth surface is obtained.

- Take the necessary measurements with a ruler and mark the corresponding dimensions on the boards. Using a saw, cut out the necessary parts.

- Use a pencil to outline paired parts - numbers 1, 2 are applied.

- Attach the end sides to the bottom with nails and screws, positioning them so that they are 2 cm below the bottom level. Such small protrusions will be the legs of the product.

- Then grout using sandpaper. Then use it to remove burrs on the board intended for transfer.

- Place the handle along the product along the transverse sides, and then secure it with nails (screws).

- If you plan to use the feeder also for wet mash, it is filled with water and allowed to swell for 6–7 days. The swollen wooden surface will smooth out all the gaps in the joints, and the product will not leak.

Video: DIY wooden tray feeder for chickens

Automatic

It involves the spontaneous pouring of food into the food container from the storage container. You can find many different models of such devices, but the most popular is the automatic feeder made of wood, equipped with a pedal.

She needs the following:

- wooden boards;

- sheets of compacted plywood;

- small blocks of wood;

- nails, bolts, screws;

- loops - 2 pcs.;

- paper for patterns;

- electric drill;

- drill;

- sandpaper;

- saw (hand);

- marker;

- roulette.

The dimensions of the product depend on the number of birds, the size and design of the chicken coop itself.

Important!Each workpiece should be sanded down with sandpaper to avoid any unevenness that could cause injury to birds. You cannot apply varnishes and paints so as not to harm the health of the chickens.

Manufacturing of standard model:

- Draw and cut out 10 blanks for the feeder. Cover for the tray (26x29 cm), 2 panels on the sides (height 40 cm, top edge 26 cm, bottom edge 29 cm), on which triangles are cut out so that the bottom is wider and protrudes slightly, rectangular bottom 29x17 cm, detail walls at the back (41x29 cm), 2 rectangular parts for the wall at the front (28x29 cm and 7x29 cm), a lid for closing on top and a pedal according to the parameters.

- Cut the wooden beams into six pieces. The 2 beams to which the pedal will be fixed will be longer in width of the box and pedal. Cut the other 2 medium bars to the size of the lid on top of the tray. The third pair is needed to connect the lifting mechanical device.

- Use a saw to cut the plywood blanks according to the patterns.

- Connect all sides with screws. It should be noted that the rear part should be placed at an angle of 15° so that the feed does not stagnate in the corner, but passes freely further. To ensure a better fit, a clamp is used.

- Secure the lid on top. This requires 2 loops.

- The pedal and bars should be assembled. Medium-sized ones are attached on the sides to the lid. Two holes are drilled at the other end of the bars. The size of one of them must be slightly larger than the diameter of the bolt, and also be located closer to the end of the bar. It should correspond to a hole in the side wall of the structure. It is necessary to embed the bolt so that the block can move in the plane of the wall.

- In the same way, fix the longest block to the pedal of the structure. The hole that will connect the block to the wall should be placed at 1/5 of the total length of the block. The second hole must be drilled closer to the end of the block.

- Attach short bars to the two free holes located on each side. This fastening must be rigid for the pedal to function, that is, you need to press the pedal and check that the lid on top opens. If this does not happen, the bolt tension should be adjusted.

- Treat the resulting structure with antiseptics.

Video: how to make an automatic chicken feeder with your own hands

Installing feeders in the chicken coop

These devices should be installed at the rate of 1 piece per 20 heads. It is advisable that access is only for the head. The structure is installed securely so that chickens cannot turn it over and do not paddle in it with their paws, as this will contribute to food contamination and the occurrence of infections. They should be located so that the impact of the external environment is minimal, that is, indoors or under a canopy.

Usually in a chicken coop, feed containers are placed closer to the door so that the chickens have an important reason to return home from free range. When installed, the edges of the feeders should be at the level of the bird's back. The feeding front for chickens is about 15 cm.

During the disinfection of the chicken coop, which is carried out 2 times a year, the feeders and drinkers must be treated with disinfectants. Experts recommend to arrange a general cleaning of equipment for feeding and watering birds with detergents at least 1 time per month.

Basic feeding rules

- Chicken feed should contain enough calcium. To do this, food includes mineral supplements (shells, chalk, meat and bone meal) and fermented milk products (whey, cottage cheese, kefir).

- Chickens should consume three types of food - dry, wet, combined.

- During the cold period and during molting, nutrition should be enhanced with vitamin and mineral supplements and sprouted grains should be given.

- Laying hens are fed 3-4 times a day.

- The main diet of poultry consists of grain crops (at least 60%). These are wheat, corn, millet, buckwheat and others. The rest of the diet consists of vegetables, green herbs, vitamin and mineral supplements.

- Follow feeding hygiene rules.

- The most convenient in terms of caring for chickens is commercial feed, but it is also the most expensive.

So, you can make a feeder for hens or chicks yourself. Many DIY projects do not require any special skills. By choosing the required type of feeder, you can achieve economical food consumption according to all standards and provide food to the inhabitants of the chicken coop in a timely manner.

So, you can make a feeder for hens or chicks yourself. Many DIY projects do not require any special skills. By choosing the required type of feeder, you can achieve economical food consumption according to all standards and provide food to the inhabitants of the chicken coop in a timely manner. Chickens are the most popular backyard bird. They are prized for their good performance at low cost. And to keep this bird, you need to take care not only of the poultry house, but also of a suitable feeding method. You can read what you need to create a chicken feeder with your own hands in this article.

Vertical feeders made of plastic pipes

There are no strict requirements for chicken feeders, but some tips will help make bird care easier and save money on feed.

The chicken is not very smart; it can easily scatter all the grain. To avoid such a scenario, simple systems are provided to protect the contents: high sides, turntables or other similar devices. It is important to maintain a balance so that, on the one hand, the chickens cannot trample in the feed, and on the other, they have unhindered access to it.

Cage feeder box

Like any thing, chicken feeders require regular maintenance: remove old feed, clean the surface from dirt, disinfection will sometimes be required.

Taking these circumstances into account, it is necessary to make a mobile structure with convenient access to all surfaces. At best, it should be easy to understand.

Dimensions should provide the entire poultry population with a sufficient amount of feed. When installing a tray structure, one adult bird should have at least 10 cm in length (5 cm is enough for chicks). If you have 20 chickens in your yard, then the length of a double-sided tray-type feeder should be at least 1 meter.

If the tray has a circular shape, then a 25 cm perimeter is sufficient. For a population of 20 chickens, the minimum circumference of a circular tray is 50 cm.

It is important that the size of the chicken feeder allows all birds to have simultaneous access to food. Thanks to this, each chicken will receive its portion and the strong ones will not drive away the weak ones.

Popular designs

To make a chicken feeder, you don't need any special skills or tools. The material at hand is suitable for the job. The finished product will meet all requirements and is convenient to use. Consider the most popular designs.

Bunker

A farmer's time is valuable, which is why automatic feeders are common. Such systems can be found in professional stores, but making them yourself is not difficult.

Making a bunker feeder

You should have at hand:

- Large plastic bucket with lid.

- A flat bowl with sections or a bowl. The diameter of the bowl should be larger than the diameter of the bucket.

- Using a utility knife, make holes in the bottom. Using screws, the bowl is secured to the bottom of the hopper. The bunker feeder for chickens is ready.

- Having poured the required amount of food into the bucket, it scatters itself in the required volume throughout the bowl. Chickens will not be able to get into the bunker itself, thanks to the closed lid. Another advantage is mobility.

Ready-made bunker feeder from a bucket

Hopper feeders can be made from plywood. You will need to cut three 0.9 meter high walls and nail them together into a box until the front wall is needed. The bottom should be longer than the side walls; the required amount of feed will be poured onto it. In order for the grain to flow freely, a piece of plywood is secured to the bottom of the box at an angle of 12°. If you plan to dispense granulated feed, then the angle should be at least 20°.

To limit the access of chickens to the feeder itself, high sides are installed: side 12 cm, front 6 cm. Another option would be a grid with large cells. This will prevent the bird from getting into the food and throwing it around.

Plywood bunker feeder

Finally, the front wall is attached. The hopper feeder is placed in the chicken coop or hung on the wall, which saves space. Large volume will allow you to add grain less often.

The only drawback is the material of manufacture - it is difficult to clean.

Wooden box feeder

In many private farmsteads, chickens are given food in old troughs, basins or boxes. Such feeders do not protect food from debris and scattering by birds.

To save feed, free space in the yard and the farmer’s time, you can make a two-story box feeder. The lower part holds a week's supply of dry food, and the upper part is designed for daily feeding with mash and other wet food (food waste, mashed potatoes, various additives).

The chicken feeder is made of boards and beams. The main part of the structure will be a box 26 cm wide and 25 cm high. The length of the box depends on the number of chickens. The side edges are made 10 cm higher than the main sides, and grooves are cut into them for the plywood flap.

The second part resembles a lid for a box. Its width corresponds to the dimensions of the lower level. A board 10 cm high is attached in the middle along the entire length of the upper box. Make small sides along the entire perimeter, the height depends on the required depth of the feeder for wet food. To prevent moisture from penetrating to the lower level, old linoleum or plastic film is laid on the bottom. The structure of the second box is installed on the ends of the first.

Such a feeder will not allow the bird to scatter the grain with its paws. A metal mesh is used to protect the mash.

- Before adding dry food, the second level is removed. The grain is poured immediately for one or two weeks.

- The upper part is installed and filled with wet food. Its volume is calculated for a single feeding or daily ration.

- At night, the lower compartment is closed with a flap to protect the food from rodents.

- In summer, the feeder can be left outdoors. In winter, both compartments are filled with dry food.

From plastic pipes

To make a feeder from a plastic pipe, you will need a hacksaw, a sewer pipe (Ø250 mm), plugs and a bend (elbow).

Vertical feeder made of plastic pipes

The minimum pipe length is 1 meter. It is divided into two parts of 0.3 and 0.7 m. They are connected using a bend, and the ends are closed with plugs. In a long pipe, make holes with a diameter of 7 cm on both sides, as shown in the photo.

The entire structure is attached to the wall. The grain is poured into a 30 cm segment and, under the influence of gravity, scatters over its entire length. A lid must be provided to protect the food from rodents.

Such a feeder will provide food for the entire livestock and will help to avoid overconsumption due to the birds’ habit of scattering grain.

Horizontal feeder made of plastic pipes

A simplified version is made with a small number of chickens from a plastic pipe Ø110 mm. Recommended length 0.7 meters. An outlet and a half outlet are attached to the bottom.

The principle of operation is the same - the filled grain is evenly distributed throughout the feeder under the influence of gravity. If necessary, several feeders are made. A visual aid about the construction of feeders and their use in a private backyard is in the video.

From this video you can see the design of plastic pipe feeders and the main advantage through the eyes of a farmer. Another design option for a bunker feeder with step-by-step manufacturing.

A bunker feeder is any device for feeding animals that has a container for storing food. It is easy to use for any farm animals. It can be filled with feed, which will be enough for a day if calculated correctly, and this will save the farmer’s time. Such a feeder has many other advantages, which we will talk about later, and also learn how to build such a device with your own hands.

Why is it better to have a bunker feeder on the farm?

Most often, inexperienced farmers resort to two types of feeding poultry - from a bowl or from the floor. But both options have more disadvantages than advantages. For example, chickens will trample in a bowl and dirt will get into the food, or they will simply turn it over and not be able to get food.

Sprinkling food on the floor is also not the best option, because the bird will be able to peck large grains, but small food will be mixed with dirt, trampled into crevices and may not even notice.

Therefore, the best option is to use a bunker container.

Important! The bunker can be filled once a day. Such a system is suitable, for example, for broilers:They eat constantly, and only such a food container can supply food uninterruptedly.

This feeder has the following advantages:

- supplies food as the chickens eat it;

- protected from birds carrying dirt and debris into it;

- can accommodate a daily dose of nutrition;

- provides free access to food at any time;

- It’s convenient to add food and clean it when necessary.

What should be the requirements for the parameters of the feeder?

There are several basic requirements for any poultry feeder:

- Protecting the container from dirt and excrement - special sides, turntables and shelters are used for this.

- Easy to maintain - food containers need to be washed and cleaned regularly, regardless of whether animals have brought dirt into them. In addition, food must be poured there at least once a day. To spend less time on this, farmers are advised to build or buy mobile, lightweight feeders from universal and quick-to-clean materials (plywood and plastic).

- Size - it is important to provide the birds with such feeders that all individuals of the livestock can have access to them at the same time, otherwise the weaker ones will be oppressed. In the tray there should be at least 10 cm per head, and in circular trays there should be up to 3 cm per individual. These figures should be halved for chickens. You don't have to make one huge power station, just make several smaller ones.

Homemade feeder made from plastic containers

It’s easiest to make a feeder from such materials - even if you don’t have a large bottle, bucket or PVC pipe in your house, buying them won’t be too expensive. Such materials are easy to clean, and the food supply system and storage container itself are quite simple to maintain.

Let's look at two options for feeders - from a bucket and PVC pipe.

Important! Only dry food can be stored in bunker feeders. If you put something wet in there, it can soften, heat up and stick to the walls.

Tools and materials

For a bucket feeder you will need:

- plastic bucket (for example, for water-based paint) 10-15 l;

- the tray is twice as large in diameter as the bucket;

- screwdriver;

- bolt.

For a vertical feeder made of PVC pipe you will need:

- pipes (take the amount you need based on one pipe for 1-2 individuals);

- a lid with a diameter like a pipe to cover it from above;

- coupling with 1 or more branches;

- brackets.

We make a feeder from a plastic container:

- Cut out windows with a diameter of 30-40 mm near the bottom of the bucket in a circle.

- Place the bucket in the tray and make a hole exactly in the middle in both objects.

- Secure these objects with a bolt.

- Pour food into the bucket and cover with a lid.

Pipe feeder:

- Place a branch coupling on the pipe.

- Attach the pipe vertically to the grate or post using brackets.

- Pour food into the pipe and cover the top with a lid to prevent dust from getting in there.

- It is better to take a pipe half the size of your height - this will make the process of filling the feed easier.

How to make a bunker feeder from wood

For the manufacture of such a power supply, sheet wood - plywood or chipboard - is suitable.

First make a drawing like the picture below. Use these dimensions as a starting point, or you can substitute your own. After creating the drawings, all data is transferred to the wooden material.

Basic tips for making an object:

- It will be possible to cut smoother and more accurately with a jigsaw;

- The lid is attached solely to the hinges so that it can be opened and closed.

Did you know? Chickens have a good memory-if one individual gets lost and does not return to the barn, then it will be remembered for many more days. And upon her return, even after a couple of days, she will be accepted back.

Tools and materials

You will need:

- plywood;

- jigsaw;

- drill;

- bolts;

- slats;

- sandpaper;

- hinges for the lid.

Hopper feeder for chickens. Review: video

Step-by-step manufacturing instructions

- Based on the size of the feeder in your drawings, we cut out parts of the object from plywood. If you follow the diagram that we attached, then we will need to cut out: two side walls, the front and back walls, the side and the bottom.

- After you have cut out all the parts from the drawings, you need to sand the edges with fine-grained sandpaper.

- Make holes with a drill in the places where you will fasten the parts of the structure. It is best to fasten the connecting joints with slats - this will strengthen the feeder.

- Assemble the structure by screwing its parts with bolts and screws.

- Attach the hinged lid to the top.

Improving the feeder with a pedal with a dispenser

For the wooden bunker feeding system, you need to separately build a special pedal and a lid for the tray with food.

It works like this: the chicken stands on the pedal and the lid rises. As long as the bird is standing on the pedal, it can eat.

The design is only suitable for a small number of chickens. In addition, it is important to consider that the pedal must weigh less than the chicken so that it can lower it.

Tools and materials

You will need:

- plywood;

- bars;

- bolts;

- 2 loops;

- drill;

- jigsaw or saw.

Did you know? The yolk inside a chicken egg is always placed at an equal distance from all sides of the shell.

Step-by-step manufacturing instructions

- When creating such an automated mechanism, take into account the parameters of your feeder and take measurements yourself for the necessary parts.

- Cut a lid from plywood to the size of the feed tray and a slightly larger rectangle that will be the pedal.

- Divide the bars into 6 parts: 2 long ones for the pedals, 2 shorter ones for the lid, 2 for fastening the previous 4.

- We take plywood, which will become a lid for the tray with food, put shorter bars on it along the edges, screw each of them with a drill.

- At the free ends of the block we make 2 holes at a distance of 5 cm - the hole closer to the end of the block should be slightly larger than the bolt. We also make holes on the side covers of the feeder and screw our structure to them. It should rise and fall freely onto the feed tray.

- We attach longer bars to the pedal using the same principle. To attach the free ends to the walls, make holes at a distance of 1/5 from the height of the block. And at the very end below, make another hole. Thus, you will have two holes on the block, placed vertically - the top one for attaching to the wall, and the bottom one for fastening with a small block.

- Now we connect the bars from the pedal and the lid with small bars. Tighten the bolts as firmly as possible so that the mount does not wobble.

- Check the operation of the structure - when you press the pedal, the lid should rise. If this does not happen, try loosening the bolts.

The bunker feeding system for poultry is very convenient to maintain and organize food. It does not need to be filled every hour, it is easy to clean and lasts a long time. And if you make such a feeder with your own hands and treat it with an antiseptic, then it will be able to feed your birds for more than one year.

Was this article helpful?

Thank you for your opinion!

Write in the comments what questions you have not received an answer to, we will definitely respond!

6

once already

helped