Living in your own home has many more advantages than even the most luxurious apartment. A private home is a place where you are free to do whatever you want. Here you will not be disturbed by noisy neighbors who want to do repairs early in the morning or late at night. Here you do not run the risk of being flooded or experiencing the inconvenience that apartment residents face. Many people are accustomed to believing that buying a plot of land, much less building a house on it, costs fabulous money. However, with the development of modern technologies in construction, the cheapest technology for building a house has become several times more accessible. Now we will look at the main question: where to start, and most importantly, what to build the cheapest house from?

Preparatory stage

The first point that needs to be determined initially is the functionality of the house. What is it for?

If this is a country cottage for seasonal living, then only materials are needed,

if this is a full-fledged home for permanent residence, then completely different.

To decide what kind of house will be, you should thoroughly study the climate and weather conditions of the region where construction is planned. After all, the choice of building materials directly depends on the temperature conditions throughout the year. For regular living, a house must be constantly heated during the cold season, which entails certain financial costs. Therefore, when choosing a material for a building, you should be guided by thermophysical properties: thermal conductivity and heat capacity, as well as shrinkage.

Each climatic region has its own temperature regime, wind speed and protection class based on the level of heat-protective properties. Therefore, when choosing a material and calculating the thickness of the walls, you need to be guided by two main parameters: the coefficient of thermal resistance and thermal conductivity.

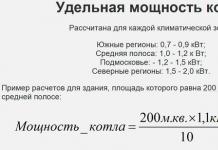

For each region, its own specially calculated thermal resistance index of the CTS is used. In order to obtain clarity about the upcoming heating costs, it is necessary to calculate the CTC of the future design. To do this, the width (δ) of the wall is divided by the thermal conductivity coefficient (λ), which is indicated in the technical characteristics of the building material R = δ / λ. The calculated value of heat transfer resistance must correspond to the standard value.

As an example, consider the use of cellular concrete, which has a thermal conductivity coefficient of 0.12 W/m* ºС. Let's take a block 0.3 meters thick and calculate: R = 0.3/ 0.12 = 2.5 W/m2 * ºС. This figure is below the norm and is only suitable for construction in the southern regions of Russia. A block 0.4 meters wide gives a heat transfer resistance of 0.4/0.12 = 3.3 W/m2 * ºС, which is slightly higher than the standard value and can be used in the construction of buildings in Moscow and St. Petersburg. The calculation is relevant only when laying blocks on glue.

The wall thickness corresponding to the best generally accepted standards in terms of energy efficiency can be determined using the same formula, where it will be equal to the product of the heat transfer resistance value and the thermal conductivity coefficient δ = λ x R.

It follows from this that in order to obtain the standard value of resistance λ = 3.2, the thickness of a wall made of solid coniferous wood (pine, spruce) will be equal to 0.18 x 3.2 = 0.576 m, of brick 0.81 x 3.2 = 2.592 m, and from concrete 2.04 x 3.2 = 6.528 m. At the same time, mineral wool insulation with a thickness of 140-150 mm corresponds to the standard: 0.045 x 3.2 = 0.14 m.

Therefore, when choosing a material and determining the thickness of the structure, heat transfer resistance and thermal conductivity should be taken into account.

Coefficient of thermal conductivity,

specific heat

and the change in linear dimensions is different for each material.

In addition, when choosing materials for building an inexpensive house, you need to study the market for building materials typical for a given region. Delivery of materials, as a rule, takes up a significant share of their cost.

Now you need to decide on the size of your future home. For example, do you want to build a one-story house inexpensively or will the house have more floors? What will be the area of the house in relation to the area of your plot?

You can calculate the area of your plot online.

Windows of standard sizes;

Practical layout without frills;

Simple roof;

Available building materials;

Flat small fireplace;

You should also take into account one important nuance: if you have a small plot of land, you can choose a simple project for a two-story house. This solution will be much cheaper than building a one-story large house.

The cost of a future home is determined by three components, on each of which you can save:

- the architectural layout is compact, maximum functionality and comfort and allows you to achieve 20% savings;

- a simple design solution should be rational and not contain any architectural excesses and will provide another 10% savings;

- modern materials make it possible to use the latest technologies in construction, allowing you to do the work yourself or with the involvement of a minimum amount of outside labor, which guarantees up to 40% savings in the final result.

The optimal solution for a family of 2-3 people is housing consisting of three rooms with a total area of approximately 50 m2. A suitable option would be a 6x9 house, including: two bedrooms, a living room in the form of a studio with a kitchen, a combined bathroom and toilet and a small hallway.

<

Layout: maximum functionality and comfort

The main principle of space planning is to extract maximum benefit from every square meter of space. In our case, this is the ratio of total and usable space. This house, consisting of three rooms with a total area of 54 m2, will fully satisfy your needs for modern housing. Moreover, the ratio of total and usable area (52 m2) is 96.3%.

But over time, you will want to increase its area. This structure is most suitable for transformation. It can be expanded in width and height.

Second option

Important! The construction of the second floor must be thought out in advance in order to lay the appropriate foundation.

Third option, first floor

Third option, second floor

Exterior view of the house, economy option

Exterior of the house after expansion

The key to savings: simplicity of design

Designs should also be approached as simply as possible, without additional frills. When building economically, there are a number of points that need to be taken into account:

- The selected house width of 6 m will allow you to install floor slabs without difficulty. The standard size will not require the construction of an additional load-bearing wall.

- Combining the dining room, kitchen and living room into a modern living room, according to European standards, will save on the absence of walls and doors.

- A sufficient width of the walls will be 30 cm, and heat resistance can be achieved due to the thickness of the layer of thermal insulation material when cladding the house. In this case, the width of the base is reduced to 25 cm.

- It is advisable to make the walls in the house from plasterboard; they do not require a foundation and are easy to install.

- The roof is made gable, without unnecessary frills - this is the most cost-effective design.

Building a cheap house with your own hands is the most economical option

Approximately half of the construction costs are fees for performing the work. When building a cheap house, it is more advisable to do the maximum amount of work with your own hands, without the involvement of hired workers.

Why do you need to purchase only modern material? Its installation technologies are designed for the average person, so construction will not require professional skills from you and will provide an opportunity to save money. One assistant can be recruited as labor. If you do not have free time to build a house with your own hands, hire a team of two people with appropriate qualifications, retaining control over the work.

Another option is to build according to standard designs. Here you do not need to participate in construction; it is enough to accept the finished house into operation, be sure to draw up an acceptance certificate for the work performed, specifying the developer’s warranty obligations.

This 6x9 house is a great version of a two story conversion.

Reviews and disputes: which cheap house is better?

To explain which cheap house is better, we suggest you read the comments we collected from various forums:

Alexander V.

I want to talk about building a cheap house. Moreover, I will touch upon not only the monetary side of the issue, but also the labor-intensive one. We buy modern materials, preferably from a construction hypermarket, where prices are much cheaper. We discard ideas about buildings made from scrap materials (clay, straw, wild stone) as untenable. In the 21st century, we can talk about clay walls and rubble foundations. We're talking about modern housing, not Grandpa Pumpkin's house. We won’t even consider the environmental friendliness of building materials. At the time of the developed world wide web, you can find the most conflicting opinions about any material.

We will not consider hired builders either. This multiplies the estimate by at least two times initially. We carry out the construction ourselves; anyone can do it. The question is the duration of the process.

And so the foundation. When building a house you cannot do without it. The most appropriate and cost-effective is a strip foundation on piles. The job is not difficult. Every 2m we drill piles, the length depends on the soil, and fill in the grillage.

Still, the cheapest construction will be a frame house insulated with mineral wool or expanded polystyrene. Building a house from brick or sides with cement mortar will increase the cost of the estimate, take a lot of time, and as a result we will get a cold structure that requires insulation.

Bogdan S.

I was going to build a 6x9 house. For two months now, I have been working on a personal project and drawing up a construction estimate. I read smart books, participate in forums on all topics of interest, and watch videos. Now I’ve read it and understand that I have everything as you said: a pile foundation, a frame house, a slate roof. Interior finishing: plasterboard, OSB boards and wallpaper. Of course, plus heating and lighting. One thing I can say is that I am not investing in 10 thousand conditional raccoons. A bit more.

Sergey Zh.

I developed a project for a 50 m2 house for a friend of mine. Nothing special, a budget option, but a home for year-round use. The foundation is solid. Wooden frame house insulated with mineral wool. There is a vapor barrier film on the outside, hardboard on the inside. The roof is slate. Quite a warm building, suitable for winter use. The appearance is not very good. Just covered with vapor barrier. You can subsequently cover it with siding. But the budget is the most modest. An acquaintance spent only 4 thousand USD. True, I built it myself, I didn’t even want to hear about any hired crew.

Looking at my house, I am increasingly convinced that it is unlikely that anything can be built cheaper than a frame house. I insulated the walls, rollers, and roof with 15 cm thick mineral wool. In addition, I built an attic floor. My roof is the simplest gable roof, covered with zerolin. The outside was finished with siding, and the inside was covered with OSB and wallpaper. It cost me the pleasure of $9500.

The frame is the cheapest and warmest, but this does not mean that it is free. Everything is relative. Some friends of mine built a house from sibit. They were happy until winter came. They were frozen through the winter, and now they are deciding how to insulate themselves and what it will cost.

Of course, the main costs are building materials, which we will talk about in more detail.

Modern building materials are the cheapest way to build a house

There is enormous competition in the modern building materials market. Therefore, having made a short walk around the main points of purchase, building materials such as a hypermarket, bazaar or warehouse, it will not be difficult to find the most reasonable price. But different materials differ significantly in price.

The author of the article does not pursue the goal of promoting this or that building material, since the site is not engaged in their sale. The main thing is that a person with a limited budget for construction can become the owner of a good and solid home.

Before reading the various house options, pay attention to Compared to other houses, it is cheap to build.

Cheap brick house?

- Brick.

As many people know, brick is one of the most durable, but also the heaviest materials. Based on this, it has both advantages and disadvantages.

Advantages:

- high strength and durability;

- excellent sound insulation;

- availability;

- environmental friendliness.

Flaws:

- large mass - a solid foundation will be required;

- insufficient energy saving;

- difficult to process;

- long process of building a building.

Modern brick allows you to build a house of any size and design.

Cheap steel structure house

- Durable steel structures.

Today it is one of the most durable and affordable building materials, which allows you to build reliable structures, houses, etc. in the shortest possible time.

Advantages:

- affordable price;

- quick and easy installation;

- versatility - you can build any structure;

- Using modern finishing materials you can create a unique exterior.

Flaws:

- low strength;

- poor thermal insulation and sound insulation without additional insulating materials.

Durable steel structures today are becoming increasingly popular in the construction of private houses.

Cheap wooden house - is it true?

- Log or timber

A modern, stylish house made of logs looks amazing, and its high environmental friendliness, strength and thermal insulation make this building material stand out from others.

Advantages:

- high strength;

- environmental friendliness;

- excellent sound insulation;

- quick and easy installation;

- high thermal insulation;

- easy to process;

- relatively light weight;

- amazing appearance.

Flaws:

- price;

- the need for additional treatment against pests;

- fire hazard without special impregnations;

- low hydraulic stability.

A modern house made of logs or beams is stylish, practical and comfortable.

Favorite: cheap house made of foam concrete

- Foam concrete is the most profitable material for building a house.

A lightweight building material that surpasses others in its characteristics.

Advantages:

- quick and easy installation;

- high load capacity and low weight;

- high strength over time;

- excellent sound and heat insulation;

- light weight;

- reasonable cost;

- easy to process;

- environmental friendliness.

Disadvantages:

- the first few years after manufacture it has low strength;

- the porous structure of foam concrete will require additional finishing work;

- hot in summer.

Foam concrete is the cheapest way to build a house.

We looked at some of the most affordable building materials that can be used to build an inexpensive house. Today they are also widely used: twin blocks, monolith, ceramic stone, etc.

For example, the cost of a one-story frame house with two rooms, a kitchen, a living room and a bathroom will cost 600-700 thousand rubles. Thus, the cheapest frame houses can be built for relatively little money.

We also recommend:

For many people, a country house is something like a cherished dream - the prospect of taking a break from the bustle of the city in a cozy corner seems quite rosy. Moreover, you want not only to purchase a ready-made building with a landscaped garden plot, but to create the estate of your dreams, in which all your wishes regarding design and layout will be correctly embodied. There is only one thing left to do - transfer your ideas to paper, and only then, having drawn up a house project and determined its location on the site, bring it to life (engage in the actual construction of the house). If regarding the second point, by definition, there can be no doubt about the need for third-party help - even if you are a professional builder, you will not be able to build the right mansion yourself, but the costs of hiring an architect can be eliminated. How can design and construction be made cheaper? Yes, it’s very simple - it’s quite possible to do the work yourself, even without any special skills in creating a private house project. Designing a house (drawing it on paper schematically) is actually not that difficult!

What should you consider when designing your own home yourself?

The most important thing is that the house construction project you develop is created based on the following principles:

Multiple functionality - that is, the house built according to this project will be convenient and practical in all respects. A do-it-yourself house design should be no worse than an architect’s;

Simplicity of design - it will not be difficult to design a house only if it does not involve any frills. The creation of some particularly complex project, the implementation of which will require a huge amount of creative delights, is highly discouraged for a person who does not have a special education, because some fundamentally important things may not be taken into account;

Aesthetics - of course, a country house should look beautiful and please the eyes of its owners. The design of a reliable house should also be spectacular!

Remember - if the project is created taking into account these principles, then it will be very good in life. Again, we are talking about a rather primitive independent structure - an amateur would not design a premium-class cottage. Only an architect should be involved in designing houses of this level - beginners here very often make mistakes.

Geological exploration of the house site

Where does “do-it-yourself home project work” begin? First of all, when working on a house project yourself, it is necessary to conduct a geological exploration of the site - assess the nature of the terrain, soil and find out the groundwater level. The best time of year for this is spring, then their level is as high as possible and it is possible to determine this indicator with maximum reliability. It is very important to do this based on the fact that this indicator is of greatest importance when laying the foundation of a private house.

To determine the depth of groundwater, we recommend contacting a specialist

Start designing a house

For a clear example, our editors used the free demo version of the Visicon program. But all the steps can be performed on a regular sheet of paper. For example, a simple project of a two-story house 10 m x 10 m was chosen

To design houses, you will need to “arm yourself” with an ordinary checkered notebook sheet and a pencil, while setting the appropriate scale. The most rational thing to do in this situation would be to do the following: ten meters of land should be designated by two squares. Thus, one centimeter on a ruler will equal 1 meter in real life - the ratio is one to one hundred.

Step 1: draw the outline of the house on a notebook sheet using a ruler and pencil on a scale of 1:100, i.e. 1 cm on paper is equal to 1 meter

Drawing on paper the outline of the site itself, as well as future buildings. In this case, all work must be carried out in strict accordance with the correct scale - by carefully measuring every meter on the ground and putting it on paper in accordance with dimensions one to a thousand, you ensure the reliability and aesthetics of the building being constructed. You can draw a project this way very quickly. It is imperative to take into account not only the contours of the site allocated for design and construction, but also all the objects located on the site that were there even before its planned construction, and at the same time there is no possibility of moving them. After this, it will be possible to begin designing the building itself - to simplify the task, we will assume that the designed house will consist of four rooms, a kitchen and two bathrooms (standard housing for a family of several people).

Basement/foundation

A few words regarding the design of the basement. It should be noted that it is not always necessary. For example, if the groundwater is high, then this will be a very expensive pleasure - it will be much easier to include another room in the project - as an additional room.

First floor project

We draw the vestibule and the hallway on the sketch - and from there there will be transitions to the kitchen and other rooms. The location of the premises must take into account the following points:

The bathroom and kitchen should be placed in close proximity to each other - thanks to this location it will be much easier to carry out communications;

It’s very good if the drawn up project implies the absence of passage rooms - this is an integral element of comfort;

On the ground floor, it is necessary to take into account the presence of all auxiliary structures and premises - their location will be very important not only to ensure the functional suitability of the house, but also for the comfortable movement of residents.

Step 2: draw all the rooms and premises of the first floor with the required size

After this, we arrange and plan all the doors of our house

Step 3: designing doors on the first floor

Then windows, taking into account the desired lighting of the rooms and your budget

Step 4: designing windows on the first floor

As a result, we get this first floor:

This is how the 3D model of the first floor turned out

Drawing the second floor

Here everything will be much easier - after all, the rooms in the house can be located identically (the most important thing is not to change the relative position of the bathrooms - in order not to complicate communications). It will be enough to design the location of the front door (many architects recommend making two entrances to the second floor - at home and from the street) and windows.

Step 5: We plan the premises of the second floor in the same way. Don’t forget about communications - we place the bathrooms and bathrooms one below the other

Step 6: Place the Doors

Step 7: draw the second floor windows

We received this 3D model of the second floor

Attic and roof design

We decided to create a house project ourselves - there would be no need to try to draw some kind of too “abstruse” roof with a lot of bends. Remember - the roof is one of the most important structural components in the house, and trying to create additional aesthetics by questioning its reliability is certainly not worth it. All this will lead to leaks occurring at the bends. If you are drawing a project, please adhere to the principles of minimalism in architecture.

To design such a roof, you cannot do without an architect.

Dependency of designing a house with insulation

There is one very important rule - all auxiliary premises must be built on the north side. Despite the fact that thermal insulation performed using building materials is of paramount importance, the relative position of the rooms should also not be overlooked - if only because of the savings in energy consumption for heating the house.

Approval of the project to begin construction

The need to adjust the project. Even if you yourself were able to depict the house of your dreams on paper, you will still need to consult with specialists before starting construction of the house - the opinion of a competent foreman or architect will not be superfluous. At a minimum, the following points will need to be agreed upon:

Carrying out electrical work;

Conducting your own sewerage system;

Carrying out water supply;

It is necessary to understand that all the above issues are not an artistic or architectural part of the project. These are all the most routine issues, a competent approach to solving which is provided only by professionals in their field. As a last resort, any oversight in independently drawing up a house project, which was made by a person who does not have a specialized education, can be corrected by a competent foreman who understands the practical side of any idea much better. Although even if the project is drawn up by professional architects, purely practical shortcomings cannot be ruled out.

Independent work on a project at home and its benefits

You can create the design of your house yourself - in order to develop drawings of the relative position of certain rooms, as well as determine the place of the house on the site, you do not need special knowledge. A competent and responsible approach to business will ensure the success of your event. However, in terms of communications, it will be necessary to consult with professionals. This way you can properly plan a house that will serve you faithfully.

5 ( 7 votes)In order to build a cottage, you need to spend a lot of money, time and effort. But you can still do it by building apartment buildings.

In addition, difficulties may arise when drawing up documentation for the construction of premises. Despite the fact that problems arise in obtaining permission, it is quite worthwhile and profitable.

Often, the first floors of buildings are rented out for shops, offices, salons, and so on. Starting from the second floor, the premises are converted into apartments. The costs quickly pay off, since the profit is quite large.

If you decide to start building such an apartment building, remember that this project will take a lot of money and effort. Time will also be spent on selling apartments. You can sell apartments quickly only if you sell them at a low price. This should not be done, because your income will be minimal.

Before you start drawing up plans for building an apartment building, you will need to decide in what area you will build it. You must think through every detail because your home must meet all the requirements.

Leave the drawing up of a house project to a special organization that has sufficient experience in this area. Such a company will be able to make all the necessary calculations. As for the construction site, you must choose it yourself.

An apartment building must be connected to all currently available communications, namely: gas supply, electricity supply, sewerage and water supply. If you follow practice, it is best to choose a place to build within the city. It will be better if you build a house on the outskirts of the city. You can also provide a plan in the area where communications will be able to withstand the load.

It is also important that all necessary communications are nearby. This includes a school, a kindergarten, and shops. The condition of the roads in this area will also be important. If the road wants to leave the best, you will need to work on lining up the roads. This will significantly increase the cost of an apartment in a house in such an area.

Also arrange the nearby area (yard), organize an underground floor with parking. Parking will provide you with additional income. This decision has already been approved by many developers. They confirm that this . The main thing is to identify the condition of the soil and find out whether it is possible to build something in this place.

Stages of construction of an apartment building

Where can I get money to start my own business? This is exactly the problem that 95% of new entrepreneurs face! In the article, we revealed the most relevant ways to obtain start-up capital for an entrepreneur. We also recommend that you carefully study the results of our experiment in exchange earnings:

Let's summarize all of the above and tell you in basic terms about all the stages of preparation for the construction of a multi-story building.

1. Select a building site. The best option is to join the general urban planning plan. Build the building in a location where residential development will take place over the next few years. Gather all the necessary information about construction options. Find out whether the utility networks can withstand the load of the new multi-story building.

2. Obtain permits to build a house

3. Draw up an estimate and a development project. Do this with the help of special organizations. Choose it based on your preferences and financial capabilities.

4. When starting the construction stage, remember that this is a very important stage. Take all stages of construction seriously: preparing the territory, digging a pit, supplying the necessary communications, laying the foundation, building the house itself. By the way, the price for the foundation is equal to half of all the costs of the construction itself.

The construction of a multi-storey building is the work of many specialists, such as architects, installers, and others. Many design organizations are also involved in construction. When it comes to construction, it becomes immediately clear that there must be contractors and subcontractors - people who create a project for your future home, design its appearance and calculate the structure of the house, and then install it.

If we consider all the works as a whole, there are quite a lot of them. All of them require responsibility and great expense and effort. But in general, building a new residential building is a very profitable and profitable business.

Of course, building a multi-story building is a long process, especially in our country. But there are technologies that make it possible to erect multi-story structures in a matter of days. Here, for example, is a technology from China (based on lightweight metal structures), which allows you to build a full-fledged hotel (without interior decoration, of course) in 90 hours:

Building a new home is always a big expense. Few people can afford to build without paying attention to estimates. Most often you have to save money to fit into the budget. However, the savings should be reasonable, because the owner and his family will live in the new place. The building should be warm, dry, comfortable, and pleasant to look at. How to achieve this without overpayments? First of all, save on a team of workers. If the developer has the necessary skills, then everything or almost everything can be done yourself. You can also choose inexpensive materials, available technologies, and a standard design. How to build a house with your own hands cheaper? What is worth saving on, and where is it better not to risk it?

Savings start with choosing a project. The more complex the architectural forms, the more expensive the construction costs. It is irrational to try to reduce costs at the expense of workers, technical supervision or quality of materials by initially choosing an expensive project.

It is better to clearly determine the required living space, without depriving the family, but also without allowing yourself extra square meters, and choose a simple roof shape. This will allow you to create a cozy home that fully meets the needs of the family, but without architectural “excesses” - a multi-pitched roof, bay windows, columns, arches.

It makes sense to consider options for building a one- or two-story structure with a residential attic.

A residential attic is much more profitable than a separate floor. The construction of the floor will require more materials - for walls, insulation, finishing

If you choose lightweight building materials and suitable technologies for building walls, you can save on the foundation. A less powerful structure will be needed, plus the formwork can be made from substandard boards or used fiberboard boards.

The only thing you don't want to cut costs on is cement. You need to buy it of high quality, otherwise the strength of the structure will be in question. The depth of the trench under the foundation must also correspond to the calculated weight of the building in order to avoid severe settlement, which can lead to cracks in the walls.

What is most often used during construction:

- brick;

- beam;

- gas block

When constructing houses and cottages, frame technology is increasingly being used. This is a promising method that allows you to build quickly and at minimal cost.

To find out what will cost the least for construction, you will have to calculate estimates for each of the options, because... the cost of the material itself is not always an indicator of benefit. For example, choosing multi-purpose resources can help reduce costs. The cost of a two-in-one hydro- and vapor barrier will ultimately be cheaper than purchasing two different types of insulation.

When making calculations, one should proceed from the fact that the finished building must be comfortable for living and comply with heat conservation and safety standards.

The advantages of a frame structure are lower time and labor costs for the construction of a building. The design is lightweight, does not create an increased load on the foundation and does not require its reinforcement

A dwelling using this technology can be built within a period of several weeks to several months, depending on whether the owner builds it himself or hires a team. Finished buildings are durable and resistant to deformation. The estimated service life is approximately 75 years.

Load-bearing structures are convenient for subsequent cladding with finishing materials, because all elements are unified. This significantly expands: siding, cassette panels, and a block house can be mounted on the walls. Sheathing increases the strength of the entire structure without significantly increasing its weight.

Video about the design

There are two main technologies, each of which has its own characteristics.

Frame-panel. How to build a house cheaper? Collected with my own hands. Of course, this will require skills and equipment. Thanks to this type of construction, this is possible, although you will need to invest a lot of time and additional money in the purchase of insulation and other things. The frame is made of wood and covered with sandwich panels. Each part has to be installed separately, which affects the timing and complexity of construction.

Frame-panel. This option is expensive, but reliable and requires much less labor. The structure is assembled from ready-made panels, which are manufactured at the factory to special order. The panels are supplied already insulated and completely ready for assembly. If we compare the prices of panel and panel buildings, the former are more expensive. However, the final cost may turn out to be the same if workers are invited to assemble frame-panel housing, because you have to pay for all types of work separately - assembly, cladding, thermal insulation, finishing.

The assembled wooden frame already looks like a finished house. It only requires cladding and finishing. Steam and waterproofing materials are installed into the walls of the structure at the factory, which helps to increase the service life of the building

Undeniable advantages of the technology:

- Economical. Light weight is an obvious opportunity to save on the foundation, and short terms - on paying workers. It is believed that houses built using frame technology are the cheapest, but the efficiency largely depends on the area of construction, the selected components, finishing, etc. Calculations by experienced engineers show that this is beneficial if the length of the building does not exceed 20 m and the number of storeys is 3. Often the design decides everything.

- High energy saving ratio. The structures warm up quickly and efficiently. The walls are made of materials with low thermal conductivity, so the structure retains heat well. The wall thickness can be 15-20 cm. Additional benefits include reduced heating costs compared to a conventional building of the same area.

- No shrinkage. The walls of the structure are strong, resistant to deformation, highly rigid, and the house itself does not shrink. This also has a positive effect on construction time: finishing work can begin immediately after the completion of the main work. The cladding does not require additional processing, which reduces finishing costs.

Disadvantages or things to consider:

- To assemble such a structure you need special knowledge and tools. The qualifications of the builders are of fundamental importance, so not every developer can do it himself, and the team will have to be carefully selected.

- Wooden frames require additional treatment with compounds for biological and fire protection.

When choosing a project, special attention should be paid to ventilation. Artificial materials provide excellent thermal insulation, but from the point of view of environmental safety they leave much to be desired. If the home is small, then theoretically you can get by with natural ventilation, but ideally, a normal air exchange system should be calculated and installed for it.

When installing frame structures, “wet” technologies are not used. This feature is a big plus, because... allows you to work at any time of the year

Tightness is one of the main advantages of a frame house, because serves as a guarantee of good thermal insulation. But it also has a downside - a violation of air exchange. To prevent human waste products, dust and other factors from worsening the microclimate in the building or reducing the amount of oxygen in the air, it is necessary to design a high-quality ventilation system

What to make it from:

- Tree. Despite all kinds of processing, wood is exposed to moisture and microorganisms. On average, such a frame lasts up to 60 years and is inferior to metal analogues in strength, lightness, and resistance to destructive environmental factors.

- Metal. A lightweight thermal profile is used for manufacturing. Its advantages are excellent fire resistance, light weight, and corrosion resistance. Metal parts are not susceptible to attacks by fungi and mold. All this can increase the service life of structures to 100 years.

What would be cheaper to build from? When drawing up estimates, a wooden frame will have a clear advantage. However, if you “look into the future” and take into account the higher performance properties of the thermal profile, then its service life fully pays for the costs.

The foundation can be chosen tile, columnar or strip depending on the type of soil. You can save on an easy-to-install roof - gable or attic. The choice is up to the developer.

Material on the construction of a veranda at a frame-type dacha may also be useful:

1 sq. m metal frame weighs 30-50 kg, with sheathing - about 200 kg. The low specific gravity of the finished house allows it to be built on unstable soils. The profile is also used in the reconstruction of buildings with heavily worn load-bearing structures

Option # 2 - brick building

Brick is one of the most popular. Houses made from it can hardly be called cheap. The walls have to be made thick, plus they require additional insulation, which leads to an even greater increase in the cost of structures. The weight of the finished structure is large, so the foundation needs to be truly strong. It is done to the entire depth of soil freezing.

It's difficult to save money on it. The disadvantages include long, labor-intensive construction. However, the durability of the structures, their fire safety and practicality largely pay for the costs.

If you look at the prices for the construction of a high-quality building on the websites of specialized companies, you get the impression that the cost is low. However, even the price of turnkey construction does not include the finishing touches: installation of flooring, interior doors, plumbing fixtures, etc.

If you do all this yourself, then only the costs of purchasing materials should be added to the cost. If you need to hire workers, then also pay for their labor. Construction is profitable only if the owner of the site initially selected the project correctly and can carry out most of the work independently.

Video: about bricks for buildings

Option #3 – aerated concrete blocks

Aerated concrete block is a worthy competitor to traditional brick. Building a box is significantly more profitable than erecting it. The wall thickness can be reduced by 1/3 without losing its thermal insulation properties. The material itself is noticeably lighter, which allows for savings at the expense of the foundation. An additional “bonus” for the home owner is good sound insulation.

A dwelling made of aerated concrete blocks “breathes”; air exchange in it is not impaired, because through pores. However, for the same reason, blocks are considered not the best option in terms of waterproofing. If construction is carried out in violation of technology, the finished structure may also be blown out. You need to pay attention to the finishing.

As for the construction time, an aerated concrete structure can be erected 2-3 times faster than a brick one; it practically does not shrink. Special adhesives are used to connect the blocks. In this case, it is undesirable to use ordinary cement mortar, because... it produces thick seams, which can cause the formation of “cold bridges”.

One of the disadvantages of aerated concrete blocks is their relatively low frost resistance, so you will have to take care of high-quality finishing. The materials you can use are plaster, siding, stone

Option #4 – economical timber buildings

For the developer, timber is more profitable than anything else. If we compare timber and brick walls in terms of heat-saving properties, it turns out that a structure made of spruce 220 mm thick and a brick 600 mm thick will be equally warm. Usually for construction they take 200 mm timber, use 100 mm thick insulation and apply a layer of plaster from 20 mm.

Advantages of timber:

- efficiency;

- fast construction (built in a few weeks);

- simple technology;

- environmental Safety;

- excellent thermal insulation;

- comfortable microclimate;

- ease of construction.

If you are choosing what is cheaper to build a house from, then timber is a win-win option. This is profitable, and the technology is simple, and almost any site owner can master it if he already has construction skills.

When building houses from timber, you need to carefully design heating and energy supply systems. The buildings are considered a fire hazard. Wood is also afraid of moisture, so it requires protection from dampness and fungus.

Compare prices per square meter

How and what is the cheapest way to build can be seen in the estimate figures. If the calculations are based on average indicators (soil freezing depth - 1.5 m, groundwater - 2.5 m, sandy loam soil), then we can determine the cost of construction of 1 square meter. Depending on the components, the numbers will be as follows:

- frame structure – 875 rubles;

- brick – 2330 rubles;

- aerated concrete – 2000 rubles;

- timber - 1900 rubles.

Review of popular materials - video

Obviously, a frame house will cost the developer the cheapest. When finally deciding on a choice, you need to take into account all the features of the project, the soil, and the site itself. The calculations do not include payment for the services of the construction team. Hired labor is an additional (and considerable!) item of expenditure.

There are more and more people wanting to settle outside the city or in a small town. In megacities it is stuffy, mentally and physically, from the inhaled air and extraneous noise. I would like, if not to move out completely, then to acquire a corner of outdoor recreation. As you know, we do not suffer from excess funds, so the problem arises: how to build a house inexpensively? In a private house you will have to put more effort into housekeeping and maintaining it will cost a little more than paying for utilities for a city apartment of equal size, but a healthy lifestyle is worth it. And if you start at least a small backyard garden with a greenhouse, then, without breaking a sweat, individual housing can be made generally profitable.

Is it cheap and fast?

A private residential building in the budget price segment may well be comfortable, warm, and reliable. And if your hands grow as they should and there is a desire to use them correctly, then you will look respectable, see fig. However, building a house cheaply is not everything. There are already almost 7.5 billion people on Earth and everything is coming. Our “ball” is not rubber, so it would be simply naive to expect that property taxes and land rents will somehow decrease over time.

Consequently, the cheapest house is not necessarily the one whose construction will cost less: when choosing the material for the house (see below), design, etc., you must keep in mind further operating costs. Especially if the construction is carried out on credit, you need to start repaying it immediately. That is, the period from the start of construction to the readiness of the house for occupancy is of great importance: while construction is going on, there will be no time to find additional income, but you have to pay for your previous housing and take out the next loan payment.

The conclusion is obvious: Having planned to build, first of all we figure out how long we will spend until the house is completely ready? This point can be significant even for a fairly experienced builder, if you need to decide whether to build it yourself or entrust some of the construction stages to a conscientious contractor with established production and well-equipped technical equipment. Savings from a reasonable distribution of cash and/or available funds according to the stages of home readiness (see below) for contract and manual work can significantly exceed all other possible items and will certainly make the choice of the main structural material of the house and its foundation - the foundation much easier.

What is a budget house?

We will consider a budget house to be a house whose construction until it is fully ready (see below), but without heating, cooking and plumbing fixtures, will cost 10,000 rubles. for 1 sq. m of total area or less. A house with 100 common squares in this case will cost up to 1 million rubles. or ok. $18,000 at today's exchange rate (2019). In certain local conditions, it is possible to reduce the cost of construction to 5500-6000 rubles. per square; if you build completely with your own hands, slowly only for your own; if there is an inexpensive former housing, then it is possible to meet 4,500 rubles. per square, but cheaper is already a fiction, who would not promise anything. Good contractors for 3000 rubles. You can still find it for a square meter, but it’s turnkey, and it will take at least the same amount to bring the house to full readiness.

Note: the given figures, as well as the averages for the Russian Federation further in this article. Here it is appropriate to recall an old joke, which is now reinterpreted in its own way in almost all countries: a nobleman gorges himself on meat, a peasant only has enough for bread. On average, for two, they eat a meat pie. So, finally, look at the prices at home - it is impossible to give a complete overview of them in one publication, and the market situation may change the next day after its publication. Here we primarily provide information on how to use technical and organizational measures to build a house cheaply and quickly without compromising its quality.

About the number of floors

The problem of taxes and land rent can be largely solved, firstly, by building a 2-story house, which will save on land payments. Some prejudice against upper floors in individual houses remains from Soviet times, when private construction of more than 1.5 floors was strictly prohibited. There is no point in building a budget 3-story building anymore: the staircase will have to give up too much usable space, and strengthen the walls of the 1st floor, which will greatly complicate, lengthen and increase the cost of the work. And in a 2-story building, the staircase to the 2nd, sleeping floor can lead directly from the living room or hallway/hall.

Secondly, the real estate tax can also be significantly reduced on a completely legal basis by making the sleeping mezzanine in the form of a Siberian attic. The diagram of the pediment of a frame residential building with a Siberian attic is given in Fig. on right. Not everyone likes houses with Siberian mansards because of the faceted roof, but in fact they are economical and convenient, and in budget construction there is no time for exquisite architectural solutions. For a budget frame house (see below), the Siberian attic is practically the only way to increase its actual number of storeys.

Note: for a house made of foam or gas blocks, there is another non-trivial opportunity to increase its living space without a significant increase in taxation and land rent, see below. This factor can be decisive in regions where 2 or more storey individual construction is prohibited due to natural conditions, for example. in seismically dangerous places or on permafrost.

Stages of home readiness

The stage (stage) of readiness of a residential building for occupancy means a completely completed cycle / complex of construction works, after which the structure can wait for the next stage to begin for some definite or indefinitely long time. A technological break between stages is most often necessary due to shrinkage of the structures of the previous cycle, but sometimes (see below) is unacceptable or possible only in the warm dry season. Work at the next stage of construction can be carried out both independently and under a contract from the same or another contractor, regardless of how the previous one was completed. The stages of bringing a budget residential building to completion are as follows:

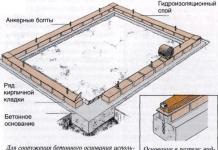

- Zero, or zero cycle - the foundation is laid, gained at least 75% strength and gave the calculated settlement. This is the most responsible, complex and time-consuming stage, at which it is most often expedient to hire an experienced team on a contract basis. Technical break before next. stage is necessary in any case.

- Box - there are walls with openings for windows and doors, covered with a roof. Load-bearing partitions were also erected inside. Communications have been established, but are currently muted. A mandatory technical break is required only for heavy (brick, stone, concrete) buildings, for their own shrinkage. In budget construction, the stage of the box as such is most often not distinguished, and for a house from SIP panels it is generally excluded.

- Turnkey - the doors and windows are in place, the frame is stable. The house can winter up to several times. It is possible that the floors are also laid, but the communications are not divorced, there is no interior decoration and insulation. A favorite bait of overly clever contractors "for cheap", so at this stage you need to carefully calculate how much it will take to eat up the rest of the work, as well as their cost, and compare it with the cost of bringing the house to full readiness by employees.

- Complete - communications are divorced, stationary household appliances are in place and ready for use. The interior decoration is done, but the exterior and insulation may not be provided for by the terms of the contract (see below). The kitchen, bathroom and boiler room / furnace are fully equipped, you can cook, wash, start the boiler and heat. It remains to bring in and arrange furniture, lay carpets, hang curtains, paintings, arrange trinkets, etc., so that you can live in the house - do not grieve.

About contractors

A conscientious contractor, firstly, must be properly registered legally - as an individual entrepreneur, LLC, etc.; accordingly, he must immediately, without a reminder, present to the customer a package of documents confirming state registration. Special licenses for ordinary construction work are not required, professional certificates (“crusts”; now - cards) of executing workers are enough.Secondly, the customer must be offered a contract on paper. An offer (public standard) or individual, it doesn’t matter, the main thing is that the rights and obligations of the parties should be clearly spelled out there. Thirdly, the warranty period for this stage (stages) of work and the conditions for compliance with warranty obligations should also be indicated there.

Good contractors on a budget offer a 2-5 year guarantee. Less is not possible due to technical interruptions. In good conscience, it’s also impossible to do more, because... local operating conditions of the building may change for the worse. They can be taken into account (“mortgaged” constructively) by using more expensive materials and technical solutions, but this will no longer be a budget construction.

About outbuildings

In popular sources and prospectuses of contractors, one can come across recommendations accompanied by draft (without reference to the place) projects: they say, we build a 6x9 house first very cheaply, and then, as funds accumulate, add more rooms to it (the original layout allows), while children and grandchildren will not be left with a huge mansion. This approach is fundamentally wrong.

Anyone more or less familiar with construction knows that adding a residential building to an existing one is a complex and not always feasible technical task. First, the old foundation has already completely settled, and the new one will give the calculated shrinkage only under the weight of the supported structure. That is, the extension cannot be immediately tightly attached to the main structure; you need to wait to see if cracks appear and seal them. In the common RuNet, it is difficult to find publicly available information about extensions to existing buildings; You can look for a small but sensible book by Dr. tech. Sciences Ferenc Sägi “How to avoid mistakes when building an individual house.” There was a Russian translation, M., Stroyizdat, 1987. It’s funny - this little book then cost 90 kopecks. Soviet

Third, even if the house is made of rubber on a gimbal, it is unacceptable to allow it to sway and sway in time with the seasonal movements of the soil from year to year. Under a house built on a correctly chosen and laid foundation, a kind of virtual (invisible) warm “pit” is formed, in which it is never below zero; the blind area around the house expands it to the sides. An extension to a house can disrupt the established thermal balance of the load-bearing soil, which can lead to accidents in the main building. Therefore, conscientious contractors set one of the guarantee conditions - no extensions not agreed with them.

Garage in the house, or the role of layout

One of the ways to get an inexpensive house for permanent residence relative to available living space is to build a house on a common foundation with a garage. Perhaps this is only for houses made of non-combustible materials; regarding the budget ones - foam and gas blocks, otherwise the firefighters will not allow the project to be approved or the squatter construction to be legalized.

However, simply attaching a garage to the house, as on the left in the figure, does not make much sense; it will do almost nothing to save costs on the construction and further maintenance of the house. It is necessary to introduce a garage of a standard size of 4X7 m inside into the structural scheme of the house, taking into account the following:

- there is no need to put a garage on a plinth, because then you will have to build an access ramp to it;

- the ceiling height in the garage is permissible 2.5 and even 2.2 m, less is simply not possible;

- It is highly desirable to have an entrance to the garage from the house, but then it is only permissible from the hallway/hall and should have a steam-tight fire-resistant door.

In this case, the garage floor slab will serve as the floor of a one-and-a-half floor, less taxed, but quite spacious. For an example of this type of layout, see the right in Fig. The space utilization rate there is not so great, but there are a lot of amenities:

- A one-and-a-half superstructure is not an extension; no special measures are required for its construction on an existing well-established building, i.e. You can build on the garage later, as your family grows.

- The staircase to the one and a half floor turns out to be low and fits into the existing hall without any special difficulties.

- Heating a garage can also be done without problems, and economically, because... it is slightly heated from the hall and kitchen.

- In the lobby of the 1.5th floor, a pressure tank of an autonomous water supply is perfectly located under the ceiling; you can also move the dressing room there, increasing the area of \u200b\u200bthe living room and bathroom.

- Since the bedroom floor is heated to some extent, in turn, from the garage, it can be done with a French window even in a fairly harsh climate.

- One basement wall is shared with the garage. Communications are wound up, of course, in the basement. That is, a sewer riser can go from the bedroom to the basement, to which a washbasin, shower and even a jacuzzi are connected upstairs.

- The entrance to the basement is also internal, through a hatch in the hall or from the garage.

Agree, a house for 4-5 people with a separate dressing room, a living room of more than 25 square meters and a French bedroom, which also has a hydromassage - this is really cool. And the total area on earth is much less than 180 square meters. m, from which the increased taxation begins. Even if in your state the basic area norm is 150-160 sq. m, the tax authorities still have to write down the house as a budget one.

Foundation and soil

When choosing the foundation of a house or checking the option proposed by a contractor, you need to take into account the geology and soil mechanics of the construction site. The soil mobility factors that most affect the cost of a house foundation are:

- Load bearing capacity.

- The degree of heaving (the amount of frost heaving).

- Normative freezing depth (NGP).

- The highest height of standing groundwater.

Bearing capacity and heaving

Massive, low-cost development is possible on non-heaving and slightly heaving soil with a bearing capacity of up to 0.7 kg/sq.m. cm, but only based on the results of thorough preliminary surveys over the entire building area with a decent margin at the edges. An experienced contractor can build a separate reliable house on medium-heaving soil with a bearing capacity of 1.1-1.3 kg/sq. m. Self-construction can be done on soil up to medium heaving with a normal load-bearing capacity of 1.7 kg/sq. cm or higher. On heavily and excessively heaving soils, budget development is impossible with rare exceptions (see below).

Note: The bearing capacity of the soil directly at the building site can be determined on your own without complex instruments, but how is a separate article.

Oil and gas reserves and groundwater

Some potentially budget houses cannot be built on a shallow foundation (see below). The heel (sole) of the foundation must be buried below the NGP by at least 0.6 m on medium heaving soils and by at least 0.3 m on slightly heaving and non-heaving soils. The base of the foundation should not reach the groundwater level by 0.5 m or more. Typical limiting cases for budgetary development: dry sandy loam (slightly heaving), NGL 1.5 m, standing water 2.5 m; foundation depth 1.8-1.9 m. Or - moderately moistened podzol (medium heaving), NGP 1.2 m, standing water 3.5 m. Foundation depth from 1.8 m.

What if there is a fire?

The question of what would be cheaper to build a house in a given location must be decided taking into account the fire danger. Hoping for the best and preparing for the worst is a universal principle, and the harmfulness (or compliance) of firefighters here ranks fifth to seventh after their own safety. Regarding possible damage from fire, the properties of materials for budget construction are divided as follows. way:

- Fire safety (this is not the opposite of fire hazard) - how difficult it is to set fire to a given material and whether it can burn outside the source of fire. In fact, is it possible to extinguish a timely detected fire using improvised means without significant damage to the structure of the building.

- Fire resistance - how long a material can resist fire without losing mechanical properties to the point of collapse of the structure and/or without emitting toxic gases. In fact, how much time do you have, if extinguishing on your own is impossible, to evacuate and remove property.

- Fire resistance - how much, after being in a fire for at least 20 minutes, the material restores its properties. In fact, suddenly the frame of the house is completely burnt out, is it possible to refurbish it as housing?

Materials

So it's time to choose the material for the house of the budget price category. Houses made of brick, corrugated timber and chamber-dried logs are, unfortunately, excluded from the budget category. They have a lot of advantages and relatively few disadvantages, but you can move into a brick house no earlier than the 3rd year from the beginning of zero: a year to settle the expensive buried foundation, a year to shrink the frame, and only then can it be delivered turnkey, plus time for the interior finishing. In addition, at current energy prices, a brick house requires expensive external insulation.

Note: houses made of wood concrete (fiber-reinforced concrete), reeds, straw blocks, etc. are not considered, because their reliability has not yet been confirmed by time and there is no established construction industry for their construction.

Chambered corrugated timber and logs, impregnated with harmless antiseptics and fire retardants, are expensive in themselves and require solid carpentry experience to build a residential building. Houses from them are considered prestigious; as a result, the cost of work is high. Also, prefabricated panel houses do not fit into the budget category: they are erected very quickly, but their construction requires qualified personnel and a high degree of mechanization of work. Given these circumstances, the choice of widely available materials is quite limited. To compare the cost of a fully finished house per unit (100%), you can take a frame house made of non-laminated veneer lumber and conventional air-dried boards. The result looks like this. way:

- Country wooden frame house made only from boards – 0.6-0.8

- House on a thin-walled steel frame - 0.85-0.9.

- Residential wooden frame house made of timber and boards – 1.00.

- A log house made from ordinary air-dried timber is 1.4-1.8.

- House made of SIP panels – 1.9-2.00.

- House made of foam or gas blocks - 2.00-2.15.

Frames and timber

The general advantages of and are low sensitivity to ground movements, they “play” with it. Therefore, it is possible to build such houses on a shallow columnar foundation, which is the simplest and cheapest. It is also possible to build a residential frame/timber budget house on highly heaving, weak soil by laying a TISE pile-strip foundation under it. A 2-story frame house cannot be built without a detailed design, but in budget construction this problem is solved by the Siberian attic, see above.

A log house is good because in regions with fairly mild winters it does not require additional insulation: a beam with a thickness of 200 mm is equivalent to a brickwork of 600 mm. Internal lining in both timber and frame houses is possible with plywood or non-combustible materials: chipboard, OSB. OSB (Oriented Strand Board) exterior cladding will give your home extra wind resistance and weather resistance. The plaster inside here and there is dry, with drywall (gypsum plasterboard) on shreds (15-20) x40 mm; it is impossible to sheathe gypsum boards without crates even completely flat walls.

The construction of a wooden frame house is well known (on the left in the figure). Without impregnation with biocides and flame retardants (which can be produced independently), all fire-fighting qualities of such houses are low, and fire resistance is generally zero, they burn out completely. Fire safety and fire resistance can be increased to an acceptable level (10-15 minutes for evacuation) if the insulation is made with ecowool (cellulose insulation). It will cost approx. 25% more expensive than mineral wool, but when heated, ecowool releases a lot of water vapor that retards fire. In addition, ecowool does not allow wood to rot: it contains an antiseptic - borax. Wet ecowool does not fall off and retains 75% of the insulating qualities, while dried out completely restores them. Warming with ecowool is possible manually without experience; No fasteners or bracing required. Hydro and vapor barriers for ecowool need inexpensive simplified ones. The estimated service life of an all-wood frame or timber house with mineral wool insulation and without external cladding is 25-40 years, depending on the quality of the wood and local conditions; the same, with ecowool insulation - up to 70 years or more.

Inexpensive house for a summer residence of a frame structure with dimensions of approx. up to 4x6 m it is possible to build from just boards with your own hands without experience, just like air drying lumber. But if the total area of the house exceeds approx. 25 sq. m and/or the number of openings in it is more than 3-4, it must be built by an experienced carpenter. In this case, the frame of the house is needed with the main load-bearing elements made of timber from 150x150 mm.

First, it is impossible to place window and door openings in a house, any size of which exceeds 6 m, at random. Computer programs are of little help here: you need to enter initial data into them and choose a calculation method based on your own experience. There is no computer construction program that would “do everything itself” yet.

Secondly, a residential frame/timber house must have at least two load-bearing partitions. Their location can be taken from a standard project, but a beginner is unlikely to be able to correctly connect the partitions to the external walls; especially if the house is made of timber.

In a log house built without experience, the problem of caulking may arise. Only a very experienced specialist can reject timber that is highly susceptible to warping when purchasing. If a seasonal country house splits, the problem is not great; the cracks can simply be plugged. In a large residential building with cracked walls, it will be possible to survive 1-2 winters, spending a lot on heating, and then it will quickly fall into disrepair due to weakening of the structure.

Houses on a thin-walled steel frame (on the right in the figure) may be somewhat cheaper than solid wood ones, but this is an apparent cheapness. The main thing is that the fire resistance of houses on a thin-walled steel frame is zero: in a fire, the frame instantly (in less than 3 minutes) loses strength, and the house collapses. In addition, it is very difficult to take into account the fatigue of elements of a complex thin-walled structure, and cases of sudden collapse of such houses for no apparent reason are not isolated in the world. In general, the service life of 100-120 years declared by manufacturers is not maintained, therefore, in a number of countries, only non-residential small architectural forms are allowed to be built on a steel frame.

SIP

A structural insulated panel (SIP, Structural Insulated Panel) is a cake made from slabs of plywood or OSB with extruded polystyrene foam (EPS) or polyurethane foam between them. For housing construction, SIPs from OSB and polyurethane foam are suitable; CIP filled with XPS in a fire release a huge amount of toxic gases. The main advantages of SIP houses are, firstly, the speed and ease of construction, see video:

Video: an example of building a house from SIP

The time it takes to bring a SIP house to move-in readiness is further reduced by the fact that they can be built on a shallow foundation such as a Swedish or Finnish slab. These foundations are cheap, their “maturation” period fits into the warm season, so the slab foundation for a SIP house can be ordered / laid with a margin for future extensions or for an extensive veranda, see fig. on right. The exterior finish of a SIP house can be any and it will look more than decent, see ibid.

No less important is the fact that SIPs themselves are an excellent heat insulator and additional insulation is not required for the house. The disadvantages of SIP houses include the need for a ventilation system, tk. the walls don't breathe. In Russian conditions, it is significant that SIP houses are unsuitable for stove heating, the panel filler heats up and gradually exudes toxic substances. The service life of SIP manufacturers also declare a small, 40-70 years. Finally, the SIP box cannot be left to winter; the house must be built at least turnkey during the warm season.

Foam blocks and gas blocks

A box can be very inexpensively, doing construction work on weekends, folded from spring to late summer on glue, without being a bricklayer at all; she will be able to overwinter once under a roof and wrapped in a film. A technical break for shrinkage of the box is not needed.

The main enemies of a foam / gas-block house are, firstly, moisture. There are plenty of pores for condensation in its walls, and it is difficult and time-consuming to dry a damp house made of foam/gas blocks. Therefore, in this case, complete (and expensive) vapor barrier is needed both outside and inside (there are household fumes and from breathing) and good external thermal insulation that “prevents” the dew point from entering the walls. As a consequence, the statement that a house made of foam/gas blocks breathes is, to put it mildly, just talk. Who lived in such a house is unlikely to argue.

In fact, the only way to 100% prevent dampness in a house made of foam/gas blocks in any conditions is a ventilated façade. Which works great, but is by no means relevant to budget construction. Comfortable and even luxury houses from foam/gas blocks can and are being built, but in warm regions and not in the budget segment.

The second enemy of a foam/gas block house is the natural wear and tear of concrete. Let's say it chips only 0.01 mm per year. In this case, it will take 300-400 years before the reinforcement in the concrete monolith is exposed, which can be ignored in the calculations of conventional buildings. But the partitions between the pores of foam/gas blocks are about 1 mm, and their safety margin of 100% will be exhausted in 20-25 years, because destruction comes from 2 sides. Therefore, the estimated service life of a house made of foam blocks or gas blocks of up to 60-100 years is clearly exaggerated. Confirmation of this is the massive (and unsuccessful) sale of aerated concrete villas in Spain, not even by cost minus depreciation, but by how much they will take. When we were building, we forgot about the microwear of the blocks, and now what to do with all this?

Summing up

So, taking into account all the accompanying circumstances, we have few options for truly budget-friendly construction:

- The main one is an all-wood frame house, insulated with ecowool.