To ensure reliable protection of the floor from moisture, hydro- and vapor barrier must be made. The first material protects against moisture in liquid form, and the second does not allow steam to destroy structures. Vapor barrier for a ceiling with a wooden floor is especially relevant when it is planned to be insulated, that is, in the thickness of the structure there is a transition between positive and negative temperatures (condensation point).

Where to put the insulation

This question is very important, because if you put the material in the wrong place, it will not work or it will be wrong. It is important to remember one rule: vapor barrier is always laid on the side of warm air, and waterproofing on the side of cold air. Usually these materials work together, providing reliable protection of the floor in the house from any type of moisture.

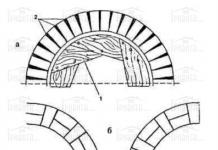

Vapor barrier film is laid on top of the floor insulation

Thus, it turns out that the vapor barrier of the wooden floor of the first floor should be carried out after the installation of heat-insulating material, and protection from moisture in the air for interfloor ceilings or attic is laid from below.

The vapor barrier film of interfloor and attic floors is laid below the insulation

The vapor barrier film of interfloor and attic floors is laid below the insulation If you lay the material correctly, then you can not worry about the safety of structures.

Vapor barrier functions

Vapor barrier when attached to the structure of the ceiling or floor in the house performs not only the above purpose. Laying material allows you to talk about the following:

Ceiling vapor barrier options

Reliable waterproofing can eliminate many problems with floors and roofs. The choice of material in a private house depends on the financial capabilities and wishes of the future owner. Previously, as a hydro-vapor barrier, polyethylene film was used almost everywhere, but it is not able to fully perform both functions when laying in the ceiling.

Polyethylene film cannot simultaneously act as a vapor barrier

Polyethylene film cannot simultaneously act as a vapor barrier It is better to give preference to more modern materials that guarantee high quality protection of the ceiling and ceilings in the house. There are several forms of release of materials. The following types of mastics for coating structures are on the market:

- cold asphalt;

- hot on the basis of bitumen;

- polyvinyl chloride;

- lingo-sulfonate based on bitumen;

- rubber;

- bitumen-based kukersolnye.

The processing of the ceiling in the house with such materials is complicated by the fact that the waterproofing of the ceilings is applied to a horizontal surface located above the height of a person. The worker will have to constantly be with his head up. Such working conditions significantly reduce the quality. To ensure reliable protection, it is recommended to consider an option such as vapor barrier membranes (not to be confused with vapor diffusion, which act as a waterproofing and release water vapor to the outside).

The following types of materials can be attributed to modern membranes for protecting the ceiling and ceilings in the house:

Features of wood ceiling vapor barrier

Installation of any material is quite simple. Due to the diversity, it is difficult to give one universal way. Most often, the manufacturer indicates the exact recommendations for the use of his material and the requirements for the performance of work.

Manufacturers most often produce both hydro and vapor protection at the same time. It is best to choose two films (vapor barrier and waterproofing) from the same company to isolate insulation and wood from moisture. This will allow us to talk about reliable protection and compliance with technology.

Regarding the fixing of the material inside the room (and it is always attached precisely from the inside, protecting the elements from the warm air of the room, regardless of which structure is being finished), the following recommendations can be given to home craftsmen:

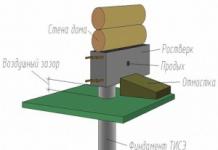

- Do not forget about the multilayer design of the ceiling. If you list the layers fixed from the inside from the bottom up, you get the following sequence: sheathing, vapor barrier, floor frame, insulation, waterproofing, floor construction. This order is suitable for interfloor and attic floors. When laying the material from the side of the attic, the location of the vapor barrier, insulation and waterproofing does not change relative to each other.

- Before laying the material, it is required to prime the surface with compositions that include antiseptic components.

- It is possible to fix subsequent layers only after the primer has completely dried.

- The vapor barrier should extend onto the wall by at least 20 cm. It is also necessary to ensure that the material sheets overlap (at least 10 cm) and the junctions and attachments to the frame are glued with adhesive tape.

- A crate is mounted on top of the vapor barrier, on which the ceiling sheathing will be attached. The crate can be either wooden or metal profile.

Upon contact with water, it ceases to fit snugly enough to the frame, and lose all thermal insulation qualities and properties. Given that the wall of a frame house consists of 75% of the total volume of heat-insulating material, then you need to pay special attention to the main points related to installation and work, the choice of the necessary one.

You should be aware that the vapor barrier membrane itself does not completely isolate from the penetration of dampness and moisture, the structure of the membrane is porous and multi-layered, and water vapor freely penetrates through it. It can reduce the rate of penetration of moisture and steam, but will not eliminate this process forever! If we consider the membrane in detail, then one of its sides is smooth, and the other has a rough surface. This is provided so that dampness and moisture settle precisely on this side of the membrane and evaporate freely from it in the future. Vapor barrier occurs with a smooth side to the insulation, and the rough part goes inside the room.

For a healthy and optimal microclimate in the house, internal circulation of fresh air is needed, and it comes not only through windows, doors and ventilation, but also through. That is why all walls are breathable - even a material such as concrete has a certain coefficient!

All vapor barrier membranes can be divided among themselves according to their properties and characteristics. Which is better? For rooms with a humid environment and elevated temperature (sauna, bath), membranes of a different quality are required, in contrast to those used in standard rooms and rooms.

The air contains a certain amount of moisture, it all depends on the climate zone, temperature regime, and the purpose of the dwelling. For example, a steam room in a bath, hot air saturated with water vapor significantly affects the walls, and if after water procedures it is not good to dry and ventilate the entire bath, you may have quite serious problems with the building of the bath.

Mold from poor vapor permeability

Mold from poor vapor permeability Sometimes this can happen in the house, for example, in the bathroom, laundry room or bathroom - these are rooms with high humidity, after which comes the kitchen and dining area, living rooms, corridors and halls. Increasing the amount of time you spend doing laundry, showering, cooking, and even just being in the house affects the amount of moisture in the air.

It is up to you to decide which vapor barrier to choose for the walls of a frame house, but this will directly depend on the purpose of your living space. For example, if you want to build a cottage or a house that will be used only in the summer, or vice versa, a full-fledged house for year-round use.

Vapor barrier membranes are used to protect the walls of a frame house from moisture and dampness vapor coming from the interior living quarters, they significantly slow down the penetration of dampness and steam into the walls, but do not completely stop this process, to ensure an optimal and healthy microclimate in the house.

Errors during installation and installation of vapor barrier

At first glance, there is nothing complicated when installing and assembling a vapor barrier membrane, it is carefully attached to the racks with a construction stapler, or bars, and then carefully glued with mounting tape or mastic. But most modern builders are not able to work neatly and jewelry. Usually, the work takes place with the appearance of any folds, cracks on the membrane, and instead of the necessary adhesive tape, the membrane is sealed with standard packing tape. Or they can even mount the vapor barrier on the other side. You will be able to notice the result of such unfavorable work only after 2-3 seasons, when the one already wet in the wall will stop working correctly.

Installation and installation of a vapor barrier membrane on the outside of the frame house

In this case, moisture vapor and dampness, passing through the wall, form condensate on the surface of the membrane, and this leads to dampening of the material. A windscreen is mounted outside the walls of the frame house, and unlike the vapor barrier membrane, it perfectly passes moisture and dampness vapors.

In this case, moisture vapor and dampness, passing through the wall, form condensate on the surface of the membrane, and this leads to dampening of the material. A windscreen is mounted outside the walls of the frame house, and unlike the vapor barrier membrane, it perfectly passes moisture and dampness vapors.

Frame house without vapor barrier

Such heaters as polystyrene foam, ecowool and polyurethane foam allow you to apply such a solution. But in this case, it is necessary to ensure sufficiently good ventilation of all rooms to remove excess moisture. The best option would be to install a forced system.

Double vapor barrier effect

Basically, this effect occurs in damp or technical rooms, when all walls are finished with special plastic panels, tiles or oilcloth, and other poorly breathing materials. As a result, moisture and dampness are trapped between two materials with little vapor barrier. To avoid this effect, use a special air gap between the wall and the finishing material, as an example, pre-sheathe the bathroom with rails, and then attach the finishing material to them. Or do not install vapor barrier in these places at all, so that dampness and moisture can easily leave through the walls, but if high humidity and dampness are constantly present, there is a risk of it accumulating in the wall. This solution is usually used for the temporary use of buildings, summer houses and cottages, and so on.

Vaporization scheme designs

To date, there are two main design schemes for the vapor barrier of the walls of a frame house.

- The first is that the vapor barrier membrane is attached to all wooden frame racks, then, on top of them, interior decoration of residential premises or clapboard is carried out.

- The second - a vertical or horizontal crate is installed on top of the vapor barrier film, which provides an air gap of 4-5 cm from the frame wall.

Consider which of these design schemes is more correct.

There are many opinions on this matter. Firstly, many of the building materials that are used in Canada or the United States are not found on our market, or they are sold at a huge price. Secondly, the difference between building materials brought from abroad and domestic producers can be significantly huge!

Provided there is sufficient ventilation to remove excess moisture and dampness contained in the air, wall design is not that important, because the correct vapor barrier of a frame house is just an additional insurance. The construction of the walls of a frame house without a certain air gap, it is advisable to use for the construction of those buildings that will be operated only in the summer or used temporarily - cottages, dining areas and guest houses, various workshops, and parking lots. But in this case, it is necessary to make ventilation, or at least install a ventilation duct, be sure to provide for conclusions from the bathroom, kitchen area, and technical rooms.

And the wall design of a frame house with an air gap is suitable for houses that will be used constantly. Because in this case there is a risk of high humidity and dampness inside a residential building.

And in conclusion, we note that vapor barrier films or membranes are produced by a number of construction companies, but the most famous manufacturers are TechnoNikol, Izospan, Tyvek.

For a long service life of the insulation in a frame house, attention should be paid to such an element of the overall design as the vapor barrier of the frame house and its quality. It is important to follow this already during the construction of the structure. Although many are still wondering: do I need a vapor barrier for a frame house?

Do I need a vapor barrier in a frame house? A well-thought-out and well-equipped vapor barrier of the internal walls of a frame house is needed for warm and at the same time humid rooms. A large amount of moisture and steam is generated in the frame house, which must be removed from the building in order to maintain optimal humidity, high quality and the appearance of a do-it-yourself frame house.

Moisture in the process of its formation and accumulation tends to go out through the walls or ceiling. First of all, moist air rises, so the vapor barrier of the floors will stop the movement of air and prevent the insulation from getting wet. If the correct vapor barrier of the frame house is not installed, then the humidity in a short time will destroy or cause quite serious damage to the construction site, and also create an unfavorable microclimate.

Vapor barrier of walls and ceiling.

Vapor barrier from inside the house is a barrier designed to protect the surface of walls, floors and ceilings from moisture, therefore, it ideally protects them from subsequent wetting.

Proper vapor barrier of a frame house is an event that is mandatory not only for baths and basements, but also for other premises built or finished using a special technology. Among the main buildings and structures where insulation is needed, it can be noted:

- Buildings insulated from the inside, especially if mineral wool or glass wool can be used as insulation. Insulation ideally retains the overall heat, but at the same time does not remove moisture at all. It gradually accumulates in heaters, whereby the base gradually loses its main purpose, and the structure of the heater is also lost.

- Structures with multilayer wall insulation. These are frame buildings with special internal insulation, respectively, protection from steam is simply necessary here.

- Frame houses with ventilated modern facades. The windproof membrane will play the role of wind protection. The installed wind protection seriously doses and softens the directed flows of external air masses.

On a note

The advantage of a well-equipped vapor barrier from inside the house is its ability to normalize heat transfer in the room.

The main mistakes of the vapor barrier

If you listen to the opinion of professionals, you can find out what difficulties and mistakes you may encounter when solving such an important issue as vapor barrier for the walls of a frame house. Among the most common shortcomings are:

The device of external walls.

- Installation of vapor barrier on the outside of the frame house. Steam will pass through the entire finish, and accumulate in the insulation. The vapor barrier layer must be located inside the building, wind protection will be sufficient from the outside;

- Installing poor vapor barrier in a tiled bathroom. In this situation, water and steam penetrate through the tile joints. All this automatically leads to a violation of not only tightness, but also the strength and reliability of fixing the finishing material in the frame house;

- Lack of moisture protection in walls insulated with mineral wool and its analogues. The absence of vapor barrier layers is permissible only if the walls are insulated with foam;

- Carrying out poor quality work. The processes associated with the installation of vapor barrier in a frame house must be carried out as clearly as possible, following the instructions. Even the most minor flaws and neglect of the rules will lead to damage.

Frame houses are known for their comfortable microclimate for everyone. For long-term preservation of it and for a serious increase in the time period of the object’s service, it is worthwhile to competently carry out all the work and activities related to construction and subsequent professional finishing.

We insulate the ceiling.

Vapor barrier materials

Modern manufacturers offer a huge variety of vapor barrier materials. What vapor barrier to choose for a frame house? The most popular of them include the following options:

- Reinforced polyethylene. A material that is becoming increasingly rare and popular solely because of its affordable cost. It is used in such a process as the vapor barrier of the floor of a frame house. In the process of its use, maximum care and strict adherence to the instructions is required. Otherwise, the frame house can turn into a steam room, that is, humid air will accumulate in the house, making living not very comfortable.

- Various types of masks. These are special mixtures that are applied to the walls of the structure before the external finishing of the frame house. Bituminous kukersol mastic, which is ideally breathable, and is sold at an affordable cost, is popular. Any type perfectly collects and retains water, completely preserving the frame of the house in its original form. This is possible only with the correct installation of the vapor barrier of the frame house.

Partition wall insulation.

- Ruberoid. Suitable for finishing modern frame buildings. The main feature of the material is the need for preliminary arrangement of a wooden crate 50 by 50 mm. Modern roofing material is universal and affordable.

- Vapor barrier films. This is a unique option with which you can create a high-quality vapor barrier for the walls of a frame house. Vapor barrier films reliably protect the structure and insulation from moisture. All this ensures the most comfortable stay in buildings built using frame technology.

All of these materials not only provide an excellent level of protection, but are characterized by such positive properties and qualities as the possibility of long-term use, ease of installation, reliability during use and perfect functionality.

Vapor barrier for walls

To equip the vapor barrier layer of modern frame objects, you will need to prepare special tools and the necessary materials. Proper vapor barrier of a frame house requires a certain sequence of work. The tools that the technology of vapor barrier of a frame house provides include:

- Adhesive construction tape with a double-sided special coating is construction tape;

- Various measuring instruments and standard scissors;

- We need metal staples, a hammer, as well as nails;

- The main vapor barrier material.

Frame wall pie.

If the installation of the vapor barrier of a frame house is carried out using the adhesion of the main layer, which protects against water and steam with the main frame with nails, you need to purchase slats made of wood or galvanized material as an addition. At the same time, it is not necessary to make a vapor barrier of the internal walls of a frame house, because there is no temperature difference in the partitions, which means that there is no air movement from hot to cold.

Vapor barrier of the floor in a frame house is simply necessary to avoid wetting of the mineral insulation, which at the same time loses its insulating properties. A vapor barrier layer is laid out on the logs, which must be glued at the joints. The counter-rail is stuffed directly on top of the lag, and only then the floor covering is mounted.

On a note

The arrangement of the vapor barrier of the walls of the frame house should be carried out after the installation of the outer layer of wind protection, as well as the layer of insulation.

Wall vapor barrier sequence

- The slats and the frame itself are carefully treated with special disinfectants.

- Walls are being measured.

- According to the obtained dimensions, elements of vapor barrier materials are cut out. In this case, an overlap of 10 mm must be taken into account.

- The material is fixed. Fasteners are installed strictly around the perimeter, and rails and a construction stapler are used here. It all depends on the base used. Installation must be done from the bottom and up. Material elements must be placed strictly horizontally. At the joints, you need to use adhesive tape, and it is important to overlap the material itself.

The vapor barrier of the walls and interfloor ceilings of the frame house was made in accordance with all the rules, and after that it is worth taking care of the ventilation in the frame house with your own hands. By the way, the vapor barrier of the partitions of the frame house is not required, because in the internal neighboring rooms the temperature does not differ from each other. But ventilation should take place between the finish and the protection layer. This will help prevent condensation from building up in the interior of the overall design pie.

Basalt wool in insulation.

Vapor barrier between floors

The division of the frame house by interfloor ceilings involves the division of the volume of the premises into parts. In these rooms of frame construction, temperature and humidity may differ. Thermal air vapors will rise upwards, thereby forming condensate on parts of the floors. To protect the load-bearing structures and insulation from moisture, a vapor barrier of interfloor ceilings is made.

Interfloor pie.

It is very important to make a vapor barrier according to all installation rules. The vapor barrier of interfloor ceilings is overlapped by about 100 mm. The joints must be glued with a special tape so that even small gaps do not remain. Only in this case, the vapor barrier will perform its functions.

Proper vapor barrier

In order to achieve an optimal result in working with vapor barrier and in the process of vapor barrier work, it is worth using special insulating and at the same time windproof membranes. The vapor barrier of a frame house with a membrane on the outside will help release moisture to the outside.

If you do not fix high-quality protection on all sides of the mounted insulation, the structure will get wet and lose its basic thermal insulation qualities. If there is no vapor barrier, and the installed insulation layer is tightly closed only with external finishing materials, the cotton wool insulation will get wet very quickly and, accordingly, will immediately lose its advantageous features.

Experts strongly advise builders and owners not to save on the purchase of building materials, as this will require material investments over time. High-quality materials, as well as proper vapor barrier in a frame house, will provide the most comfortable indoor climate, and will retain the overall performance of the building for a long time.

Vapor barrier in a wooden house. Everyone who builds a frame wooden house asks about this first of all! I already wrote about vapor barrier and waterproofing, but I decided to separately cover the topic of combating steam, since errors in vapor barrier are very critical for the future home.

- What is vapor barrier

- Which side to lay (lay) the vapor barrier?

- Vapor barrier for the walls of a frame / wooden house

- Vapor barrier of partitions

- Vapor barrier between floors

- FAQ. Film FAQs

What is vapor barrier?

vapor barrier- this is any film with low vapor permeability, which is mounted in a frame house from the INSIDE to prevent steam from getting into the insulation and keep the latter from constant wetting.

Do not confuse it with waterproofing, which is placed outside and is needed to protect the wooden frame from moisture! They use special membranes.

Do I need a vapor barrier for a frame house

Yes. The technology of frame housing construction necessarily implies the presence of vapor barrier materials in the walls, in the floor and ceilings! We must create a complete contour of the vapor barrier, which is why often the framers are called "thermos houses".

Why do you need a vapor barrier film:

- does not allow the insulation to get wet (does not let moisture into it)

- stabilizes the climate in a frame house

For this, a special vapor barrier material is used, spunbond and other films will not work.

Which side to lay (lay) the vapor barrier?

And you take an ordinary vapor barrier film, then you won’t need to look at the wrong side. But if you have already taken a specialized steam film, then look at the instructions. EVERYTHING is written there. Just don't be lazy or force the builders.

In addition to the manufacturer, no one knows how to properly lay the vapor barrier of his production, each of them has its own notes. But it is logical that a part with his brand be inside and we can see it, they did their best for us!

At Izospana-B everything is simple. A rough surface inside, moisture remains on it, the smooth side of this vapor film is placed against the insulation.

This concludes the questions about how to lay the vapor barrier. You can go to the website of the vapor barrier film manufacturer and see the exact information there, for example, on the Yutafol website (Isospan does not have a normal website).

Vapor barrier for the walls of a frame house

In the walls of a wooden or frame house, steam is isolated BEFORE the wall, that is, inside. You can’t lock it from the outside, the walls will rot.

Vapor barrier of frame house partitions

Partitions do not need to be vapor-insulated, with the exception of damp rooms. It's really better to put a PE film on the inside! But not on both sides of the wall.

If you are worried that the insulation will collect dust and get into your lungs - put a vapor-permeable membrane in the partitions on both sides!

Vapor barrier floor and ceiling in a frame house

You can vapor barrier the floor with a film (standard), but it can be a little easier - lining under the laminate + plywood or OSB on the floor gives a good result. Or even linoleum. The floor is not the place where most of the steam goes, because the steam goes mostly up!

The ceiling is more difficult. The ceiling needs to be vapor-proofed exactly with a film, because all the steam goes up. I have a text about how it looks in my house - Installing a wooden crate on the ceiling.

Vapor barrier of the ceiling in a frame house

It is NOT necessary to vapor barrier the ceiling between floors, as there is warm air from above and below. But the upper floor is another matter, there we work the same way as with the ceiling.

FAQ. Frequently asked questions about the vapor barrier of a frame house

Vapor barrier. Inside or outside?

Of course inside! Steam goes from hot to cold.

What vapor barrier to choose for the walls of a frame house

For walls, and in general, the best vapor barrier for a frame house is an ordinary plastic film 200 microns thick (not thinner).

But if you really want that you can buy Isospan or Yutafol vapor barrier, but for me it's a waste of money. Americans usually use polyethylene and without any brands.

Is it possible to have a frame house without vapor barrier?

In some climates, such as southern climates, it is indeed possible to build frame houses without a vapor barrier film. But these options are individual and you need to calculate pies and dew point very clearly. I wouldn't experiment like that

Do I need to glue the vapor barrier and how?

Yes! The film can be glued either with special butyl rubber tape or with glue. The only way is right, it is impossible not to glue the vapor barrier.

How to make vapor barrier on video:

Thermal insulation in frame houses is the main means of retaining heat. The walls are 75% made of insulation, for which special conditions must be created. It loses its positive properties under the influence of moisture from the inside. It is important that the thermal insulation fits snugly against the frame. To do this, it must always remain dry, which also requires a vapor barrier of the frame house: walls, floor, ceiling and roof.

The use of vapor barrier in the frame house insulation system

Vapor barrier characteristics

A vapor barrier is a porous membrane that can significantly reduce the negative process of moisture accumulation in thermal insulation. The porous layer allows the house to "breathe", providing air exchange. In this case, the greenhouse effect is excluded. Up to 35% of air is let through by wooden structures.

The mistake of many owners is to protect the frame house from the inside with plastic wrap. Over time, water accumulates under it, causing rotting of wooden structures.

The vapor barrier is not a film with many holes, but a complex multilayer porous package. It is tightly laid with the rough side inside the house, and the smooth side - to the insulation. This is necessary so that moisture settles better on a rough surface, and subsequently evaporates freely.

Features of laying vapor barrier when insulating a house

The film is the same on both sides. Then there is no difference which side it will face the thermal insulation. In any case, before installation, read the instructions for the specific type of membrane.

Many membranes have a specific structure. They can have a specific purpose: for residential and non-residential buildings or for rooms with different humidity. The material is selected depending on the way buildings are used, the characteristics of the region, the conditions of use, etc.

In rooms with a humid environment and elevated temperatures, membranes are needed that differ in properties from those used in ordinary homes. For example, reflective aluminum screens are used in saunas and baths.

Vapor barrier of the walls and ceiling of the bath

Thus, the vapor barrier protects the structure of the house from water vapor only partially.

Features of vapor barrier frame houses

Vapor barrier for the outer walls of a frame house is made according to a scheme that is in many ways similar to other types of houses. The only difference is that the supporting structures do not perform the function of insulation here.

Walls in cross section look like this:

- external finishing with siding, clapboard or OSB boards;

- waterproofing film;

- frame;

- thermal insulation;

- vapor barrier;

- crate;

- interior decoration.

At first glance, it seems that the vapor barrier is easy to lay, you just need to fix it by turning it in the right direction. Fixation is carried out using a construction stapler or galvanized nails, with sealing of joints with adhesive tape.

Fastening the vapor barrier with a construction stapler

Basic rules to follow:

- it is unacceptable to leave membrane ruptures;

- the number of folds should be minimal;

- gluing and sealing of seams must be of high quality;

- the places of contact of the tree with the vapor barrier are treated with an antiseptic;

- the diffusion membrane can be laid directly on the thermal insulation, in other cases a gap of about 5 cm is left between them;

- it is not allowed to confuse the sides of the membrane when laying.

Any miscalculation will lead to the fact that the insulation will cease to perform its functions after a short time. As a result, you will have to re-insulate the house. Not all owners or builders are able to show the necessary accuracy during installation, and it lasts for 2-3 seasons, after which the insulation gets wet and stops working properly.

The installation technology provides for laying the vapor barrier from top to bottom. The overlap is made at least 100 mm with sizing tape designed for it. The connection to wooden structures should be carefully checked.

Depending on the type of insulation, sometimes a vapor barrier is not required. A similar decision is made when foam, ecowool and polyurethane foam are used. When using such thermal insulation, the exit of moisture from the premises is difficult. Therefore, it is necessary to create their high-quality ventilation. In such a situation, forced air intake and exhaust are needed.

Vapor barrier is not required in houses without additional insulation, when the walls are built of brick or foam blocks. Also, it is not done on the interior partitions of the house. The insulation absorbs steam in the event of a temperature difference on the outer walls.

Frame house vapor barrier schemes

Differences in the construction of houses provide different conditions for the removal of moisture from the premises.

Double vapor barrier

If the wall is finished on both sides with poorly “breathable” materials (tile, oilcloth, plastic), moisture can accumulate between them. To eliminate this negative effect, a ventilation gap is made between the wall and the cladding. At the same time, you need to make sure that air circulates in it and leaves somewhere.

Basic vapor barrier schemes

Moisture protection in frame houses is usually done in two ways:

- The membrane is attached to the racks of the frame, and then the interior is finished (Fig. a below).

- On top of the vapor barrier film, a horizontal or vertical crate is installed, on which the cladding is attached. As a result, a ventilation gap of 4-5 cm is formed inside (Fig. b).

Ways of vapor barrier of the walls of a frame house

The latter option is preferably done with permanent residence in the house, when there is a risk of moisture accumulation between the walls. Without an air gap, it is allowed to build buildings for temporary visits. They are ventilated with the installation of a box. Be sure to make an extract from rooms with high humidity.

When equipping a house with effective ventilation, the role of vapor barrier is reduced. Here it serves only as an additional insurance against the accumulation of moisture in the walls.

Vapor barrier for external insulation of the house

The vapor barrier cannot be laid on a smooth wooden surface.. First, slats 2.5 cm thick are stuffed onto the wall in increments of 1 m, and a membrane is attached to them with a stapler. It should be facing the rough or fleecy side outward, and the smooth side to the wall. Then a crate is stuffed on top, thermal insulation is laid on it, and a waterproofing film is stretched on top. After that, the final exterior decoration of the house is carried out.

External insulation of the house

The method provides a special microclimate in a house made of logs, timber or a frame structure, since there is no need to cover the tree inside with a finishing material.

The disadvantage of this option is the need to dry the structure, which takes several years. Additional work is also added to protect the joints with sealant and seal the grooves on both sides. Only hydrophobic materials can be used for insulation.

Vapor barrier of the floor in a wooden house

Hydro and vapor barriers are needed for an insulated floor due to the action of two factors:

- moisture from the basement or basement passing through the ground;

- steam from the premises.

When insulating the floor, waterproofing is first laid in the space between the lags on the subfloor. Film strips are placed with overlapping and gluing with special adhesive tape.

Plates or rolls of insulation 15 cm thick are placed in the cells of the frame, and then covered with a vapor barrier film. It also requires overlapping and gluing joints.

Boards 30 cm thick and in increments of 40-60 cm are placed across the log. They are fastened with self-tapping screws or other suitable fasteners. Due to them, a ventilation gap is created between the floor and the vapor barrier.

Across the crate, a tongue-and-groove floorboard of 25-30 mm or edged board of 40-50 mm is tightly laid and fastened. From above the finishing floor covering is arranged.

Floor insulation on the first floor

The use of vapor barrier for the floor is effective only together with a breathable insulation. Styrofoam and similar materials are not suitable here. It is advisable to use mineral wool with a density of 37-57 kg / m3, since there is no load on it in the floor structure.

Ceiling insulation and vapor barrier

Up to 80% of frame houses are insulated with mineral wool. In addition to it, expanded polystyrene, ecowool, expanded clay, etc. are used.

The ceiling is insulated as follows:

- A vapor barrier film is stretched onto the beams from below and attached to them with a stapler. Then the board is stuffed in increments of about 40 cm.

- Mineral wool is laid tightly on top of the entire ceiling. At the same time, the walls are lapped. With a thickness of 50 mm boards, they should be laid in three layers to create a standard size of 150 mm. They are stacked in a checkerboard pattern, and the ceiling beams are covered with the top layer.

- From above, the insulation is covered with a vapor barrier film if the attic is made warm. It is rolled out over the entire ceiling with an overlap of at least 10 cm and sealing of the joints. If the attic is unheated, such protection from above can be omitted.

- The floor is laid on top of the insulation. Between it and the vapor barrier there should be a ventilation gap of about 5 cm.

A properly laid ceiling “pie” prevents the accumulation of moisture in the insulation both from below and from above.

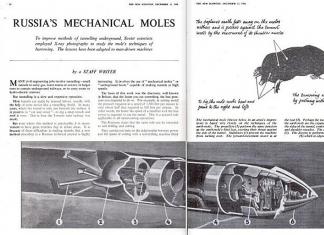

Roof insulation and vapor barrier

The roof is insulated like walls, but there are some features here. Waterproofing is laid on top of the rafters. It is fixed by a crate on which the roof is attached. After that, insulation boards are inserted between the rafters. It is better to take them rigid so that the material does not deform.

Plates are installed with a gap from the waterproofing film. It is necessary for ventilation and removal of moisture that forms under the roof. For better circulation, two conclusions are made from the gap - from different sides of the house. It is advisable to choose a fireproof material.

Roof insulation

Waterproofing must be airtight, otherwise moisture will get on the insulation, and it will lose a significant proportion of its useful properties.

From the inside, a vapor barrier is nailed to the rafters and a crate is installed. A facing material is attached to it. These can be QSB-plates, drywall, etc. For cladding, a frame of profiles is installed, as for walls.

With high-quality insulation and reliable protection against moisture in the attic, you can install a heating system. Then at any time of the year it will be a full-fledged living space.

Video: frame house insulation

Laying vapor barrier in a frame house is carried out taking into account the sequence, the specifics of installation, as well as the features of the technology. If there is a non-residential premises under the roof, it can not be insulated, but thermal insulation significantly reduces noise during rain.

The correct choice and installation of vapor barrier membranes fully ensures their useful functions in protecting the frame house from moisture.

IZOSPAN in internal walls (interior partitions)

- Finishing

- counter rake

- Vapor barrier Izospan V

- insulation

When erecting internal walls (partitions) in a room, it is extremely important to ensure that the following conditions are met:

- vapor barrier of the partition structure and the insulation included in it (heat and sound insulation);

- dust removal of the internal space of the room from the penetration of small particles of insulation into it;

- corrosion protection (mold, fungus, etc.)

The two-layer polypropylene vapor barrier film "IZOSPAN B" effectively copes with these tasks. It is she who is recommended for use in the construction of internal frame walls (partitions). Instead of the Izospan-V film, other IZOSPAN materials can be used in the construction of internal frame walls:

The layout of these IZOSPAN materials is similar to the installation of "Izospan V".

Buy roof insulation/sten?

We will deliver together with vapor barrier and OSB. Stock! Have questions?

BUY ISOROK INSULATION FOR ROOFING

Installation instructions "Izospan V" in the construction of partitions (internal frame walls)

The vapor barrier film "Izospan V" is laid on the supporting elements of the partition frame (beams, racks) or along the rough sheathing on both sides of the insulation (heat-insulating layer) with the smooth side inward - to the insulation.

In order not to forget how to install vapor barrier, you need to remember a simple rule: the rough side of the vapor barrier ensures the retention of drops of condensate that forms at the “dew point” - the contact boundary between warm and cold air. In the future, these drops of condensate evaporate due to ventilation in a specially equipped ventilation gap.

If this temporary retention of condensate drops is not provided, chaotically flowing moisture can cause wetting of the underlying structures, which, as a result of this wetting, will collapse prematurely.

Vapor barrier "Izospan V" is pre-tensioned and fixed with a construction stapler or galvanized nails. Laying of vapor barrier sheets is carried out from the bottom up with horizontal panels. The next panel of vapor barrier is mounted with an overlap with a mandatory overlap at the joints of at least 15 cm.

Further, the vapor barrier is finally fixed with wooden antiseptic counter-battens or galvanized profiles (depending on the finishing material of the room). The thickness of these profiles (counter rails) sets the value of the ventilation gap (minimum 4x5 cm). The interior decoration of the room is also attached to them.

To ensure maximum tightness of the vapor barrier (especially in rooms with high humidity), it is recommended to glue the Izospan V vapor barrier panels together with the Izospan KL or Izospan SL connecting tape.

The places where the Izospan B vapor barrier film adjoins wooden, concrete and other surfaces are recommended to be glued with Izospan ML proff adhesive tape to eliminate wetting and corrosion of these surfaces under the film.

See also:

Other materials IZOSPAN.

Geotextile and vapor barrier MEGAIZOL.

Which side to put the vapor barrier to the insulation on the ceiling in the bath? Vapor barrier for a ceiling in a wooden floor which side

Even if it seems that the air inside the house is very dry, and even specially purchased humidifiers, it still contains a large amount of moisture vapor. Before the advent of energy-saving materials in construction, no one paid attention to this. Modern thermal insulation materials based on mineral wool were ineffective and lost most of their heat-preserving qualities due to gradual wetting. Therefore, special films appeared on sale, some of which are mounted only outside and are wind and moisture resistant, while the latter are located from the inside, from the side of the room and prevent the penetration of steam. The article will focus on the correct vapor barrier at home.

Why do you need a vapor barrier in the house

A house without the use of vapor barrier can be if it is insulated with foam plastic, foam plastic or does not have a heat-insulating layer at all, for example, foam block and brick.

- But in order to save on heating and to improve the heat-preserving characteristics of houses in modern construction, natural insulation made from cellulose (ecowool) or basalt wool is almost always used. But here we must remember about the constant moisture exchange that occurs in the living room.

- So, if the house is too humid, then water vapor will inevitably be absorbed by the walls and ceiling, and, conversely, if the air is too dry, this moisture will return to the rooms. From which it follows that if the insulation in the wall is not protected by a vapor barrier film, then moisture will accumulate in it, filling all the air cavities between the mineral wool fibers, thereby depriving it of all its thermal insulation characteristics.

Tip: the exception is the internal partitions in the house. One of the most important factors in which mineral-based insulation absorbs steam is the temperature difference that occurs at the outer walls. In this case, condensate accumulates inside, which is most dangerous for the material. But there is no such effect in interior partitions, so they are not covered with vapor barrier material.

Cases where the installation of a vapor barrier is required

- When the walls bordering the street are insulated with mineral wool from the outside;

- if the "pie" of the wall consists of several layers, one of which is a cotton wool insulation. In this case, the vapor barrier film is mounted on the inside. The most striking example of such a device is frame houses;

- when arranging ventilated facades. Mineral insulation should be closed from the outside with a waterproof film, and from the inside with a vapor barrier. The first will protect the thermal insulation from water and air currents, and the second from the side of the interior from steam. A good example is a wooden house sheathed with siding or wooden clapboard.

Vapor barrier films are produced in several types and, according to their purpose, are divided into wall and roofing:

- roof vapor barrier. It is attached from the side of the dwelling, protecting the thermal insulation from rising vapors. This is an important stage, since the evaporation of moisture rises with warm air and can get into the insulation. This threatens not only with loss of heat, but also with the formation of mold and fungus. It is needed only when arranging an operated and heated attic. If the attic is cold, then vapor barrier is not done, limited to a windproof membrane under the roofing material itself, which protects it from condensation;

- house wall vapor barrier. It should be carried out with special materials, which, on the one hand, should not allow steam to pass to the insulation, and on the other hand, freely bring it out if moisture somehow gets inside. This happens due to possible gaps or incorrectly made joints of rolled materials. It is better to choose special diffusion materials, instead of the usual plastic films or glassine;

- floor vapor barrier. It must also be done, as condensate can accumulate from rising vapors $

- floor vapor barrier. It is necessary in rooms with high humidity or in houses where the floor is insulated with mineral wool. In this case, a waterproofing film is placed on the underside, and a vapor barrier is laid on top. A vapor barrier is also equipped when the concrete floor slabs are located directly above the ground.

If the question is whether a vapor barrier is needed in a wooden house, then you must again rely on the presence of a heater. If it is not there, and the wall of the house consists entirely of only timber or logs, then it makes no sense to install a vapor barrier film.

Types of vapor barrier materials

Until recently, glassine was the only vapor barrier material used in Russia. But with the development of technology, they gradually began to build on it, preferring more durable and high-quality materials.

- polyethylene films. They are best used for vapor barrier ceiling in a residential area. Most often, interfloor ceilings are insulated with mineral wool, as it has the best soundproofing properties. The polyethylene film will reliably protect it from even a small amount of moisture. On sale you can find ordinary materials, reinforced or with a foil layer.

- Polypropylene films. Best used for ceiling insulation in a residential attic. They are distinguished by increased strength to mechanical damage and resistance to UV radiation. With its arrangement, you can safely repair the roof without fear that moisture will seep inside the house.

- Membrane. This popular and frequently used type of vapor barrier is produced in the form of a single-layer or multi-layer rolled material. These nonwoven materials can be single-sided or double-sided, depending on their location and functionality. The use of inexpensive double-sided non-woven membranes is considered optimal.

- Breathable films or breathable membranes. They completely exclude the possibility of water vapor penetrating inside to the thermal insulation, but at the same time they do not in the least prevent their exit from the inside. They allow you to save on living space, since their operation does not require equipping a ventilation gap.

- Ordinary vapor barrier film. Its function is to create a vapor barrier on the inside of the walls and roof. It protects the heat-insulating material from steam ingress from inside the heated room.

- Vapor barrier membrane with reflex coating. Able to partially reflect heat back into the room. This helps to increase the thermal protection of the room and roof up to 10%. Compared to standard counterparts, they have great vapor barrier characteristics, so it is advisable to use them in rooms with high humidity.

- Vapor barrier membrane with limited permeability. They have diffusion abilities that allow steam to be removed from rooms that are used irregularly. For example, it can be a garden house that is actively used in summer, but in winter it can be heated only a few times.

- Vapor barrier with variable vapor barrier properties. Ideal for renovation work, as they can be mounted from the outside without dismantling the inner cladding.

Manufacturers of vapor barrier films

TechnoNicole

This well-known company guarantees that its vapor barrier films will last for decades. There are 3 main types of this product on sale:

- vapor barrier film TechnoNikol. Used for interior work. A fairly versatile material that is suitable for insulating walls, ceilings and pitched attic roofs. The price of a roll is 1500 rubles;

- diffusion membrane films TechnoNikol designed to isolate the roofing insulation from the formation of condensate in it. Represents a nonwoven polymer fabric and protection of both sides from polypropylene fabrics. Unlike conventional vapor barrier materials, this is a breathable film. The cost for a standard roll is about 3200 rubles;

- non-perforated vapor barrier film TechnoNikol. Highly targeted material for roof vapor barrier. Protects against both water and dust. For maximum strength, it is reinforced with a special mesh fabric. The approximate cost is 1200-1500 rubles / roll.

Izospan

This is the rare case when a domestic company presents high-quality world-class material at an affordable price.

- Izospan C. This is a two-layer film that protects the insulation from the inside of the room. It can also be used as a roofing film on non-insulated roofs. One side of it has a roughness, the role of which is to retain excess moisture and with its further evaporation. The second side is smooth, it is mounted on a heater.

- Izospan V. An analogue of the previous material, it is also chosen for the vapor barrier of the walls of a frame or wooden house from the inside.

- IzospanD. This is the most versatile vapor barrier film from the entire Izospan product line. It has an anti-condensation coating that can protect mineral wool from both internal steam and external moisture and wind. Its strength is so high that it can be used as an independent roof covering for 3 months even in winter. When installing it on the walls from the outside, it is allowed to postpone the arrangement of the finishing cladding for up to 6 months. The price of a roll is 2500 rubles.

Installation of vapor barrier walls in a wooden house

The vapor barrier installation technology implies its fastening from the inside of the house between the insulation and the crate, to which the facing material is mounted. If modern membrane material is used, then it is placed with a smooth side close to the insulation. In this case, the vapor barrier will evenly distribute the flows of moist air, bringing it into the ventilation system.

The method of fastening the vapor barrier depends on the purpose of the room in the house. In little-used or non-residential rooms in which low humidity is allowed to use a one-sided method of arranging a ventilation gap. In all other cases, professionals advise to provide for bilateral ventilation, which is much more efficient. Often, the membrane manufacturer on the packaging indicates the recommended installation method.

Stages of work

- If the house is not new, but repairs are being carried out, then first the entire cladding is dismantled to the wooden frame of the wall. If possible, inspect the insulation or wood for damage, if necessary, eliminate them.

- Walls and thermal insulation must be thoroughly dried. It is advisable to carry out work in the warm season, since frost can form in winter, which, closing with a vapor barrier, will turn into a large amount of moisture over time.

- If the house is framed, then the membrane is rolled out along the length of the entire wall and cut off so that in the corners there is an overlap on the adjacent wall of 10-15 cm. It is fixed in stages to each vertical board of the frame using a stapler. There should be no distortions, cracks or folds. Therefore, it is better to do the work together. The tension should be so strong that the insulation in the wall is located tightly without falling out of the wall.

- On top, again with an overlap, the next layer of vapor barrier is rolled out and fastened in the same way. After that, the joints are glued with adhesive tape. A frame of slats is stuffed on top, which tightly presses the vapor barrier and at the same time serves as a frame for the cladding. Represents sosboy vertilkany slats, which are mounted on self-tapping screws in increments of 60 cm (the distance corresponds to the width of the insulation and the frame of the walls of the house). In addition, the film is also fixed with rails around the perimeter of all door and window openings.

- If the vapor barrier of the house is made of timber, then the frame is first stuffed under the insulation to the walls and tightly laid there. Further, all work is carried out in a similar way.

Do-it-yourself ceiling vapor barrier in the house

Most often it is done if the interfloor ceiling is made of wooden logs and insulated with mineral or basalt wool. Two people are required to complete this work, it will be extremely difficult to do it alone.

- Before starting work, the ceiling must be disassembled and consist only of logs.

- Then, from below, that is, from the side of the living room, a vapor barrier is attached along the logs. This should be done along the longer side of the room in order to form as few joints as possible.

- The required length is measured and cut off on the floor and already with the prepared segment they rise to the ceiling. It is convenient when 2 masters are located on opposite sides of the room. This allows you to correctly position the vapor barrier and make sure that it does not warp during fastening.

- For the convenience of work, at first you can simply “grab” it in several places (but do it firmly). And after making sure of its correct location, already fix it thoroughly.

- So they pass the entire ceiling, not forgetting about the overlaps and their gluing.

- From below, it is attached to the logs with wooden slats, regardless of what the ceiling covering will be.

Tip: the work is quite painstaking and it often happens when an accidental tear occurs on an already fixed area. In this case, a patch is cut out of the membrane with an allowance of 10-15 cm along the edges. It is inserted into the hole formed and glued along the edge with glue. This creates a fairly airtight layer. The top is additionally glued with adhesive tape.

- Having finished fastening the vapor barrier, a heater is placed in the formed cells from the side of the second floor.

Errors in vapor barrier in a frame house

- Poor quality installation. At first glance, it seems that it is simply impossible to make a mistake when attaching a vapor barrier film. What could be easier than stretching it well, attaching it to the frame and gluing the joints. But it is precisely because of the seeming simplicity that some builders neglect accuracy during work. As a result, gaps or folds are formed. But the worst mistake can be the wrong location of the membrane, or rather the wrong side, as a result of which it starts to work incorrectly. If all this was already covered with interior decoration, then the consequences of such work can be guessed only after a couple of seasons, when the heat-insulating layer starts to work worse.

- Installation of vapor barrier film on the outside of the house. This gross mistake leads to the fact that steam, seeping from inside the house and passing through the insulation, rests against the vapor barrier and settles on it with condensate. In a very short period, the insulation dampens, not being able to ventilate. For external protection, it is necessary to use exclusively windproof films that are able to let excess moisture out.

- Lack of vapor barrier in a frame house. There are a number of materials that allow the absence of a vapor barrier. This is foam or extruded polystyrene foam. Most often it is made in houses from sandwich panels. But, in order to remove excess moisture from the house, in this case it is necessary to install a high-quality forced ventilation system. When insulating with ecowool or mineral wool, vapor barrier must be present in all cases.

- Double vapor barrier. It happens that a vapor barrier layer is placed in rooms with high humidity, and a facing material with low vapor-permeable properties, such as plastic panels or tiles, is laid on top. It turns out that after passing through the joints of the grout or the joints of the panels, the steam gets between the vapor barrier and the tile, without the possibility of escaping. Therefore, for cladding in such rooms, it is recommended to make a crate on the wall that borders the street.

- Or simply abandon the vapor barrier in this place, but there will be a risk that, getting into the insulation, the steam will not have time to vent through the windproof membrane from the outside. This is permissible only for frame houses that are used as summer cottages.

Choosing a vapor barrier installation method. In total, 2 ways to use a vapor barrier are used. In the first case, the film is attached to the wall frame, and sheathing material (drywall, lining, etc.) is mounted on top of the same load-bearing wall boards. In the second version, the film is similarly nailed to the wall frame, but under the sheathing material of the walls, an additional frame is made of slats 2-3 cm thick. Which method is more correct?

- The first option has the right to exist, but only if the materials of the highest quality are used for decoration. Otherwise, the repair will quickly become unusable, due to the lack of a ventilation gap. Or use this method when the building has an economic purpose and is not used year-round. But even here it is necessary to make ventilation wiring throughout the room.

- The second option with the arrangement of a ventilation fence is more acceptable for houses intended for permanent residence. This helps eliminate the risk of excess moisture in the air.

The wooden framework is the bearing element of a partition.

It is calculated based on what functions the structure will perform during operation. For example, if furniture and household appliances are not hung on the partition, then the frame is made of a beam of small section. Its bearing capacity must be sufficient to support its own weight with the cladding.

In typical frame houses, the partition frame is assembled from a bar with a section of 100 × 40 mm. As a rule, air-dried lumber is used. The beam is installed vertically in the form of support posts.

The distance between adjacent posts will depend on a number of factors, including the required load-bearing capacity of the partition wall. In a standard situation, the distance between the posts is determined by the width of the used roll insulation (120 mm). A distance corresponding to the width of the selected door is left under the doorway.

The racks of the frame are necessarily reinforced with horizontal jumpers. They are necessary to give rigidity to the structure.

Qualitative properties of the material

Private developers with a small construction budget choose simple and cheaper materials. In particular, the budget version of the vapor barrier requires the use of glassine.

But today there are many such materials that are characterized by greater efficiency and durability. The high quality steam roof closure is made from high strength polymers with improved properties.

Vapor blocking can be effective if the material meets the following requirements:

- Ability to work in a wide temperature range. The optimal parameters should correspond to temperatures from -70 to +100 degrees.

- Correct vapor permeability. Modern materials do not exceed 0.4 g / m2, but outdated options may have a vapor permeability of up to 20 g / m2.

- Long period of operation. The recommended service life of the vapor barrier must match the service life of the roofing material.

- Good elasticity. A material that can bend well, not only makes it easy to assemble, but also breaks during the laying process.

In addition, it must have a high quality, high strength flying barrier. When properly installed, the strong fabric is capable of holding back snow, melting and precipitation in the event of damage to the roof material.

Steam or hydro

Let's start with the fact that the main mistake is to mix steam and moisture into one concept. Steam and moisture are completely different things!

Formally, steam and moisture are water, but in different states of aggregation, respectively, having a different set of properties.

Water, it is also moisture, it is also “hydra” (hydro from ancient Greek ὕδωρ “water”) - this is what we see with our eyes and can feel. Tap water, rain, river, dew, condensate. In other words, it's a liquid. It is in this state that the term "water" is commonly used.

Steam is the gaseous state of water, water dissolved in air .

When an ordinary person talks about steam, for some reason he thinks that it is necessarily something visible and tangible. Steam from the nose of a kettle, in a bathhouse, in a bathroom, etc. But actually it is not.

Vapor is present in the air always and everywhere. Even as you read this article, there is steam in the air around you. It underlies the very humidity of the air, which you have probably heard about and complained more than once that the humidity is too high or too low. Although no one saw this moisture with their eyes.

In a situation where there is no steam in the air, a person will not live long.

By taking advantage of the different physical properties of water in liquid and gaseous states, science and industry have been able to create materials that allow steam to pass through, but not water.

That is, this is a kind of sieve that can pass steam, but will not let water in a liquid state.

At the same time, especially smart scientists, and then manufacturers, figured out how to make a material that will conduct water in only one direction. How exactly this is done is not important to us. There are few such membranes on the market.

Vapor permeable membrane - allows steam to pass through in both directions, but does not allow moisture to pass through

So, a construction film that is impervious to water, but passes steam equally in both directions - is called waterproofing paro permeable membrane. That is, it passes steam freely in both directions, but does not pass water (hydra) at all or only in one direction.

paro insulation - this is a material that does not let anything through, neither steam nor water. Moreover, at the moment, vapor barrier membranes- that is, materials that have one-sided vapor permeability have not yet been invented.

Remember as "Our Father" - there is no universal "parohydro membrane". There is a vapor barrier and vapor permeable waterproofing. These are fundamentally different materials - with different purposes. The use of these films in the wrong place and in the wrong place can lead to extremely sad consequences for your home!

Formally, vapor barrier can be called vapor barrier, since it does not let water or steam through. But using the term is a path to dangerous mistakes.

Therefore, once again, in frame construction, as well as in insulated roofs, two types of films are used

- paro insulating- which do not let steam or water through and are not membranes

- Waterproofing steam permeable membranes (also called windproof, due to extremely low air permeability or superdiffusion)

These materials have different properties and using them for other purposes is almost guaranteed to lead to problems with your home.

Where the builder goes wrong

Each specialist has his own approach to the implementation of the upcoming work. Experienced craftsmen identify several unreasonable manipulations with vapor barrier material, leading, if not to the complete destruction of this ability, then to a strong decrease in performance during operation.

outdoor installation

First mistake. If you fix the vapor barrier, then there will be no sense from this. The problem lies in the protection from moisture coming from the inside and condensing on the heat insulator. Outside, the wall is protected by facing material and wind protection.

Double layer of insulation

Wanting to improve the performance of inexpensive material, it is fixed in two layers. Of course the effect  will, but then the air circulation inside the partitions will be completely blocked. And since absolute sealing of the joints is impossible, sooner or later moisture will penetrate inside. The absence of a circulating process will affect here. The liquid will accumulate on the heat insulator and wooden partitions, starting an irreparable process of destruction.

will, but then the air circulation inside the partitions will be completely blocked. And since absolute sealing of the joints is impossible, sooner or later moisture will penetrate inside. The absence of a circulating process will affect here. The liquid will accumulate on the heat insulator and wooden partitions, starting an irreparable process of destruction.

Refusal of vapor barrier

In fact, this is permissible if plates conducting water molecules are used as a heat-insulating material. It can be polystyrene, polystyrene or ecowool. These materials promote natural air circulation, but it must be remembered that they are not recommended for residential areas. And if you use them in work, you need to take care of reliable sewing from the inside. So that vapors from the material do not get inside the room and do not create discomfort with an extraneous smell.

Any deviations and small flaws in the vapor barrier will subsequently result in more serious problems. Violation of the integrity of the heat insulator is still flowers in comparison with the destruction and putrefactive processes of load-bearing structures.

Hydrowindproof vapor permeable membrane

This film is completely different in properties from the vapor barrier. She keeps moisture out outside the house into the insulation and on the wooden parts of the house, while releasing steam from the inside. Despite the fact that we closed the insulation from the inside with a vapor barrier, a little residual steam still passes into the insulation and we need to release this steam. For this, the membrane vapor-permeable.

In addition, these membranes are usually windproof and at the same time protect the insulation from blowing heat.

Where is a hydro-windproof film used in a frame house:

The walls of the frame house - outside (or under the counter-lattice under the wooden facade or immediately under the siding according to OSP-3)

In the floor of a frame house (lower floor) - from below under the insulation so that the wind does not blow ()

In the ceiling of a frame house (upper floor) - on top of the insulation so that the insulation does not blow out (if it is ecowool or sawdust, etc. loose insulation)

Definition and marking of vapor barrier for coating

The vapor barrier film is a special material in the composition of the roof cake, which can vaporise as much as possible.

According to the laws of physics, hot air saturated with water vapor rises from the school direction and is part of the process of human life. In a room under the roof, it turns into condensate, and in this form it settles on the rafters, it causes rotting of wooden structures and damages the insulation.

The use of materials to protect against a pair of covers helps to solve the following problems:

- Ensuring the quality properties of the heat-insulating material. Laying the vapor barrier prevents condensation, which adversely affects the quality of the insulation.

- Extending the life of the roofing material. Vapor barrier protects the roofing material from the negative effects of moisture and corrosion inside.

- Protection of the wooden elements of the scissor system from rotting. Due to the protection of the vapor barrier film, molded condensate does not affect the wooden frame, so the wood remains dry and does not rub.

When deciding how to properly build a vapor barrier on a roof, it is necessary to choose the right material.

This takes into account several factors: climatic conditions, roof construction, type of roofing material. Incorrect selection may cause condensation.

Installation and installation of a vapor barrier membrane on the outside of the frame house

In this case, moisture vapor and dampness, passing through the wall, form condensate on the surface of the membrane, and this leads to dampening of the material. A windscreen is mounted outside the walls of the frame house, and unlike the vapor barrier membrane, it perfectly passes moisture and dampness vapors.

Frame house without vapor barrier

Such heaters as polystyrene foam, ecowool and polyurethane foam allow you to apply such a solution. But in this case, it is necessary to ensure sufficiently good ventilation of all rooms to remove excess moisture. The best option would be to install a forced exhaust ventilation system.

Double vapor barrier effect

Basically, this effect occurs in damp or technical rooms, when all walls are finished with special plastic panels, tiles or oilcloth, and other poorly breathing materials. As a result, moisture and dampness are trapped between two materials with little vapor barrier. To avoid this effect, use a special air gap between the wall and the finishing material, as an example, pre-sheathe the bathroom with rails, and then attach the finishing material to them. Or do not install vapor barrier in these places at all, so that dampness and moisture can easily leave through the walls, but if high humidity and dampness are constantly present, there is a risk of it accumulating in the wall. This solution is usually used for the temporary use of buildings, summer houses and cottages, and so on.

Vaporization scheme designs

To date, there are two main design schemes for the vapor barrier of the walls of a frame house.

- The first - a vapor barrier membrane is attached to all racks of a wooden frame, then, on top of them, interior decoration of residential premises with plasterboard or clapboard is carried out.

- The second - a vertical or horizontal crate is installed on top of the vapor barrier film, which provides an air gap of 4-5 cm from the frame wall.

Consider which of these design schemes is more correct.

There are many opinions on this matter. Firstly, many of the building materials that are used in Canada or the United States are not found on our market, or they are sold at a huge price. Secondly, the difference between building materials brought from abroad and domestic producers can be significantly huge!

Provided there is sufficient ventilation to remove excess moisture and dampness contained in the air, wall design is not that important, because the correct vapor barrier of a frame house is just an additional insurance. The construction of the walls of a frame house without a certain air gap, it is advisable to use for the construction of those buildings that will be operated only in the summer or used temporarily - cottages, dining areas and guest houses, various workshops, and parking lots. But in this case, it is necessary to make ventilation, or at least install a ventilation duct, be sure to provide for conclusions from the bathroom, kitchen area, and technical rooms.

And the wall design of a frame house with an air gap is suitable for houses that will be used constantly. Because in this case there is a risk of high humidity and dampness inside a residential building.

And in conclusion, we note that vapor barrier films or membranes are produced by a number of construction companies, but the most famous manufacturers are TechnoNikol, Izospan, Tyvek.

https://www.youtube.com/watch?v=GNjxQobTssUhttps://www.youtube.com/watch?v=GNjxQobTssUhttps://www.youtube.com/watch?v=k-mLaZrSgso

9 best construction and furniture stores!

- Parket-sale.ru - A huge range of laminate, parquet, linoleum, carpet and related materials!

- Akson.ru is an online hypermarket of building and finishing materials!

- homex.ru - HomeX.ru offers a large selection of high-quality finishing, materials, lighting and plumbing from the best manufacturers with fast delivery in Moscow and Russia.

- Instrumtorg.ru is an online store of construction, automotive, fastening, cutting and other tools that every craftsman needs.

- Qpstol.ru - "Kupistol" strives to provide the best service to its customers. 5 stars on YandexMarket.

- Lifemebel.ru is a furniture hypermarket with a turnover of more than 50,000,000 per month!

- Ezakaz.ru- The furniture presented on the site is made at its own factory in Moscow, as well as by trusted manufacturers from China, Indonesia, Malaysia and Taiwan.

- Mebelion.ru is the largest online store selling furniture, lamps, interior decor and other goods for a beautiful and cozy home.

Accounting for shrinkage of the house during installation

Each homeowner can independently make a partition in a frame house, regardless of the type of construction, features of the house and its layout. If in a frame house or from aerated concrete installation is carried out without special rules, then in houses made of materials that eventually shrink the entire structure, it is worth installing partitions only after the end of the process of shrinkage of the supporting structures.

On a note

If it is impossible to wait for the process of shrinkage to end due to the limited delivery time of the object, small gaps in the structure can be foreseen in advance. In the future, these gaps will be eliminated in the process of shrinkage of the house.

Features and major bugs

The most common insulation is mineral wool (it is also called stone or basalt wool). That's why:

- from the side of the outer planes and floor surfaces, a PVC waterproofing film or a moisture and sound-proofing special polymer coating is laid. Here the effect of humidity from the "street" side is much stronger;

- on the inside of the wall, it is imperative to lay a vapor barrier membrane - a thinner film.

Inside the heat-insulating layer, the temperature decreases from its inner part to its outer one. But if it is winter outside, then inside the insulation there will be a layer where water vapor will certainly condense. If you do not protect the dispersed stone wool from "communication" with the internal atmosphere of the house, then sooner or later such insulation will inevitably be saturated with moisture and lose its insulating properties.

The main mistake is that many are limited only to the waterproofing outer layer, which is unacceptable. In addition to insulation, the wooden parts of the frame also need to be limited from interacting with moisture. They are strongly recommended to be used exclusively dried to furniture humidity (that is, up to 6-8%), but for a long time (from 10 years or more), the tree is able to absorb moisture from the air in limited portions, and therefore deform. So the vapor barrier of the house from the inside is a matter not only of maintaining heat, but also of the strength of the building.

Vapor barrier - the next process after warming the house

Partition device

Frame partitions in a wooden house are represented by a wide variety of options. Frame wall structures are versatile due to various types of installation and materials used.

Walls in the attic of the house.

Walls in the attic of the house.

Types of partitions

Interior partitions of a frame house can be divided into several types:

- Stationary partitions are wooden vertical posts, which are filled with soundproofing material and sheathed with any finishing material. Partitions form a modular system and can be installed anywhere.

- Sliding partitions are distinguished by the presence of a special roller mechanism that facilitates the movement of the canvas in any direction if necessary. Sliding partitions in the house are divided into radial, suspended and folding.