Reading time: 7 minutes.

Today, pumping equipment is available both in the industrial segment and for solving household issues. Several companies are involved in its production. The Danish concern Grundfos UPS has gained authority in the international market, using modern technologies and introducing the developments of its engineers into this industry. The company's product range includes a variety of mechanisms even for highly demanding consumers: circulation pumps for air conditioning, heating, water supply, sewerage installations.

In this material, we invite you to take a closer look at Danish products and consider common models. The information presented in the article will make it easier to find the necessary pumping equipment among a variety of units.

General information

Particularly relevant in private homes with individual heating is the choice of an installation such as a circulation pump, which ensures uniform heat distribution throughout the living space. The main purpose of Grundfos pumping equipment of the second and third series is the circulation of liquid in cold water supply systems, air conditioning, and heating systems. Pumps, the body of which is made of stainless steel, can be used for hot water supply.

The mechanisms of the leading European manufacturer are equipped with a function that maintains a certain thermal regime. They are attractive due to the following characteristics:

- wide functionality;

- low power consumption;

- compact dimensions;

- ease of installation;

- reliability in operation.

The most innovative and technological developments are used in production. Grundfos adheres to high quality standards, and all products comply with international environmental standards. When purchasing products from a Danish company, you receive instructions that provide the most detailed information on their installation, operation and further maintenance.

Of course, there is a replacement for Grundfos, however, a wide range of pumping equipment from this manufacturer receives real positive feedback, a high assessment of the effectiveness of the products. Let us consider in detail the characteristic features of pumps of the second and third model range.

Features of Grundfos Alpha 2 and Alpha

All Grundfos pumps are quite similar in appearance. The main difference is the rotor system used. Today, Alpha 2 and Grundfos Alpha 3 are the most popular among consumers.

Alpha 2 is an innovative "family" of high efficiency circulators with the following features:

- AUTO function ADAPT, compatible with most systems, adjusting the optimal parameters;

- night operation - an automatic type option that reduces the unit's performance in a stepwise manner at night;

- integrated management;

- the presence of a display depicting the actual power, frontal control panel;

- motor with compact rotor/permanent magnet technology.

The following advantages of this series are highlighted:

- Flexibility (can be installed in existing systems).

- Convenient to use due to ease of installation and configuration.

- Low noise level.

- Rational energy saving. Automatic differential pressure control.

- Compact design.

- Possibility of regulating pressure drops.

- Built-in frequency converter and thermal protection.

Alpha 2 devices are optimized for “A” class energy consumption. Class "A" shows the degree of energy saving of the pump on the energy efficiency scale.

Therefore, the installation of the second model range equipment will significantly reduce energy consumption and the noise level arising from the operation of valves and similar accessories, improve the management of heating and water supply in general.

The scope of application is wide, the pumps are suitable for various systems: with constant/variable flow, with variable values in the pressure pipe temperature, etc. The mechanisms are hidden in a cast-iron self-ventilating case, which gives strength and extends the period of use.

The catalog contains a huge range of devices, but the following are widely used:

- Grundfos Alpha 2 25 40. At temperature pump. water from 2 to 110 degrees Celsius, a device with automatic monitoring of the liquid level and a quiet engine gives a throughput of 2.4 cubic meters / h, power - 18 watts. Installation can be done in any position. During its operation, a pressure of 10 bar is permissible.

- Grundfos Alpha 2 25 80. Direction - water supply, heating purposes. The technical characteristics include: productivity - 3.4 cubic meters / h, 8-meter head, working pressure - 10 bar. Max. power consumption does not exceed 50 W.

- Grundfos Alpha 2 L 25 40 180. Dimensions: 180x156x153 mm. Has 7 operating modes. Operates at a maximum pressure of 4 m. Throughput – 2.4 cubic meters/hour. Slave. pressure – 10 bar. Max/min power consumption is 25/5 W. Horizontal type installation. A special plug ensures quick connection.

- Grundfos Alpha 2 25 60 A 180. Surface pump with a power of 45 W can be installed in any position. Max. pressure – 6 m. Throughput – 2.4 cubic meters/hour with dimensions 99x137x180 mm.

- Grundfos Alpha 2 25 60 130 - a device designed for the circulation of only clean water with the possibility of vertical / horizontal positioning. Quiet motor provides max. productivity 3 cubic meters per hour, pressure exceeds 6 m. Dimensions: 95x130x156 mm. The throughput is the same.

- Grundfos Alpha 2 32 60 180. Hydrostat. the pressure reaches 6 m at a pressure of 10 bar. Pump power from 3 to 34 W. With an installation length of 180 mm, the unit consumption is 3 cubic meters. m/h.

- Grundfos Alpha 2 L 32 40 – surface pump with max. pressure 4 m. Compact – 180x95x153 mm. A volumetric water flow rate of 2.4 cubic meters per hour passes through the valve. Working pressure is standard. The power ranges from 5 W to 25. The rotor type is “wet”.

- Grundfos Alpha 2 32 80 with 3 fixed speeds and 6 pressure modes. Max. pressure – 8 m. Dimensions: 180x121x155 mm. The throughput is 3.4 cubic meters/hour. Power consumption increased – 50 W.

Series number two has been replaced by a new generation of pumps - Grundfos Alpha 3. Thanks to their modern ability to use the Grundfos GO Balance mobile application and the ALPHA Reade external communication module, hydraulic balancing of heating can be easily and quickly carried out. In addition, new functions and additional built-in protection options increase the reliability of the equipment and the entire heating system.

Features of Alpha 3 pumps

Alpha 3 has the following advantages:

- 11 operating modes, including: 3 – constant pressure. 3 – proportional, 3 fixed speeds, summer and night mode function;

- dry running protection with automatic restart, which extends the life cycle of the device;

- the presence of such connecting elements as a plug, nuts in the kit;

- improved starting characteristics that start the rotor even after a long period of pump inactivity, and others.

The units of the third model series are characterized by economical operating modes and ease of operation. By installing these pumps, you can save about 20% on utility heating bills. Compared to conventional units, Alpha 3 provides energy savings of 85% by analyzing the current operating mode and automatically adjusting the output power, reducing it to 3 W (at low consumption).

Pumps are used for installation in the following systems:

- heating - “warm floor”;

- (stainless steel version);

- heating single-pipe/double-pipe;

- in which it is advisable to optimize the position of the operating point of the unit.

The circulation equipment has the best energy efficiency index of 0.15. Technical equipment, distinctive design features, automatic configuration (AUTOADAPT function), updated plug, intuitive user interface make Grundfos Alpha 3 the best in its class and provide convenient connection and startup. It is worth noting that the products in this series meet the requirements of the Directive (EuP) on the design of energy-consuming products. The technologies on which Alpha 3 pumps are created exceed the requirements of the relevant regulatory documents.

The devices are suitable for pumping clean, low-viscosity, non-aggressive liquids, softened water. When using a pump to circulate a liquid of high viscosity, its performance decreases. Impurities containing mineral oil and flammable liquids, which the rotary oil pump handles, must not be present in the operating environment of the equipment. It is also prohibited to use it to remove air from the system as a whole.

Most popular:

- Grundfos Alpha 3 25 60. The horizontally installed pumping apparatus produces a 6-meter head and a power of 34 W. The throughput capacity, like all pumps, is 3.4 cubic meters per hour. Used in adjustable heating systems, the unit will provide a comfortable temperature in all rooms of your home.

- Grundfos Alpha 3 25 40 – model with a power consumption of 18 W. Installed horizontally. The throughput capacity is lower than standard and is 2.55 cubic meters per hour. The temperature range of the liquid is 2..110 degrees Celsius. Grundfos Alpha 3 25 40 guarantees savings on flow meters.

Comparison of Grundfos UPS and Alpha2 circulation pumps (video)

Since October 2013, updated pumps of the ALPHA2 line have gone on sale.

The new ALPHA2 pumps are the world's most energy efficient pumps in their class: the pump energy efficiency index is 0.15 for the ALPHA2 25-40 and ALPHA2 32-40 models and 0.16 for the ALPHA2 25-60 and ALPHA2 32-60 models!!

Distinctive features of the updated Grundfos ALPHA2 circulation pumps:

11 operating modes (AutoAdapt, 3 proportional pressure modes, 3 constant pressure modes, 3 fixed speeds, night mode);

Built-in flow meter facilitates pump setup, diagnostics and system balancing;

Reduced overall dimensions make installation easier;

The improved plug allows you to connect the electrical wiring without the use of an additional tool;

The location and design of the terminal box allows the pump to be used with cold liquids from + 2С о, regardless of the ambient temperature: the pump is not afraid of condensate;

A set of connecting nuts is supplied with the ALPHA2 25-40 and ALPHA2 25-60 pumps.

| Name | vendor code | Power, W | Max. pressure, m. |

Dimensions (HxWxD), cm | price, rub. | |

| Grundfos ALPHA2 25-40 (cast iron body) |

99420002 | 3-18 | 4 | 18x12.1x15.5 | ||

| Grundfos ALPHA2 25-60 (cast iron body) |

99420013 | 3-34 | 6 | 18x12.1x15.5 | ||

| Grundfos ALPHA2 25-80 (cast iron body) |

99420015 | 3-50 | 8 | 18x12.1x15.5 | ||

| Grundfos ALPHA2 25-80 130 (cast iron body) |

99411163 | 3-50 | 8 | 13x12.1x15.5 | ||

| Grundfos ALPHA2 32-40 (cast iron body) |

99420016 | 3-18 | 4 | 18x12.1x15.5 | ||

| Grundfos ALPHA2 32-60 (cast iron body) |

99420018 | 3-34 | 6 | 18x12.1x15.5 | ||

| Grundfos ALPHA2 32-80 (cast iron body) |

99420020 | 3-50 | 8 | 18x12.1x15.5 | ||

|

Grundfos ALPHA2 25-40 N (housing stainless steel) |

99411365 | 3-18 | 4 | 18x12.1x15.5 | |

| Grundfos ALPHA2 25-60 N (housing stainless steel) |

99411424 | 3-34 | 6 | 18x12.1x15.5 | ||

| Grundfos ALPHA2 25-80 N (housing stainless steel) |

99411428 | 3-50 | 8 | 18x12.1x15.5 | ||

| Grundfos ALPHA2 32-80 N (housing stainless steel) |

99411449 | 3-50 | 8 | 18x12.1x15.5 |

Symbol

Grundfos ALPHA2

Purpose

Grundfos ALPHA2 circulation pumps are designed specifically for use in heating systems. Pumps are also used for circulation in hot water systems, as well as in refrigeration and air conditioning systems.

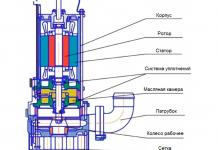

Design

Grundfos ALPHA2 pumps are pumps with a rotor isolated from the stator by a sealed sleeve, i.e. The pump and electric motor form a single unit without shaft seals, which uses only two sealing gaskets.

The bearings are lubricated by the pumped liquid.

Features of these pumps:

- shaft and radial bearings made of ceramics

- graphite thrust bearing

- rotor protection sleeve and bearing plate made of stainless steel

- impeller made of corrosion-resistant material

- pump housing made of cast iron, bronze or stainless steel.

Advantages of a variable pump

In the case of a variable pump, the system pressure can be varied proportionally or maintained at a constant level by adjusting the flow rate.

Unlike unregulated pumps, Grundfos ALPHA2 reduces the pressure in the heating system in response to reduced heat demand.

With a decrease in heat consumption, the thermostatic valves close, which leads to a change in the characteristic, a decrease in flow and an increase in the pump head on H1. The operating point A1 of the fixed pump in this case changes to A2.

In systems with variable pumps, the pressure in the system will be lower by H2, compared to a system with a fixed pump.

If an unregulated pump is installed in the system, then when the thermostatic valve is closed, the pressure drop across it increases due to an increase in the pump head in the area of low productivity.

This increased pressure drop across the valve leads to a local increase in water velocity, which in turn causes unpleasant cavitation noise. If a GRUNDFOS ALPHA2 pump is installed in the system, the pressure in the system in front of the valve will drop when the pump flow is reduced, that is, the cause of the noise will be eliminated.

Pump head adjustment

The Grundfos ALPHA2 pump is adjusted using a key.

Operating modes of Grundfos ALPHA2 pumps:

- in ALPHA2 AUTOADAPT function

- 2 modes for maintaining constant pressure

- 2 proportional pressure control modes

- 3 fixed rotation speeds

- night mode

Heating systems

Grundfos ALPHA2 pumps are used for various heating systems. The automation of the ALPHA2 pump regulates the pressure drop in accordance with the current needs of the system without the use of external elements. The pumps are mainly used for one- or two-pipe heating systems, but can also be used in mixing circuits of larger systems. For underfloor heating systems, it is recommended to use bronze pumps: ALPHA2 N in stainless steel, since the pumped liquid often contains a large amount of air, which causes corrosion of the cast iron body. |

Single pipe heating system

Two-pipe heating system

Underfloor heating system

|

Specification of materials

|

|

Installation

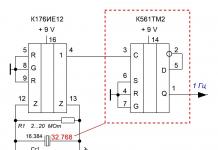

Electric motor

Four-pole permanent magnet synchronous motor. The pump control system is built into the control unit, which is attached to the stator housing using two screws and connected to the stator using a cable connector. The control unit is equipped with two keys. The following terminal box positions are possible: |

|

Grundfos ALPHA2 pump settings and performance characteristics

Relationship between pump settings and performance characteristics

In the figure, the dotted lines represent the relationship between the pump settings and its performance characteristics.

Settings |

Pump characteristic curve |

Function |

| AUTOADAPT (factory setting) | Proportional control curve from highest to lowest pressure value | Using the AUTOADAPT function, the ALPHA2 pump automatically adjusts the pump characteristic within the set performance range, thereby adjusting: - Adjustment of pump characteristics according to system size. - Adjustment of pump characteristics in accordance with load fluctuations over time. In AUTOADAPT the pump is configured for proportional pressure control. |

| PP1 | Proportional control curve with lowest head value | The pump operating point will move up or down along the lowest proportional pressure control curve, depending on the coolant flow. Head (pressure) drops as flow decreases and increases as flow increases |

| PP2 | Proportional control curve with highest head value | The pump operating point will move up or down along the highest proportional pressure control curve, depending on the coolant flow. Head (pressure) drops as flow decreases and increases as flow increases |

| CP1 | Control curve with lowest constant pressure value | The operating point of the pump will be on the curve with the lowest pressure value, depending on the coolant flow in the system. The pressure (pressure) remains constant, regardless of coolant flow |

| CP2 | Control curve with the highest constant pressure value | The operating point of the pump will be on the curve with the highest pressure value, depending on the coolant flow in the system. The pressure (pressure) remains constant, regardless of coolant flow |

| III | Speed III | The ALPHA2 pump operates at a fixed speed. Speed III corresponds to the maximum operating characteristic. To quickly bleed the pump, set the pump to speed III for a short period of time |

| II | Speed II | The ALPHA2 pump operates at a fixed speed. Speed II corresponds to the average operating characteristic |

| I | Speed I | The ALPHA2 pump operates at a fixed speed. Speed I corresponds to the minimum operating characteristic. |

| ALPHA2 switches to the night mode curve, i.e. for minimum performance and energy consumption subject to certain conditions |

Pumped liquids

Depending on the model, Grundfos circulation pumps can be used for pumping:

- clean, non-viscous, non-aggressive liquids that do not contain solid particles or fibres;

- coolants that do not contain mineral oils;

- hot water in water supply systems;

- softened water.

The kinematic viscosity of water is 1 mm2/s (1 cSt) at 20 o C. If the circulation pump is used to pump liquid with a higher viscosity value, then its hydraulic characteristics are reduced.

Example: A concentration of 50% glycol at 20°C will increase the viscosity of the aqueous solution to approximately 10 mm2/s (10 cSt), which will cause a decrease in the hydraulic performance of the pump by approximately 15%.

When choosing a pump, it is necessary to take into account the kinematic viscosity and density of the pumped liquid.

Inlet pressure

To avoid cavitation noise and damage to pump bearings at high temperatures, a minimum pressure must be maintained in the pump suction pipe, the values of which are indicated in the following table:

Circulation pump ALPHA2 thanks to the patented technologies of the GRUNDFOS company, it is an excellent choice for heating and hot water systems, focused on maximum energy savings.

Using ALPHA2 you don't have to worry about complex pump settings. It is enough to install the pump and leave the factory settings using the AUTOADAPT mode. ALPHA2 will independently analyze the heating system, find the optimal operating point and continue to optimize its operation as the needs of the heating system change.

The delivery set includes: pump, heat-insulating casing, ALPHA plug, rubber seals, installation instructions. Models ALPHA2 25-xx are additionally equipped with threaded connections.

Pumps of the ALPHA2 series are included in the GRUNDFOS premium program “Service in 24 hours”. 5 year warranty.

Purpose

ALPHA series pumps are designed to circulate water in heating systems, local hot water supply systems (version “N”), as well as in air conditioning and refrigeration systems. The design of ALPHA pumps allows pumping liquids in the temperature range from + 2 °C to +110 °C. The range includes ALPHA series pumps with an air separator (version “A”).

Energy efficiency

Grundfos supports the development of energy-efficient equipment that reduces energy costs and preserves the environment. The European energy efficiency standard EuP requires that the energy efficiency level EEI for circulation pumps should be no higher than 0.23. The EEI value of the ALPHA2 pump does not exceed 0.15, which is an order of magnitude ahead of the current EuP standards.

Features and Benefits

- Unrivaled Energy Efficiency, EEI< 0,15 – самый экономичный циркуляционный насос в мире ;

- Patented AUTO function ADAPT, which automatically adjusts the pump performance in accordance with the current needs of the system. In addition, ALPHA2 has 3 fixed speeds, 3 constant pressure modes and 3 proportional pressure modes;

- Indication of energy consumption and consumption;

- Dry running protection with automatic restart (in new versions);

- Increased starting torque up to 27 N*m, allowing you to start the pump even if the rotor is blocked after a long period of inactivity;

- Summer mode function; (in new versions)

- Night mode function;

- Resistance to scale adhesion, allowing to avoid deposits in high-precision clearances of pump bases;

- Permanent magnet electric motor;

- Built-in thermal protection;

- Instant connection to the network using the ALPHA plug;

- Compact design;

- 5 year warranty;

- Premium “Service in 24 hours” from GRUNDFOS.

The Grundfos ALPHA pump guarantees excellent energy savings, incorporating the best technological solutions from the Grundfos concern. Choosing this pump for heating systems will be an excellent and optimal solution with a temperature range of the pumped coolant up to 110 °C.

In air conditioning systems, the pump is capable of pumping liquid from +2 °C. Man is designed in such a way that he associates a cozy home with a warm and cozy interior environment. In a modern home, circulation pumps for heating are a mandatory component.

The Grundfos ALPHA Circulation Pump successfully copes with the tasks set, participating in their solution in the heating system for a private house. The Grundfos ALPHA pump will ensure the movement of the coolant from the heating boiler through the pipes to the radiator, in addition, the pump will perfectly cope with optimal heat regulation, reducing the inertia of the entire heating system.

To date, seven main energy efficiency classes have been established: A, B, C, D, E, F, G. The Grundfos ALPHA 2 circulation pump with an energy saving index of "A" consumes 80% less electricity than a typical model with an index of "D". Thus providing annual savings in utility bills for electricity of up to 10%.

The main purpose for using the pumps of the Grundfos ALPHA 3, ALPHA 2, ALPHA 2 L series is the circulation of water or a glycol-containing carrier in radiator heating systems, floor heating systems, air conditioning and cooling systems, as well as hot water supply systems. The GRUNDFOS ALPHA 2 and ALPHA 3 pump is equipped with a night performance mode.

To effectively use the night mode, you need to take into account one nuance. The pump must be installed at the outlet of the boiler, at the supply. Since it is the supply temperature that is controlled. The night mode only works in conjunction with “smart” boilers that support this function.

The GRUNDFOS ALPHA pump with automatically controlled speed, which successfully helps them cope with their tasks in:

- Systems where there is a constant or variable flow, that is, where there is a need to optimize the operating point of the pump;

- One-pipe and two-pipe systems;

- Underfloor heating systems;

- In hot water recirculation systems;

- Systems where it is necessary to reduce performance to achieve energy savings at night.

- Systems with an unstable temperature in the pressure pipeline;

The AUTO-adapt function in the ALPHA 2 pump is designed to regulate the pressure, taking into account the current need of the system. The consumer does not need to switch pump speeds. The Grundfos ALPHA pump will automatically determine the desired rotation speed. In addition, the Grundfos ALPHA pump has a fixed speed in three positions, as well as three constant and three proportional pressure modes.

In simple words, this can be explained like this: For example, on a winter day the sun is shining brightly outside the window and you feel a little hot, and you decide to turn off one of the radiators in your house. As a result, the flow rate in the heating system decreased, and thereby the pressure increased. Firstly, most likely, your system will begin to make noise in this case, causing a lot of discomfort to your household.

Secondly, the pump continues to operate at full power, consuming electricity in full. So, the Grundfos ALPHA 2 Pump with frequency control will independently reduce engine rotation, accordingly reducing energy consumption, and secondly, it will adjust the speed in such a way as to equalize the increased pressure specifically for a system with the radiator turned off.

Design feature:

ALPHA 3, ALPHA 2 and ALPHA 2 L pumps with a “wet rotor”; the rotor in such designs is isolated from the stator by a sealed stainless steel cup. Structurally, the hydraulic part and the electric motor form a common unit without a mechanical shaft seal. Only two seals protect against leaks. Bearings are lubricated and cooled using liquid pumped by the pump.

Let's take a look at the differences between these models.

With built-in pressure regulation system,  as we mentioned above, the system perfectly adjusts the pressure created by the pump to the actual requirements. The Grundfos ALPHA 2 pump with the index “L” differs from the ALPHA 2 in that it has reduced functionality (in particular, there is no Auto-Adapt, no heat-insulating casing, no night mode, and we had to save on the energy consumption indicator).

as we mentioned above, the system perfectly adjusts the pressure created by the pump to the actual requirements. The Grundfos ALPHA 2 pump with the index “L” differs from the ALPHA 2 in that it has reduced functionality (in particular, there is no Auto-Adapt, no heat-insulating casing, no night mode, and we had to save on the energy consumption indicator).

Such changes ultimately made it possible to make the model more accessible in the mid-price category.

The modern pump complements the functionality of the Grundfos Alpha 2 and Alpha2 L pump series. Grundfos Concern  presented to the consumer a new product - the external module ALPHA-Reader. Using the module, it is possible to adjust the balance of single-pipe and two-pipe heating systems, as well as balance the “warm floor” system. All that owners of the ALPHA3 pump and the ALPHA Reader communication module need to do is install the Grundfos GO Balance software on their smartphone, open the application and follow the program’s advice.

presented to the consumer a new product - the external module ALPHA-Reader. Using the module, it is possible to adjust the balance of single-pipe and two-pipe heating systems, as well as balance the “warm floor” system. All that owners of the ALPHA3 pump and the ALPHA Reader communication module need to do is install the Grundfos GO Balance software on their smartphone, open the application and follow the program’s advice.

Installing GRUNDFOS ALPHA2 L means:

* easy installation and setup

- The pump is easy to install.With factory settings, as a rule, the pump can be started without any additional settings.

* high level of comfort

- Minimal noise from valves, etc.

* low power consumption

- Low energy consumption compared to conventional circulation pumps

Operating modes of GRUNDFOS ALPHA2 L:

Constant differential pressure mode

This mode is used in those systems where the coolant flow varies over time, and the pressure drop value must remain constant. A striking example of such systems is the collector distribution of heated floor circuits (see figure)

Proportional differential pressure control mode

This mode is used in those systems where, with a time-varying coolant flow rate, it is permissible to change the pressure drop in order to reduce energy costs. An excellent example is a two-pipe heating system for a private house using thermostatic valves (see figure).

Fixed speed mode

This mode is provided for those systems where it is necessary to operate the pump at a fixed speed. For example, for installation on boiler loading. And also for those systems where the operating point does not fall within the characteristics of the AUTO Adapt function. An example is a single-pipe heating system for a private house without thermostatic valves (see figure)

Note. This mode also serves to remove air when starting the pump.