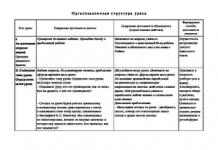

The construction market does not stand still, which leads to the emergence of new materials that have improved characteristics compared to analogues of the previous generation. Relatively recently, fiberglass reinforcement has appeared in the construction field, which has become a serious competitor to metal rods.

Until recently, steel reinforcement was the only material that was used in the production of reinforced concrete products to increase the strength of foundations and other elements building structures. However new material It is characterized by more advanced properties, which attracts the attention of the consumer.

Description of the material and its types

Fiberglass reinforcement is a non-metallic rod wound with fibers of a composite material or sprayed with fine abrasive powder. The diameter of reinforced rods can range from 4 to 18 mm.

Depending on the material used as the basis for the manufacture of the rod, there are several types of composite reinforcement:

- Basalt products (denoted by the letters ABP) are produced on the basis of basalt fibers, bound with resin of organic origin. Such fittings are characterized by high resistance to aggressive environments, including gases, alkalis and salts.

- Fiberglass reinforcement (abbreviation ASP) is made from fiberglass fibers connected using thermosetting resins. The advantage of such rods is their low weight and high strength characteristics.

- Carbon fiber reinforcement (designation AUP) is produced on the basis of hydrocarbons. The material is characterized by increased strength, but has a very high cost, which significantly reduces its popularity.

- The combined products (abbreviation ACC) are based on basalt and fiberglass. This material is wear-resistant and has a wide range of applications.

Among the listed types of composite reinforcement, fiberglass products are the most popular, so you should study this material in more detail.

Advantages and scope of use of fiberglass reinforcement

Unlike steel rods, fiberglass reinforcement has a number of significant advantages:

- Light weight, making it more convenient to transport material and perform various actions with him.

- High resistance to aggressive environments, including gases, alkalis and salts.

- Resistant to the formation of corrosion spots.

- High tensile strength.

All of the listed characteristics significantly expand the scope of use of composite fiberglass reinforcement:

- With its help, they strengthen walls and partitions made of bricks and various blocks.

- Using fiberglass reinforcement, load-bearing walls are connected to facing partitions. By the way, we have interesting article on the topic "".

- Fiberglass reinforcement is excellent for strengthening and, the sole of which lies significantly below the freezing level of the soil. In addition, it is recommended to use composite reinforcement to strengthen foundations operating in aggressive environments.

Fiberglass composite reinforcement can be used to strengthen any type of foundation for low-rise buildings. However, in the case of strip and column foundations for buildings of no more than three floors, composite rods have received many positive recommendations. In other words, fiberglass reinforcement can be used to strengthen a monolithic concrete strip under private house or a cottage of one or two floors, a bathhouse, a garage or outbuildings. Our website has information about that, and, and much more. You can use the site search to find the information you are interested in.

It is worth recalling that fiberglass reinforcement is a new material, the properties of which have not been fully studied. Therefore, it is better to use the material for structural reinforcement, avoiding moments where increased bending and torsional strength is required.

Calculation of fiberglass reinforcement

Building a foundation with your own hands requires calculating the amount of building materials, including composite reinforcement.

Taking into account various factors, materials should be calculated using the following algorithm:

- Determination of the total length of the foundation, taking into account the length of the internal load-bearing partition.

- Calculation of the length of the reinforcement bars, taking into account that the reinforcement will be laid in two tiers (4 bars).

- Determining the number of connections. It should be taken into account that the connection of fiberglass reinforcement bars is carried out not by welding, but by overlap. Therefore, you need to add 1 meter to each corner.

- Perform cross connection calculations.

For a complete understanding, you can take an example of calculating reinforcement for the foundation of a house measuring 6 * 8 meters, the internal load-bearing wall of which is 6 meters.

The total length of the foundation is determined as follows:

(6+8)*2+6=34 meters.

The total length of the rods, taking into account that the two-level structure consists of 4 parallel rods, is:

34*4=136 meters.

The number of connections and, accordingly, the length of the reinforcement for this purpose is determined as follows: the number of main walls is multiplied by 1 meter of overlap and by the number of rods. It turns out the following:

(4+1)*1*4=20 meters.

Therefore, for a foundation of the specified dimensions, taking into account additional material The following number of longitudinal rods will be required for docking:

136+20=156 meters.

The number of transverse ring connections should also be calculated. According to the technology for laying the reinforcing frame, the connecting rings should be located at a distance of 50 cm from each other. To determine the number of transverse connecting rings, it is necessary to divide the total length of the reinforcement by 0.5 meters. It turns out the following:

To calculate the length of reinforcement required for this number of cross members, the dimensions of the frame are taken into account. For example, if the frame lattice has a size of 60*30 cm, then the length of the rod for one ring will be equal to the following:

(0.6+0.3)*2*68=122.4 meters.

In addition, it is imperative to add a certain amount of material for reserve. That is, you should take not 122, but 130 meters of reinforcement.

Summarizing the results of calculations of the longitudinal and transverse elements of the frame, we obtain the result:

When choosing a material for foundation reinforcement, all significant factors should be taken into account. Despite large number positive characteristics, fiberglass reinforcement is a new material, and metal rods are time-tested.

Fiberglass reinforcement for foundations is an innovative material that eliminates destruction in concrete structures. It is a worthy alternative to metal analogues. Its unique characteristics make it stand out from other products for this purpose. In this regard, fittings are in demand among large construction organizations and private developers.

Specifications

Data from numerous studies conducted by competent organizations have shown that fiberglass reinforcement for strip foundations has unique properties. It is convenient to use fiberglass-based reinforcing bars in construction due to their light weight. It is used to reinforce lightweight structures made of cellular concrete. Thus, the weight of the structures as a whole is significantly reduced.

An important technical characteristic, as shown by reviews of fiberglass reinforcement for foundations, is improved tensile properties. It is three times stronger than its steel counterpart. Also, fiberglass products are not subjected to negative influence corrosion. Experts, when comparing corrosion resistance with metal-based products, found that this indicator is ten times higher. They are resistant to the aggressive alkaline environment of concrete.

Pouring concrete with reinforcement.

Builders can reinforce the foundation with fiberglass reinforcement on objects that require unhindered penetration of waves of various frequencies. This is possible due to the radio transparency of this fitting. The material is a dielectric that does not conduct electric current. It is completely transparent to electromagnetic waves.

Among the technical characteristics, experts note a much lower level of thermal conductivity. This characteristic eliminates the possible appearance of cold bridges in concrete structures. This indicator can significantly increase the energy efficiency of facilities built using this building material.

Just a note.

The coefficient of thermal expansion of a frame made of fiberglass elements is almost similar to that of concrete structures. Due to this, when using these materials, the probability of crack formation is reduced several times..

Advantages of fiberglass reinforcement

Having considered the advantages of fiberglass-based reinforcement, we can make right choice. Builders, based on the indicators of which foundation to choose for fiberglass reinforcement, give preference to it, based on its resistance to chemically active environments.

This characteristic determines the long service life of the material, which is at least eighty years. The wear resistance of the material is comparable to steel structure. The light weight of fiberglass reinforcement eliminates significant load on the foundation of the building, thereby extending its service life.

Separately, builders emphasize the increased flexibility of fiberglass reinforcement. Shipment of building materials can be made to the customer in coils, without first cutting them into separate rods. Thus, the number of overlaps is reduced, which reduces material costs.

Also, this parameter can increase the strength of the concrete structure being built. The compact form of the packaging allows the reinforcement to be placed in the trunk of a passenger car, which reduces the cost of transporting the material to the construction site.

In construction, composite reinforcement is widely used due to the variability of the operating temperature range. It ranges from -10 to +100 degrees. Using materials at extreme temperatures, technical specifications remain at the same level.

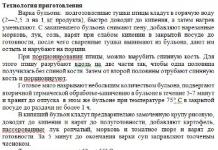

Calculation of fiberglass reinforcement

Strip foundation

You can calculate a foundation made of fiberglass reinforcement by adhering to SNiP 52-01-2003 “Concrete and reinforced concrete structures”. You can calculate everything accurately using online calculator A. For these purposes, several factors must be taken into account.

Strip foundation.

Strip foundation.

The first step is to decide on the number of load-bearing walls and on what principle they will be located. The brand of concrete should be taken into account. You also need to know the parameters of the tape: width, length, height and thickness. Accurate calculations will be obtained taking into account the size of the purchasing rod. You should decide on the class and cross-section of the reinforcement.

It is worth remembering that the diameter of the fiberglass reinforcement for the foundation affects the final strength of the structure. In this regard, it is more correct to take into account the mass of the structure.

Just a note.

This indicator is calculated in accordance with the indicators of the foundation and materials used in construction. On the website www.stroiproekt77.ru you will find a large number of projects of frame houses and strip foundations.

Slab foundation

This type of foundation can be calculated using an online calculator for this type of foundation. Using it, foundation slab calculations of formwork, diameter and volume of concrete are performed. The data obtained allows us to determine exactly how much material is needed to build this type of foundation for a house and other buildings.

Monolithic slab under frame house.

Monolithic slab under frame house. This foundation is affordable and easy to construct. When compared to tape, it will not be necessary to perform in large volume earthworks. Basically, builders use this fiberglass reinforcement for the foundation of a house in the construction of country houses and other buildings that do not have a basement.

Just a note.

When constructing a building, an accurate reinforcement diagram is necessary when organizing the work. It allows builders to strengthen the structure. All components together ensure its long service life.

Comparison of fiberglass and metal

Implementation innovative technologies in the construction industry poses the question to builders of which reinforcement is more appropriate to use to strengthen concrete structures. Deciding on fiberglass or metal reinforcement for the foundation can only be done by understanding all their positive aspects. Unlike metal-based products, fiberglass reinforcement weighs nine times less, which reduces the load on the foundation of the structure.

Professionals comparing metal and fiberglass reinforcement are unanimous in the opinion that the latter is not influenced by chemically active environments. In this regard, in winter period The strip foundation is reinforced with fiberglass reinforcement. Their choice is explained by the fact that in winter salt solutions are added to concrete to promote its hardening.

The distinctive characteristics of metal fittings compared to fiberglass products is the ease of use of the latter. For these purposes, it is not necessary to use welding equipment. You can verify this by watching how a foundation with fiberglass reinforcement is laid in the video.

Fiberglass elements of reinforcing frames, compared with their metal counterparts, cope more effectively with tensile loads. Therefore, they are applicable in strengthening critical structures based on concrete. Comparing metal reinforcement with fiberglass, experts specifically point out that the latter does not affect the decrease in the strength characteristics of foundation structures over a long period of time.

All this is due to the fact that fiberglass elements are not susceptible to oxidative processes. Having compared metal-plastic with fiberglass reinforcement, experts came to the conclusion that when using the latter, reliable frame structures can be created.

Reinforcement technology

Knitting reinforcement

Many people ask experienced builders how to knit fiberglass reinforcement for the foundation. This method of connecting reinforcing bars is optimal compared to welding, which requires the involvement of specialists and is not stable under the influence of high temperatures.

Before knitting fiberglass reinforcement for a strip foundation, experts recommend preparing tools: reinforcing bars, a crochet hook and steel wire. It should be soft. Also, preparing for work requires first deciding on the cross-section of the reinforcement, the placement and number of rods.

Installation of foundation reinforcement can be performed horizontally and vertically. The first option is preferable, as it compensates for the uneven load on the foundation. The strength characteristics of the structure are ensured by a steel frame of vertical reinforcement.

Wire knitting

A foundation made of fiberglass reinforcement can be knitted using wire. First, you will need to cut it thirty centimeters long and fold it in half. You should hold the wire with your left hand and hold the crochet hook with your right. It must be connected to the fittings. The hook is inserted into a loop of wire that goes around the entire reinforcement.

Professionals advise making three turns of the hook to securely fasten the reinforcement. After this, the hook is removed from the loop. A special knitting gun can greatly facilitate the entire process.

Knitting with clamps

This method does not require special skills or equipment. This ensures excellent fixation of the elements. The use of plastic clamps minimizes the use of corrosive materials. Good integrity of the fill is ensured by plastic-based clamps with metal filling.

Competent builders understand how important it is to introduce new technologies and materials into their practice. The world has known about composite reinforcement for a long time, but its mass production and use began only a few years ago. We will talk about the features of working with fiberglass reinforcement using the example of a foundation.

Strengths and weaknesses of composite reinforcement

Don't expect any building material will turn out to be a unique and unified offer. However, proper application in accordance with operating conditions allows you to achieve truly outstanding results. It’s the same with composite reinforcement: using it positive qualities and by leveling out the negative ones, it is possible to ensure long-term operation at lower material costs.

The main advantage of glass-polymer reinforcement is its inherent high limit of destructive impact - almost 2.5 times higher than that of steel. Composite reinforcement is much better at compensating for tensile forces in a concrete mass than steel. Especially when you consider that during production, plastic rods can be provided with a surface texture that promotes maximum effective adhesion to the concrete mass.

Another obvious advantage is the extremely high resistance to aggressive environments. Concrete structures that are permanently exposed to high humidity or exposed to saline solutions have a much longer service life when reinforced with composite materials. We must not forget about the manifestations of electrolysis: the dielectric properties of plastic can be both a plus and a minus.

There is also a fly in the ointment: fiberglass reinforcement irreversibly loses its properties when heated. This forces us to reconsider the feasibility of its use from the point of view fire safety. When heated to 150-200 °C, the reinforcement loses its strength properties, but if thermosetting polymers were used as a binder, the reinforcement loses its strength irreversibly.

Another disadvantage of composite reinforcement is its low modulus of elasticity, that is, low bending resistance. Because of this, in structures with concentrated impacts, the laying of fiberglass reinforcement is required in quantities up to 4 times higher than the content norm for the cross section in comparison with steel reinforcement.

Benefits in the context of the foundation

The flexibility of polymer reinforcement allows it to be transported in reels, so the length of a single element is practically unlimited. Together with the low weight of the material (3-4 times less than steel), all other properties ensure cheap delivery without the use of long vehicles, as well as high ease of use.

Foundations are not exposed to open flames and high temperatures during a fire, which is why low heat resistance is not a significant drawback. High flexibility of reinforcement can only be important when working in structures that have nodes of concentrated influences, for example, when installing grillages. However, the resistance of concrete to bending loads can be restored by laying a relatively small amount of steel reinforcement, or simply by increasing the number of piles.

Much more important for foundations is the corrosion resistance of fiberglass. It is not so important for subsequent waterproofing and waterproofing of concrete; however, the susceptibility of strip foundations to rupture due to an increase in corroding metal in volume can be ignored in the case of using polymer reinforcement. Fiberglass is optimally suited for constructing floating foundations in areas without drainage and with a high content of chemically active compounds in the perched water. Even under normal conditions, the use of fiberglass reinforcement makes it possible to reduce the protective layer of concrete to a minimum of 15-20 mm, thereby making it possible to move the reinforcement to the zone of maximum effective load absorption.

Calculation of composite reinforcement

While the methods for calculating steel reinforcement are well mastered by most builders, the design of foundations with fiberglass reinforcement is still considered an insufficiently covered topic. The reason for this is the different physical and mechanical properties of the reinforcement, which have not yet been taken into account in most current building regulations. The simplest way calculation of composite reinforcement - a method of equal-strength replacement, in which steel rods are replaced with fiberglass with a reduction in standard size by two values (that is, 8 mm instead of 12 mm or 14 mm instead of 18 mm). However, it is recommended to perform calculations of complex foundations according to general scheme from scratch, so as not to lose sight of the significant difference in the elastic modulus.

The first part of the foundation calculation contains the determination of the impacts on the foundation of the building and is performed in the same way as for reinforced concrete structures. The second part begins with determining sufficient cross-sectional dimensions of concrete structural elements and here the first differences can be observed. Since the tensile strength of fiberglass reinforcement is higher and the protective layer is minimal, the sufficient cross-sectional area is 25-30% lower than the standard minimum for a reinforced concrete product with an equal cross-section of the reinforcing elements. This does not apply to determining the width of the lower plane of the foundation, which is always determined by the current loads and the supporting capacity of the soil. Therefore, when reinforcing with composite reinforcement, it is beneficial to pay attention to foundations with complex sections.

The next stage is the choice of an equivalent replacement for steel reinforcement, which consists of preserving not only strength, but also all other physical and mechanical properties. The main nuance is that fiberglass reinforcement experiences 3-4 times greater linear elongation before it ceases to resist destructive effects. This means that the total cross-section of the reinforcing elements in the zone of bearing tensile loads must be correspondingly higher than when using steel reinforcement. The benefit from using fiberglass reinforcement in this case is expressed only by high tolerances for crack opening - for polymer reinforcement, contact with air or moisture is not critical, but one should not lose sight of the effect of frost forces on concrete. The general trend is this: the results of saving on the volume of concrete mixture should be directed to strengthening composite reinforcement in designated areas.

Rules for working with material

The differences in working with polymer reinforcement lie not only in the calculation method, but also in the methods of processing the material. In particular:

- Cutting fiberglass rebar should be done with either a hot cutter or a bolt cutter. Sawing polymer reinforcement by any means leads to the formation of harmful microscopic chips.

- Bending of reinforcement is allowed only in the manufacture of structural reinforcement elements. It is performed by heating the bent section to 100-120 °C using an electric hair dryer, followed by natural cooling after the product takes the required shape.

- When storing composite reinforcement, it should be protected from direct sunlight and high temperatures.

- When unwinding the reinforcement, its high elasticity should be taken into account. To relieve tension in the coils, the end of the reinforcement should be temporarily secured to the coil body with a meter-long piece of chain. If the coil is supplied without a coil, before cutting the clamps, it is necessary to secure 2-3 wire rings on the coil that do not prevent the rods from slipping.

Knitting of spatial reinforcing structures

The process of assembling a frame from glass-polymer reinforcement is decidedly different from knitting metal. The root of most of the differences is the almost unlimited length of the rods: parallel bundles of rods are used extremely rarely. Because of this, it is much more convenient to knit the frame for the entire product in place and then load it into the formwork. This is also facilitated by low weight and resistance to corrosion: to preserve the fiberglass reinforcement, it is enough to just cover it from sunlight.

The preparation of frame parts, as in the case of steel rods, should be done before assembly begins, that is, all work is carried out primarily using the manufacturing method. The joining of rows at corners and junctions should be done by knitting crosses, and if necessary, increasing the moldings should be done by parallel tying with an overlap of at least 20 diameters. The crosshairs are knitted by braiding each of the perpendicular rods into a ring that tightens the reinforcement together. For parallel binding, 3-5 encircling clamps are installed in 2 turns. You can use both nylon ties and PET tape with its subsequent heat shrink for these purposes.

If it is necessary to include anchors of complex shape in the reinforcement, they are bent from metal, or factory-bent products are used in those joints of the structure where fiberglass reinforcement can do its job. In this case, it is necessary to increase the thickness of the protective layer at the installation site of the steel elements, and to bind dissimilar materials using polymer wire.

The foundation is the foundation of a structure that supports the main load. For this reason, it needs to be built from durable materials with good wear and tear. Particular attention should be paid to the fastening elements that will hold the structure and also protect it from premature destruction. Most suitable option is fiberglass reinforcement for the foundation. This is a new material that has recently become very popular. But first, it’s worth considering its advantages and important features.

Fiberglass reinforcement is a whole system of glued glass fibers. A polymer composition is used as a binder.

Typically, the reinforcement has the form of a rod, which has several constituent elements:

- main trunk It has a core that consists of parallel fibers. They are glued together using polymer resin. This ensures high structural strength;

- outer shell. The sheath fibers are wound around the AKS barrel in a spiral sequence. Sometimes sand spraying is used.

Advantages and Disadvantages

Fiberglass reinforcement is an excellent option for strengthening the foundation. This material increases its strength, increases service life and allows it to withstand high loads.

If you are thinking which reinforcement is better - fiberglass or metal, it is worth considering important positive features of composite reinforcement over steel:

Do not forget about the disadvantages of composite products:

- Fiberglass reinforcement has a low modulus of elasticity and can be easily bent. During the construction of the foundation and paths, this drawback is not noticeable. But if the products are used in the construction of floors, then this nuance should not be missed; it is important to carry out all the necessary calculations;

- The products have an insufficient level of heat resistance. You should not combine fiberglass reinforcement with concrete mortar under strong temperature changes, otherwise it may completely lose its binding properties;

- fragility. Over time, composite products wear out and begin to deteriorate; exposure to an alkaline environment also has a huge impact on rapid wear. But manufacturers, in order to increase the service life of fiberglass reinforcement, began to add rare earth metals to its composition;

- not intended for welding.

Reinforcement calculation

When building a foundation with your own hands, it is important to correctly calculate necessary materials, including fiberglass reinforcement. The calculation must be carried out in accordance with the following important nuances:

When building a foundation with your own hands, it is important to correctly calculate necessary materials, including fiberglass reinforcement. The calculation must be carried out in accordance with the following important nuances:

- The correct determination of the base length parameters must be carried out. When taking measurements, it is necessary to take into account the length of the internal load-bearing partition;

- it is required to calculate the length of the reinforcing rods. It should be taken into account that the reinforcing elements will be placed in several tiers;

- you need to determine the number of places with connections. Composite products are joined not by welding, but by overlap. For this reason, 100 cm is added to the area of each corner;

- Calculations must be carried out for transverse connections.

To understand exactly how the calculation of fiberglass reinforcement bars is performed, it is worth considering an example using the parameters of a house with a base size of 12x12 meters, which was made using tape technology.

During the calculation the following actions will be performed:

- the perimeter of the house is calculated. P = 2*(12+12) = 48 m;

- the total length of the reinforcement elements, which are stretched into two tiers of 4 edge bars, will be calculated as follows - D = 48 * 4 = 192 m.

- the number of jumpers must be calculated taking into account the minimum permissible run-up of 0.5 meters. In an example it looks like this, P = 48/0.5 = 96 pieces;

- Calculations of the perimeter of the frame (500x500 mm) must be carried out. Pk = (0.5+0.5)*2 = 2 m;

- calculations are made of the length of the reinforcing rings - Dk = 96 pcs * 2m = 192 m. In this case, trimming must be taken into account - 192 + 5% = 202 m;

- in the end you will need - 192 + 202 = 394 meters of product with the same profile;

- It is worth calculating the required number of clamps for knitting - X = 96 pcs * 4 = 384 pcs.

In order for the composite material to protect and strengthen the foundation, it is recommended to follow important recommendations when working with it:

In order for the composite material to protect and strengthen the foundation, it is recommended to follow important recommendations when working with it:

- Rebar cutting is done using a hot torch or bolt cutter. Sawing polymer reinforcement products with any other devices causes the formation of harmful microscopic chips;

- bending of reinforcement is allowed only in the manufacture of structural reinforcement products. This process is performed using an electric hair dryer; this tool heats the bent area to 100-120 0 C, and then, after taking the required shape, everything is cooled;

- the fittings should be stored in a cool, dark place, protected from sunlight;

- When unwinding coils with rods, it is recommended to take into account the degree of elasticity of the composite material. To relieve its strong tension, one end of the reinforcement must be secured for some time to the coil body using a meter-long piece of chain.

How to reinforce a foundation with fiberglass reinforcement

Fiberglass reinforcement is often used for strip foundations. It strengthens it, enhances its strength. But in order for the reinforcement process to proceed correctly, it should be approached with all responsibility.

Preparation

When using composite products for the base, it is worth preparing the necessary tools for the job:

- to take the required measurements you will need a tape measure;

- Bulgarian. This tool is needed for fitting and cutting fiberglass rods;

- personal protective equipment;

- water level;

- plastic clamps. They are necessary to connect the rods.

At the preparatory stage, you need to dig a trench. It is carried out according to the data specified in the project of the future building. Important features of earthworks include:

- After digging the trench, it is recommended to level and compact the bottom well;

- then sand is poured in the form of a layer, its thickness should be 10-15 cm;

- the layer is watered and thoroughly compacted;

- crushed stone is poured on top of the sand with the same thickness as sand and thoroughly compacted;

- As a result, a kind of cushion of sand and crushed stone is formed at the bottom.

It is important to do everything correctly. The bottom of the trench should be perfectly flat so that after laying the fiberglass reinforcement there are no distortions. This will require the use of a water level.

Construction of formwork

For a strip foundation, formwork is required; it gives it the required shape and protects it from distortions. It is made from boards that are connected in the form of shields. It is recommended to use nails and screws for fastening. The caps of fasteners should be located on the inside. Additionally, the structure should be strengthened with special spacers.

For a strip foundation, formwork is required; it gives it the required shape and protects it from distortions. It is made from boards that are connected in the form of shields. It is recommended to use nails and screws for fastening. The caps of fasteners should be located on the inside. Additionally, the structure should be strengthened with special spacers.

The surface of the formwork walls is covered with polyethylene film, which is attached using a construction stapler. The use of film is desirable; it will keep the boards clean and also prevent liquid from leaking out of the concrete mixture.

On the walls of the formwork it is necessary to mark the level to which the concrete solution will be poured. It will also serve as a guide when installing a frame made of fiberglass reinforcement. To get everything right, you should use a water level.

Features of the construction of a frame made of reinforcement

After installing the formwork, reinforcement must be carried out. When constructing a frame, the following important conditions should be observed:

After constructing the frame, the concrete mixture can be poured. It is recommended to pour the solution carefully; it should completely fill the space between the frame elements. Be sure to periodically pierce the concrete with a metal rod, this will eliminate air voids.

If you have already decided on the construction site of the building, prepared a detailed construction plan and performed a soil analysis, then laying the foundation - the foundations of your home - is on the agenda. The foundation is a supporting structure that evenly distributes the weight of the building over the surface of the earth. The service life of a future building directly depends on the type of foundation (strip, monolithic or columnar), blind area, and on the quality of drainage and heat/waterproofing. But, do not forget that reinforcement of the foundation is also very important, since without it the foundation will not last long. How exactly does rebar reinforcement work in reinforced concrete structures? The foundation of a building is often subject to uneven loads, due to variations in the mass of the parts that are built on it, as well as due to the heterogeneous soil beneath it. Since concrete is not particularly flexible, the properties of a strip or monolithic foundation do not differ in bending strength. As a result, the base may crack in tension zones. This is why rebar reinforcement is so important as it prevents cracks from forming, giving rigidity to the entire structure.

The reinforcement of the foundation was always carried out using metal reinforcing bars. But, nowadays there is an innovative material made of fiberglass. That's what we'll talk about. You will learn the advantages of fiberglass reinforcement, how to reinforce strip foundation fiberglass reinforcement, as well as how to use the material for aerated concrete blocks.

A little about fiberglass reinforcement for foundations

From the name it becomes clear that the material is not made of metal at all, but of fiberglass. This is a collection of glass fibers that are held together thanks to a polymer composition. Externally, it is no different from ordinary fittings, only in color. Reinforcement of any foundation with fiberglass reinforcement can be made of two types of material:

For installing a strip or monolithic foundation, the second option is better, since the ribs will provide good adhesion to the concrete. And for reinforcing aerated concrete blocks, smooth reinforcement will do. This material is in no way inferior to its predecessor, and even has some advantages, which we will talk about later.

Advantages of fiberglass reinforcement

Why is fiberglass reinforcement so good? I would like to note a number of positive properties that will not leave you indifferent:

Indeed, fiberglass reinforcement can be called an innovative, progressive material that has a lot of advantages for the same cost. Moreover, it will not be difficult to carry out reinforcement work. What is the technology for laying reinforcement? Let's find out.

Reinforcement with fiberglass reinforcement

How does the process differ from the usual one? What tools will you need for the job? Let's look at the process using the example of a strip foundation.

First of all, you need to have the following tools in your arsenal:

- tape measure or meter to take measurements;

- plastic clamps;

- grinder to adjust and cut rods to the desired size;

- goggles and gloves for personal protection;

- building level.

That's all you need. The list is small, the tools are ordinary and easily accessible. The whole process can be divided into several stages.

That's how easy it is, you can reinforce the foundation using fiberglass reinforcement. The process is simple and practically no different from conventional reinforcement. What about aerated concrete blocks?

Block reinforcement

As for aerated concrete blocks, according to technology they must be reinforced in order to give rigidity to the structure. The process is also no different from the classic one, using steel rods. To reinforce the blocks, two parallel grooves are made along the entire perimeter, at a distance of 6 cm (if glue is used) and 4 cm (if cement mortar is used). The fittings are installed in them and covered with the mixture.