It is difficult for owners of large agricultural lands to do without mechanized devices. A hay chopper becomes a real assistant for a farmer. There are units of various modifications on sale, differing in size and power, but not everyone can afford them. For anyone who is more or less familiar with technology, it will not be difficult to make a hay crusher with your own hands.

Design features of the device

Particularly savvy craftsmen, assembling various devices for grinding hay, manage to use broken vacuum cleaners or pumps. The operation of such a mechanized device is simple.

Homemade cutting blades are attached to the rod, which rotates due to an electric motor. A bucket usually serves as a bunker into which straw or hay is poured. Once in it, the dried grass is crushed to the desired size.

Unfortunately, such homemade devices for cutting hay are not highly productive, which is why they are only suitable for providing food for several heads of small livestock. When you need to crush a huge amount of raw materials, you need a crusher that has greater power and productivity.

The heart of this kind of mechanism is the working unit, which is a metal container in which sharp blades rotate. They are firmly attached to a steel disk extending from the motor axis.

To ensure safe operation so that no one is injured by touching the moving blades when processing components, they try to make the bunker high and cylindrical in shape. Its lower part is made at an angle. A pipe is installed there through which the processed hay is discharged. The height of the stand, as a rule, should be such that there is enough space under the hopper for the electric motor, which is attached to the bottom by means of a plate.

Tools and materials for assembly

To make a hay crusher with your own hands, you will need metalworking tools, which every self-respecting owner has. In addition, at certain stages of the technological process you will need a welding machine, an angle grinder and a drill. Materials provided for this design:

If the farm has an old circular saw or hacksaw blades of a metal-cutting machine, then they can be used to make knives. Of course, the best solution would be to get high-quality carbon steel, but the proposed options will do just fine. A pipe segment with a diameter of 300 mm or an unnecessary barrel will eliminate unnecessary work on installing the chopper body.

Important note: if a device that converts electrical energy into mechanical energy has a speed of more than 2000, then it is highly undesirable to install knives on its shaft. It's better to tinker a little, but make a more powerful belt-driven hay chopper that can crush roots and even branches.

Shredder Making Guide

Before constructing a hay crusher at home, you need to sketch a sketch of the processing machine or familiarize yourself with the existing drawings. With the help of properly designed graphic diagrams it will be much easier to understand the dimensions of the parts and their installation location. When everything is ready You can proceed directly to the installation itself, adhering to the following algorithm of actions:

To prevent the finished chaff from scattering to the sides when exiting the side pipe, it is necessary to make a special collection. A plastic barrel is suitable for this, with a hole cut out on the side wall to receive chopped hay.

If you have all the attributes necessary to make a crusher, You can make such a device at home in a matter of hours.. Even if the work takes a long time, it will save money, and this is an important factor.

Attention, TODAY only!

(23

ratings, average: 4,39

out of 5)

Many people who have their own garden require certain methods and devices to maintain the beauty and fertility of their plot. For better decomposition of thick stems of greenery, it is recommended to chop them. You can buy a herb grinder or make one yourself. The choice of device depends on the volume of raw materials that need to be worked on. With the least amount of work, you can use a simple chop. This refers to a plate with a triangle shape, which is equipped with a durable and sharpened edge at the bottom. Chopper, chopping machine - a device for chopping grass. If you are going to do a small amount of work, you may not need to purchase an electric grass cutter.

Many people who have their own garden require certain methods and devices to maintain the beauty and fertility of their plot. For better decomposition of thick stems of greenery, it is recommended to chop them. You can buy a herb grinder or make one yourself. The choice of device depends on the volume of raw materials that need to be worked on. With the least amount of work, you can use a simple chop. This refers to a plate with a triangle shape, which is equipped with a durable and sharpened edge at the bottom. Chopper, chopping machine - a device for chopping grass. If you are going to do a small amount of work, you may not need to purchase an electric grass cutter.

The first way to create a grass cutter with your own hands

The main device we need in creating a homemade crusher, this is a drill:

- the crushing process is similar to the operation of a conventional combine: in a special case, which is considered a simple bucket, it contains a good knife;

- when scrolling it in a circle with high acceleration, the grass is cut. To make this crusher with your own hands, a dual-mode “Temp” drill with high power is used. The knife is created from a hacksaw blade. The most important thing is the correct sharpening of the knife. If it is made correctly, the grass will not wrap around the blade. The knife must remain clean and sharp. You can sharpen a knife using a one-sided sharpening;

- If you want to chop fresh grass, it is better to take a knife with a narrow diamond shape, then the grass will be easy to cut and will not wrap around the blade.

Second creation method: “Typhoon”

The working principle of this grass cutter no different from the previous one. It just looks better and the quality of work is higher. In this case, the raw material passes through the upper hole, and the finished substrate exits through the lower one, which is located in the side of the apparatus.

The working principle of this grass cutter no different from the previous one. It just looks better and the quality of work is higher. In this case, the raw material passes through the upper hole, and the finished substrate exits through the lower one, which is located in the side of the apparatus.

To avoid negative consequences, you should use a protective casing. This homemade crusher does not look ideal, but you will get it for free. Typically, the chopped grass is placed in a bucket, which is placed under the outlet. Old vacuum cleaner body "Typhoon" Perfect for garden herb shredder. It has a top hole with the right size. Remember, this is a great option, but not the only one! Any cylindrical container is suitable, be it a pan, bucket or a piece of pipe. The engine can be obtained from an old washing machine.

Knives can be made from an old hacksaw blade, and a rectangular profile can be used as stands. The bushing on which the knives are mounted must be turned on a lathe. The engine with the parts removed is mounted on studs from below to the container. To clamp the knives, you need to use plumbing nuts. When creating bushings, first cut threads for these nuts.

Then make a hole for the motor shaft. For better fixation on the shaft, two holes of 7 mm in diameter with threads for locking bolts are made in the bushing. On the other side of the motor shaft, platforms are created to increase the fixation of the bushing with special bolts. The next step is to remove the edges and put on the knives. To make knives correctly, you need to make four pieces of canvas using a grinder. Square holes are created in the center of each workpiece with a side of 26 mm.

The width of any part depends on the source material. Knives should be placed closer to the bottom. The platform must be reliable and stable. To do this, the base should be made larger than the top. The platform holds the chopper and protects the engine. It needs to be attached to the container with 3 bolts m6x45. The edges on the sides are covered with sheets of tin. In the racks it is worth cutting threads for M3 bolts, with which the sheets are secured to the platform.

Third option: using improvised means

After carefully describing the process of creating the previous device, you can easily create something similar and useful. For a simple do-it-yourself crusher you will need:

After carefully describing the process of creating the previous device, you can easily create something similar and useful. For a simple do-it-yourself crusher you will need:

- pump or any electric motor capable of making 3000 rpm;

- aluminum pan;

- wood hacksaw;

- button from the washing machine to start;

- plug and power cord.

That's all the basic tools for creating a do-it-yourself feed chopper. The last option is a DIY straw cutter or hay chopper. Such a device is made quickly, but according to a slightly different scheme. The creation procedure is described in the video.

When creating this device, they can be used in the same way vacuum cleaners and washing machines. The straw cutter and hay cutter are similar in many ways to a conventional grass chopper. Only the blades need to be sharper and tougher to cope with the straw.

Conclusion

A do-it-yourself hay cutter or hay crusher is easier than a grass chopper. The main thing is to gain experience, read more, and then you will succeed! Experienced gardeners need to remember that homemade shredders require careful care. Hay and straw are very difficult to grind, especially if you have made a poor-quality straw cutter. If you don't want to suffer, you can purchase garden supplies and a hay breaker from the store. The garden feed chopper is also made from a conventional washing machine.

It is difficult for owners of their own farms to do without the help of small-scale mechanization. One of these assistants is a hay and straw chopper for private farmsteads. You can buy a ready-made unit, but such models are not cheap. For those who are well versed in technology, it will be more profitable to make it yourself.

Why is a shredder needed?

Hay becomes the main feed for livestock during the winter months. It is also used for flooring in barns, mulching the soil, making fuel briquettes, and so on. Therefore, hay has to be harvested in large quantities. For ease of use and storage, it is processed. The easiest way to do this is with a hay and straw chopper for private farmsteads.

Hay becomes the main feed for livestock during the winter months. It is also used for flooring in barns, mulching the soil, making fuel briquettes, and so on. Therefore, hay has to be harvested in large quantities. For ease of use and storage, it is processed. The easiest way to do this is with a hay and straw chopper for private farmsteads.

These crushers are manufactured in various capacities and sizes. The operating principle of the device is based on the operation of rotating knives. The hay is fed into a special bunker. Passing through a drum with knives, it is ground and enters the recoil hopper.

These crushers are manufactured in various capacities and sizes. The operating principle of the device is based on the operation of rotating knives. The hay is fed into a special bunker. Passing through a drum with knives, it is ground and enters the recoil hopper.

Design features

The design of the straw and hay chopper includes the following main elements:

The design of the straw and hay chopper includes the following main elements:

- Electric motor. The processing speed will depend on its power.

- A container into which unprocessed hay or straw is fed. It can have different dimensions, depending on the amount of raw materials that you plan to grind.

- The shaft on which the knives and counterknives are mounted. They must be made of durable steel and well sharpened.

- Bunker for waste materials. For convenience, it is mounted on a tilted floor.

- Supports. Most often they are made from pipes with a diameter of at least 25 mm. Their height is selected based on the dimensions of the electric motor.

Popular factory models

For those who do not want to spend time and effort making such a device, it is better to purchase a ready-made model in a store. Among the most popular hay and straw choppers for private farmsteads are:

You need to choose a specific model based on the amount of raw materials that will have to be processed. If your livestock is small, there is no point in overpaying for powerful units. It is better to save money and buy a small capacity grinder.

Choose goods only from trusted manufacturers. A low-quality shredder with an underpowered motor will perform its functions poorly and will quickly break down.

The absence of complex parts and devices in the design allows an experienced craftsman to make a grass and hay chopper himself. It is enough to purchase an engine of sufficient power; all other elements can be found in every household. Before making a chopper, study its drawing

How to make a grinder yourself?

If you do not want to spend a lot of money on the purchase of equipment, then you can make a hay and straw chopper with your own hands. To do this, follow a few recommendations:

If you do not want to spend a lot of money on the purchase of equipment, then you can make a hay and straw chopper with your own hands. To do this, follow a few recommendations:

- Choose the right motor. If you plan to process up to 200 liters of raw materials, then give preference to models with a power of 2 to 5 kW. For a small amount of hay, take a smaller capacity unit.

- The assembly of the device is carried out in accordance with the drawing. Today on the Internet you can find a lot of options. You just have to choose the right one.

- To make metal parts of the structure, use metal with a thickness of at least 3 mm. For engine support, choose a thicker material.

- The working part of the unit is a metal cylinder, inside of which a disk with sharp knives is mounted. The axle must be securely fastened to the engine.

- You can use an old metal barrel as a container for loading hay.

- A support for the engine is welded to the working part. For reliability, they are equipped with scarves.

- The engine is secured to the support using bolts and self-tapping screws.

- Electrical installation can be done only after all parts of the structure have been assembled and securely fixed.

If you have skills in handling a welding machine and understand the operation of an electric motor, such a unit can be manufactured in one day. If some subtleties remain unclear to you, watch the video on how to make a hay chopper:

If you have skills in handling a welding machine and understand the operation of an electric motor, such a unit can be manufactured in one day. If some subtleties remain unclear to you, watch the video on how to make a hay chopper:

A straw cutter often becomes a reliable assistant for the owner of a large farm. Today there is a large selection of units that differ in size and shape. Below we will look at what parts a hay and straw chopper consists of, and how to make such a unit with your own hands.

Hay chopper - equipment device

All straw crushers have a similar design and consist of the same elements. The difference between them is only in size and shape. Let's look at the device using the KR 02 model as an example. The design of this household unit includes:

- The electric motor is the main part that powers the entire structure. The characteristics of the motor directly depend on the purpose of the crusher. For industrial purposes, large, powerful motors are used, while for domestic purposes, a medium and low power motor is well suited. The main thing, at the same time, is that the engine speed does not exceed 2 thousand rpm;

- Bunker for feeding hay and straw. The dimensions of the hopper also depend on the applications of the grinder;

- Metal plate to accommodate the motor;

- The bracket for mounting the motor is a part that holds the motor and absorbs its vibration;

- The supports for installing the chopper on the workplace are a kind of tripod that should hold the structure motionless;

- Knives and shaft are parts for directly cutting straw and hay;

- Unloading mechanism - this element has the form of a side pipe, which is attached to the structure body for supplying processed raw materials.

Both industrial and household straw roll shredders are equipped with a separate hopper, which contains chaff and other waste.

All hay crushers work on the same principle. To begin, the device is connected to the mains. After this, raw materials are supplied to the loading hopper, which, falling on the knives, are crushed, and enter the receiving hopper. All unground hay exits through the side hole into the waste container.

Tools and procedure for assembling a homemade chopper

Before constructing a straw cutter, you must carefully read the design drawings. With the help of a correctly drawn up diagram, you can figure out the dimensions of the parts and the location of their installation.

All metal components of the device must be made of sheet steel with a diameter of no more than 3 mm. To make the bracket, thicker metal should be used. Other parts of straw cutters for private farmsteads should be used:

- The electric motor can be taken from any household appliance;

- 200-liter iron barrel, which will act as a loading hopper;

- Several metal sheets welded into one area, at least 3 mm thick;

- 3 metal pipes, 2.5 cm in diameter - they will serve as support for the structure;

- Food processor knives that will need sharpening;

- Shaft - taken from any unnecessary equipment. The main thing is that it is smooth and properly balanced. Otherwise, the structure will vibrate and shake violently.

As an unloading device, you can use a plastic pipe that will be attached to the side of the barrel for loading. In this case, one hole is made in both the barrel and the pipe. The pipe must be installed so that its hole coincides with the hole in the barrel.

To make a hay grinder into flour, you will need certain tools:

- Sander;

- Drill;

- Welding apparatus;

- Standard set for metalwork.

Having prepared everything you need, you can make a straw cutter without any problems. Unlike a simple manual design, it will require a minimum of effort from you, and will process raw materials much faster and more efficiently.

How to make a straw cutter with your own hands - detailed description

The working unit of the product is a container welded from metal, inside of which a disk with sharp knives is installed. The disk itself must be securely fastened to the shaft of the electric motor. The bottom is welded to the body of the device, which also acts as a loading container, and a bracket is installed below it.

Metal supports are attached to the bracket, which can be equipped with gussets that will give the supports the necessary rigidity. Next, you will need to weld the unloading mechanism to the body.

The electric motor is mounted to a steel plate using self-tapping screws and bolts. This way, your homemade hay chopper will produce minimal vibration. A disk with welded knives must be mounted on the motor axis.

It just so happens that the owner of a private farm constantly requires various devices and means of small-scale mechanization, including a straw cutter. Of course, similar units of different designs and performance are available for sale, there is plenty to choose from. But it’s much cheaper to make a straw chopper yourself, especially since the unit’s design is primitively simple. In this article you will find tips on how to make it in the easiest way.

Straw chopper design

A homely owner who has a plot of land and, in addition, has various living creatures, knows perfectly well why such a machine is needed. We will only add one more area of application to the list: you can chop hay and straw to make fuel briquettes at home. If someone is planning such a thing, then you can’t do it without a straw cutter; try cutting or chopping this amount of straw by hand.

Home craftsmen have adapted to making various handicraft straw choppers from old pumps and vacuum cleaners. The principle of their operation is the same as that of knives mounted on a rod rotated by an electric drill. The hopper is an ordinary old bucket, into which grass or straw is placed, after which rotating knives are lowered into it and thus chopping occurs. Descriptions of such devices are easy to find on the Internet.

Only these mechanized cutting tools are too inefficient and impractical, and are only suitable for preparing food for a dozen rabbits. For the production of briquettes or other purposes when you need to process a lot of raw materials, you will need a reliable homemade straw chopper with sufficient power and performance. This is exactly what we will make.

The heart of any straw cutter is the working unit, which is a metal hopper with sharp knives rotating inside. The latter are rigidly fixed on a steel disk, and that one is on the axis of the electric motor. The bunker has a cylindrical shape and for safety reasons it is made high so that you cannot accidentally touch the knives with your hands when loading the straw. At the bottom of the bunker there is a branch pipe for ejection of chopped straw, for convenience it is made inclined.

Note. Some craftsmen make a bunker of small height, but with a lid where a small hole is made to load raw materials.

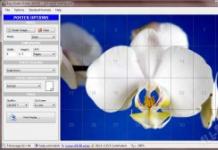

The bunker rests on a tripod of such height that an electric motor can be placed below, attached to its bottom by means of a plate. A detailed drawing of the straw chopper is shown in the figure:

1 – bunker; 2 – cover; 3 – tripod support; 4 – electric motor; 5 – engine mounting plate; 6 – control panel; 7 – amplification band; 8 – control buttons; 9 - outlet pipe; 10 – engine mounting bracket; 11 - thrust bearing; 12 – scarf; 13 - lamp - indicator; 14 - disk with knives; 15 - faceplate; 16 - rubber gasket; 17 - jumper; 18 - M5 bolt (8 pcs.); 19 – scraper; 21 - hinges for the cover.

Note. A disk with knives is a part that is quite difficult to manufacture. Therefore, the design of the knives can be arbitrary, as long as your product is well balanced and does not make the whole machine shake from vibration.

The operation of the apparatus is simple. By turning on the electric motor with the button and opening the lid, straw is loaded into the hopper. The finished chaff flies out of the side pipe; it is worth using some kind of container to catch it. A plastic barrel with a hole cut out on the side will do, so the straw won't fly away in all directions.

Tools and materials

The tool kit you will need is a regular locksmith kit, which is available to every thrifty owner. In addition, you need a welding machine, an angle grinder and a drill. As for materials, we will present a list provided for by this design, and you can use metal available on the farm. So, to make a household shredder, you will need:

- single or three-phase electric motor at 1500 rpm;

- sheet metal 2 mm thick - for the cover and lintel;

- the same, 3 mm thick - for the hopper, pipe, gussets and thrust bearings;

- metal 5 mm thick for the bracket;

- steel plate 10 mm thick;

- pipe Ø25 mm or similar angles - on supports;

- metal strip 25 x 3 mm - for reinforcement.

Knives are made from high-quality carbon steel, for example, St45, or cut from an old circular saw, you can - from hacksaw blades of metal-cutting machines. A piece of pipe Ø300 mm or an old barrel can save you the extra work of making the machine body. To make connections you need electrodes and bolts with nuts.

Advice. If you have found an electric motor with a speed of over 2000 on your farm, then it is highly undesirable to directly put knives on its shaft. It is better to spend more time, but to make a more powerful machine with a belt drive, in which it will be possible not only to chop straw, but even crush branches and root crops. The diagram below shows a straw chopper device with a decrease in speed and an increase in power:

The metal must be marked and the blanks cut out in accordance with the drawing. Cut pipes and angles to the required length and clean them. The bottom is welded to the hopper, and a bracket for mounting the electric motor is attached to it. The steel plate is attached vertically to the bracket, first you need to make holes in it that match the counterpart of the engine. To strengthen it, gussets are welded to the side of the slab.

Supports are attached to the body at an angle, scarves are also welded to them, playing the role of stiffeners. When a do-it-yourself straw chopper is already on supports, a chaff ejection pipe is attached to it. Then the electric motor is bolted to the plate, and knives are mounted on its axis and securely fixed. Lastly, a cover is attached and the electrical part is installed.

It is not at all necessary to repeat the design presented in the article. The main thing is to correctly make a working unit with knives, and you can adapt an electric drive to it in any convenient way. Just remember that the speed of the cutting shaft shaft should be within 2000 rpm. And then, if the span of the knives is no larger than those shown in the drawing. Otherwise, the machine will become a source of increased danger.

Conclusion

If you have all the tools and materials, you can make such a useful shredder with your own hands within one day. Especially when you have good plumbing and welding skills. But even if the work takes much more time, it will save you money, and this is important.