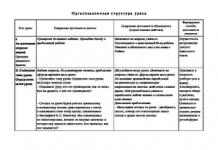

This idea was not born by chance. The fact is that on my model the engine sometimes stalled at high speeds. Patience ran out when the spring burst and the recoil starter cord eventually broke...

To begin with, I purchased a gearbox for an internal combustion engine, which replaced the old manual starter... Well, directly the electric motor from the screwdriver

But there’s a problem (there’s not enough space. I had to make a gearbox that would separate the electric motor from the gearbox on the internal combustion engine. I started by making a housing for this gearbox.

.

It may seem strange that there are so many gears, but I had to make such a “row” in order, as I already said, to move the electric motor away, due to lack of space. And the spacer between the plates was made of moisture-resistant plywood.

And finally the result It’s a little shabby, so I decided to sand it with sandpaper)

As you can see in the photo, a pin is installed on the drive shaft for engagement with the gearbox on the internal combustion engine.

Now it's time to install this miracle on your car. I thought for a long time about how to do this. And here's what I thought... And finally everything is assembled...

Although the model has become about 300 grams heavier)) But it starts upooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooo300 grams-heavier the model are this model And + better grip!!

And here is the video report:

In the very near future I plan to connect all this to the 3rd channel. I will describe the details in the second part of the article... In the meantime, I am waiting for the arrival of the parts necessary to complete the project!

A cordless screwdriver is a great helper in the household. The tool works together with the master in the house and in the garden, works in the garage or in the field. Until the battery runs out. The number of charge-discharge cycles of a battery is limited; the battery also deteriorates from idleness: self-discharge destroys the cells. On average, a battery lasts 3 years, after which it has to be replaced. You can save the instrument by converting it into a network one. Remodeling is done in different ways.

Is it really worth redoing?

Without batteries, a screwdriver turns into a piece of iron. When the batteries stop holding a charge, you have to look for new batteries. Firstly, it is expensive - the price of batteries is up to 80% of the cost of a screwdriver; it is more efficient to buy a new tool. Secondly, batteries are not always on sale, for example, if a model is discontinued. Thirdly, a thrifty owner strives to use every opportunity to save money.

Converting a cordless screwdriver to work from electrical network- a good way out. What does it give:

- The tool receives new life.

- No more batteries needing to be charged.

- The torque of the tool does not depend on the battery charge.

The disadvantage of the redesigned design is the dependence on the outlet and the length of the network cable.

Attention! Work at a height exceeding two meters with a converted screwdriver is not allowed.

How to convert a cordless screwdriver to work on a 220 Volt network

Craftsmen have come up with several ways to convert a screwdriver to work from an electrical network. They all involve providing the motor with the required supply voltage using an intermediate source or converter.

Table: power supply options for a corded screwdriver

| Power supply | Advantages | Flaws |

| Complete screwdriver charger. |

| The charger takes up space on the desk. |

| A ready-made power supply placed in the housing of an old battery. |

|

|

| A homemade power supply placed in the housing of an old battery. |

|

|

| External power supply | An easy modification. |

|

| Computer power supply |

|

|

Connecting the screwdriver to the charger

Attention! At low voltage, losses in the wire are high, so the cable between the charger and the tool should be no longer than 1 meter, with a cross-section of at least 2.5 square meters. mm.

Sequence of actions:

- Disassemble the old battery and remove the dead cells from it.

- Drill a hole in the battery case for the cable, thread the cable into the hole. It is advisable to seal the connection with electrical tape or heat-shrink tubing to prevent the wire from tearing out of the housing.

- Elements removed from the battery will disrupt the weight distribution of the screwdriver - your hand will get tired. To restore balance, a weight should be placed in the body - it can be dense wood or a piece of rubber.

- Solder the cable to the terminals former battery, connected to a screwdriver.

- Assemble the battery housing.

- All that remains is to test the updated tool in action.

Solder or attach two wires with alligator clips to the terminals of the charger.

Installation of a finished power supply in the housing of an old battery

Attention! In a closed case, the power supply is poorly cooled. It is recommended to make holes in the walls of the housing. Do not operate the tool continuously for more than 15 minutes.

Procedure:

- Disassemble the old battery and remove the non-functioning elements from it.

- Install the power supply into the battery case. Connect contacts high voltage and low voltage terminals.

- Assemble and close the battery case.

- Install the battery into the screwdriver.

- Plug the power supply into the outlet and check the updated network tool in operation.

Homemade power supply

Attention! Follow electrical safety rules. Solder and connect with the device de-energized.

Step by step instructions:

- Disassemble the housing of the old battery and remove the dead batteries from it.

- Install the elements of the electrical circuit of the power supply onto the circuit board, solder the contacts.

- Install collected fee into the body. Use a tester to check the presence of voltage at the output.

Power supply in case

- Connect the low voltage wires to the terminals of the old battery. Assemble the body.

All that remains is to assemble the battery case

Connect the screwdriver to the electrical network and check its operation.

Video: homemade lithium battery for a screwdriver

Connecting to an external power supply

Attention! During the modification process, you will need to disassemble the screwdriver body and interfere with the electrical circuit. Remember the disassembly sequence to reassemble all the parts in reverse order.

What to do:

Connecting to a power supply from a computer

Instructions:

- Find or buy a computer power supply with a power of at least 300 W.

- Disassemble the screwdriver body. Find the motor power wires inside. Solder the connectors for the computer power supply to the wires.

- Remove the connectors for connecting the computer power supply from the case.

- Connect the screwdriver to the new power supply.

- Connect the power supply to the network and check the operation of the device.

Video: power supply for a screwdriver from a computer power supply

How to power a screwdriver while maintaining its autonomy

If the master works in a building that does not have electricity, and the batteries have already deteriorated, there are ways to power the screwdriver:

- replace old battery banks with new ones;

- connect the screwdriver to the car battery;

- connect the tool to another battery, for example, taken from an uninterruptible power supply.

Replacing old elements

Attention! When replacing batteries, pay attention to the correct polarity of connecting the elements.

Procedure:

Attention! The converted battery should only be charged with a specially selected charger.

Connecting to an external battery

Sequence of actions:

- Buy or find an external battery, for example, take it from an unnecessary uninterruptible power supply.

- Take a wire with a cross-section of at least 2.5 square meters. mm. Remove the insulation and install clamp terminals suitable for mounting on the battery onto the copper ends.

- Place the other end of the cable in the body of the old battery and solder it to the terminals that are inserted into the screwdriver.

- Insert the battery case into the screwdriver, connect the cable with terminals to the battery.

- Test the restored tool in action.

A cordless electric tool lasts several times longer than the batteries that power it. Throwing a screwdriver with unusable elements into the trash is unwise. The real owner will be able to repair the device by switching it to another power source, thereby giving it a new life.

The screwdriver is widely used in various fields of activity for working with fasteners different types: self-tapping screws, screws, bolts with nuts, furniture confirmations, screws and others. This power tool can also be used to drill holes in various materials, for example, in various metals, lumber, and concrete. In this case, the functionality of the model being used is determined by the magnitude of its power and torque, and the presence of a shock function.

From a screwdriver you can make a variety of equipment and tools for household use at home. In addition to the power tool itself, conversion in many cases will require additional parts and materials. But homemade devices will still cost less than factory analogues, allowing automation and making manual labor more efficient.

The entire range of screwdrivers is divided into mains and battery models. Both types of products operate using electrical energy, which drives an electric motor. Only the electric motor itself in network devices is designed for an alternating voltage of 220 V, while in battery-powered equipment it is designed for a constant voltage of different values, for example, 12 V, 14.4 V. These design features together with the technical characteristics, they largely determine what kind of homemade products can be assembled from a screwdriver.

Electricity is one of the main types of energy used by humanity. Operates using electricity household appliances, industrial equipment, machine tools, power tools. The work is performed by electric motors of different designs and power, which are powered by alternating or direct current. For this reason, the following technical devices can be assembled on the basis of a screwdriver or from its individual parts:

- garden grass and branches shredder;

- trimmer (electric scythe);

- camping manual generator;

- engraver (mini-drill, dremel, drill);

- wind generator;

- lawnmower;

- grinder;

- mini-machines: drilling, grinding, surface planer, lathe, sawing, sharpening;

- tool for tying reinforcement;

- gate opener drive;

- means of transportation for children: ATV, bicycle, scooter;

- a small ice auger, a hole drill, a construction or kitchen mixer.

The powerful impact model can also be converted into a concrete compactor using a special attachment.

The implementation of each option takes different times and requires additional (insignificant) costs, or is done without them at all.

Assembling a manual camping electric generator and a homemade wind generator

Using battery-powered models of the tool, it won’t be difficult to make a homemade generator that will produce electricity when you rotate the attached handle by hand. This device will come in handy when traveling. To make a dynamo, you do not need to radically modify the product. Everything necessary to create a camping generator is already included in the design of the device; only minor modifications will be needed.

Using the created equipment it will be possible to charge 6 or 12 V batteries.

A power tool is suitable for remodeling. with operating voltage from 18V and above. The modification is carried out in the following way:

- disassemble the electric screwdriver;

- carefully unsolder the electronic board;

- instead of batteries, they install a diode bridge that is suitable in terms of parameters (dimensions, technical characteristics) inside the battery case;

- make a comfortable handle with a handle;

- the end without a handle is secured in the chuck.

The final design after the manipulations will look something like the photo below.

A diode bridge is necessary so that the handle of the electric generator can be turned in any direction. Instead of a handle, you can insert a nozzle with blades. Then you will get a simple wind generator.

Electric generator powered by wind, are also made in another way, in the form of a weather vane. In this case, do the following with the battery device:

- disassemble the screwdriver;

- take out the electric motor by disconnecting its contacts;

- remove the cartridge with gearbox (rotor part);

- the electric motor shaft is inserted into the cartridge, clamping it;

- a round metal plate about 1 mm thick is bolted to the gearbox gear, which will serve as the basis for fixing blades made, for example, from plastic pipes;

- a clamp with a clamp is placed on the shaft between the chuck and the gear;

- cut out a rectangular base from plywood or thin metal;

- using a clamp with a clamp, attach the engine with the cartridge to it, drilling holes for the mount in the right places;

- they make a casing to protect the wind generator (from precipitation, dust and other unforeseen influences), for example, from under a coffee can;

- insert the base with the motor and cartridge inside, securing the elements with glue, and the cover with sealant;

- blades are made by attaching them to the round plate of the unit;

- make a weather vane;

- the assembled generator is mounted on one of its ends;

- connect the wiring to the motor outputs;

- use a multimeter to check the output voltage by rotating the blades by hand.

There are many options for wind generators. They even attach the entire screwdriver to the support, equipping it with an attachment with blades.

Converting a screwdriver into an angle grinder

If corner grinder If it breaks or is missing altogether, it can be temporarily replaced with a cordless or corded electric screwdriver. At the same time, there are various options reworking. The easiest way is to use ready-made or homemade nozzles or adapters. An example of an adapter is shown in the photo below. One end of it is fixed in the chuck, and a disk is attached to the other.

Another option that allows you to convert a drill-driver into an angle grinder is to use a special type of attachment, equipped with gearbox. When implementing the method, the power tool is disassembled, its gearbox is removed, and an attachment is installed in its place. After the transformations, you will get a tool similar in appearance to an angle grinder.

It should be taken into account that such a special attachment is expensive, and modification work requires a lot of time.

Homemade nozzles are made from studs of suitable diameter, nuts and washers. They are even used with cordless electric screwdrivers.

The efficiency of homemade grinders is significantly lower than that of factory grinders. This is due to the large difference in rotation speeds of the attachments: approximately 3000 rpm for a screwdriver versus about 11,000 rpm for an angle grinder. The insignificant amount of power together with the low speed significantly limits the functionality of the device.

The devices made should be used only in emergency situations. Because of reverse capabilities on the instrument being remodeled, it is necessary to monitor the direction of rotation of the disk so as not to injure yourself.

Converting a screwdriver into a trimmer or lawn mower

To make an electric scythe with your own hands, you will need the following parts and materials:

- piece plastic pipe about 2 m long;

- soldering iron with soldering kit;

- fasteners: self-tapping screws, bolts with nuts;

- 45 degree plastic corner;

- pipe plug;

- 12 V motor from an electric screwdriver and a battery from it;

- wire;

- adapter from 40 to 50 mm for plastic pipes;

- power button;

- plastic bucket;

- contact clips (crocodiles) – 2 pcs;

- blades from stationery knives.

The work uses a pipe and an angle to it with a diameter of 40 mm.

The conversion process is carried out as follows:

- Having disassembled the electric screwdriver, take out the motor;

- attach it to the plug, having previously marked and drilled mounting holes in it;

- attach the electric motor with 2 screws;

- solder the output to the motor;

- install the electric motor by inserting its wiring into the pipe;

- mark the location of the future switch with a marker on the tube;

- drill a hole;

- connect to the wiring switch, mount it;

- contact clamps are attached to the ends of the outgoing wires to allow quick connection to the battery;

- a battery holder is made from the adapter;

- connect the drive, connect the adapter to the tube;

- make knives from blades;

- using a conventional terminal clamp, the nozzle is connected to the motor shaft;

- a protective casing is made from a plastic bucket;

- glue the part to the pipe;

- check the functionality of the structure.

The created device will allow you to mow only grass with soft stems. There are many different options for lawn mowers based on networked models of drills and screwdrivers. The photographs below show two homemade products.

First, a base is created from metal, plywood or other materials, to which wheels are then attached, as well as a control handle. The electric screwdriver is secured with clamps or to the stand. A cutting attachment is inserted into the chuck. To protect the feet from flying grass, a cover is attached to the back of the base. Power is supplied via a button or directly from the network.

To assemble a sufficiently functional lawn mower, you need to take a drill-driver with a power of 0.5 kW or more.

A cordless or corded model of an electric screwdriver can be turned into an engraver, which is also called a dremel, drill, mini-drill, or straight grinder. It's quite simple for this buy a nozzle in the store and grind any bat to fit it.

A homemade chuck will allow you to use a variety of accessories designed for Dremels.

The following video demonstrates the process of creating a flexible shaft engraver.

Making a garden shredder

A garden shredder for grass and thin twigs (less than 1 cm thick) can be made on the basis of a corded drill-driver.

Create an aggregate like this:

- choose a suitable container, for example, zinc boiler;

- a hole is drilled in the center of the bottom for the shaft on which a knife or several blades will be fixed;

- make a wooden or metal frame to install the container or place it on the edge of the table;

- a drill-driver is attached to the frame or bottom of the boiler, which is equipped with knives;

- install an on/off button;

- make a slot in the side of the container - cut out a rectangle 10 by 20 cm in front of the bottom;

- A sleeve is made from tin for disposing of crushed plants;

- attach it to the container;

- check the functionality of the unit.

Knives are easiest to make from hacksaw blades. They need to be installed with the point down. In this case, you can make several versions of blades for different grasses. If you make an attachment in the form of knives for a drill-driver, then you can simply chop the grass in a bucket or other suitable container.

Screwdriver machines

Craftsmen have made many different-purpose machines from screwdrivers. They cope well with everyday tasks.

If you need to work professionally, then you cannot do without more serious equipment.

One of the options for how to remake a drill-driver V drilling machine , demonstrated in the video below.

A way to create a simple one lathe shown in the video below.

Also, based on a drill-driver, it is possible to assemble the simplest milling and grinding machines , which is demonstrated in the following videos.

Other non-standard ways to use the tool

Non-standard use of a screwdriver is not limited to the options considered. The video below shows how to use this power tool as a ATV drive and for opening doors (gates), for drilling ice, as a mixer. The video also contains other non-traditional options.

Using a housing with a battery, you can make a good flashlight. The whole assembly process LED lamp demonstrates the video below.

How to adapt a screwdriver motor to make electric bike is shown in the videos below.

Another version of a bicycle with a motor contains the video below.

Using a hook inserted into the screwdriver chuck, you can knit reinforcement during the construction of various objects. The following video demonstrates how this is done.

By connecting the tool to the auger of a manual meat grinder, you can automate the process of twisting vegetables and meat.

It should be borne in mind that homemade products of this kind are often very limited in load. But if they don’t provide any practical benefit, then entertainment is guaranteed.

The unconventional use of a screwdriver is not limited to this. Craftsmen are constantly putting forward new ideas, and at the same time their practical implementation is taking place. Other specialists adapt homemade devices to their own needs, thereby obtaining various modifications of homemade equipment. You can also come up with something on your own, showing technical knowledge and imagination, giving free rein to your imagination and creativity. The main thing to remember: when starting to manufacture various devices, it is necessary to take into account that the created mechanisms are safe.

When batteries stop working, many people wonder how to convert a cordless screwdriver into a corded one. It is impossible to repair batteries with damaged elements. The cost of new power supplies is almost equal to the price of a screwdriver. It is not always possible to find suitable elements; models are often discontinued. But for zealous and skillful owners there is a way out - to power the screwdriver from the network.

Mains power supply for a screwdriver - 2 main options

The converted tool has one drawback: it is tied to an outlet. But for indoor work this is not so significant. But there are more advantages. Now you don’t have to worry about recharging the battery, there will be no downtime. The current strength remains stable all the time and does not depend on the discharge of the battery, which means constant torque.

Before you go looking for a power supply (hereinafter referred to as PSU), study the screwdriver parameters that are indicated on the case or in the passport. Pay attention to the tension. A 12-volt tool is more common; finding a power supply for it is not difficult. If the tension is greater, the search may take longer. It is necessary to find out the current consumption, which is not indicated in the technical specifications. The purchased unit must produce an average current value (between the battery capacity and the standard charger). Data can be found from the labeling.

There are two main modification options cordless screwdriver at 220 Volts. The first is to use an external power supply. Any rectifier capable of delivering the required DC voltage will do. Even if it is big and bulky, there is no problem. After all, you don’t have to carry it around the room. The block is installed near the outlet, and the cord to the instrument is made of the required length.

Remember that as the voltage decreases, the current increases if the power remains the same. This means that the cross-section of the low-voltage cord must be larger than that from a 220 V network.

The second option is that the power supply is mounted in a battery-powered case. The only obstacle when choosing this method may be the size of the transformer. Mobility is maintained, the radius of use depends on the length of the power cord. It is important to remember that the instrument is supplied with 220 V power, so the cord must be reliable, and the input itself must be made carefully and carefully insulated.

What external units can be used - an old computer or a laptop charger?

Available power supplies can be used as an external source:

- charger for car batteries;

- PSU from an old computer;

- laptop charging;

- homemade power supply.

You can buy an old charger inexpensively on the market. Nowadays, pulse chargers are mainly used, and old devices are often sold as unnecessary. This type of charger, with the ability to manually adjust voltage and current, is ideal for any screwdriver, regardless of its operating voltage. The whole modification consists of connecting a low-voltage cord to the output contacts of the charger.

The computer power supply is purchased from older models; it must have a power off button. It will not be needed, but this is exactly the version of the "AT" format that is needed. On the radio market, a unit with a power of 300–350 watts is selected, which will ensure reliable operation of low- and medium-power screwdrivers. All technical specifications indicated on the sticker on the case. The unit has a cooling fan and overload protection. To convert a computer power supply with your own hands to an external one for a screwdriver, we perform simple operations:

- disassemble the body;

- on the large square connector we find a green wire and any black one;

- We connect both wires to each other and insulate them;

- on the other smaller connector, remove all the wires, leaving yellow and black;

- We solder the cable cord to them.

To maintain polarity, you should know: yellow wire is positive, black wire is negative . The tool operates with a voltage of up to 14 Volts from a computer power supply.

Most laptop chargers have characteristics that allow them to be used as a power source for a screwdriver. Chargers with an output voltage of 12–19 Volts are suitable. The only changes that will need to be made are to the output plug. It should be cut off, strip the wires and solder a cable of the required length to them.

Persons who have an understanding of electrical engineering can make a homemade power supply. Its circuit is quite simple and includes a step-down transformer, a diode rectifier and two capacitors. All parts can be bought or taken from old radio equipment. A transformer from a tube TV with an output of 24–30 V is suitable. A rectifying diode bridge is required. The capacitors used are not in short supply, from old technology: one is 0.1 µF and the other is electrolytic at 4700 µF.

Attention! The structure must be enclosed in a housing. To protect against short circuits, it is necessary to install fuses at the input and output.

How to place a power supply in a case - 3 different possibilities

The mains can be placed in the battery case or in the handle. Possible options:

- any power supply unit suitable in terms of characteristics and size;

- Chinese 24 V power supply;

- homemade.

A power supply with the required parameters is selected on the radio market. At home, you should carefully remove it from the case and place it in your screwdriver, securely fastening all the components. If the wires are short, lengthen them so that they do not touch metal parts. Place the transformer and the board separately. For better cooling, install additional radiators on microcircuits. It would also be a good idea to have holes in the housing to allow air to circulate and heat to be removed during operation.

In a radio parts store we buy a 24 V power supply, current 9 A. Screwdrivers operate on 12 or 18 Volts, so the task is to reduce the voltage to the required level. To perform such work, minimal knowledge of radio engineering is required. Output voltage supported by resistor R10 with a nominal value of 2320 Ohms. Instead, you should install a 10 kOhm trimmer resistor. How to configure the power supply is described below:

- remove the constant resistor;

- set the resistance of the trimming resistor to 2300 Ohms on the device;

- solder the tuning resistor in place of the constant one;

- With the power supply turned on, adjust the voltage.

The design of a homemade power supply will be based on electronic transformer Feron or Taschibra at 60 W. You can buy them at an electrical supply store and they are designed for halogen lamps. They do not require any modification. By diverting the secondary winding from the midpoint, it was possible to use two Schottky diodes instead of the usual four. The operation of the power supply is controlled by the HL1 LED. The diagram shows all the necessary details.

Transformer T1 winds itself. A non-scarce ferrite ring NM2000 with dimensions 28×16×9 is used. Before winding, the corners are cleaned with a file, and the ring is wrapped with FUM tape. The completed unit is mounted on an aluminum plate 3 mm thick or more, placed in the battery housing. It also serves as a common wire.

How to carry out installation correctly - is a counterweight needed?

Operational reliability and safety depend on the reliability of the installation of the electrical part. A soft multi-core cable is used as a network and low-voltage cable. If the device is external, the ends of the cable should be connected to its terminals. We treat copper wiring and brass contacts with soldering acid, after which they are easily soldered. In practice, special clamps – “crocodiles” – are often used. In the screwdriver itself you cannot do without soldering; the “crocodiles” do not hold so tightly that the contacts do not separate during operation.

The ideal option is to use an old battery case. It is disassembled and the entire internal part is removed. At the same time, they stand out harmful substances, care should be taken to protect the respiratory tract and skin. The body is washed with soda solution, running water and dried. On the inside of the contacts, solder the ends of the cable, observing polarity. In order not to guess, we temporarily connect the cable, turn on the screwdriver and see in which direction the spindle rotates, mark the wires. We make a hole in the bottom of the case and pass the wires through. Inside the housing, the cord should be securely fixed by wrapping insulating tape around it. This thickening will prevent the wiring from stretching and breaking. Then we solder the ends to the contacts.

We place a counterweight inside the body. The best material there will be pressed rubber. It has the necessary characteristics: high density, insulating properties. To prevent the rubber from dangling inside, we cut it out with a slight overlap. To place the counterweight in the housing, we bend the material slightly and place it so that it will not oscillate and will serve as additional insulation. Perhaps the counterweight may seem unnecessary to some, but it is not. The design of the screwdriver ensures that the center of gravity is in the handle. This loads the arm, but relieves the hand. When batteries are removed from the case, the center of gravity shifts, increasing the load on the hand. Work becomes uncomfortable and difficult. A homemade counterweight restores the center of gravity close to the factory one.

How to use a corded screwdriver - simple rules

You have seen how easy it is to convert a cordless screwdriver into a corded one. The practice of craftsmen suggested simple and useful tips instructions for use:

- after 20 minutes of work, you should give the screwdriver a five-minute rest;

- fix the electrical cable on your hand so that it does not interfere with your work;

- The power supply should be regularly cleaned of dust;

- do not use extension cords to connect the power supply to the network;

- The power supply must be grounded;

- It is prohibited to use corded screwdrivers when working at heights.

Compliance with these rules will extend the life of the updated instrument. Mobility has been lost a little, but the unit does not require recharging and works smoothly and confidently.

Those who have used a cordless screwdriver appreciate its convenience. At any time, without getting tangled in wires, you can crawl into hard-to-reach niches. Until it runs out.

This is the first drawback - it needs regular recharging. Sooner or later recharge cycles.

This is the second drawback. This moment will come sooner, the cheaper your instrument is. To save money when purchasing, we most often purchase inexpensive Chinese “no-name” devices.

There is nothing wrong with this, but you should be aware: the manufacturer saves as much as you do. Consequently, the most expensive unit (and this is the battery) will be the cheapest when completed. As a result, we get an excellent tool with a working engine and a non-worn gearbox, which does not work due to a low-quality battery.

There is an option to purchase a new set of batteries, or replace the faulty ones in the unit. However, this is a budget event. The cost is comparable to the purchase.

The second option is to use a spare or old car battery (if you have one). But the starter battery is heavy, and using such a tandem is not very comfortable.

IMPORTANT! Many screwdrivers have an operating voltage of 16-19 volts. Even a fully charged car battery will not provide such voltage. And we mean using a used battery, where there can be a maximum of 10.5-11.5 volts at the terminals.

There is a solution - converting the screwdriver into a network one

Yes, this loses one of the advantages of a cordless tool – mobility. But for work in rooms with access to a 220-volt network, this is an excellent solution. Moreover, you are giving new life to a broken instrument.

There are two concepts on how to turn a cordless screwdriver into a corded one:

- External power supply. The idea is not as absurd as it might seem. Even a large and heavy step-down rectifier can simply sit near the outlet. You are equally tied to the power supply and to the plugged-in power plug. And the low-voltage cord can be made of any length;

- Power supply in the case from the battery. Mobility is maintained, you are limited only by the length of the network cable. The only problem is how to squeeze a sufficiently powerful transformer into a small housing. You don’t have to ask questions about how a store-bought compact screwdriver works from the mains. A 220 volt motor was initially installed there. Let's remember Ohm's law again and understand that a powerful 220-volt electric motor can be compact.

IMPORTANT! Ohm's law states that for the same power, by decreasing the voltage, we increase the current!

Accordingly, a 12-19 volt power cord should have a larger cross-section than a 220 volt one.