It is difficult for a non-specialist to know which foundation to choose for a house. Traditional strip and slab laying is not used in all cases - there are a number of restrictions. In addition, they are quite expensive, which is not always justified economically.

A pile foundation with a grillage will require less investment, therefore, if conditions permit, it is more profitable to use it.

It seems that this is a house “on legs” Source sampochinil.ru

What is a grillage type pile foundation?

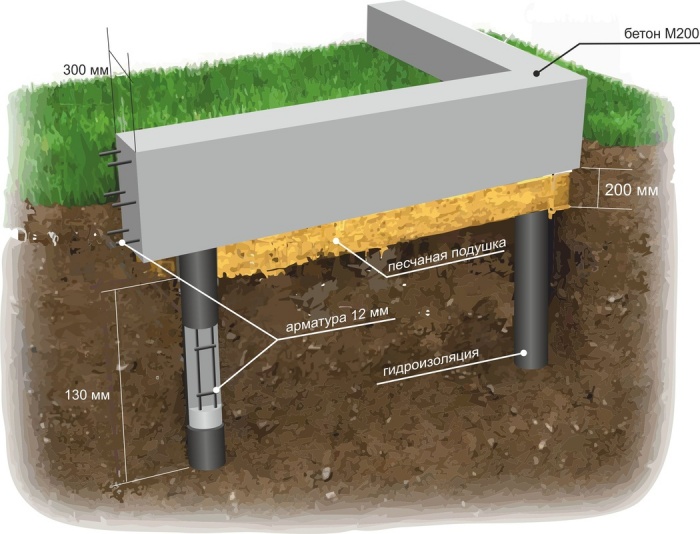

Such a foundation is a structure of piles buried in the ground below the freezing depth of the soil, and connected at the top using a metal or concrete strip (grillage). The supports can be combined by one common slab located at ground level or slightly above. The structure, built in accordance with all the rules, is reliable and has a long service life - several decades.

Here you can clearly see what a foundation grillage is - this is the entire upper part of any pile foundation, which is also called the “cap”. The purpose of the grillage is to evenly distribute the load from the load-bearing elements of the structure onto the piles and, accordingly, onto the ground.

There are several types of grillage:

- Made. It consists of separate elements, which are a structure of three piles reinforced with a welded frame. To install them, you will need a crane.

- Monolithic reinforced concrete. It is a solid plate or strip. Poured directly at the construction site.

- Prefabricated monolithic. An intermediate option, made from prefabricated parts, which in turn are assembled in a factory, and are already cemented in place using locks and key connections.

Advantages and disadvantages of a pile-grillage foundation

Each of the listed types of foundation has advantages and disadvantages that are taken into account during design in order to prevent excessive consumption of materials, deformations and cracks in supporting structures. Among the most common types of foundation, designers have a choice between strip, slab, pile-grillage and pile. If we compare the pros and cons of a pile-grillage foundation with other types of foundations, then SRF wins in many ways.

In fact, the advantages of a pile-grillage foundation far outweigh the disadvantages Source lowcarb-ernaehrung.info

The properties of a foundation with a grillage determine the following advantages of its use:

- applicable for any soil, including mobile and unstable, water-saturated or peaty;

- convenient when building a house in an area with uneven terrain (for example, on a slope);

- does not require large consumption of materials;

- has a significant service life;

- installation is slightly dependent on weather conditions - work is allowed at air temperatures down to -10°C;

- It is stable and has good load-bearing capacity.

On water-saturated soils, building a foundation requires special skill and accurate calculations Source termeszetvedelem.hu

- there are restrictions related to bearing capacity: the foundation is used only for one- and two-story buildings;

- construction of a basement or basement is possible, but involves complex and costly design solutions;

- installation requires high precision, so it is strongly recommended to entrust it to specialists;

- installation work require the use of special equipment.

Types of pile-grillage foundations according to the method of immersion in the ground

- Driven. The supports are driven into the ground using construction equipment.

- Printed. It involves drilling wells, which are subsequently filled with concrete.

- Screw. It is a method of screwing in piles using special equipment.

A special expense item is the use of special equipment Source blog-potolok.ru

On our website you can find contacts of construction companies that offer foundation design and repair services. You can communicate directly with representatives by visiting the “Low-Rise Country” exhibition of houses.

Types of piles used

Depending on the method of immersion, piles are selected:

- Hammers. For them, wells are prepared in advance, with a depth of 1/3 of the height of the pile. For installation, a special construction equipment: pressing machine, vibrating hammer, vibrating hammer. Wooden, steel, reinforced concrete and hollow supports are used as driven supports.

Reinforced concrete piles: if the installation technology is followed, the supports will last for many decades Source block-gbi.ru

- Bored. Formwork and reinforcement are placed in the well for strength, then filled with concrete.

- Drilling Wells are drilled in advance, into which reinforced concrete supports are then installed.

- Screw. They are hollow pipes, at the bottom of which there are blades and a pointed tip. The supports are screwed into the ground using special equipment.

Piles can have a rectangular or circular cross-section. The materials used for them are concrete, reinforced concrete, steel of various grades, and mostly coniferous wood. Of the tree species, the most suitable is considered to be larch, containing large number resins that protect piles from rotting.

Driven metal piles are one of the cheapest and most durable Source blog-potolok.ru

Advantages of piles:

- relative cheapness;

- insignificant time costs for installation;

- independence from groundwater levels;

- reliability (subject to installation technology).

Screw piles are used even in permafrost conditions Source museblog.ru

All of the above types of piles are used when installing a pile-grillage foundation. When choosing piles, the characteristics of the soil and load are taken into account. For private houses, bored and screw piles.

Classification by depth

Depending on the position relative to the ground, there are 3 types of grillage:

- Low or recessed. Its peculiarity is that it is installed below ground level, that is, in the ground. The grillage is placed on a sand cushion.

- Ground. Located at surface level.

- Tall or hanging. It is located above ground level on high supports. If groundwater flows close to the surface, this type of grillage is used.

Recessed grillages are used only in cases of extreme necessity, since their installation is comparable in complexity to the installation of a shallow grillage strip foundation: it is necessary to dig a pit, arrange a drainage sand cushion, make formwork, but also install piles.

Unlike buried and above-ground grillages, hanging grillages are not as labor-intensive and, as a result, less expensive.

Stages of installation of a pile foundation with a grillage

The equipment of a pile-grillage foundation is divided into the preparatory stage and the installation itself. At each stage you have to perform several types of work:

Preliminary work

- To build a foundation, you first need project, which is created based on calculations of loads, the expected depth of immersion of piles, and what materials the foundation is planned from.

A project from a professional is a guarantee of safety, long service life, as well as savings in materials and finances Source nl.decorexpro.com

- Then the site is being prepared: debris, topsoil and plant roots are removed.

- Conducted territory marking: mark the location of supports, grillage, load-bearing structures of partitions.

Attention! Deviation from the project is always a reason negative consequences, such as curvature of the foundation, the occurrence of unforeseen expense items and more. Therefore, it is important that the project is drawn up by professionals and is tied to the area.

The work of a “professional” is immediately visible Source blog-potolok.ru

- A trench is dug for the grillage. Its walls and bottom are checked for evenness with a level. After this, a sand cushion is laid and compacted.

- Wells are being drilled for supports, at the bottom of which a sand cushion is also placed. Waterproofing is placed in the pit: you can use a special film, several layers of roofing felt, or plastic pipes.

Technology for installing a pile-grillage foundation

- For the grillage, reinforced concrete beams are used or a monolithic tape is poured. A wooden rectangular formwork is prepared for it, which is secured with supports and lintels. At this stage it is also worth taking care of the sewerage and pipeline.

Photo of a pile-grillage foundation - after the concrete has dried, the formwork is removed Source bestroof.ru

- To increase the strength of the structure, a reinforced frame is placed in the well - 4 metal rods tied with wire. Then the concrete is poured. The tape is also reinforced.

- Next, concrete is poured first into the wells, then into the formwork. The concrete will take at least 10 days to set, after which the formwork will be dismantled.

How is the need for foundation materials calculated?

An accurate calculation can only be performed by a specialist - a civil engineer, who will rely on the requirements of SNiP and a number of indicators such as the strength of supports, grillage, bearing capacity of the foundation, soil resistance force, degree of shrinkage of the support under the influence of vertical load, etc. The specialist will determine the depth of immersion of the supports, their diameter, number, type of grillage and develop a diagram.

For a person without specialized education, calculations for a pile-grillage foundation look something like this Source ask.fm

When calculating the number of supports, they are based primarily on the load on the foundation, which consists of several indicators. Here it is necessary to know the mass of load-bearing walls, partitions, roofs, floor slabs, i.e. the entire mass of the building above the foundation. The payload produced by residents, household items and all other things is also taken into account. In calculations for private houses, an indicator of 150 kg/m² is used.

The last parameter for determining the total load is the weight of the snow mass that can accumulate on the roof in winter. The value generally used is 180 kg/m², but for a number of regions of the country it is slightly different. The resulting sum of loads is multiplied by the safety factor, which is 1.1 (sometimes 1.2 is used). Next, you can calculate the load on one pile.

It would not be out of place to add that online calculators for calculating materials that are widespread on the Internet should be treated very carefully. They may not take into account a number of important parameters.

Video description

For an example of an online calculator, see the video:

Installing additional items

When constructing a pile-grillage foundation, it is necessary to equip ventilation holes in the foundation and lay pipes that can be used for heating, sewer, water supply systems and other communications. If you do not take care of the engineering and technical equipment of the house in time, later, to install them, you will have to partially destroy the grillage.

To ensure the safety of the foundation, it is imperative to provide vents for ventilation. Source remontstroy.net

Requirements for creating a high-quality grillage foundation

Since the main loads on the grillage are bending forces, one of the key points when creating a grillage foundation is reinforcement, which significantly increases the strength of the structure.

The second significant point concerns the hardening time of the concrete structure - which is a whole month. The grillage will be able to withstand the proper loads only after the concrete has completely hardened.

Possible mistakes when arranging the foundation

- The piles are not firmly attached to the grillage - thermal expansion during seasonal temperature fluctuations will soon loosen the fastening point.

- The piles are laid at too shallow a depth. Here, both excessive shrinkage of the foundation and squeezing out of loose piles in the layer below the freezing of the ground by forces of soil heaving cannot be ruled out. All this can lead to the destruction of the building.

- Inaccurate calculations. It's just a powder keg - you never know what might happen.

Video description

About the features of a pile strip foundation, watch the video:

These are typical, but not all mistakes that unqualified builders make. There are many stories on the Internet about what went wrong during self-construction, but even knowledge of other people’s mistakes often does not compensate for the presence of real skills and experience. As a result, everyone should mind their own business.

Qualified specialists must calculate and build Source pinterest.com

What does the cost of SRF depend on?

If the project provides for the installation of a pile-grillage foundation, then what the cost of the SRF depends on is determined by a whole group of factors:

- scale of construction;

- type and number of supports, their diameter and length;

- dimensions of the foundation tape;

- use of special equipment;

- region;

- construction company policy.

Online foundation calculator

To find out approximate cost foundation type “grillage on piles”, use the following calculator:

Video description

For a clear picture of the cost of a pile-grillage foundation, see the video:

Conclusion

A pile-grillage foundation is considered more reliable than a pile foundation, and more advantageous than a strip foundation, and in some situations it is the only possible one. But only qualified specialists can correctly make calculations and equip it. Otherwise, such a foundation will have insufficient strength or excessive cost, which equally neutralizes all its advantages.

The foundation on bored piles, with a widening at the base - a “heel” and hanging above the ground, is popular among FORUMHOUSE participants. The availability of technology and the possibility of independently manufacturing this type of base are reflected.

However, as with any construction, certain features must be taken into account when constructing one. In this regard, the practical experience and “tricks” of the users of our portal, which they use when building such a foundation, are interesting.

Vzik User FORUMHOUSE

I already have a house made of aerated concrete, a bathhouse, a gazebo, a garage and a brick fence on this type of foundation. I can say that with proper calculations and adherence to construction technology, no problems arise with this foundation.

Although our users have accumulated extensive experience in constructing a pile-grillage structure with a widening at the base of the pile, it cannot be considered universal solution, suitable for any type of soil and structures.

The choice of design is, first of all, based on data from a geological study of the site. Based on the results obtained, the bearing capacity of the soil, soil composition, groundwater level, the presence of subsidence foundations, etc. are determined. After this, taking into account the weight of the building and the collection of loads that the foundation (in this case, the “heels” of the piles) must redistribute to the ground, the most appropriate and cost-effective type of foundation is selected.

Based on practical experience, we can say that a pile-grillage foundation with an expansion at the base of the pile is most in demand on highly heaving soils, in areas with large differences in elevation. Under these conditions, the use of another type of base may not be economically viable due to large volume earth and concrete works.

It should also be remembered that the calculation of a pile-grillage foundation is not as simple as it might seem at first glance. In case of gross violation of technology construction, without knowing the type of soil, the level of occurrence groundwater etc. such a foundation can turn into a “time bomb” under the house. Moreover, to the final cost of a pile-grillage foundation, it is necessary to add measures for its insulation, installation of a blind area, drainage of surface and groundwater, and installation of a water intake.

The fence is installed around the perimeter of the basement and closes the underground space under the house so that the wind does not blow around there.

This approach will allow you to understand whether it is profitable or not to arrange this type of foundation. A pile-grillage foundation is a “ribbon” (grillage) torn from the ground, to which piles are added. Hence (based on calculations) it may turn out that in some cases it is more economically profitable to build a classic shallow insulated strip foundation.

The main features of a pile-grillage foundation, with a widening at the base of the pile, include:

- The pile is laid below the freezing depth (depending on the region).

- At the bottom of the pile, a widening is made - “heel” with a certain ratio to the diameter of the pile and the calculated load-bearing capacity. Thus, the pile is reliably “anchored” in the ground.

- Grillage shouldn't touch or lie on the ground.

The above measures help minimize the forces of frost heaving.

Vzik User FOUMHOUSE

I am installing gates. By virtue of my professional activity, I often see problems that arise with driveway support posts. Due to the influence of frost heaving forces, poles “walk”, gate leaves warp, gates jam, etc. Of course, you can pour a monolithic concrete strip under the entire perimeter of the fence, but this is also not a panacea. I have seen a lot of “torn” ones, and in terms of money this option turns out to be the most expensive.

Based on my knowledge and experience gained during the construction of the house, Vzik I decided that it would also be suitable for a fence TISE foundation. As four years of experience in operating a heavy brick fence showed, the forum member was right. Despite the frosts and winters with little snow, during which the ground freezes deeply, the fence remains level and standing. No movement of the foundation, no distortions of the entrance group - swing gates and gates - did not arise during operation. The more interesting is the design and method of erecting this foundation.

To build a fence Vzik started back in 2012, doing it simultaneously with the construction of the garage.

On its site, the soil consists of the following layers:

- “fertility” - about 20-30 cm;

- sand 0.5 m.

The forum member advises not to drill a pile pit manually, but to rent a motorized drill with an auger with a diameter of 25 cm.

Vzik

While I was still drilling holes for the foundation of a house, I realized that doing it manually is a thankless task. Compare: on the first day, two people were able to make one pit “on clay” with a diameter of 25 cm, a depth of 1.8 m and a lower widening of 60 cm. In 10 days, only 30 piles were completely mastered, and 50 were needed! We decided to continue drilling with a motorized drill.

After renting a motorized drill, things started to get more fun. In just 2 hours, 20 preparatory holes with a depth of 1.5 m were drilled. After that, they were deepened to 1.8 m and widened at the bottom with a Tises drill.

Therefore, when it came to making holes for the foundation for the fence, the choice was obvious - to drill everything only with a motor drill. In one day, 50 holes were drilled to a depth of 1.5 meters, after which they were deepened with a hand drill to 2 meters and a lower expansion was made.

Advice: it is better to do the “heels” immediately before pouring the concrete, otherwise they may crumble ahead of time.

When manufacturing this type of foundation, we adhere to the following technology:

- Because the speed of preparation of extensions drilled manually is low; there is no need to order a mixer with factory-made concrete. The pile is filled with self-mixed concrete. You can do 5 piles per day. This saves money and makes you less tired.

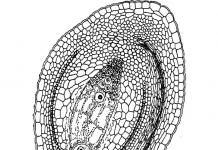

- For a pile with a diameter of 25 cm, we knit the frame from 4 reinforcing bars with a diameter of 10-12 mm. A welded metal mesh with a cell of 15x15 cm is used as a connecting element. Such a square fits well into the drilled hole. Releases of 2 cm on each side set the direction for the reinforcement cage and provide a protective layer of concrete.

- The reinforcement frame can be knitted not with knitting wire, but with plastic ties. Although this method is somewhat more expensive than using wire, it saves time and greatly simplifies the process of knitting the frame. The strength of the screeds is sufficient for the reinforcement cage to withstand pouring concrete mixture and further vibration. After the concrete hardens, the screeds no longer bear any force load.

Vzik

At my construction site, I tied all the reinforcement frames (under a house, a fence, etc.) with ties and did not use wire at all. Of course, if you knit with wire, it is a little more reliable, but practice has shown that a plastic tie can cope with the task.

By the way, when using ties instead of wire, we get another bonus that concerns the pouring of piles with widening at the bottom. What is the essence of the idea that the user with the nickname used Destructor, clearly visible in the following photos.

We bend the “legs” (at the bottom of the frame) of each of the four reinforcing bars at an angle of 90 degrees. The curved ends look inside the frame. We knit the frame using plastic ties. Next we proceed as follows:

- Pour some concrete into the heel.

- We lower the frame into the drilled hole.

- We turn the reinforcing bars “legs” bent at an angle with the ends outward.

- As a result, the ends of the “opened” reinforcing bars enter the “heel”, ensuring a reliable connection of the widening with the “body” of the pile after the concrete hardens.

Destructor User FOUMHOUSE

When the “legs” are opened, the reinforcement slides well in the plastic screed. If you tie everything together with wire, it takes more time, and it will be difficult to turn the reinforcing rod.

In order for concrete to be poured into the hole “without a hitch”, we do it this way: we insert a special device into the drilled hole - an adjustable “neck” made from rolled tin and wooden blocks (you can come up with your own version of the device).

Advice: it is better to have several such devices in order to pour several piles at once. You shouldn’t take them off right away, because... the concrete has not yet hardened. Let the “neck” stand for about an hour, but you also don’t need to leave it for a long time, otherwise they will be caught by the concrete, and then you won’t be able to remove the “neck”. After removing the “neck”, you can put a plastic bag on the head of the pile. This is necessary so that the moisture does not evaporate and the normal process of concrete hardening occurs.

A sleeve rolled from roofing felt is inserted into the “neck” and the hole. Then we lower the reinforcement cage and pour the concrete, not forgetting to vibrate it properly, using a vibrator, and not the “bayonet” method. We make the concrete mixture as “hard” as possible, i.e. with the minimum amount of water required to mix it.

Concrete should not be liquid, i.e. spread, as beginners often do, thinking that it’s easier to lay it this way. To improve the workability of the “hard” mixture, we do not hesitate to use plasticizers.

Using a vibrator with a long mace, you can easily vibrate and thoroughly compact even hard concrete.

One more point that needs to be paid attention to. To make piles, it is often recommended to use sewer or asbestos pipes the required diameter. According to users of our portal, the most budget-friendly and easiest way to fill a pile is to use a roofing felt “shirt” for this. Moreover, it can be used even if you need to fill high piles that will protrude 0.5-1 meter or more above the ground.

Oldvist User FOUMHOUSE

I poured the piles in roofing felt. The height above the ground was 50 cm. The diameter of the piles was 20 cm. Ruberoid was wrapped with tape only in two places where the pile protruded above the ground. To make a cylinder from a piece of roofing felt, I wound it around a suitable diameter sewer pipe. Then he lowered them into the well and took out the pipe. I filled the pile with self-mixed concrete. Everything vibrated properly, nothing broke or came apart.

If you need to fill a pile more than 1 meter above the ground, then you can proceed as follows: make two roofing felt “shirts”. First, pour concrete into the first one so that it does not reach the top edge of 10 cm. We insert the second “shirt” inside the first one, adjusting the required level, lowering or raising the roofing material cylinder. Then we pour the concrete further.

BraniganZ User FOUMHOUSE

I poured a pile 1.1 meters high from the ground like this, nothing fell.

An interesting method for making a roofing felt “shirt”, proposed by a forum member with the nickname face_ltd.

Due to the high cost and complexity of installation on slopes, a new type of foundation appeared - pile-grillage. Its peculiarity is that it is a combination of strip and column foundations and is used in the construction of buildings on slopes. For mountainous areas, this type of foundation is considered a priority, although it is quite expensive due to its design and design complexity.

What type of foundation is this?

A grillage is a slab or beam that connects piles directly on the surface of the ground. This is actually the main load-bearing reinforced concrete belt, onto which the load-bearing walls of the building itself are then mounted. As a rule, when designing and calculating a grillage, detailed drawings of all elements are used, because the main load falls directly on the slabs themselves.

Accordingly, any scheme of such a design already provides for calculations of permissible loads on each pile separately, as well as on the base slabs. It is also worth considering that the width of the strip base is significantly larger than the walls themselves. This is done in order to distribute the mass of the building’s load-bearing structures over the entire plane of the slabs and ensure good stability even with direct movement of an individual support.

Where is grillage used?

- During the construction of baths, technical buildings with a small mass of load-bearing structures;

- When constructing residential buildings on slopes with a large inclination angle;

- If you need to make a garage or basement built into the depths;

- When stratification is detected during soil surveys, especially when combining clay and sandy soil;

- When restoring stone and concrete foundations of old buildings, if subsidence of individual corners is detected. Then special supports are placed under the base, then the platform is poured and only then the supporting grillage is spread around the outer part.

Selection of piles for the future foundation

As a rule, it is relatively difficult to make a pile-grillage foundation with your own hands, but it is technically possible. To do this, the type of piles is first selected, and they can be reinforced concrete, concrete, metal and even wood.

Today, it is possible to fill a pile grillage even with ready-made piles, which are driven into the soil with pneumatic hammers, but this technology is expensive and is more often used in the construction of large industrial, administrative and residential buildings.

There are also so-called injection piles with a diameter of up to 120 mm and a single reinforcing rod, but they are used exclusively for strengthening and repairing existing foundations.

Location of piles in the grillage

- Single pile - here each pile is located under its own support, and all supports are connected into a single whole by reinforcement;

- Tape connection. A uniform distribution of all piles is provided and their distance is indicated in the drawing;

- The strip arrangement of piles is used in the construction of massive and large buildings;

- The location is bushy. A whole bunch of piles is installed in one place and takes on increased loads;

- Location by field. This is the case when a monolithic slab is poured over the piles, and all the piles are installed in a checkerboard pattern according to a diagram with clear calculations of the length of each unit.

Construction of a pile-grillage foundation

- Determination of soil type and its structure. Here it is advisable to obtain a geodetic section of the soil with detailed data on each soil layer. After all, piles are often driven to a depth of two meters;

- Preparing a pit or trench. It is advisable to do it on flat surfaces; on slopes it does not provide any effectiveness. The optimal solution is to prepare small depressions in which a sand cushion is made;

- Installation of formwork. You can do it, or you can not. If a private owner is ready to make a foundation with permanent formwork with his own hands, then such a foundation will have excellent waterproofing characteristics;

- Now you can carry out the process of deepening finished piles or pouring reinforcement with concrete mixture. The holes for the piles are drilled using special equipment, then the external contours are covered with roofing felt. Asbestos pipes are installed inside the wells, which are additionally reinforced to increase the strength of the supporting structure. After the piles are fully installed, the procedure of pouring concrete into the piles and creating an intermediate bedding begins;

- After the piles reach the specified strength, The frame is reinforced along the entire horizontal perimeter. The reinforcement must be filled with concrete.

Errors in the design and installation of a reinforced concrete grillage

- Lack of a clear project with a detailed calculation of all locations of piles, their thickness, length, as well as a geodetic map of the territory.

- There is no clear rigid connection between the pile pillars and the load-bearing slab. If the ground begins to freeze in winter, then it expands. As a result, under the lower part of the insulated floor, the soil cools more slowly and multidirectional forces arise. This force tends to overturn the pillar, the frozen ground presses on the upper layers of the pillar, and the lower layer takes the load upon itself. As a result, the pillar begins to tilt, and if they are not firmly fixed at the top, then they will definitely be torn out of the grooves of the poured grillage.

- Not provided at the bottom of the grillage airbag. If the bedding under the grillage is not removed, then due to seasonal temperature changes it will be subject to significant force. Over time, it will lead to rupture of the supporting platforms and damage to the grillage tape. To prevent this from happening, during pouring, polystyrene foam slabs are placed at the bottom of the pit, which act as a shock absorber and protect the soil from freezing.

- Incorrect calculation of the permissible depth of immersion of piles. If they are not driven deep enough, then the building will settle in this place, the supporting structure will skew and one corner will collapse. Over time, the slab itself collapses due to excessive loads and the base of the building. Also, due to incorrect calculations or design of the grillage structure, a sharp rise of one or more piles is possible, and this inevitably entails the destruction of the ceilings with the further destruction of the building itself.

- The bearing capacity of the foundation was calculated incorrectly. This mistake can often be found among novice designers without work experience and practice. The problem here is the wrong choice of soil type, because the whole calculation is based on this. Rocks and stony soils have the greatest bearing capacity, while fine-grained sandy soils have the least. If you make a mistake in the calculations, there is a risk that the future building will constantly sink into the ground over time, and this process will be very difficult to stop. Therefore, a complete diagram of the location, length and diameter of each pile is needed.

Pile foundations various types and from different materials used on difficult soils. The piles go deep underground and rest on denser and more stable layers. They are not afraid of frost heaving and high groundwater levels. Typically, such foundations are made with a grillage - a beam made of concrete, metal or wood connecting the piles. One of the options for such a foundation is a pile foundation with a monolithic grillage.

Application

A foundation with a monolithic grillage is suitable for areas with elevation changes and wet, unstable soils, where a conventional strip foundation would experience too much load, in areas with permafrost, and with high groundwater levels. The grillage in this type of foundation evenly distributes the load (weight of the house) across all supports. A pile-grillage foundation is suitable for small, not too heavy buildings, but for very small houses it is not economically justified.

Species

The pile-grillage foundation can be

- hanging (with a high grillage),

- with embedding of piles into a monolithic base.

In the first case, there is a distance of 0.7-1 m between the floor and the ground. In this case, the soil has minimal impact on the base.

In the second case, the grillage is located directly at ground level (elevated), or somewhat recessed (low grillage), you can make a small plinth. In this case, the grillage never rests directly on the ground; a small layer of soil (10-15 cm) is removed from under it. This is done so that the forces of frost heaving of the soil do not act on the concrete structure. If the grillage is deepened, then the pile heads must be waterproofed. A buried grillage is not made on highly heaving soils, which can increase in volume by more than the height of the gap and deform or break the foundation.

The grillage itself is made in the form of a strip, so such a foundation is also sometimes called a pile-tape foundation, or with a slab-shaped ceiling. The second option requires significantly more concrete and reinforcement.

Pros and cons of a pile-grillage foundation

This type of base has its advantages.

- Small amount of excavation work.

- Less labor intensive than for a strip foundation.

- With proper thermal insulation, a hanging grillage can reduce heat loss due to the fact that it does not come into contact with the ground.

- There is less consumption of building materials, and therefore less money, than for the construction of a strip foundation if a small number of piles are made (savings can be up to 30%).

The disadvantages and difficulties of this type of foundation include

- the need to drill deep wells when installing bored piles,

- the need to insulate the floor, and sometimes to create an imitation base in the case of a hanging grillage to insulate the house.

Reinforced concrete is most popular in individual construction for houses as a material for grillages - both monolithic and prefabricated. It compares favorably with wood and metal, since wood is susceptible to rotting and metal is susceptible to corrosion. A monolithic foundation has properties that distinguish it from a prefabricated foundation. First of all, it has higher strength and reliability, since it is cast as a single unit.

Types of piles

For pile-grillage foundation use

- driving,

- bored,

- screw piles.

The first option for the construction of private houses is rarely used, since driving requires special equipment, the rental and especially the purchase of which will significantly increase costs.

Screw piles have recently gained popularity due to the speed of their installation and the absence of excavation work - they are simply screwed into the ground, this can be done independently with the efforts of two or three people or you can order an installation service from a company that sells piles.

Bored piles are made directly on site. To do this, they drill wells, lower formwork and reinforcement into them, and pour concrete.

To accurately calculate a foundation based on piles, it is best to contact a specialist engineer. Also, before building any house, it is recommended to conduct an engineering and geodetic examination to find out the structure and characteristics of the soil.

Foundation on bored piles

Site preparation

Before creating the foundation, it is necessary to clear the area, mark it in accordance with the building design, and mark the places where the wells will be drilled. The piles are placed around the perimeter of the building, under the internal load-bearing frames and at the corners. The step between them should not exceed 2 m.

Piles

Bored piles are made by pouring concrete into prepared holes. Typically, formwork is installed in wells, the role of which can be played by asbestos-cement pipes, plastic pipes, roofing felt, or PVC film. These materials not only give the pile its shape and increase its strength, but also perform a waterproofing function.

The depth of the wells depends on the depth of soil freezing; they should be 50 cm deeper than this level. 20 cm of them fall on the sand cushion. On average the depth will be about 10 m.

You can hire a team of workers for drilling, or you can do it yourself using a hand drill. The diameter of the well should be approximately 20 cm.

After pouring the sand cushion, pipes are lowered into the wells. They should rise above the soil level to the same height; this can be checked using a level or level. Next, the fittings are lowered into the pipes. Metal rods are used to reinforce the piles; 3 or 4 of them are needed for each support. The rods are connected with transverse clamps, resulting in a structure like the one in the photo.

The reinforcement should rise 40-50 cm above the top of the piles so that it can be connected to the grillage reinforcement. They install it in the pipes so that there is at least 2 cm between the reinforcement and the shell - this will allow the frame to be completely covered with concrete.

After this, concrete is poured into the pipes. A vibrator is used for compaction, but if you don’t have one, you can use the bayonet method using a metal rod or pipe. The poured piles are left for 4 weeks to harden and gain strength.

Reinforced concrete grillage

First, the formwork is installed. It can be made from an edged board in the form of a gutter no less wide than the thickness of the future walls, and about 30 cm high. A certain difficulty lies in the fact that the grillage has hanging parts, under which supports will need to be placed while the concrete hardens. The formwork is installed at the required height and removed after the concrete has hardened. You can also use permanent formwork, for example, from penoplex, which will act as insulation and waterproofing.

The reinforced concrete grillage is also necessarily reinforced. For reinforcement, metal rods with a thickness of 10-12 mm are used; they are located along the sides of the structure. They are connected to each other into two belts with transverse reinforcement 6-8 mm thick, which can be smooth. The vertical ribs connecting the belts are made from the same reinforcement. Wooden blocks are placed under the lower belt so that the reinforcement is completely immersed in concrete. Using a binding wire, the grillage frame is connected to the protruding part of the pile reinforcement; they can also be welded.

Important! All frame elements must be firmly connected to each other; this directly affects the strength of the grillage.

The video shows how to properly reinforce a pile-grillage foundation.

The grillage is poured at one time, so you need to immediately prepare the required amount of concrete. It is important that there are no cavities or bubbles in the concrete layer. After pouring, the concrete is compacted.

Grillage on screw piles

If the grillage is made on screw piles, then it must be reinforced before the formwork is installed. To do this, reinforcement with a thickness of 12-18 mm is knitted onto the piles; for this, holes are drilled in the piles into which embedded reinforcement is passed. The longitudinal elements of the frame are attached to the mortgages. Reinforcement is also lowered inside the pile, connecting it to the grillage frame. When concreting, concrete is first poured into the piles and then into the grillage formwork.

A foundation on piles with a monolithic grillage allows you to successfully build a house on heaving soils. Bored or screw piles are usually used for it. It should be remembered that large, heavy buildings cannot be built on such a foundation.

The construction of a pile-grillage foundation is common in areas with mobile clay and sandy foundations. This type of load-bearing structure is used mainly for high-rise buildings for residential, commercial and industrial purposes, but cases of use are more prevalent in private housing construction.

Construction of a pile-grillage foundation

As the name implies, the foundation consists of piles tied with a grillage.

Piles can be of two different types:

- Bored;

- Reinforced concrete;

- Wooden;

- Steel.

Piles are divided into subtypes according to their cross-sectional shape: square and round.

Their main task is to transfer and distribute the load from the building to the base along its entire length.

Depending on the type, support pillars are inserted into the ground in different ways:

- Screw ones are screwed in manually or using a special installation;

- Bored ones are collected directly in the ground;

- Reinforced concrete ones are hammered with a piledriver.

Screw ones can be screwed even near existing buildings without the risk of breaking part of the structure.

A monolithic or prefabricated (suspended) grillage plays the role of a load-bearing beam on which walls and ceilings are mounted. It redistributes the load from structures above the ground, transferring it to the piles. It can be reinforced concrete or wood, depending on the material of the supports and walls. The design of the grillage implies its location above the ground; it is not placed on the ground.

When is it advisable to use a pile-grillage foundation?

Installation of piles and strapping beams is a labor-intensive and financially expensive process. In what cases will material and resource losses be well spent:

- At high groundwater levels;

- With loose and weak foundations of sand, clay and loam;

- For the construction of wooden and foam concrete houses.

For lightweight houses with frame-panel walls, a grillage made of channel bars is suitable, wooden beam. For heavier structures you will need monolithic or precast concrete.

A pile-grillage foundation for a house made of aerated concrete is simply a godsend: it will withstand a load of even 2 storey building and will save your budget relative to choosing a base of a different design.

Advantages of a pile-grillage foundation

This or that type of foundation is adopted on the basis of structural calculations, where the maximum load on the foundation and the size of all elements making up the structure are determined. But still, engineers often face the question of which design to adopt, based on the results of the study. Why do they prefer a pile-grillage foundation:

- The high load-bearing capacity of the supports allows them to be used for buildings and structures of any size. They reliably and rigidly enter loose soil, reaching its hard layers. When the ground vibrates due to seismic activity or seasonal changes in temperature and humidity, the soil moves but the pile remains motionless. This prevents the destruction of the building and violation of the integrity of its supporting frame. Because of this feature, this type of foundation is widely used in areas where earthquakes occur frequently.

- Lightweight steel piles are suitable for construction small houses and utility buildings.

- Different lengths support pillars allows you to create a level base for the construction of buildings on hilly and mountainous areas; it is enough to choose the right length and distribute it over an uneven area. This technique is used to create multi-level houses.

- Low cost of material and work relative to strip foundations.

- Piles are not afraid of groundwater: in deep layers where support occurs, they are often absent. This indicator is not accepted for foundation calculations.

- The level of soil freezing in the region or locality is also neglected, since the lower layers of the soil section are not subject to temperature fluctuations, and the grillage does not come into contact with the ground. Determining the level of winter freezing is pointless.

- The absence of contact between the grillage and the ground ensures dry walls and reduces the risk of rodents entering the house.

- Short installation time and ease of installation;

- Maintainability of the elements making up the foundation;

- The foundation does not require preparatory soil work, the site does not need to be leveled, which reduces the cost of its arrangement.

- You can make the installation of a supporting structure even cheaper by replacing the labor of hired workers with your own. After studying some instructions, each developer can easily arrange the piles and assemble the grillage on his own.

An impressive list of advantages of the design encourages its choice. In order not to make hasty conclusions, it is worth familiarizing yourself with the other side of the coin.

Disadvantages of a pile-grillage foundation

What you need to pay attention to:

- It is not easy to collect loads without knowing the calculation rules. An approximate calculation will most likely lead to an overexpenditure of material and funds, and a lack of pillars can lead to the destruction of an unfinished house or its uneven subsidence.

- The inability of piles to accommodate heavy buildings is a significant disadvantage. To increase the load-bearing capacity, their diameter is increased, but this creates the need for serious installation technology with the attendant costs.

- Difficulty in designing a basement, which is extremely rare with pile foundations. At the same time, there is a need to cover the gap between the soil and the grillage to protect against cooling, blowing and freezing.

- On loose soils, uneven settlement of piles is possible with subsequent deformation of the grillage. To avoid this, sand cushions are placed under the base of the pillars to compensate for movement.

- If the reinforcement is installed incorrectly, it may become exposed and subsequently rust, which weakens the entire base. But this is rather an exception to the rule. The same thing swings steel pipe: If its material is of poor quality, it will begin to corrode in the near future.

Independent calculation of the number of supports for a house

Engineering calculations are an expensive pleasure. If you have neither money nor time, and the pile-grillage foundation suits you in all respects, you can decide on the distance of the pillars yourself.

- Draw a house plan to scale, observing all proportions.

- Place dots in the corners of the perimeter, where the walls intersect.

- Piles are placed under load-bearing walls every 2-3 meters, but no more. If the distance between adjacent pillars even slightly exceeds the norm, feel free to place another point between them.

- Count the quantity.

To determine the diameter yourself, use the table.

| Base diameter, mm | 100 | 150 | 200 | 250 | 300 | 400 | 500 | ||

| Base area, cm2 | 78,5 | 177 | 314 | 491 | 707 | 1256 | 1963 | ||

| Design soil resistance, MPa | Pile bearing capacity | ||||||||

| Coarse sands with any humidity | Average | 3,5 | 275 | 618 | 1099 | 1717 | 2473 | 4396 | 6869 |

| Dense | 4,5 | 353 | 795 | 1413 | 2208 | 3179 | 5652 | 8831 | |

| Sands of medium coarseness with any humidity | Average | 2,5 | 196 | 442 | 785 | 1227 | 1766 | 3140 | 4906 |

| Dense | 3,5 | 275 | 618 | 1099 | 1717 | 2473 | 4396 | 6869 | |

| Low-moisture fine sands | Average | 2 | 157 | 353 | 628 | 981 | 1413 | 2512 | 3925 |

| Dense | 3 | 236 | 530 | 942 | 1472 | 2120 | 3768 | 5888 | |

| Dusty sands saturated with moisture | Average | 2,5 | 196 | 442 | 785 | 1227 | 1766 | 3140 | 4906 |

| Dense | 3,5 | 275 | 618 | 1099 | 1717 | 2473 | 4396 | 6869 | |

| Hard clays | Average | 3 | 236 | 530 | 942 | 1472 | 2120 | 3768 | 5888 |

| Dense | 6 | 471 | 1060 | 1884 | 2944 | 4239 | 7536 | 11775 | |

| Plastic clays | Average | 1 | 79 | 177 | 314 | 491 | 707 | 1256 | 1963 |

| Dense | 3 | 236 | 530 | 942 | 1472 | 2120 | 3768 | 5888 | |

| Coarse soil (crushed stone, pebbles, gravel) | Average | 5 | 393 | 1570 | 2453 | 3533 | 6280 | 3768 | 9813 |

| Dense | 6 | 471 | 1060 | 1884 | 2944 | 4239 | 7536 | 11775 | |

The calculation presents values for the most commonly used bored piles for private construction. Collect all the loads from the structures and distribute them approximately equally across the pillars of one bush (bearing capacity). For central supports, the resulting loads are divided by 4, for corner supports - by 2.

The driving depth is determined based on calculations. On average:

- Bored - 10-30 meters;

- Reinforced concrete - from 3 and 4 meters;

- Screw from 2 meters.

Depending on the conditions:

- In seismically hazardous areas, supports are buried at least 4 m;

- When resting on wet foundations - at least 8 m;

- According to SNiP.