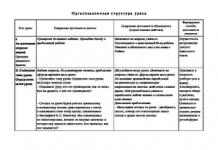

Are there devices and instruments that can be used to search hidden wiring and its diagnosis? Of course, there are both domestic and imported ones. Let's look at some of them. With the help of domestic phase indicator EI-5001 by contact you can determine the phase wire, and using portable indicator UNP-1-750 find out if the wire is live.

Phase indicator EI-5001

Designed to determine the phase rotation order in three-phase circuits AC in the frequency range from 40 to 1000 Hz.

Voltage range from 50 to 600 V.

Duration of activation is no more than 3 s with intervals between activations of at least 30 s.

Dimensions: 65x65x45 mm.

Weight: 0.19 kg.

Portable voltage indicator UNP-1-750

Designed to check the presence (or absence) of voltage between non-insulated live parts, as well as between them and grounded parts in AC and AC circuits. DC with rated voltage from 75 to 750 V.

AC voltage range..... 75... 750 V, 50 Hz;

DC voltage range..... 90...750 V;

Duration of the working cycle.............. no more than 10 s;

Operating temperature range............... from -45°С to +45 "С.

Universal probe PU-82

The device will help to determine by contact whether there is a break in the network and whether it is energized.

Portable high voltage indicator UVNP-1 -10000

Designed to check the presence of voltage in high-voltage AC installations of industrial frequency with voltage from 2 to 10 kV. Together With With additional resistance, the indicator can be used for phasing overhead lines, cables and transformers. The operating principle of the pointer is based on the indicator glowing when a capacitive current flows.

Specifications:

AC voltage range 2... 10 kV;

Operating mode......................................... intermittent;

Operating cycle duration......no more than 10 s;

Operating temperature range......from -45°C to +45°C.

Probe (screwdriver-indicator)MS-18

Designed for professional use in electrical and electronics, and it is also necessary in everyday life. The device is made using space technology from high-strength, reliable and safe plastic. The device must be used at temperatures from -10°C to +50°C and frequencies from 50 to 500 Hz.

Specifications:

AC Voltage Definition contact method 70...250 V;

Determination of alternating voltage by non-contact method 70...600 V;

Determination of polarity................................................... ......... 1.5...36 V;

Checking circuit continuity................................................... .0...5 MOhm;

Determination of microwave radiation...................................from 5 mW/cm.

SampleMS-48 M

Designed to check the presence of alternating voltage, identifying a wire/socket with a phase and a break point in wires with alternating voltage, points with high voltage and hidden wiring. Checking is carried out by contact and non-contact methods. Let's use it at home.

Specifications:

Determination of alternating voltage by contact method 70...250 V;

Determination of alternating voltage by non-contact method 70... 10000V;

Determination of DC voltage................................... up to 250 V;

Determination of polarity................................................... ......... 1.2...36 V;

Checking continuity:

“O” from 0 to 5 MOhm, “L” from 0 to 50 MOhm, “L” from 0 to 100 MOhm;

Determination of microwave radiation...................................from 5 mW/cm 2.

The invention relates to electrical measuring technology and can be used as a portable device for monitoring the operation of various electrical installations during commissioning, installation and operational work in various areas national economy. The purpose of the invention is to expand the functionality and increase the reliability of the device. For this purpose, the universal probe contains a voltage monitoring unit, a resistance indication circuit, including resistors, transistors, light-emitting elements, and a zener diode. What is new in the device is that the resistance indication circuit includes a current amplifier made on the first and second transistors according to the emitter follower circuit, and a voltage monitoring circuit is connected to the base of the first transistor and between the base of the first transistor 4 and the collectors of the first and second transistors 4, 5, a zener diode 8 is connected. A light-emitting element is connected to the emitter circuit of the second transistor, to which a DC power supply is connected in series, the second output of which is connected to the collector of the second transistor. The detachable probe is connected to the punch circuit through a threaded connection. 1 salary f-ly, 1 ill.

The invention relates to electrical measuring equipment and can be used as a portable device for monitoring the operation of various electrical installations during commissioning, installation and operational work in various areas of the national economy. The universal probe PU-82 is known. The probe consists of three main components: an input amplifier, a voltage-controlled generator, and a voltage presence indication terminal. The disadvantage of the device is its complexity in manufacturing and repair, low functionality, and the use of expensive components, namely three microcircuits. A probe of type UP-71 is known. The probe circuit consists of the following main elements: DC amplifiers assembled on transistors, an amplitude limiter with a rectifier and filter consisting of diodes, zener diodes and a capacitor, limiting input resistance, additional resistance, indicator lights. The disadvantage of the device is its low functionality, since the device does not indicate the presence of voltage in electrical circuits that are known to be energized, and serves only to determine the integrity of the electrical circuit. The device is uneconomical, since expensive components are used in its manufacture. In addition, the integrity of the electrical circuit inside the device is disrupted as a result of the contact of the sliding contacts of the probe, which is installed in the working position. The purpose of the invention is to expand the functionality and increase the reliability of the device. To do this, in a universal probe containing a circuit for monitoring the presence of voltage, a resistance indication circuit, including resistors, transistors, light-emitting elements, a zener diode, a current amplifier is connected to the resistance indication circuit, made on the first and second transistors, according to the emitter follower circuit, and to the base of the first The transistor is connected to a voltage monitoring circuit and a zener diode is connected between the base of the first transistor and the collectors of the first and second transistors, and a light-emitting element is connected to the emitter circuit of the second transistor, to which a DC power source is connected in series, the second output of which is connected to the collector of the second transistor. In addition, the connection between the detachable probe and the probe circuit is carried out through a threaded connection. An emitter follower is widely known, for example, in radio engineering devices as a buffer or matching stage between circuits with high output impedance and circuits with high input capacitance and low input impedance. In this case, the use of an emitter follower with a load in the emitter circuit in the form of a light-emitting element (LED) makes it possible to increase the sensitivity of the circuit, and this expands the range of values controlled by the probe. The proposed device circuit is reliably protected from breakdown in case of accidental exposure to voltage, since the collector-emitter junction is under the same potential as a result of connecting a DC power source in series to the light-emitting element in the emitter circuit of the second transistor, and the second terminal of the power source is connected to the collector second transistor. The design of a detachable probe with a thread at the end ensures reliable uninterrupted operation of the device as a result of eliminating the violation of the integrity of the electrical circuit of the device when installing the probe in the working position. A comparative analysis of the proposed solution with the prototype showed that the claimed solution is distinguished by the use of an emitter follower in the resistance indication circuit with a load in the emitter circuit in the form of a light-emitting element. This allows us to conclude that the proposed solution meets the “novelty” criterion. A comparative analysis of the proposed solution with other known solutions in this field did not allow us to identify devices with a similar set of features. This allows us to conclude that the proposed solution meets the criteria of the invention." significant differences". The drawing shows circuit diagram devices. The device contains a circuit for monitoring the presence of voltage, which consists of light-emitting elements 1 and 2, connected in parallel and counter, and a resistor 3. LEDs of the AL 307VM type, green and red, respectively, are used as light-emitting elements 1 and 2. The circuit for indicating the resistance of the controlled circuit includes a current amplifier assembled using a two-stage emitter follower system, namely transistors 4, 5 (for example, based on MP-25 type triodes), with a load in the emitter circuit of transistor 5 in the form of a light-emitting element 6. As Light-emitting element 6 uses a yellow LED AL 307VM. Resistor 7 and zener diode 8 (type D814A) protect the input of the current amplifier from unacceptable voltage levels. The device circuit contains a traditional probe, including an alligator clip 9 connected by a flexible wire 10 to the circuit, an incandescent lamp 11 (2.5 V), a DC power source 12 (for example, two A332 elements), a detachable probe 13. For connection with electronic circuit The device has a clamp with threaded elements 14, as well as a microswitch 15 (for example, MP 210203) with 16 normally closed and 17 normally open contacts. Detachable probe 13 is made with a thread at the end. Thanks to this, the probe 13 is screwed into the threaded elements 14 of the clamp, making reliable contact. The universal probe circuit is assembled on an insulating board, placed in a detachable plastic case for protection from mechanical damage (not shown in the drawing). The device works as follows. It is first necessary to check the serviceability of the circuit and its readiness for operation. To do this, screw the probe 13 into the threaded elements 14 of the clamp until it stops. In this case, the leakage current of the amplifier, which includes transistors 4, 5 (I Y = l Y4 x K 4 x K 5, where K 4 and K 5 are the gains of the first and second stages), gives the threshold radiation of the yellow color of the light-emitting element 6. The device is working properly and ready to go. When checking resistors, one terminal of the resistor is connected to terminal 9, and the other to probe 13. In this case, through resistor 7, the negative potential of power source 12 is supplied to the base of transistor 4, which opens the base-emitter junction, and the potential flows to the base of transistor 5. Leaks base current l B4 along the minus circuit of power source 12 - probe 13 - resistor 7 - base of transistor 4, base of transistor 5 - light-emitting element 6 - normally closed contact 16 of microswitch 15 - "plus" of power source 12. The base current l B4 opens the collector-emitter junction of transistor 4, and current l B4 x K 4 flows through the minus circuit of power source 12 - probe 13 - collector-emitter junction of transistor 4 - base-emitter transistor 5 - light-emitting element 6 - normal closed contact 16 of microswitch 15 is the “plus” of power source 12. The current of the first stage l B4 x K 4 opens the collector-emitter junction of transistor 5, and the flowing current l B4 x K 4 x K 5 along the minus circuit of the power source 12 - probe 13 - collector-emitter junction of transistor 5 - LED 6 - normal closed contact 16 of the microswitch 15 - the “plus” of the power source 12 causes the light-emitting element 6 to emit yellow light. The brightness of the radiation determines the serviceability of the controlled resistor. If there is no jump in the brightness of the radiation, then there is either a break in the resistor or it is more than 5 MOhm. In comparison with the brightness of radiation, similar in value to a known good resistance, one can judge the value of the resistance. In the same way, the serviceability of capacitors is checked, and, judging by the time and amount of charge or discharge, the value of their capacitance in comparison with the brightness of the radiation when checking a known-good capacitor, known by the size of the capacitance. So, if the yellow light-emitting element 6 emits threshold light, the capacitor has a break; if element 6 constantly emits maximum light, the capacitor is broken. The insulation of electric motor windings in relation to its body is checked in the same way. If a jump in the emission stage of the light-emitting element 6 is noticed, then the motor winding is wet, less than 0.5 MOhm, and the motor must be dried; if not, voltage can be applied. When checking for the presence of a voltage above 6V, zener diode 8 is triggered, shunting the input of transistor 4. Voltage is supplied to light-emitting elements 1 and 2 through resistor 3. When an alternating voltage is applied, both light-emitting elements 1 and 2 emit green and red light. When a constant voltage is applied, if there is a negative potential on the probe 13, the light-emitting element 1 emits green light, the element 2 is locked. If the probe shows a positive potential, light-emitting element 2 emits red light and element 1 is locked. To check electrical circuit diagrams for integrity, terminal 9 is connected to one end of the circuit. Without pressing the microswitch, find the second end of the circuit based on the maximum brightness of the light-emitting element 6. Press the microswitch 15, closing contact 17. This puts the traditional probe circuit into operation. If lamp 11 is bright, then the resistance is less than 10 Ohms and the circuit is intact, i.e. the second end of the chain is found correctly. Thus, the universal probe allows you to expand the scope of application compared to existing ones. The technical and economic efficiency of the invention lies in increasing the efficiency and reducing the cost of the device by simplifying the design and eliminating the use of expensive components containing precious metals. The device is easy to use.

Even many experienced summer residents often confuse a cultivator and a walk-behind tractor, implying that these are the names of the same item.

However, what is the difference between a walk-behind tractor and a cultivator? Both of these types of equipment are used for agricultural work, but they have different purposes:

- A cultivator, as you might guess from the name, its main function involves cultivating (cultivating) the land. It is equipped with special cutters that carry out plowing and loosening of the soil.

- A walk-behind tractor is a mechanism whose purpose depends on what attachments are installed on it. It itself is a mechanism with an engine that brings this equipment into working condition. Thus, it can serve as a snow blower or a rotary mower.

A walk-behind tractor can equally well perform the functions of a cultivator, while the latter has a narrow specialization consisting only of soil cultivation.

You should also dwell on the technical nuances:

- Walk-behind tractors are heavier than cultivators;

- They are characterized by the presence of a reinforced body, gearbox and handle;

- The standard walk-behind tractor usually has pneumatic wheels, while the basic configuration of the cultivator does not include them.

The only thing common between walk-behind tractors and cultivators is demand. Both of these types of gardening equipment are extremely in demand among farmers and gardeners. GardenGear offers cultivators and walk-behind tractors of exceptional quality from trusted manufacturers at the best prices in this segment.

Are there devices and instruments that can be used to search for hidden wiring and diagnose it? Of course, there are both domestic and imported ones. Let's look at some of them. Using the domestic phase indicator EI-5001, you can determine the phase wire by contact, and using the portable indicator UNP-1-750, you can find out whether the wire is energized.

Phase indicator EI-5001

Designed to determine the phase rotation order in three-phase AC circuits in the frequency range from 40 to 1000 Hz.

Voltage range from 50 to 600 V.

Duration of switching on is no more than 3 s with intervals between switching on of at least 30 s.

Overall dimensions: 65x65x45 mm.

Weight: 0.19 kg.

Portable voltage indicator UNP-1-750

Designed to check the presence (or absence) of voltage between non-insulated live parts, as well as between them and grounded parts in AC and DC circuits with a rated voltage of 75 to 750 V.

Specifications: AC voltage range DC voltage range

Operating mode.............................................

Working cycle time.....

Operating temperature range.... 75—750 V, 50 Hz,

........................ 90—7S0B

intermittent

.................... no more than 10 s

.......... from -45 ®С to +45 °С

Universal probe PU-82

The device will help to determine by contact whether there is a break in the network and whether it is energized.

Resonance device RA-2M(Fig. 4.77) is designed for burning defective insulation down to small sections of transition resistance at the location of the defect in cable lines with voltages of 1, 3, 6, 10, 20 and 35 kV up to 6 km long. The device consists of primary winding coils 1 , secondary winding 2, core 3, casing 5, laboratory clamps 4.

The principle of operation of the device is based on the resonant process that occurs in its secondary circuit due to the cable capacitance and the inductance of the winding.

The device is used when performing electrical installation work and to determine damage locations using the acoustic method.

Supply voltage

network, V......................... 220

Supply current frequency, Hz.................................... 50

Current consumption, A 10-200

Open voltage

stroke, kV................... 1.5; 2.5; 3.1; 5

Current in the burning mode in the primary winding, A................................. 50-75

Primary connection

windings........................Parall-Serial-

flattering

Current in burn mode

secondary winding, A:

throughout the entire winding 1.4 0.6

on the tap... 3.5 1.8

Open circuit voltage, kV:

throughout the entire winding 5.0 2.5

on the tap.... 3.1 1.4

Current in resonance mode, A:

in the primary winding 160-200 50-70 in the secondary winding.................................... 8-10 4-6

Mode voltage

resonance, kV:

on the entire winding 23-26 16-19 on the tap.... 4-6 2-3

Repeat mode

inclusions, %:

in voltage resonance mode 0.3 1.5 in burning mode 9.0 100 Allowable operating time, min:

in resonance mode 1.5 5.0

in burn mode 20 long

Overall dimensions,

mm........................................ 370X340X680

Weight, kg......................... 80

OKP code 48 3453 6901.

Universal probe

PU-82(Fig. 4.78) is designed to monitor the integrity of the primary and secondary switching circuits of electrical installations when the voltage is completely removed and to indicate the presence of voltage upon accidental touching of live parts energized up to 460 V DC or up to 380 V AC with a frequency of up to 400 Hz. The probe can be used in various sectors of the national economy for commissioning and electrical installation work at industrial enterprises, as well as for testing semiconductor products (diodes, transistors).

The PU-82 includes the following components:

input amplifier 1 , which forms such a characteristic of the output signal that allows you to indicate the resistance of the controlled circuit in three subranges; generator 2, generating a sequence of pulses, the frequency of which depends on the resistance of the controlled circuit in subband II;

indication unit 3 presence of voltage above 10 V in the controlled circuit;

security chain 4, limiting currents and voltages on circuit elements and power supply;

power supply 5, input probes 6.

The probe can be used both indoors and outdoors at an air temperature of 1-40° C and a relative humidity of 80%.

Technical data

Controlled resistance indication range

chains, Ohm................................... 0-syu

Including:

first sub-range (diode emits continuously) 0-10

second sub-band (diode emits in pulsed mode) .... 10-8000

third subband (diode does not emit) .... 8000-00

Maximum permissible indication error

|

|

resistance of the controlled circuit in the second sub-range, Ohm:

lower limit. . . 10±10

upper limit. . . 8000 ±2000

Maximum permissible voltage between the probe and the probe plug, V 380, 460

The minimum voltage between the probe and the plug, indicated by the probe,

IN................................................. .................... 10

Insulation resistance of input circuits relative to the housing, MOhm...... 10 Supply voltage, V 4.5 Overall dimensions, mm 150X70X40 Weight, kg........................ ................. 0.3

Used in the sample modern means electronics, as well as design and circuit solutions that ensure high reliability of the device.

Intercom PU-71 serves for communication via wires or free cable cores during installation or commissioning work, made on the basis of the TMG-1 telephone and microphone headset.

The main element of the PU-71 is a two-stage single-ended low-frequency resistor amplifier. The device has the ability to control the volume, and there is protection in case of accidental connection to live parts that are energized.

Technical data

Supply voltage (battery 3336LU, GOST2583-83), V................................................... ... 4.4

Output power at frequency 1000 Hz, mW.................................................... .. 3

Current consumption at a supply voltage of at least 4.2 V and the absence of a useful signal, mA.... 22

Signal frequency in mode

call, Hz......................... 1000 + 600

Length of flexible connecting wire with alligator clip, mm. . . 1500

Overall dimensions of the case

amplifier, mm........................ 140X80X30

Weight with power supply, kg................................... 0.25

OKP code 48 3457 0801.

TU 36-1531-76.

Pulse generator GI-IDS-2

(Fig. 4.79) is intended for pulsed-arc welding with a consumable electrode of aluminum and its alloys, stainless steels, alloys

titanium in an argon environment in all spatial positions when working together with welded rectifiers or DC generators.

When working outdoors, measures must be taken to protect the generator from precipitation.

Technical data

Power consumption

kV-A................................................... ............. 13.4

Supply voltage, V 380

Number of phases........................................................ ......... 3

Frequency, Hz................................................... ..... 50

Effective value of secondary voltage of transformer TR-1, V. . .70, 78, 88, 96

Repetition frequency of current pulses, Hz.................................... 100

Amplitude of current pulses, A 200-1200

Pulse duration,

10-3s................................... 1- 2.5

Effective current value of transformer TR-1 (nominal), A:

secondary current. . . 250

primary current... 64

Overall dimensions, mm 564X483X700

Weight, kg................................................... ......... 100

TU 36-1498-71.

Load transformers TON are used for testing the primary current of maximum releases of automatic circuit breakers in switchgears with a voltage of 0.4 kV (Table 4.19).

TU 36-2492-82.

Valve BB-0.5/180UZ designed for operation in rectification circuits of mobile and stationary high-voltage rectifier units. The valve is made on the basis of rectifier posts KTs201D.

Table 4.19

Technical data

Permissible reverse voltage (amplitude value), kV.................................................... ................. 180

Test reverse voltage (amplitude value), kV.................................................... ....... 200

Maximum permissible rectifier current (average value), mA.................................... 500

Reverse current (average value) at permissible reverse voltage, µA.................................... 100

Service life, h................................... 5000

Overall dimensions (lengths

Хdiameter), mm......................... 570X200

Weight, kg................................................... ............. 15

OKP code 48 3457 0101.

TU 36-1942-76.

Silicon Small Gates

VVKM-0.05/140, VVKM-0.05/180 designed for operation in rectification circuits of portable and stationary rectifier installations.

The valve is assembled from semiconductor sections. Each section includes a KTs-105D silicon pillar.

Audio frequency generator GZCH-M Designed to use the induction method to find routes and damage to the insulation of power cable lines at a frequency of 1000 Hz.

The generator operates either in pulsed (identification) or continuous mode.

Technical data

Voltage single-phase network

power supply frequency 50 Hz, V 220

Smooth setting range

frequency, Hz......................... 800-1200

Frequency change during voltage fluctuations, Hz, no more.................................... ............... ±4

Maximum current consumed from the network (rms value), A, no more than 25

Maximum output current when operating on an active-inductive load, A, not less:

at /?=1 Ohm; L=

0.25 mH........................ 30

at L = 4.5 Ohm; 1 = 2mH 8.5

Overall dimensions, mm 500Х400Х170

Weight, kg........................................ 30

Technical data

VVKM-0.05/140 VVKM-0.05/180

Permissible reverse voltage (amplitude value), kV.................................................... ........................................... 140 180

Test reverse voltage (amplitude value), kV.................................................... .............. 160 200

Maximum permissible rectified current

(average value), mA................................................... .......... 50

Reverse current (average value) at permissible reverse voltage, µA.................................................... 10

Service life, h................................................... ........................... 5000

Overall dimensions (length X diameter), mm 360X140 400X140

Weight, kg, no more................................................... ...................... 8

OKP code................................................... ................................... 48 3457 0102 48 3457 0103

TU 36-1943-76 TU 36-1944-76

Function generator GF-1 is designed to generate standard signals at the inputs, which can be applied to the inputs of elements and the device of regulation and control systems of electrical appliances for the purpose of removing and adjusting characteristics, testing modes and other operations during the commissioning process.

Technical data

Maximum load current at outputs 1 and 2 on all ranges, mA.... 50

Range of regulation of the speed of voltage rise of a special form (intensity controller),

V/s............................... 1.5-15

Overall dimensions, mm 300X250X150 Weight, kg..................................... 6

OKP code 48 3457 0721.

TU 36.18.34.01-05-87.

Command signal generator GKS

is designed to generate standard signals that can be fed to the inputs of elements and devices of electrical wire regulation and control systems for the purpose of removing and adjusting characteristics, testing modes and other operations during the commissioning process.

OKP code 48 3457 0712.

TU 36-1956-76.

Backpack mounting semi-automaticPRM-4 with attachment PV-400 designed for welding work in installation conditions with a consumable electrode in a shielding gas environment (Fig. 4.80).

|

|

The PV-400 attachment, complete with a welding transformer ST and a choke, is designed for welding aluminum busbars with rectified current using consumable electrodes in a shielding gas environment at any location of the seam.

OKP code 48 3452 8103.

Technical data

Semi-automatic PRM-4

Rated welding

current, A........................................................ .......... 500

Diameter of aluminum welding wire, mm 0.8-2.0

Wire feed speed,

m/h........................................................ .......... 960

Supply voltage of the equipment cabinet, V... 220

Control................................Manual

Thickness of welded products, mm................................... Up to 10

Overall dimensions, mm:

hardware cabinet 204X295X436

satchel..................................... 130X282X372

large burner. . . 40X162X240

small burner.... 38ХП0Х225

Weight, kg:

hardware cabinet 20.5

knapsack......................................... 5.8

large burner with

barbells........................................................ 3, 6

small burner with rods 2.6

PV-400 attachment

Rated welding

current, A........................................ 370

Set-top box supply voltage, V.................................................... 65

Rectified voltage

current, V........................................ 63

Overall dimensions, mm:

length with carrier. . . 1600

length without carrier. . . 540

width................................... 425

height................................... 550

Weight of the attachment, kg. . . . 76.5

TU 36-1848-75.

Digital device for measuring control angles RS-TsM(Fig. 4.81) is intended for commissioning work on electrical equipment industrial enterprises.

The device is designed to measure angles in the main circuits and control circuits of valve converters of control units between two pulse input signals or between pulse and sinusoidal signals of the same frequency (45-55 Hz).

Device composition: control clamps /, 6; switches 2, 5 signal source; regulator 3 24 V source output; switch 4 operating mode; socket 7 for 24 V source output; pen 8; toggle switch 9 sensitivity settings; connectors 10, 11 for supplying input signals; fuse 12; ground bolt 13.

Technical data

|

|

Rated voltage (single-phase) of the supply network with a frequency of 50 Hz, V

Power consumption

V-A......................................................... ................. 10

Range of measured frequencies, Hz.................................... 45-55

Measuring range of electrical regulation angles,

hail................................................... .. O-360

Overall dimensions, mm 310Х260Х120 Weight, kg............................................... 5

OKP code 48 3457 0503.

TU 36.18.34.01-08-88.

Thyristor regulator current RT-1 designed to regulate the current of the primary winding of TON load transformers when testing maximum releases of AC circuit breakers in power supply networks with voltages up to 1000 V.

Unlike previously used autotransformers, a pulse testing method with phase regulation of the voltage of load transformers is used.

In order to increase accuracy, a pulse current meter with a correction device is used, which provides determination and digital indication of the equivalent value of the sinusoidal current of the overload release setting.

Technical data

Operating mode.........................Short-term and long-term

Current duration setting range in short-term mode, s... 0.02-0.8

Duration of continuous operation at /≤40 A, min, not less than 15

Maximum effective value of the regulator current at duty cycle = 2% and cycle duration 10 min, A... 400

Current regulation range I Max, I O. . . . . . . . . . 5-10

Mains voltage (single-phase, 50 Hz), V 220-380

Overall dimensions, mm 320Х260Х160 Weight, kg.................................................... 8

Receiver and PC Designed for finding fault locations using the induction method in power cable lines with operating voltages up to 10 kV inclusive.

The device includes a receiver, an antenna with a handle and headphones.

The device is used in conjunction with an audio frequency generator, which provides frequencies in the range of 900-1100 Hz to fix the magnetic field of the audio frequency current sent into the generator cable.

Technical data

Rated frequency value, Hz 1000

Bandwidth at frequency level 0.7, Hz:

narrow........................................ 60

wide........................................ 200

Bandwidth at frequency level 0.1, Hz, no more than 600 Voltage from galvanic cells type A332 (GOST 12333-74), V: at the beginning of the service life

element................................... 2X4.5

at the end of service life

elements........................ 2X3.3

Duration of continuous operation of the IPC, hours, not less than 4 Overall dimensions of the receiver, mm 200X70X120

Antenna height, mm.... 250

Handle length, mm. . . . 500

Weight (receiver, antenna with handle and headphones), kg, no more than 4